BodyShop Business, October 2013

-

Upload

babcox-media -

Category

Documents

-

view

228 -

download

9

description

Transcript of BodyShop Business, October 2013

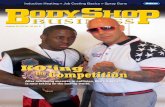

Waterborne Prep » Frame Machine Technology » SEMA Preview

October2013//Vol. 32 No.10 www.bodyshopbusiness.com

Show Issue

The days of getting by without ongoingtraining are over.

Training Time

Circle 1 for Reader Service

InsideOctoberOctober 2013 Vol. 32 No. 10

BODYSHOP BUSINESS (ISSN 0730-7241) (October 2013, Volume 32, Number 10): Publishedmonthly by Babcox Media, Inc., 3550 EmbassyParkway, Akron, OH 44333 U.S.A. Phone (330)670-1234, FAX (330) 670-0874. Copyright 2013Babcox Media, Inc. All Rights Reserved. Periodicalpostage paid at Akron, OH 44333 and additionalmailing offices. POSTMASTER: Send addresschanges to BODYSHOP BUSINESS, P.O. Box13260, Akron, OH 44334-3912.

Member, BPA Worldwide

Guess the Car ....................................................................................4Industry Update ..............................................................................12Tech Focus ......................................................................................30NASCAR Performance ......................................................................32Product Showcase..........................................................................115The Shop ......................................................................................120

Training TimeThe days of getting by without ongoing training are over. Sowhat are you going to do?

ON THE COVER

34

52

64

FEATURESTECHNICAL

Preparing for WaterborneThere’s no stopping the waterborne train, so here are the stepsyou have to take to prepare yourself for the change.

SHOW COVERAGE

Place Your Bets!Are you dreaming of the big win in Vegas? Look no furtherthan the SEMA Show.

DEPARTMENTS

810162026

SHOP TALK

Editor’s NotesEmpathy: The key to life?

Publisher’s PerspectiveWhy didn’t I think of that?

ViewpointWe must take a stand and take back control of our businesses.

Clark’s CornerWe’ve come a long way with pulling and measuring.

Web Presence ManagementIncrease your visibility with Facebook Offers.

76 Booth PreviewsTake a sneak peek at some of the vendors and their products thatwill be front-and-center at the SEMA and AAPEX shows.

Circle 3 for Reader Service

Guessthe Car

4 October 2013 | BodyShop BusinessCircle 4 for Reader Service

What vehicle MODEL does this picture represent? Fax your guess

to (330) 670-0874. Include name, title, shop name, city, state and

phone number. Or submit your guess with our online contest form

by visiting bodyshopbusiness.com/guessthecar. The winner will be

randomly selected from correct entries and awarded $50. Entries

must be received by Oct. 31, 2013.

*Only one winnerwill be selected.Chances of winningare dependent uponthe number ofcorrect entriesreceived. Employeesof Babcox, industrymanufacturers andBSB advertisers arenot eligible to enter.

See the November

issue for winner of

Guess the Car

#126.

Rod Hessler, owner, Al’s Body Shop,

Billings, Mont.

SOLVED!

Yukon gold = (GMC) Yukon#127

#126

IQ = (Scion) iQ

Reader Contest! Win $50!

#125“ I’m going for the gold!”

WINNER!

Circle 5 for Reader Service

Circle 7 for Reader Service

Scott Deming was one of thosemotivators. His talk was focusedon “perceptual reality” and howeveryone’s perception is differentbased on the experiences in theirlives that shaped who they are.One of his points was that yourcustomer’s perception of yourshop or the service they were givenmight be completely different thanyours. Actually, not might, but

probably is.The thing thatreally hit homewith me, how-ever, was hisdeclaration thatempathy is thekey to life.

Wow! That’s

a pretty strong statement. If youwould have asked me what the keyto life was, I probably would havelisted many things. But there itwas, one single, solitary secret tolife: empathy.

I’ve been told by some industryexperts that empathy plays a hugerole in the collision industry. Somehave gone so far as to say that ifshops showed true empathytoward their customers on a dailybasis, they could increase sales sev-eral times over. Is this proven? I’mnot sure, but it makes sense to me.I think most of us would admit wedon’t do a good enough job atbeing empathetic towardcustomers. I don’t know if it’s insome people’s DNA to be that way;if that’s the case, those peopleshouldn’t be your estimators or“care agents.” Isn’t that really whatthey should be called?

I don’t think you can teachsomeone empathy; they either

have it or they don’t. Find oneswho do and put them onyour front lines. Your busi-ness will be better off for it.

Editor’sNotes Publisher

S. Scott Shriber, ext. 229 [email protected]

EditorJason Stahl, ext. 226 [email protected]

Associate EditorGina Kuzmick, ext. 244 [email protected]

Contributing EditorsCharlie Barone, Mitch Becker,Mark Clark, Mark Claypool,Erica Eversman, Tom Ferry,Curt Harler, John D. LymanSr., Hank Nunn, Carl Wilson

Graphic DesignerLisa DiPaolo, ext. [email protected]

Advertising ServicesKelly McAleese, ext. [email protected]

Director of CirculationPat Robinson, ext. [email protected]

Director of eMedia & Audience DevelopmentBrad Mitchell, ext. [email protected]

Subscription ServicesEllen Mays, ext. [email protected]

Tel: (330) 670-1234Fax: (330) 670-0874Website: bodyshopbusiness.com

Corporate

Bill Babcox, PresidentGregory Cira, Vice President,

Chief Financial OfficerJeff Stankard, Vice PresidentBeth Scheetz, Controller

A limited number of complimentary subscrip-tions are available to those who qualify. Call(330) 670-1234, ext. 288, or fax us at (330) 670-5335. Paid subscriptions are available for non-qualified subscribers at: U.S.: $69 for one year.Canada/Mexico: $89 for one year. Canadian ratesinclude GST. Ohio residents add current countysales tax. Other foreign rates/via air mail: $129for one year. Payable in advance in U.S. funds.Mail payment to BodyShop Business, P.O. Box75692, Cleveland, OH 44101-4755. VISA, MasterCard or American Express accepted.

Irecently attended the PPG MVP Conference in beautiful AmeliaIsland, Fla., and what a great experience it was. Many of PPG’s val-ued customers got to take a much-deserved break from the hustle andbustle of their businesses, spend some quality time with their signifi-

cant others, shop some of the latest and greatest products in the industry,and learn from some of the top motivators in the business world. That’sright, motivators, not “speakers” or “presenters” because they did somuch more than just present information.

Empathy Rules

Jason Stahl, Editor

Email comments to [email protected]

Circle 9 for Reader Service

Why Didn’t I Think of That?

Earlier this week, I had such a moment.From time to time, people send products inhopes that they’ll spark some interest andwe’ll publish them in our Product Showcasesection. Typically, we run them if appropriatefor your review, and that’s the end of it. Themarket decides quickly if the product hasmerit. That’s the beauty of our free marketsystem. Occasionally, I see something that’sreally clever or useful and grabs my atten-tion. Rarely will I write about it, but there arethose rare instances.

This product pictured to theright is one of them. Last week,

a product called VaccUFlexcame in the mail. Most proba-bly would have thought thatit was fairly mundane, but tome, it was sheer genius. Asmany of you know, I’m anavid car guy and all-aroundtool junkie. You can see from

the picture what this thingdoes. If not, you won’t use

it anyway. Howmany times have

you looked at anarea and said,“I sure wish Icould get myvacuum inthere.”Well, askno more.This thinggets youright un-

der that fridge and cleans those dust bun-nies off the coils. Or, what about betweenthose seats in a console-equipped vehicle? If you work on stuff, your mind already hasmany more uses than I can rattle off here.

Just seeing the product should have beenenough, but I needed to talk to the guy whocame up with this, partly because I was jeal-ous and partly because I’m somewhat entre-preneurial. His name is Joe, and as with mostof these kinds of items, he came upon it outof necessity. Joe’s wife fell in love with a newlight fixture for the front porch and it turnedout to be very difficult to clean. Joe tried touse his vacuum, but it just didn’t get in there.And there you have it! Several iterations lat-er, his problem and ours were solved.

I guess my point here is this: the nexttime you’re faced with a situation that re-quires some ingenuity, stop and ask your-self, “Can I solve this?” If so, do it and thenask, “Does anyone else have this problem?”If so, look into getting it made. What theheck, it might just be the next big thing.

And hurry up! I’m probably strugglingwith the same problem and not cleverenough to solve it.

Publisher’sPerspective

S. Scott Shriber, Publisher

Email comments to [email protected]

Iwish I had a dollar for every time I’ve said that to myself. The other frustrating thing iswhen I see some great idea that I had previously thought of but didn’t do anythingabout. I’m sure you’ve all been in one or both of these situations.

Circle 11 for Reader Service

Hundreds of PPG’s valued customers got to frolick in the surf and the sun at the PPG MVP Conference in Amelia Island, Fla., Sept. 8-10. Afun-filled golf outing, the “MVP Randy Dewing Memorial Golf Tournament,” kicked things off, followed by several educational sessionswhere expert speakers from inside and outside the collision repair industry discussed a mix of topics. Prominent keynote speakersincluded Scott Deming, David Horsager and Michael Hoffman. Deming, a customer service and emotional brand building guru, discussed“perceptual reality.” Horsager focused on trust and how it has the ability to accelerate or destroy any business, while Hoffman pumped upthe crowd with his talk on “Igniting Performance in the Tornado of Business.” Breakout sessions covered such topics as successionplanning, paint shop throughput, and paint and materials. Attendees walked away refreshed, rejuvenated and ready to bring new ideas andenthusiasm to their businesses!

Eddie Quintela, owner andpresident of Collision Con-cepts of Delray Beach, Fla.,has once again filed a law-suit against 21st CenturyInsurance on behalf of acustomer who made aclaim under their policywith the carrier.

In 2012, Quintela, on be-half of his customers, filedthree separate lawsuits

against 21st Century,which the company agreedto pay before the trialdates. In addition to thedisputed amounts, the in-surer paid all of Quintela’slegal fees and costs.

The new lawsuit stemsfrom 21st Century claimsrepresentatives electing toagain deny payments forhis posted labor rates,

processes and proceduresdeemed reasonable andnecessary to restore hiscustomer’s vehicle.

“As in the past with thiscompany, they pay us onlyafter we file suit but beforethey go before a judgeand/or jury,” said Quin-tela. “Thereafter, they payin full for every neededmaterial, process and rates

for awhile, then abruptlychange back to their oldways. I’m puzzled, andI’m confident their compa-ny shareholders would beas well since the insurerhas often paid 20 times theamounts in dispute, oftenpaying upwards of $2,500in legal fees and costs for a dispute that may be under $100.”

IndustryUpdate

12 October 2013 | BodyShop Business

21st Century Insurance Sued Again by Florida Repairer for Short-Pays

Attendees of PPG MVP Conference Get Sun, Surf and Inspiration in Amelia Island, Fla.

The Society of Col-lision Repair Spe-cialists (SCRS)has issued a posi-

tion statement regardinginsurer mandates. Itreads as follows:

In representation of col-lision repair businessesacross the United States,The Society of CollisionRepair Specialists (SCRS)takes exception to businessmandates that propertyand casualty insurers im-

pose upon collision repairbusinesses; particularlythose that specify requiredvendors, business plat-forms or internal processesthat must be followed inorder to be included in, oravoid being excluded from,certain lines of work. As anexample, insurer mandatessurrounding parts procure-ment platforms may inhibitindependent collision re-pair businesses from utiliz-ing parts vendors with

whom they have an exist-ing relationship, providinginsurers with greater influ-ence and control over theparts supply chain. SCRSbelieves this control fallsoutside of the scope of theinsurance business. Someinsurers are stipulatingagreement to these terms,as a condition of being rec-ognized in Direct RepairPrograms (DRP). SCRSsupports efforts that right-fully seek to eliminate such

»| Industry Update |«

www.bodyshopbusiness.com 13

SCRS Issues Position Statement on Insurer Mandates

intrusion into the collisionrepair business, and en-forcement of existing laws,regulations and codes thatcurrently prohibit such ac-tions. It is the opinion ofSCRS that voluntaryagreements cannot includestipulations which violateexisting laws, rules andregulations.

SCRS believes that col-lision businesses are capa-ble of establishingsuccessful vendor relation-ships and internal process-es that will bestaccommodate the needs ofthe consumer, and thatservice providers will con-tinue to respond to themarket with increasinglycreative solutions thatdrive performance for theircustomers and the respec-tive market entities. We

Continued on pg. 80

By Jason Stahl

Aat the July Colli-sion Industry Con-ference (CIC), a

panel of collision indus-try professionals wasasked, “Are the laws andregulations governingthe collision industryworking?”

The panel was moder-ated by Steve Regan ofRegan Strategies. Panelmembers included:

� Rick Tuuri, Audatex� Randy Hansen,

Allstate� Darrell Amberson,

Lamettry’s Collision

� Ron Reichen, Preci-sion Auto Body & Paint

� Colette Bruce, TeamSafety

� Janet Chaney, Mon-tana Collision Repair Specialists

The general consensuswas that success in thecollision legislativerealm was a mixed bag.“Yes and no” seemed tobe the most common an-swer, including the one

given by Amberson.“Some of the laws are

working, but conditionscontinue to change andwe need to monitorwhat’s going on,” said

USA Today Puts National Spotlight on Advanced Materials in Vehicles

In an article titled, “Lighter Cars Add Weight to Repair Costs,” USA Today has put a

national spotlight on advanced materials in vehicles, informing consumers about how

their cars may have specific requirements when it comes to repairing them.

The article explains the huge pressure automakers are under to both save weight for

gas mileage and meet stricter crash test standards. It also details the various materials

coming into play: aluminum, carbon fiber and high-strength steel.

It also quotes well-known collision industry professional Darrell Amberson, vice presi-

dent of LaMettry’s Collision, a seven-store operation in greater Minneapolis.

“[Having specialized equipment] is something that’s going to differentiate our indus-

try,” he told USA Today.

Continued on pg. 84

CIC Panel Discusses Effectiveness of Collision Repair Legislation

Panel members (left to right) Colette Bruce; Ron Reichen; Darrell Amberson; Randy Hansen; Rick Tuuri;Janet Chaney; and moderator Steve Regan.

Circle 14 for Reader Service

Circle 15 for Reader Service

Viewpoint

A Call to Arms

The views expressed in this editorial do not necessarily reflect those of BodyShop Business magazine.

As many in our industry are nowaware, the Mississippi CollisionRepair Association has initiated anattempt to legally block

PartsTrader from entering ourmarket, viewing it as an un-precedented and illegal intrusioninto the collision repair industry.The shop owners who havesigned their names to this cam-paign, or may in the future, areholding themselves up for theworld to see and are taking risksmany have been unwilling totake – not just to benefit them-selves, but for the general welfare of our in-dustry. The road we have before uspromises to be a long one with lots oftwists, turns and obstacles along the way.

Everyone’s a Critic » It has been disap-pointing, to say the least, that news of thiseffort has been met with criticism by somein our industry who hide protected in thecloset of anonymity that screen names pro-vide and hurl insults and unfounded accu-sations through the crack in the door. Thosewho engage in this behavior should con-sider doing one of three things:

1. Take credit for their remarks, using theirreal names, and list all the contributions theyhave made that have benefitted the industryso that we understand the credentials thatqualify them to insult and vilify others.

2. Publicly pledge, once again using theirreal names, to never take advantage of anybenefits to our industry that may be real-ized as a result of the hard work and riskstaken by those joining this effort.

3. Stand down and allow others to try toslay this dragon without helping the drag-

on. The fact that some parties to this lawsuitcurrently participate in DRP programs cer-tainly doesn’t justify the verbal assault

against an issue that so urgentlyneeds to be addressed – and it cer-tainly doesn’t negate the fact thatPartsTrader has to be stopped.

Root of All Evil? » It’s simplisticto believe that the DRPs that havepervaded our industry are theroot of all the evil and that theirabolishment would solve all ourproblems. DRPs are just one of along line of control mechanisms

that have been inflicted upon us by the in-surance industry for decades and are notthe sole cause of all our current problems.Our industry had profound problems longbefore DRP controls were put in place. Re-member the 1963 Consent Decree? Therewere no DRPs then, but insurer intrusionand illegal business practices that had goneon for decades became so egregious that theU.S. attorney general had to step in and re-store order. That didn’t just happen; bravemen and women set that in motion, too.

Many shop owners initially adopted theDRP approach to doing business, not outof greed but as an alternative to the delaysin the repair process due to insurer med-dling and incompetence in establishing astreamlined approach to repairs. It was ashort-sighted way to get insurance compa-nies out of our day-to-day business. With-out having to face delay after delay andwaiting for the insurers to approve the addition of parts or procedures to the seri-ously deficient repair estimates (manytimes prepared by them), cycle times im-proved dramatically and we were able to

By Bill Fowler

16 October 2013 | BodyShop Business

Circle 17 for Reader Service

process more repairs because wehad more control of the process.

“We don’t pay for that,” “It’s in-cluded” and “You’re the only one”were already facts of life. In retro-spect, we can see that the DRP busi-ness model has morphed by designinto what we now have: just anoth-er way to take us to the edge of the

precipice, where we currently findourselves. There is little questionthat the DRP business modelshould be abandoned, but we’renow facing a much more pressingissue in the form of a mandatedparts procurement program thatthreatens our very existence as in-dependent small businesses.

PartsTrader » To believe thatsimply removing one’s businessfrom a DRP list will result in Parts-Trader withering and dying fromlack of interest is incredibly naïve.

Pay attention to what our friendsin other countries such as Australiaand New Zealand, where Parts-Trader has been in place for severalyears, are saying. Like the cancer itis, PartsTrader will be much easierto stop before it spreads any further.

Pay attention to what the busi-nesses in the “test” markets aretelling us. The program providesnone of the benefits claimed and isan administrative nightmare. Re-ports are already coming in thatother insurance companies areadopting their own parts procure-ment programs and imposing theprices and sources for parts pro-cured through the use of such aprogram on those who have noDRP agreements. In short, it’s com-ing to you, whether you want it ornot. Doing nothing to stop it en-sures that it will eventually be justanother part of the way we’reforced to conduct business.

Take a Stand » Have the courageto stand with those who realizethey must fight back, and at leastmake an attempt to take back con-trol of your business. Insurance executives in boardrooms acrossthe country must be laughing,comforted in what has become anall too predictable reaction fromthe collision repair industry. Whenthey attack us, we respond by at-tacking each other. Think aboutdisappointing them this time bytaking a stand against an industrythat has had their foot on our neckfor far too long. This could be yourlast chance. BSB

Bill Fowler has owned Bill Fowler’sBodyworks in Southaven, Miss., since1997. His collision career began in 1968building funny cars and repairingCorvettes. He can be reached [email protected].

»|Viewpoint |«

18 October 2013 | BodyShop BusinessCircle 18 for Reader Service

Circle 19 for Reader Service

Today, we joke about shops thatpulled out collision damage using atree stump and log chains. As a PBEjobber with customers in

rural Iowa in the 1970s, I knewsome of those guys. When carswere built with perimeter framesand conventional steel, a talentedtech could actually get the carsquare enough to line up thefront end (with a box of shims)by using a frame dimensionbook that listed the speci-fications for most Ameri-can cars (in inches)and a tape measure. Agood guy could heatand tug until the rails came close to spec.

Stumped » What were those hardy pio-neers using to tug with? Once the framewas anchored to the tree stump withunhardened log chains (what breakageproblem?), they pulled out the damageusing a come-along, a Porta Power ram orthe shop truck. Really!

In the ’70s, I sold floor pots and 10-tonpulling towers to lots of those shade treeguys. Not only were 18 or 20 pots easier touse than one oak tree, they laid flush to thefloor and didn’t impede other collisionwork when not in use. Without a rigidmount, the first few extensions of the 10-ton ram were just to pull the slack out ofthe anchor chains. Jamming jack stands un-der the chains until they were tighter savedlots of time and moved metal sooner.

Rack ’Em » Anchoring the vehicle framedirectly to rigid clamps on a frame rack waseven faster yet because the first inch of travel

on the ram moved metal. In those early days,only the biggest shops could afford a hugeframe rack built into a floor pit, but boy could

they unwind some hard hit stuff. Usingfloor pots and portable pullingtowers or free standing racks withbuilt-in towers, we pulled andtugged our way to repair andalignment for many years. Andthen…the gas crunch of 1973 hap-

pened. In a country where big-ger was always better, we

became miles-per-gallonconscious overnight. Ittook Detroit until 1979 tomass produce the first ofthe new frame-less cars,

the X-Body General Motors Citation.

Welcome to the New Style » Duringthose intervening years, the first casualty ofexpensive and scarce gasoline was big V8engines. The second was the bridge-girderheavy perimeter frame, and the third wasthe thick, heavy gauge sheet metal. Smallerfour-cylinder engines, the three-boxunicoupe body construction and the hightensile strength thinner metals hit theindustry like a bomb.

Older folks will recall that the Inter-Industry Conference on Auto Collision Re-pair (I-CAR) was formed to teach our techshow to safely repair these new-style autos.You couldn’t heat the metal with a torch be-cause it ruined the strength. You couldn’tpull on the sheet metal box with 20 tons ofhydraulic force because it tore the car apart;and without a perimeter frame, it was diffi-cult to anchor the car rigidly.

In those confusing days of the early ’80s,many shops went shopping for a better

20 October 2013 | BodyShop Business

Clark’sCorner By Mark Clark

Faster Than an Oak Tree

Circle 21 for Reader Service

method to repair the new unibodyvehicles. The choices to hold theframeless car steady, pull the sheetmetal in several directions at onceand measure the boxes back to exactfactory spec fell into three basicstyles, all costing about $25,000 in1980 – a huge blow in an industrywhere the previous most expensivething was the $10,000 fireproof boxthey painted cars in!

Dedicated Benches » Dedicatedbenches used a jig system similarto the fixtures the bodies were builton at the factory. Each unique bodystyle required a specific set of armsand clamps to locate all the variousmeasuring points. Whileunarguably accurate, they weretime consuming. The suspension,engine and drivetrain often had tocome out of their cradles becausethose same mounting holes were

where the fixture pins went. Somelarge dealership shops could affordto buy the measuring fixtures fortheir own models, but most every-body else rented fixtures from theequipment manufacturers. Manytimes, there was a delay as the fix-tures were already rented toanother shop and they were slowto return them. Also, if the priorshop misused the fixtures, theycould arrive bent and out of spec.

Laser Systems » Laser systemswere desirable because they couldbe used to repair anything, evenfull frame cars and trucks. In 1980,only about 2 percent of the cars onthe road were unicoupes. The shopowned the hanging targets and thelaser, so there was no waiting foranother source to begin repairs.

I sold several laser measuringsystems in the early ’80s and was

impressed with their versatility. Mycustomers who did the best withthem employed smart technicians.I’ve discovered over the years thatnot everyone repairing cars is goodat math. Using an early laser systemrequired that the tech be able to cal-culate distances and angles withouta specific set of directions. As thesystems evolved, the math effortwas significantly reduced by exactdirections on where to hang targetsand where to locate the lasers.

Universal Benches » Universalbenches used a box full of pipesand pins and braces much like Tin-ker Toys, which were stucktogether to build a measuringframework. They had the advan-tage of locating most structuralpoints without removing drivetrain or suspension components;they were all on-hand so there was

»| Clark’s Corner |«

22 October 2013 | BodyShop BusinessCircle 22 for Reader Service

Circle 23 for Reader Service

no waiting, and the best ones camewith exact instructions on how tobuild the fixtures for each modelcar. They were quick to use, it waseasy to diagnose the damage andthey could be used by ordinarytechnicians. Clearly I’m still a fan,even though the $25,000 cost ismore like $75,000 these days.

Measure, Pull and Hold » Allthree styles – dedicated, universaland laser measuring systems – havea rigid base with pinchweld clampsto hold the unibody completely stilland multiple pulling arms toreverse the collision damage in sev-eral directions at once. The commonwisdom in those early days wasthat a shop could not repair a hardhit unicoupe car without the threekey elements: measure, pull andhold (MPH). I’ve found thattalented body techs can doanything, and a skilled guy with thefloor pots and a tape measure couldget the three-box car straight again.It just took a really long time. Theyhad to pull, cross measure, pull,measure, pull, measure, etc., untilthey reached spec. Part of the 25grand entrance fee was quicklyrecovered because, with any of thethree styles, once the pin hit thehole or the laser hit the target, youwere done pulling and could moveon. Labor time was and is the mostexpensive thing in collision repair.A rigid hold on the damage, pullingin several directions at once and ago/no go measuring system ismuch faster than an oak tree andlogging chains. Safer, too! BSB

Mark R. Clark isthe owner of Pro-fessional PBE Sys-tems in Waterloo,Iowa; he is a well-known industryspeaker and con-sultant. He is cel-ebrating his 25th

year as a contributing editor toBodyShop Business.

»| Clark’s Corner |«

Circle 123 for Reader Service

Circle 24 for Reader Service

Circle 25 for Reader Service

Web PresenceManagement

Increase Your Visibility With Facebook Offers

If you’re on Facebook a lot, you’ve likelyseen “offers” of discounts, coupons andspecials for certain businesses’ productsand services showing up in your news-

feed. Most of these come from majorbrands, but Facebook Offers are not exclu-sive to these big name brands. You, too, canuse them.

Mmm, Ice Cream » An offer from an icecream shop that I’ve been going to since Iwas a kid (yes, they had ice cream backthen!) recently caught my eye on Facebook.The offer was a free small sundae with thepurchase of any size sundae. Awesome! Icould get my usual large, plus a small too! Iclicked on it. Moments later, Facebookemailed me with two choices: I could printthe offer or show it to them on my phone.

Not known for being patient when itcomes to ice cream, I arranged a trip to theshop that day. I got my sundaes and atethem both up moments later. Life was goodfor both me and the business. I checked inwith Facebook from the shop, mentionedthe offer and at least three friends did thesame thing.

Let’s consider this from a body shop per-spective. While you certainly don’t haveanything as tasty as my favorite ice cream,you do have services I need. How about of-fering a percentage off a detailing job, gascards for a certain amount spent on a re-pair, etc.? Use your imagination! Brain-storm with your staff. These offers willthen show up on your Facebook fans’newsfeeds, potentially reaching a largenumber of them. If they take you up onyour offer, it shows up on the newsfeeds oftheir friends, too.

Why Try It? » Any business with at least100 fans can create a Facebook Offer. SinceFacebook has gone public, they need tocharge for things like this, but fret not, it’svery cheap for the impressions you getcompared to print advertising, radio or TV.

Here are the top three reasons to tryFacebook Offers:

Word of mouth promotion…Facebookstyle. When someone claims your offer, itshows up on their newsfeed. Their friendssee that and there will be a certain amountof monkey see, monkey do.

Performance metrics. Facebook makes iteasy to track the success of your offers. InFacebook’s Insights, you can see all kinds ofanalytics, including how many peopleclaimed your offer and how many times youroffer showed up on someone’s computerscreen (impressions). Have these offers link toa coupon and track the number of claimed of-fers that actually come in the door. All theperson has to do is click on “Get Offer” andfollow the instructions from there.

Online shopping accounted for morethan $200 billion in sales last year. Peopleare clearly comfortable claiming offers andshopping online.

Making an Offer

Step 1: In your status update box, youhave a few options. Click “Offer” and the“In Store Only” option.

By Mark Claypool

26 October 2013 | BodyShop Business

Circle 27 for Reader Service

Step 2: Upload a simple imagedemonstrating your offer. Yourlogo works if you don’t have any-thing else. Then add the Offer Titleabove the picture. Tip: To gainmore claims, make it feel limited orscarce. Example: “The First 200Claims Get a Free $25 Gas CardWith Repair.”

Step 3: Set up the expirationdate, your Terms and Conditions,and a reminder time. Also, set alimit on how many people canclaim the offer, plus include a re-demption code to be used whenshowing the offer to your recep-tionist/CSR.

Step 4: Set up your budget andtarget audiences. You can set yourtarget options by gender, age andlocation. Narrow it down to reachmore people likely to be interested.Keep it close to your location.

Target your town and a few sur-rounding towns near you. The po-tential reach and price are based onyour target area and your existingfan base. Your fans will have thechance to see your offer without itcosting you anything.

Real-Life Example » As men-tioned above, when describingperformance metrics, Facebookgives a tremendous amount ofinsights on an offer. Let’s take alook at a real life example from

A+ Auto Body in Kentucky.A+ Auto Body’s offer reached

more than 12,000 people! Face-book also allows you to see howmany people were engaged, i.e.how many people actually clickedon the offer and opened it up. Youcan also get a really close look athow many people interacted withyour Offer – the number of peoplewho actually claimed it, liked itand shared it. This is all repre-sented in the graphic above.

Be Soft » A soft sell works best;people aren’t on Facebook thinkingbody shop offers. Test a few thingsand see what works best. Send alink to your offer to your emaildatabase, too, and share the offeron your personal page. Let usknow how it works for you! BSB

BSB Contributing EditorMark Claypool has morethan 30 years of experi-ence in the fields of workforce development,business/education part-nerships, apprenticeships

and Web presence management. He is theCEO of Optima Automotive (www.optimaautomotive.com), which provideswebsite design, development, search engine optimization (SEO) services andsocial media management services. Clay-pool’s work history includes stints atMetro Paint Supplies, VeriFacts Automo-tive, the National Auto Body Council(NABC), the I-CAR Education Founda-tion and SkillsUSA. He is the founder ofMentors At Work and co-founder of theCollision Industry Foundation. He served,on a volunteer basis, as the SkillsUSAWorld Team Leader for the WorldSkillsChampionships from 2003 to 2011.

»|Web Presence |«

28 October 2013 | BodyShop Business

Circle 28 for Reader Service

Circle 29 for Reader Service

TechnologyFocus

30 October 2013 | BodyShop Business

Chief Automotive Technologies’ frameracks like the Chief impulse-E/VHT,Goliath and Titan-360 provide mul-tiple, simultaneous pulls with equal-ized pressure. This technique appliesthe same amount of pressure acrossmultiple points of the damaged areaat the exact same time to preventripping, tearing, bending or rollingof high-strength steel. These pullingsystems also supply 10 tons of pullingpower at the hook. All of Chief’s

laser measuring systems constantly measure multiple points simultaneously,even during pulls, so technicians are less likely to miss damage or to putmore damage into the vehicle while pulling. They’re also far more efficientthan those who have to stop and re-measure after every pull.

Pivoting ActionWedge Clamp Systems offers a 3-Dpivot measuring system designed togive you maximum performance inrestoring total vehicle symmetry inthe fastest possible time. Attached toa Wedge Clamp system or to mostother frame equipment with adapters,the Pivot system measures from underthe front bumper to under the rearbumper. Because of the pivoting action,measuring any point from front toback is much quicker than other sys-tems. Not only does the pivot meas-uring make upper body measuringeasy, points inside the vehicle suchas door latches can be measured, too.So whether it’s for damage analysisor simply to have accurate targets topull to, the system does it all. It workswith any standard 3-D vehicle meas-uring specification. Combine it withthe Wedge Clamp Eclipse electronicmeasuring system #E1000 for full up-per and lower body measuring.

Spanesi’s approach to structural re-pairs is unique because, since 1969,Orazio Spanesi has operated hisown body shop. His insight into thestruggles technicians have makingrepairs has inspired him to designand incorporate features to enhancethe operations of all the equipmentSpanesi designs. The features includea high adjustable lifting heights, removable and adjustabledrive on platforms, and a universal fixturing systemthat was designed more than 20 years ago and stillmaintains the original components with no upgrades orchanges, still working efficiently on today’s vehicle plat-forms and suitable for future models based on whatOEMs have shared. Also, the universal jig has a rack

gear system that, using the fixture,allows you to pull up and downdirectly. Because of the tower de-signs, all systems come with “true”10-ton pulling power. Spanesi man-ufactures benches that are portablein operation to permanent aboveground or flush floor installationswith sizes for unibody and full

frame vehicles. In addition, the popular Multibench 12turns every work area into a highly productive efficientwork environment, again helping to reduce cycle times.It combines lifting and pulling so the system is used for every repair in the shop.

No Towers in the WayBlackjack’s Multiple Vector Pull gives you total access to the bottom of acar without having to push big, bulky pull towers out of the way. Beingable to put multiple pulls close together on one rail makes pulling safer byevenly distributing the pull load.

Frame Machines andMeasuring Systems

Body Shop-Influenced Design

Multipoint Pulling and Measuring

Circle 31 for Reader Service

Track Talk

NASCAR racecars require hun-dreds of welds – and every single one of them has to be perfect.

At 200 miles per hour andaround every corner, racecars arepushed to their very limits. Theyhave to be strong for safety, but light for performance.

The cars built at StewartHaas Racing are no exception.

Back at the shop, masterfabricators like Daniel Smithspend hours making sure everyweld is just right.

For Smith, simply put, it’shis passion.

“I’ve always wanted toweld,” said Smith, a native ofConcord, N.C., born and raisedin the heart of motorsportscountry.

After graduating fromNASCAR Technical Institute

and 5 Off 5 On Pit Crew U in2004, 19-year old Smith land-ed a full-time position at whatwas then Haas CNC Racing.Being a typical adventurousteen, Smith quickly earned thenickname “Danger” among hispeers at the shop, but that didn’t stop him from putting inlong hours of hard work andsacrifice to perfect his craft.

“In the beginning, I spenta lot of time in the shop,”Smith reminisced. “I wouldstay after work on my own timeto pick up pointers from otherwelders. I was welding any-thing and everything I couldget my hands on in the shop.”

Smith began his racingcareer in the teardown depart-ment, but soon earned a pro-motion to the fab shop.

Today, the 29-year-old vet-eran juggles bothpit crew and shopduties.

“On Sundays,I go over-the-wallas the rear tire changer on the No. 14,”explained Smith.“On Mondaymornings at 7a.m. sharp, I’mback at the shop,welding andbuilding suspen-sion pieces, uppercontrol arms, oiltanks, spindles,and exhaustpipes.”

Smith’s day job iscritical.

About 95 percent ofNASCAR racecars areTIG-welded by hand.Long before the racecarhits the track, weldingand fabrication consumeroughly 950 man hourson each racecar back atthe shop.

Lincoln Electric,which has provided StewartHaas Racing with weldingmachines, consumables andapparel since 2008, says weld-ing plays an important role inNASCAR keeping drivers safefirst and foremost.

“Critical components suchas the roll cage, seat and chassisneed to withstand forcefulimpacts at speeds of 200+mph,” said Mickey Holmes,sports marketing manager forLincoln Electric. “Quality weldshelp achieve this.”

Most welds join intersect-ing tubes that make up theframe and roll cage. Thesecomponents are fabricatedfrom mild steel, which allowsthe racecar to absorb theforces of a crash in a bend-before-break mode.

When drivers often walkaway from high-speed crashesunhurt, it can be attributed tooverall safety improvementsin the chassis design – andweld quality.

Smith works with a varietyof Lincoln equipment at theshop, including Invertec V311-

T AC/DC, Precision TIG375,Invertec V205-T AC/DC, PowerMIG 350MP, Power MIG 256,and Power MIG 180Cs.

The team’s transports (or“crash carts” as they’re com-monly called) are equippedwith Power MIG 180Cs andInvertec V205s.

“The welding technologyis really amazing,” said Smith.“They’re solid machines. Youcan kind of get spoiled workingwith all the nice equipment atthe shop.”

Smith understands if apart breaks on the track, it can-not break at the weld. Heknows the importance of asound weld, and that a driver'slife is on the line.

“My standards are a littlehigher from working inNASCAR – the welds have tolook nice and be clean andsound,” said Smith. “The steer-ing shaft has to hold up at everyturn. Holding all of the sus-pension components togetheris very vital in racing.”

Double-duty: Daniel Smith is a welder/fabricator at Stewart Haas Racing and rear tire changer

on the No. 14 Mobil 1/Bass Pro Shops Chevrolet. Do you have a passion for welding, too? Start

your project today with help from Lincoln Electric at lincolnelectric.com/moneymatters.

Where There’s a Weld, There’s a Way

By Kimberly Hyde,NASCAR

Follow NASCAR Performance on Twitter and Facebookwww.twitter.com/NASCARauto ■ www.facebook.com/NASCARPerformance

Circle 33 for Reader Service

By Curt Harler

If you think education is expensive, try ignorance.Nowhere is that more true than in collisionrepair where change is a near constantand the materials, tools and technolo-

gies are evolving at a lightning pace. Many in the industry claim techs

are vastly under-trained, especiallyconsidering the rocket ships rollingoff assembly lines today. But shop

margins have been severely eroded,and many owners say they can’tafford training.

Two Philosophies » There seemto be two philosophies in thebody shop business when it comesto training. One school of thought

invests a lot of time and money inclasses to keep current. The other schooldownplays continuing education, pre-

ferring to hire techs who alreadyhave certifications.

COVER STORY

The days of getting by without ongoing training areover. So what will you do? Recruit people who arealready trained, or take on the training yourself?

34 October 2013 | BodyShop Business

People who are not doing trainingwill fall behind and be left behind,says John Cole, owner of Cole’s Col-lision Centers based in Albany withfour locations in upstate New York.

“Training is a necessary componentof any business, whether you’re fix-ing computers or cars,” Cole says.“How can you call yourself a pro-fessional repairer if you’re not up to date?”

Adds Rob Alexander, body shopmanager for Brown Body & PaintCentre, Toledo, Ohio, “Fixing a carbecomes trial-and-error if you’re notproperly trained. We’re really bigon training.”

While Alexander can’t point toany extra sales as a resultof training certifications,

he does say it’s a dif-

ferentiator with insurance companiesand some customers. He points tothe new steels, processing, welding,bonding, foams and plastics used in

today’s cars and trucks. Restraintsystems seem to change by the modelyear. Admittedly, Alexander is soldon training – for a while, he was alocal I-CAR chairman, and his pro-

duction manager today holds thatposition. Yet even he has problemskeeping the shop up to date.

“We’re in a big time of change.Unfortunately, a lot of our industrydoes not recognize it,” says Jeff Peevy,senior director of field operationsand segment development for I-CAR.

Adds Craig J. Camacho, marketingdirector for Keenan Auto Body Inc.,in Clifton Heights, Pa., an MSO thathas a dozen locations in the greaterPhiladelphia area, “A trained tech isan efficient tech.” They’re a certifiedaluminum repair center and have ap-provals from a host of organizationsand companies including I-CAR, ASE,3M, Cromax Pro, NABC and DuPont.

“We pay for ongoing I-CAR train-ing, ASE training and whatever else

COVER STORY » Training Time

www.bodyshopbusiness.com 35

Angelo Campanella, I-CARinstructor, teaches the livedemo class, “BlueprintingProcess and DamageDiscovery.”

“How can you callyourself a

professionalrepairer if you’re not

up to date?”

— John Cole, Cole’s Collision

Centers

may be available in that person’sposition,” Camacho says. Their com-mitment to trained techs goes so farthat they created a non–paid intern-ship called C.R.O.P. (Collision RepairOpportunity Program). C.R.O.P al-lows Keenan to reach out to techni-cians prior to graduating fromtechnical high schools and vocational

schools and provides a nine-month,hands-on training program. The techneeds to fulfill requirements through-out different stages of the course inorder to graduate. Although the stu-dents are not required to work at aKeenan facility post-graduation,Keenan typically offers them full-time employment.

It’s not just the industry giantsthat see the need for training. MattPenney, who runs Penney’s AutoBody at two locations in Garrettsvilleand Ravenna, Ohio, says they alwaysinvest in at least two hours of trainingfor each employee each year.

“We like to spread it around,” Pen-ney says, speaking of both the classsubjects and the people involved.That keeps everyone up to date.

Penney himself has completedmore than 80 hours of training inthe past two decades. “Otherwise,you’d be taking a lot of chanceswhen you put a car back together,”he says.

It starts the moment the vehicleappears at the shop door. “Knowingthe scope of damage and writingproper estimates on vehicles willimpact the bottom line. You need tolook at proper training as an invest-ment in your business. It’s not just abudget item,” says Jon McCreath,president, Vale Training Solutions,Arlington, Texas.

To write good estimates requiresknowledge of new materials andnew systems. “You are never goingto get away from supplemental andhidden damage,” McCreath says.

Says Keenan’s Camacho, “Ouremployees feel empowered by thetraining that is made available to them.”

Keenan requires all shops to attainI-CAR Gold status. “With that, ourtechs have to meet certain educationrequirements individually, includingI-CAR Platinum. Our A.R.C. (Alu-minum Repair Center) techniciansare required to stay current with theUHSS technologies that are constant-ly changing.”

Adds I-CAR’s Peevy, “The daysof getting by without ongoing train-ing are over. Training – and moreimportant, knowledge – is the keyto surviving. I honestly see training,more importantly knowledge, as theway to survive and more impor-tantly thrive. The shops that continueto see training as simply a require-ment for a recognition program or

COVER STORY » Training Time

36 October 2013 | BodyShop BusinessCircle 36 for Reader Service

Circle 37 for Reader Service

to be on a DRP will not survive. Re-cent research (see sidebar pg. 40)proves that even if a shop sendstechs to classes but fails to embracethe experience as an opportunity to

learn and apply, they see only smallgains. Shops embracing training asan opportunity to gain knowledge,share it and apply it see amazingresults over their fellow shops.”

Falling Behind » “While there stillare some smaller shops that dependon the certifications that their newhires bring with them as their onlymeans of being certified, the majority

COVER STORY » Training Time

38 October 2013 | BodyShop BusinessCircle 38 for Reader Service

Keenan Auto Body Inc. has created a non-paid internship that offers nine months of hands-on training to technicians prior tothem graduating from technical high schools or vocational schools.

Circle 39 for Reader Service

of larger shops with DRP contractsand MSOs have no real choice andend up biting the bullet to provideongoing training for their techs,” Ca-macho says. That’s because the poolof vehicles untrained techs will beable to work on will grow smallereach passing year until they closetheir doors.

“When a shop fails to stay abreastof changes in technology, they fallfurther and further behind,” Peevysays.

Besides the risk of a bad repairand increasing liability of the shopand technician, there is the issue ofCSI and cycle time. If a shop focuseson improving cycle time, for example,but then fails to keep up with newtechnology, the cycle time the shopwas once proud of will increase moreand more over time, he says.

COVER STORY » Training Time

40 October 2013 | BodyShop BusinessCircle 40 for Reader Service

Getting the Most ROI for Your Training Bucks

Given the pace of change – 240 industry-wide changes in vehicle construction

between 2010 and 2014, including new composites and electronics – training

is the future of the industry. Just as certain is that training is expensive and get-

ting more so. How can a shop maximize its ROI?

“We must first change the way we as an industry even think about the subject

of training,” says I-CAR’s Jeff Peevy.

First, he says, the industry must stop thinking of training as a requirement but as

a solution to business challenges. “Think of ‘knowledge’ as opposed to just sending

someone to a class, and then work on changing the culture within your operation.”

Look for Peevy to speak at a number of industry events this fall on the concept

of the “Organizational Culture of Learning” and how a collision repair facility can

begin this journey of future success. “The bottom line,” he says, “is a repair facil-

ity needs to think of knowledge as something to go out and harvest and then

bring back and share within the whole operation.”

KPI (key performance indicator) statistics show it works. Shops that simply

sent techs to class saw a 3.6 percent improvement in a vital KPI like cycle time.

The culture-focused shops – those that shared the learning around the shop –

saw a 28.9 percent improvement. That’s a 25 percent return on a simple manage-

ment change.

The key is not to focus on “things,” but on knowledge-sharing.

Circle 41 for Reader Service

“It is your responsibility as a busi-ness owner to stay up on technology,”Cole states.

Squeezing Nickels » The economyhas been weak, and insurance com-panies are squeezing nickels. Thatmeans body shops are hard-pressedto keep up with training.

“We’ve had to cut back a littlebit,” Alexander says. The shopachieved I-CAR Gold status for its12 technicians. It also is Blue Shieldcertified and BASF certified. “It wasan achievement to get that manypeople trained for I-CAR. But as thecriteria for Gold Class kept changing,we lapsed a bit.”

Part of the problem was findingclasses close to Toledo. Detroit,about an hour away, has classes,but Columbus and Cleveland area couple of hours drive and thatgets expensive. As a GM shop,they have the advantage of GMrolling its training into I-CAR. Still,it has been tough to keep up, saysAlexander.

In the Budget? » Training atKeenan is a fixed budget item.

“Budgeting includes calculatingeducation requirements for eachshop based on the amount of em-ployees who need the training, andthat amount of money is includedin each shop’s budget for the year,”Camacho explains.

At Brown Body, there also is abudget for training; however, Alexan-der judges each course on its merits.“I do what I need to do. We evaluateeach course to see if it will be worth-while. I want to be sure that we willget some benefit out of it.”

Right now, two dozen I-CARcoupons that Alexander needs toappropriate out to techs who needtraining sit on his desk. They werepaid for at the beginning of the yearand will be used shortly.

As a dealership, the operation isproactive regarding training in allof its departments. For the rightclass, the money is there.

Cole knows some shop ownerswho have cut back on training.“That’s their problem,” he says, dis-missing the idea. “I’m a businessowner. The decisions that steer mybusiness and cause my success aremine alone. Eventually, they’ll losedata for updating their shop andwill fall behind.”

Keenan uses ALLDATA along withVeriFacts and Motor procedures viaCCC One. Cole uses I-CAR but alsoavails the shop of training with job-bers and paint suppliers who teachtechs how to replicate special finishes,for example. “I want everyone onthe same page,” Cole says.

Penney, too, is sold on I-CAR but

COVER STORY » Training Time

42 October 2013 | BodyShop BusinessCircle 42 for Reader Service

Circle 43 for Reader Service

would like to see more cross-trainingopportunities versus specialty classes –a good idea in a smaller operation.

Cole is big on ALLDATA repairsheets, especially when it comes towelds.

“You have to be sure you do it perthe manufacturer’s specifications,”he says. He finds that, with such doc-

umentation in hand confirming Fordor Toyota’s specifications, the insur-ance company will pay for the specificrepair 90 percent of the time. “Theother 10 percent, they’ll write whatthey write,” he says.

Keeping Current » One way tokeep up with new auto technologies

is to use new learning technologieslike online courses.

Alexander says he’s looking intocomputer-based training modulesto avoid the need for extensive (andexpensive) travel.

Cole is big on online training, too.He notes that I-CAR has online train-ing, and most OEs offer free modulesfor repair techs.

Online and classroom trainingeach have advantages, Cole says.Some techs learn better in a classroomwith a teacher guiding them, whileothers prefer the computer wherethey can go study a topic over andover until they get it right withoutfeeling embarrassed.

“There is some advantage to beingable to send a seam seal around aclassroom and let the techs feel it,”Cole counters.

On the other hand, it’s convenientfor technicians to work on the com-puter in lulls, at night or at home attheir own speed.

No matter which route is taken,“Progressive training is better thannone at all,” Cole states.

Sharing knowledge around theshop works, too. Shop owners them-selves need to be aware of the latestrepair technologies and trends.

“Once the owner knows, he orshe can then pass it down to hisor her staff fixing the vehicles,”Camacho says. “We find that read-ing trade publications, utilizingthird-party quality audits, attend-ing industry events and commu-nicating with fellow owners/operators is a very effective wayto find the latest information tostay current.”

Adds Dunn, “Independent shopowners are better off to spend theirmoney on training than to whinebecause they don’t have the expertiseto fix a car.”

He says the A shops will continueto invest and profit from training. Bshops will get training when regu-larly confronted with jobs they cannotfix. C shops will syphon off whateverbusiness is left.

COVER STORY » Training Time

44 October 2013 | BodyShop BusinessCircle 44 for Reader Service

Circle 45 for Reader Service

To be sure their techs can handlewelding advanced metals like high strength steel and aluminum,Keenan looks to third-party verifying of quality.

“Providers of OE information arealso good sources for up-to-date in-formation,” Camacho says, notingthat shops need to ensure that their

equipment can handle the repairproperly and also must provide theirtechs with the latest informationavailable. “Ultra-high strength steelvehicles require a separate blueprintof repair procedures.”

Including the specified equipmentand an area that’s conducive to alu-minum repair is an additional in-

vestment. Keenan has invested inthese technologies by purchasingthe required equipment and trainingto be both Mercedes-Benz Certifiedand BMW Factory Authorized.

Cole is another shop owner who’sbig on internal training. He flat-outstates, “Most of the people I hirefrom competitors suck. I end upfiring them.” His advice? “Pick theplayer, not the position.”

He says he would rather hire agood person with a great attitudeand invest in training them thanhire someone else’s mistake.

Value » Peevy could be the autoindustry’s equivalent of the Greeks’Cassandra – speaking the truth butnot believed by many. He has pre-dicted a tsunami of change in theindustry ever since the CAFE stan-dards were implemented. That tidalwave now is happening. OEMs, col-lectively, are on a pace to institute80 vehicle changes every modelyear. And it’s not just on high-endexotic vehicles.

“We’re beginning to see sophis-ticated technology in mainstream,high-volume vehicles,” Peevy says.“Ironically, a tech must have soundbasics in order to fully understandmany of the newer concepts in vehicle designs and materials we’re about to see. Without thefoundation of sound basics, thenew stuff can be misunderstoodor just not fully understood and this could lead to less-than-desirable consequences.”

The result is that more shops arebecoming aligned with the idea, and today there are more shops Gold Class or pursuing Gold Classthan in the history of the program, Peevy says.

Penney likes what I-CAR provides.However, he sees OEM classes takingover. “The trend is toward OEM cer-tification,” Penney says. He says hesuspects the manufacturers do notgive the aftermarket schools all ofthe information they might require.“So far, I-CAR has kept up, but cer-

COVER STORY » Training Time

46 October 2013 | BodyShop BusinessCircle 46 for Reader Service

Circle 47 for Reader Service

tain lines are becoming too special-ized,” he continues.

Dunn agrees that it seems OEssometimes are slow to share tech-nology. However, he says that per-ception might be due, in part, to thespeed of information change in to-day’s body business. “We are madeaware of changes more quickly. So,it seems like it takes longer,” he says.

Dunn says the unrecognized forcein all of his is the millions of con-sumers. “All of the posturing andchest pounding by so-called leadersin the industry does not mean a lot,”he says. “But those millions of con-sumers have a lot of clout.”

Forgotten in the situation, he adds,is the OE’s obligation to the cus-tomers who buy the vehicles andwho simply expect their vehicles tocome back as good as new.

McCreath says he has not foundOEMs withholding information. All

of Vale’s instructors are I-CAR cer-tified and he feels they get the latestinformation in those classes.

Camacho says he believes OEMscould make it easier on shops byproviding correct repair standardsfree of charge for their vehicles toshops that fix them. The websitewww.oemonestop.com has at least con-solidated a lot of the informationand reduced the time searchingaround.

Training can help you in court,too. There is always the growingrisk of liability.

“There is little doubt increased li-ability will grow as the momentumof change increases. No one wantsto be brought into court to explainhow their ‘professional business’knew how to properly repair thevehicle in question, when they canprovide no evidence of ongoing tech-nician training,” Peevy warns. “No

matter how you look at it, the daysof getting by without ongoing training are over.”

Camacho notes that, without train-ing, it will be increasingly more dif-ficult to compete. “From a safetystandpoint, the shop inherits the riskof being sued. The lack of traininghas always been a liability. This willbe more prevalent as vehicle tech-nologies continue to evolve andshops that are sued will be in jeop-ardy of losing their business licenseor business in general.

“We’re hoping that the insurancecompanies would hold shops to astandard to expect proper repairsrather than assume a proper repairand to compensate the shops thathave made the investment in equip-ment and employee training viahourly rates.”

Welding is a great example of increased risks. Peevy asked two

COVER STORY » Training Time

48 October 2013 | BodyShop BusinessCircle 48 for Reader Service

Circle 49 for Reader Service

simple questions during CIC inBoston: Do you believe poor weldson structural repairs compromisestructural integrity? Do you believecompromised structural integrity de-creases occupant safety?

“Can you imagine being a shopowner in a trial being asked thesequestions and having no evidenceyou had made any effort to ensureyour shop’s welds were made cor-rectly?” Peevy asks. “If a shop can’tor won’t invest in the necessary in-frastructure, equipment and training,then the amount of work they’requalified to work on will continueto decrease rapidly.”

Everyone needs training. “A tech’stenure has no real bearing on theirtraining,” Camacho says.

“The only thing worse than toinvest in your people and havethem leave is not to invest in yourpeople and have them stay,” quips

Dunn. Masters School emphasizesleadership and management, andDunn says it is important for a shop owner to be proactive ratherthan reactive when it comes to new technologies.

At his own shop, Dunn empha-sizes its own training programs.

Where to Start » “Ultimately, oldervehicles won’t be fixed…they willbe totaled out,” McCreath says. Withthem will go a shop’s future.

“You can’t ignore the new tech-nology. Investing in training even-tually will help the bottom line anddrive business your way in the DRPmarket,” McCreath says. Noting thesqueeze on shops, he adds, “Youmay get beaten up, but it is steadybusiness.”

How can a shop owner ensurethat techs can handle welding high-strength steel and aluminum? Peevy

says he would start with gettingeveryone in an operation that weldsto participate in and successfullypass something like the I-CAR Weld-ing Qualification Tests. The in-shopevents have a shop’s techs weldingon the shop’s own equipment, drivenby the shop’s electrical infrastructure.Pass the test, and an owner can havea level of confidence in the shopand its equipment…and securitythat the techs have what it takes tomake proper welds.

Those tests will now have to beupdated, at a minimum every threeto five years, just to stay relevant.Yes, it will cost money. However,ignorance will prove to be even morecostly. BSB

Curt Harler is a Cleveland-based free-lancer specializing in the auto, technologyand environmental areas. He can bereached at [email protected].

COVER STORY » Training Time

50 October 2013 | BodyShop BusinessCircle 50 for Reader Service

Circle 51 for Reader Service

By Carl Wilson

Waterborne/low-VOCpaint technology is here.In fact, it’s been here forawhile. Maybe not in

your state, maybe not in your shop,maybe not in your face. But it willbe, I assure you, no maybe about it.

Oh sure, you’ve also heard of low-VOC solvent, but waterborne is morecommon. It may exist, but as I un-derstand it, the lion’s share of everymanufacturer’s color developmentgoes to waterborne. So while theremay be a niche market for low-VOCsolvent, the major effort is for water-

borne, and for the purpose of this ar-ticle, that is what we will deal with.

The Mental Change » There are anumber of fundamental proceduresand principles that apply to solventcoatings which transfer over to waterborne/low-VOC. In addition,there are a few procedures and tech-niques that may be new to you. Be-fore we close the gap on that, weneed to saddle and break the mostdifficult bronco in the corral. Youknow what I’m talking about: re-sistance. The mindset of the painters.

I’m talking about preparing yourselfmentally for the change. That’s thelogical first step in this sequence.

In many ways, I believe the tran-sition is easier for some of us olddogs, as we’ve already been throughmany changes. Many of us “cut ourteeth” on lacquer. Acrylic enamelpromised increased production dueto not having to buff a shine on it,but it did take longer to dry. Fur-thermore, single-stage enamelmetallics benefitted from an orien-tation/dropcoat technique similarto what some of the waterborne sys-tems require. Remember when“basecoat” showed up? Until then,we could clear or not, our choice.Basecoat demands it always.

Basecoat/clearcoat urethane is afantastic product, which I supposemost of us have embraced and most

TECHNICAL

Haven’t switched to waterborne/low-VOC coatings yet?Here are some steps you have to take to prepareyourself…because there’s no stopping this train.

52 October 2013 | BodyShop Business

Circle 53 for Reader Service

young painters have always used. Ican appreciate any reluctance andresistance to switch, as we humansall tend to try to avoid change, butthere is no stopping this train. The

tracks are laid. We all must get onboard, or be left behind.

Educate Yourself » My recommen-dation is to start with education. Get

your jobber and paint manufacturerreps – you know, the pros – to startthe process. In many areas, this is al-ready being done. I suspect the vari-ous personalities will dictate thestrategies employed; some will appealto, “You’ll like it better once youchange; no one ever wants to go backto solvent,” while other painters willneed to hear, “You have no choice.”Regardless, ensuring their success inthe transition will get everyone onboard. Once the learning curve hasbeen conquered and new habits es-tablished, everyone will be back tobusiness as usual. Of course, somewill pine for the good ol’ days, andsome will champion the new kid intown, waterborne/low-VOC. Doesn’tmatter. Like it or not, that’s the desti-

TECHNICAL » Preparing for Waterborne

54 October 2013 | BodyShop BusinessCircle 54 for Reader Service

When it comes to block sanding or anyother kind of sanding, don’t cheat theprocess because it will only cheat the endproduct.

Circle 55 for Reader Service

nation we’ll all arrive at. Let’s getthe discussion going.

Shop Environment » So, with theproper mindset being formulated,we need to address the shop envi-ronment to assure as pain-free atransition as possible. Do not blindlybumble into predictable failure byignoring facts.

Waterborne/low-VOC paintmakes a few non-negotiable de-mands. Clean, dry compressed airis one. This can be achieved througha nice, new compressor or by a state-of-the-art air filtration system – or acombination of the two. If you havean old rig that’s been blowing oilpast the rings for years, your airlinesare contaminated and in bad shape.A new compressor on the front endalone will not solve your challenges.

Here again, get the pros fromyour local support system to analyzeyour situation and come up withoptions for you. There are unrealizedyet predictable benefits of air that’sclean and dry enough for water-borne/low-VOC, besides the obviousbenefit of fewer headache-causingcontaminants. With the proper per-sonal protective equipment or PPE,you can breathe this air. In addition,an increased level of awareness will,by default, result in better attentionto detail.

Spraybooth » Another piece of thepuzzle essential to the success ofwaterborne/low-VOC in your shopis a spraybooth designed for it. Ofcourse, retrofitting is also an option.Also, with a refinishing professionalwith the proper mindset, armed with

56 October 2013 | BodyShop BusinessCircle 56 for Reader Service

A brand-new panel should also be cleaned.

Who knows how many “greasy porkchop sandwich hands” have handled it?

TECHNICAL » Preparing for Waterborne

Circle 57 for Reader Service

a proper understanding of the nu-ances of waterborne and a minimalamount of equipment, many boothsare adequate as-is.

Depending what part of the coun-try you live in, you may need aheated booth. The water must evap-orate into the air. If it’s too cold ortoo humid, the process will takelonger than you want. Also facili-tating the evaporation process is adisruption of the surface tension ofthe waterborne/low-VOC paint. Inother words, air blowing across thesurface. This is typically done with

a fan of some sort or an air amplifier.Again, there are booths designedfrom the ground up for this, after-market retrofit kits and a host ofequipment manufacturers whoseproducts can help achieve victory.

There are some fantastic sprayguns out there that make applicationa breeze. You may get by with yourold stuff and your experience andexpertise, but just recognize thatthere are new spray guns designedspecifically for waterborne. May aswell make it easy on yourself. Be-sides, who doesn’t want another

spray gun? Or a whole new fleet ofspray guns?

Changing Habits » On to the thirdstep, which dovetails with the firststep, and may be the most challeng-ing for the painter: changing habits.No, I’m not suggesting that all habitsmust be changed; just the ones thatneed to be changed. I will outlinesome fundamentals and principlesthat have generic applications, buthere again, you need to get the prosinvolved to ensure specific proce-dures and techniques relating to

TECHNICAL » Preparing for Waterborne

58 October 2013 | BodyShop BusinessCircle 58 for Reader Service

Waterborne is only a harsh mistressif you fail to give her what she wants

and shortchange her with poor prep.

Circle 59 for Reader Service

their product are learned and observed. Let’s face it: there are someflat-out bad habits out there, someof which aren’t disastrous due tothe forgiving nature of solvent. Wa-terborne is only harsh mistress ifyou fail to give her what she wantsand shortchange her with poor prep.But treat her properly and you’llhave a blissful union.

There are some fantastic paintersin the field, some who came fromformal schooling with accomplishedinstructors, some who apprenticedunder geniuses and some who wereastute enough to figure out the coursewith a map and compass on theirown. But with some guys you wonder,“Where did he come from? The Cam-brian Explosion?” There is no evidencein the fossil record that demonstratestheir ancestry or lineage. It’s as if theysimply appeared with their habits,

and we’re left scratching our heads,trying to figure out the logic to them.However, I would suggest that moreimportant than the history of whereyou’ve been is an open mind as towhere you’re going. My point is,under almost all circumstances forpainters of all skill levels, you needto get the pros involved for the specifictutorial required by whatever paintline you’re using. There’s no need toreinvent the wheel here – the proshave already figured out how to makeyou successful with their product.

Fundamentals » Here are somegeneral fundamentals.

Cleaning the panel. You can cleanthe car first if you want; some carsneed it, some do not. But clean thepanel regardless. By clean, I meanclean it with purpose. Don’t just gothrough the motions. Clean it, either

with soap and water or low-VOCwaterborne cleaner. Spray on, wipeoff. This will take care of most ofthe organic contaminants such asdirt and bird poop. You may alsohave moss to deal with dependingon which part of the country youlive in.

Follow up with a wax and greaseremover to clean road tar and otherpetroleum contaminants. Spray on,wipe off. At this point, you mayneed to come back with one of thecleaners and a mildly abrasive scuffpad and gently scrub the panel. Sim-ilar to washing dishes, you aren’ttrying to “scrub and scratch” thepanel, just clean it.

“Why should I waste my time,Carl?” you ask. “That seems like alot of cleaning.” Because water-borne/low-VOC paint is less for-giving of surface contaminants that

TECHNICAL » Preparing for Waterborne

60 October 2013 | BodyShop BusinessCircle 60 for Reader Service

Circle 61 for Reader Service

are ground into the panel by thesanding operation.

And by the way, a brand-newpanel should also be cleaned. Whoknows how many “greasy pork chopsandwich hands” have handled thepart before you got it? It’s not awaste of time. You’ll need to cleaneverything again after sanding andprior to painting, so let’s be in thehabit of having both cleaners in somesort of a pressurized sprayer. Ifthey’re handy, then you’ll use them.

Also, keep in mind that not allpaper towels are created equally;some rapidly break down and depositmicro fibers on your panel whenusing a low-VOC waterborne cleaner,while others fail to absorb well andleave a film behind. Get the propertowels for the job. They aren’t moreexpensive, just different. Those trustypros can help make a choice here.

Sanding. Assuming you’re notfrom the Cambrian Explosion, youprobably have a grasp of the fun-damentals of grit selection for thevarious operations. Featheredging,block sanding, final prep for sealing,final prep for blending, etc. Sufficeit to say, don’t cheat the processwhich the pros have dictated. Theyare vested in your success and arenot attempting to sell you on un-necessary procedures. The edgescan possibly be trimmed for econo-my of motion later, but for now, getthose habits ingrained.

If you’re still wet sanding, I wouldask, “Why?” Of course it works quitefine, but it certainly isn’t necessary.There are those of you who havebeen dry sanding since you started,and when you sand with 800 or 1000grit dry paper, well, you alreadyknow why the panel needs to be

clean. Bear in mind, there is a varyingdegree of scratch severity betweendry sanding, wet sanding, handsanding and orbital sanding evenwhen you’re using 400 grit paper ineach of those operations.

In addition, there are products weuse that can be applied over “prop-erly cleaned E-coats” or “properlycleaned plastic.” So obviously thereare instances where we do not needto sand, but “no sanding” is notsynonymous with “no prepping.”Properly cleaning a panel is a pro-cedure in prepping. Whether wemake paint stick through mechanicalmeans such as sanding or through achemical adhesion promoter, weneed to be certain the panel is cleanand dust-free.

One more thing regarding low-VOC cleaners: they defeat static elec-tricity, which isn’t much of a problemin high humidity areas but is elec-trifying in low humidity areas.

You may have noticed a reoc-curring theme here: the pros. Thepros here and the pros there, well,they’re the experts with their prod-ucts and you need to tap into theirexpertise. Do they know every-thing? Are they infallible? Ofcourse not. This is the real world.But by getting their assistanceahead of time, you’ll be virtuallyguaranteed their attention. Waituntil the last moment when thetsunami is about to strike, and youmay find you have to “take a num-ber and get in line.” I can assureyou it’s an easier transition to wa-terborne at your leisure now ratherthan after the train has left thestation. And finally, get preparedfor increased productivity. BSB

Carl Wilson has been painting fornearly 30 years, with formal trainingfrom the GM Training Center, ASE,I-CAR and multiple product and colorcourses. He currently works as a painterat RPMS Auto Body & Paint in Kailua,Hawaii. He can be reached at [email protected].

TECHNICAL » Preparing for Waterborne

62 October 2013 | BodyShop BusinessCircle 62 for Reader Service

Join the social networking revolution by followingus on Twitter and becoming our fans on Facebook!

twitter.com/bsbmagazinefacebook.com/BodyShopBusiness

BodyShop Business Is On Facebook And Twitter!

Circle 63 for Reader Service

By Jason Stahl and Gina Kuzmick

Just when the leaves havefallen in other parts of thecountry and Old Man Winteris bracing to give everyone

a butt whuppin’, the sun shinesbright, the dice roll and the carssparkle at the SEMA Show. If theamazing custom showpiecesweren’t enough, everyone enjoysescaping the frigid temperaturesand their normal work routines fora little vehicle love.

But let us not get too sucked intothe dream of climbing into one ofthese beauties and tearing off theshow floor and into the sunset witha stylish squeal of rubber. No, folks,there’s work to be done and learningto be had!

The learning comes in the form ofthe fourth annual Repairer DrivenEducation (RDE) track of seminarsoffered by the Society of CollisionRepair Specialists (SCRS). This year,the classes have been organized intotracks so collision repairers can moreclearly identify what courses are

most aligned with their businessneeds.

“Each year, we wipe the slate cleanand ask what seemed to get goodfeedback and what didn’t,” saysSCRS Executive Director Aaron Schu-lenburg. “We treat each year like anew learning experience for the de-velopment of the programs. The factthat we have three delineated tracksthis year stems especially from at-tendee feedback. There is so muchgreat content, it’s hard to pick. Oneattendee told us there were differentbusinesses there for different reasons,

It’s SEMA Show timeagain, and you know whatthat means: dreaming of the big win in Vegas. Buteven if you lose at the table,you can still walk awayflush by taking in the greateducation, networking andcutting-edge equipment.

64 October 2013 | BodyShop Business

SHOW PREVIEW

Place Your Bets!

Circle 65 for Reader Service

and he wished we would spell itout for attendees and say, ‘If you’rehere for this reason, these are thetracks you need to go to.’ Anybodycan pick whatever they want – it’sall a la carte – but if someone wantsto follow the track we think willhelp them given the parameters ofwhy they’re there, let’s line that out.”

Those three tracks are “Understand-ing Your Business,” “Enhancing YourBusiness” and “Positioning Your Busi-ness” (see schedule below).

There will also be a slate of freesessions, one per day, including“Accessing OEM Repair Informa-tion” by Toby Chess; “DispellingCollision Repair Technical Myths”by Mark Algie, Shawn Collins andDennis Keicher, 3M; “How Did TheyDo That? Secrets of the RefinishMasters” by Dr. Jane Valenta andDr. Gareth Hughes, PPG Refinish;

and “Equipping Yourself forIndustry Certifications” by JoeBlanton, Car-O-Liner.

Other Activities » Let’s notforget the Collision IndustryConference (CIC) will also behappening 8 a.m. to noon onWednesday, Nov. 6 and Thurs-day, Nov. 7. This event regularlyfeatures 200 to 300 collision industrypeople discussing and debating thelatest issues and controversial topics.There will also be a reception Wednes-day at 6:30 p.m.

SCRS will also be holding an openboard meeting Nov. 5 from 5:30 to 7p.m. at the Collision Repair & Re-finish Stage in the North Hall. Therewill also be an RDE after-party onThursday, Nov. 7 from 8 p.m. tomidnight for those who bought aRDE Full Series Pass. BSB

Show Floor R&I DemosMembers of the SCRS Education

Committee worked with the United

Application Standards Group

(UASG), which represents hundreds