Assessing contamination control of pre-sterilised …...phases and potentially in final production...

Transcript of Assessing contamination control of pre-sterilised …...phases and potentially in final production...

90

*Corresponding author: Berit Reinmüller, Building Services Engineering,Chalmers University of Technology, SE 41296 Goteborg, Sweden. Email:[email protected]

European Journal of Parenteral & Pharmaceutical Sciences 2016; 21(3): 90–101© 2016 Pharmaceutical and Healthcare Sciences Society

Bengt Ljungqvist1, Berit Reinmüller1*, Corinna Maier2 and Ann-Catherine Roth21 Chalmers University of Technology, Goteborg, Sweden 2 Aseptic Processing Technologies & GMP Compliance, Franz Ziel GmbH, Billerbeck, Germany

Assessing contamination control of pre-sterilised container tub transfers into anaseptic manufacturing filling isolator via a de-bagging/no-touch-transfer process step

IntroductionThere is a significant trend in the market towards biologicalproducts with more targeted delivery systems and improvedefficacy which can be given in smaller doses andmanufactured on a smaller scale1. Personalised medicines,advanced therapeutic medicinal products and investigationalmedicinal products have to be filled in controlledenvironments, but in much smaller batches at clinical trialphases and potentially in final production batches.Consequently, new product types are supported by newtechnology developments including increasing use of pre-sterilised single-use disposable systems for sterile productholding, and fluid pathways that transfer product to point offill. Pre-sterilised product containers in different formats

(syringes, vials and cartridges) are particularly useful forsterile medicinal products manufactured in small batches2.This increased use of pre-sterilised product containers haschallenged established container tub transfer methods forentry into filling line isolators/restricted access barriersystems (RABS).

The industry response has been developments inprocess/scale compatible manufacturing technologies, andhere we examine an important development in pre-sterilisedcontainer processing. Transferring tubs of pre-sterilisedcontainers into the Grade A/ISO 5 filling zone traditionallynecessitates bio-decontamination of the outside of the tub ofcontainers at entry into the filling zone. Transfer of materialmust not compromise the stringent requirements for goodmanufacturing practice (GMP) EU controlled environmentclassification – Grade A/ISO 53–5.

Traditionally, pre-sterilised container manufacturersprovided no assurance that the tub outer surfaces were sterileat manufacture and through the supply chain, so by default an

Experimental contamination transfer challenge studies were designed to assess whethercontamination control and sterility are maintained when using a no-touch-transfer (NTT) de-bagging tub transfer method to introduce pre-sterilised containers into a FlexPro50 asepticmanufacturing isolator/restricted-access barrier system filling line system. Importantly, the steriletubs of product containers are enclosed in double steri-bags, and remain sterile through the supplychain to point of filling. Use of NTT means that any of the current automated bio-decontaminationsteps usually employed prior to material transfer into Grade A areas are rendered unnecessary; sincethe bag contents remain sterile and protected and can be transferred without exposing the Grade Aaseptic processing zone to the outer bag. To support this rationale, two key contamination controlstudies were undertaken during processing of tub transfers with the NTT/de-bagging technology; 1)surface-to-surface transfer of human commensal microorganisms representing the challenge of‘worst case’ operator handling, and 2) a structured approach evaluating the risk of airbornecontamination as tubs move through the NTT process steps into the Grade A isolator environment bya particle challenge method (limitation of risks method). In these studies, the barrier–isolatorenvironment remained robust to adverse particle movement, without microbial contaminationtransfer. In addition, the sterile tub outer surfaces were confirmed as maintaining sterility during theNTT process step. These results provide proof of concept of NTT technology.

Key words: Pre-sterilised containers, no-touch-transfer (NTT), de-bagging, aseptic manufacturing fillingisolator, L-R method.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 90

91 BENGT LJUNGQVIST, BERIT REINMÜLLER, CORINNAMAIER, ANN-CATHERINE ROTH

automated decontamination step at entry to filling lineswas required; tub surface bio-decontamination steps wereeither eBeam, cold/low temperature plasma or vaporisedhydrogen peroxide6–8.

Recent developments presented by pre-sterilisedcontainer manufacturers have provided the necessaryassurance that outer tub surfaces are sterile at manufacturewith assurance this sterility is maintained through thesupply chain via use of tamper proof carton closing. Suchassurance of sterility is a prerequisite to implementation ofno-touch-transfer (NTT) process steps that furthermaintain the tub sterility in transfer to point of de-lidding(removal of tub TyvekR cover) and filling/containerclosing9.

Currently, if specified, the outer tub surface bio-decontamination step, e.g. eBeam, requires the tub to beunpackaged from the protective steri-bag with consequentexposure to contamination in the surroundingenvironment or lower classification environments, soeven if the tub outer surfaces were sterile, due to the in-process contamination risks, a tub outer surfacedecontamination step was required at entry to Grade Afilling environments. If a tub surface bio-decontaminationstep is specified, it is acceptable to process pre-sterilisedcontainers starting with a single steri-bag and withoutassurance the outer tub surfaces are sterile.

Considering alternative methodology, with theassurance that outer tub surfaces of pre-sterilisedcontainer tubs are also sterile, NTT technology can beapplied that does not expose the tub to a lowerenvironmental classification than Grade A through

process steps of outer packaging removal and tub transferinto Grade A processing zones. The NTT de-baggingmethod requires double steri-bag packaging and removesthe need for a post-delivery automated bio-decontamination process step by ensuring the sterile tubsand contents are transferred to the aseptic environmentunder controlled environmental conditions, includingoperator to process separation via RABS in the final steri-bag NTT/ de-bagging step9,10.

Carefully controlled NTT techniques are used fordouble bags to remove the initial outer-bag at entry toeither a Grade B cleanroom with a RABS-filling barriersystem or at entry to a RABS–NTT system in a Grade Ccleanroom where filling is completed in an isolator fillingsystem. The RABS–NTT has a controlled environment toGrade B with a Grade A air supply at the transfer point ofthe sterile tub. It is recommended that a manualdisinfection wipe step is used to reduce bioburdenentering the Grade C cleanroom on the double-baggedtubs. At the final entry into the Grade A filling zones, theapplication of semi-automated or fully automated de-bagging/NTT technology, depending on the line fillingspeed, with sterile tub transfer under Grade A air supplyconditions is applied, and thus the tub pre-sterilisedcontainers are protected throughout a continuum fromprimary manufacture to filling (see Figure 1).

Every new technology requires experimental evidenceto prove the concept and validate its use in a processoperating with GMP3-5. Although a small number of USFood and Drug Administration/EU-approved facilities areusing de-bagging technology, supportive data in the public

Figure 1. Pre-sterilised containers manufacturing, supply chain distribution and NTT process steps for transfer into Grade A processingzones for filling.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 91

92 BENGT LJUNGQVIST, BERIT REINMÜLLER, CORINNAMAIER, ANN-CATHERINE ROTH

domain is required that sterile tubs (inside and out) whichhave the necessary assurance of sterility can be transferredtogether with sterile containers into Grade A/ISO 5 zonesvia the NTT process whilst sterility and environmentalcontrol is maintained.

The study objective was to verify that tubs of sterilecontainers which are protected by a steri-bag can enter thefilling zone without contaminating the sterile tub outersurface or the filling zone when using a de-bagging NTTmechanism that does not employ an automated tub surfacebio-decontamination step. This study simulates a worstcase contamination scenario to fully interrogate therobustness of the NTT process. Human commensalsrepresenting the most likely contamination challengethrough packaged tub handling, were deliberatelyinoculated onto the steri-bag outer and the bag cuttingblade. To challenge the NTT–RABS environment, thetubs were singly wrapped in a steri-bag rather than doublybagged so there was no NTT step at bag loading to theRABS that contained the final NTT mechanism at entry tothe Grade A isolator. Furthermore, the surroundingcleanroom was Grade D, although Grade C is therecommendation for isolators filling sterile products11.

It was considered that if the process was robust toa worst case scenario, it would operate at acceptable riskreduction to potential contamination in a manufacturingfacility working under GMP and using good aseptictechnique. The focus points for environmental monitoringof the contamination transfer studies are shown in Figure2, which is a diagrammatic representation of the NTTprocess.

The NTT process has been described previously byDrinkwater et al.9, but in brief the process comprises ofthe following steps. The pre-sterilised containers fortransfer in the NTT process, e.g. nested filling containersin tubs are placed in membrane steri-bags (double bags)made of TyvekR filter material. A number of bagged tubsare then placed in a perforated carton – all layers allowethylene oxide (ETO) to pass through into the productcontainers to render the contents sterile. After thisclassical certified sterilisation step, the carton of steriletubs of containers are then secured by a tamper-prooflabel-tape to provide assurance of maintained sterilitythrough the supply chain.

On receipt at a manufacturing facility, the cartontamper-proof closures are checked for integrity and ifvalid the bagged tubs are removed and transferred withinthe facility to point of use following documentedprocedures. The still-enclosed bag contents are moved to atub loading preparation area for material transfer via NTT.

During the final de-bagging step, the steri-bag is cutopen by a semi-automatic blade cutting mechanism whilstclamped so that particles do not enter inside the bag ontothe tub. The operator (or machine) then completes theNTT process and pushes the sterile tub into the Grade Aarea under Grade A air supply protection without touchingthe sterile tub (Figure 2).

The NTT concept relies on the fact the tubs are ETOsterilised together with double steri-bags and the processof NTT is only under Grade A airflow protection and thetransfer zones are protected from contamination via outerbag surfaces using the NTT technology. In principle, no

Figure 2. NTT of single-use systems and pre‐sterilised containers.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 92

PRE-STERILISED CONTAINER NO-TOUCH-TRANSFER (NTT) PROOF OF CONCEPT 93

decontamination step is required other than initial manualdisinfection on tub packaging at transfer into a Grade Ccleanroom if isolator technology is used in the fillingprocess.

The experiments reported here were conducted in anisolator engineering facility with an isolator filling systemhoused in a Grade D cleanroom (Figure 3). Two potentialroutes of contamination were identified: 1) surface-to-surface microbiological contamination transfer, and 2)airborne contamination transfer that may be in the form ofnon-viable particulate or microbe carrying particles. Toreproduce the most likely microbiological challenge, themicroorganisms collected to inoculate surfaces werehuman commensals from finger touch.

To risk assess the possibility of airbornecontamination during the process, the method forlimitation of risks (the L-R method) was applied with itsvisualisation and challenge test. Airborne contaminationtransfer through the NTT tub transfer was evaluated bymonitoring of particle concentration during the particle(smoke) challenge test to study if there was compromiseto the controlled process environments. In these studies,the barrier technology remained robust to adverseparticle movement during the NTT/de-bagging process.

Furthermore, zero colony forming units (CFU) wererecorded via environmental monitoring in the Grade Afilling area and on outer tub surfaces after the ‘worst casescenario’ purposeful inoculation of the steri-bags and NTTequipment. These results provide proof of concept of NTTtechnology and it is up to individual sites to qualify NTTfor a given application.

Materials and methodsContamination transfer challenge studies includedanalysis of potential airborne and surface contaminationduring the process of tub transfer via the de-bagging/NTTprinciples into a FlexPro50 de-lidding/filling machine

(Groninger GmbH) inside a small batch isolatorconnected to a RABS enclosing the NTT mechanism witha surrounding Grade D cleanroom environment (F. ZielGmbH), as shown in Figures 3, 4(a) and 4(b).

All environmental zone classifications were verified byclassical environmental monitoring as EU Annex 1 GMPcompliant before the tub transfer studies3,11. The transfertubs were pre-sterilised containers sealed with TyvekR lidsand were provided by an approved supplier, Nuovo OmpiStevenato Group, Italy.

Tub transfer studies were completed with a single outerpackaging bag as an experimental worst case scenario. Inmanufacturing process operations, double bagged steriletubs are best practice11. Single wrapped sterile tubs ofnested containers used in the study were not disinfected onentry to the RABS Grade B NTT zone to provide anadditional contamination challenge. Furthermore operatorgowning in the Grade D Cleanroom was deliberatelybasic – an overall, shoe covers and no hair cover tocontribute to the worst case challenge scenario.

Two key experiments were conducted: Experiment 1) astructural approach to physical risk assessment usingparticles from a smoke pencil as tracer and challenge andan optical particle sensor for detection, and Experiment 2)confirmation of absence of surface contamination transferwith NTT technology via classical microbiologicalenvironmental monitoring methods which comprisedcontact plates and swabs.

Qualification of room and isolator environmentalconditionsPrequalification testing verified that the isolator interiorcomplies with EU-GMP Grade A (ISO Class 5, the de-bagger unit (RABS) in front of isolator in-feed ‘mouse-hole’ complies with EU-GMP Grade B – with Grade A airsupply at critical tub opening/transfer point.

Operator intervention into the de-bagging NTT zone isonly possible via RABS gloves. Tub initial entry from the

Figure 3. RABS and isolator set up in study facility.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 93

94 BENGT LJUNGQVIST, BERIT REINMÜLLER, CORINNAMAIER, ANN-CATHERINE ROTH

Grade D Cleanroom into a preparation area with uni-directional airflow (UDF) protection in front of a tub entry‘mouse-hole’ performs to EU-GMP Grade C compliance.These classifications were determined in advance of thetub transfer/contamination challenge studies byenvironmental monitoring methods as referenced in EUGMP Annex 13–5,11.

Experiment 1: L-R methodExperiment 1 utilised the application of the L-R methodwith its visualisation of air movements and its challengetest of the process environment. The L-R method providesa reliable procedure for assessing potential ‘microbecarrying particles’ as microbiological risks of airborne

contamination in clean zones in a systematic way. It reliesupon sensitive measurements of potentially non-visibleparticle movements and not simple visualisation of smokemovement. Particle challenge testing and calculation ofthe risk factor presents an effective way for measuringdifferent types of risk in medicinal product manufactureand environmental monitoring12.

It can be used for tracing the dispersion routes ofairborne contamination, for identification of risksituations, for evaluating risks connected to single processsteps, for immediate evaluation of changes, and forassessment of potential risks. A modification of the L-Rmethod can be used for evaluating the response ofsampling locations in clean zones.

Figure 4. NTT equipment: pre-sterilised container transfer into filling system.

(a)

(b)

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 94

PRE-STERILISED CONTAINER NO-TOUCH-TRANSFER (NTT) PROOF OF CONCEPT 95

The illustrative technique of smoke studies provides auseful technique for visualising air movements anddispersal of contaminants. This technique requires thatisothermal smoke is released continuously and almostmomentum free using a diffuser. The smoke pattern can berecorded by means of still photography and video.Ljungqvist et al. demonstrated that smoke particles aretypically so small that under normal turbulent conditions,they are dispersed in the same way as gases13.

During the challenge test, the process simulation andoperating conditions should preferably exaggerate thehuman interference and interventions in order to morerapidly identify potential risk situations. To assure theresult, generally not less than three measurements of notless than 1 minute each should be performed for eachintervention and at each representative location. Themaximum concentration (number/ft3) value of eachintervention and location, respectively, forms the base forrisk factor calculations. The advantage with this approachis the uncomplicated, immediate registration of resultsusing electronic discrete particle counters. The criticalregions become contaminated only by non-viableparticles, and this approach can be safely used inmicrobiological clean zones with no added risk ofcontamination12–16.

In this study, the barrier technology was challengedwith a smoke pencil during NTT to represent an airbornechallenge (simulating total particulates into airborne

microorganisms’ movements) and a particle counter wasused to scan and map the particle movements.

The first step of risk assessment with the L-R methodwas a confirmation study that the de-bagger/NTT zoneoperates to Grade B with Grade A air supply and that theFlexPro 50 isolator modules meet Grade A (particles andmicroorganism levels) requirements. Figure 5 shows thetesting environment and probe placement (P1–P8). TheL-R method is performed in three steps12,14.

1. Visualisation (by using the smoke technique) of themain air movements and identification of turbulentregions and critical vortices where contaminants canbe accumulated or dispersed in an unpredictable way.

2. The particle challenge test, which identifies potentialrisk situations. It involves placing the probe of aparticle counter in the critical area where duringnormal operations the product is exposed, and takingcontinuous total particle counts while generatingparticles in the surrounding air (e.g. by using aircurrent test tubes) to a challenge level of more than300,000 particles equal to and larger than 0.5 µm percubic foot (~ 107 particles per m3). Thesemeasurements were carried out during simulated tubtransfer production activity.

3. The third step is to evaluate the risk situation bycalculating the risk factor, which is defined as the ratiobetween measured particle concentration (number/ft3)

Figure 5. LR-method: diagram of probe placement.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 95

96 BENGT LJUNGQVIST, BERIT REINMÜLLER, CORINNAMAIER, ANN-CATHERINE ROTH

in the critical region and the challenge level in thesurrounding air. Because of limited measurementaccuracy at high concentrations, a value of300,000/ft3 is used as a challenge level in all riskfactor calculations.

Experiment 2: Contamination transferchallenge studiesThe standard environmental monitoring techniqueselected to assess surface contamination transfer wascontact plating. More extensive environmentalmonitoring was carried out as a control during set up toconfirm the contamination control status of the testingenvironment. Due to the accuracy of Experiment 1 (L-Rmethod) in visualising airborne contamination risk at‘mouse-hole’ entry, settle plates were not sampledduring NTT as it was considered there was no addedvalue.

In this experiment, surfaces of the manufacturing setup were purposefully contaminated with humancommensals as previously stated to be a ‘worst case’scenario including the bag opening cutting knife andouter single steri-bag. A simple method of non-glovedhand inoculation was selected as the most likely ‘realworld’ source of contamination over test isolates as asimulation for operator error. NTT was carried out andto check for contamination in Grade A areas via contactplating on the tub post-NTT, sampling of both the outertub surfaces and inner TyvekR cover was conducted toconfirm maintained sterility (Figure 6).

The first step of the contamination transfer challengestudies was to confirm environmental control zones metEU GMP Annex 1/ISO 14644-1 environmentalclassifications. The zones included RABS (de-bagger)grade B zone, Grade A air supply at tub transfer point intoGrade A filling isolator (de-lidding section), and de-

lidding/filling Grade A isolator. The small batch isolatorinterior conformed to GMP Class A/ISO grade 5 conditionsconcerning particle limits and microbiological air quality.The de-bagger conformed to GMP Class B conditionsconcerning particle limits and microbiological air quality.

Furthermore, the UDF unit used for opening the firststeri-bag (when used) conformed to Grade C and thecleanroom Grade D. Additionally, as a pre-qualificationto the NTT studies, the tub outer surface was confirmedsterile inside a Grade A microbiology laboratory isolatorindependent of an NTT step. For this control test, thebag was manually surface disinfected then opened underGrade A conditions with good aseptic technique andcontact plate samples of the tub surfaces taken toconfirm they were sterile as per the manufacturersguarantee. Furthermore, active air sampling in theRABS–NTT at the critical material transfer location wascarried out as a prequalification to ensure the RABSenvironment conformed to Grade B and critical tubtransfer zone conformed to Grade A air supply(particulate and microbiological levels). Settle platingwas also carried out in classification to prove thecontrolled environments met classification conditions.The following experiment was then carried out.

1. Inoculation of the challenge surfaces were carried outas shown in Figure 7. Initially, the tub outer bag wasinoculated. The inoculum was human commensalfrom finger dabs. Inoculation of the outer bag was viahuman commensal skin contact onto each of the 10tubs before the transfer process. The sample sizeselected was 10 tub transfers (single wrapped) fromGrade C (preparation area) to Grade B (debagger,RABS) through the mouse-hole into a Grade Aisolator. Bioburden studies were completed to confirmthe human commensal challenge.

Figure 6. Contamination transfer challenge studies of NTT to a Grade A filling zone: diagram showing inoculated surfaces andenvironmental monitoring sample locations and type.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 96

PRE-STERILISED CONTAINER NO-TOUCH-TRANSFER (NTT) PROOF OF CONCEPT 97

2. The study design for environmental monitoringsampling was via contact plates for each consecutivesteri-bag before the NTT process step (outside theGrade A isolator) and directly on tub outer surfacesafter the NTT process step and arrival into the Grade Afilling isolator.

To reduce the amount of activity and materials inthe Grade A isolator, tubs were recovered (in sterilebags) from the filling isolator after NTT and moved to atest isolator in an adjacent microbiological laboratoryfor inner TyvekR tub lid surface contact plating.

3. Completion of an actual (not simulated) tub transferprocedure with NTT de-bagging into de-lidding/fillingisolator.

4. Following the initial five tub transfers at the midwaypoint in the experiments, the cutting knife (which opensthe bag) was also inoculated. As before, it was inoculated

with human commensals via direct skin contact and thenthe remaining five tub transfers were completed.

5. The focus of the study microbiological samplingduring the NTT process steps was via contact plates onouter surfaces of the tub after transfer into the Grade Aprocess isolator to confirm maintained sterility.Surface contact plate sampling of the sterile tub outersurfaces after transfer was undertaken as shown inFigure 8 (a) and in additional steps in a laboratoryisolator (Figure 8 (b) and (c)) of inside the TyvekR tublid and on the top of the tub liner.

Contact plating was completed on the outer singlesteri-bag before NTT as a bioburden confirmation.

The first eight tubs had a single contact platesample after the NTT process and the last two (worstcase) tub transfers had duplicate contact plate samplesto check tub top side and underside for sterility.

Figure 7. Inoculation procedure and example of recovered bioburden.

Figure 8. Contact plating of the tub inner and outer surfaces.

(a) (b) (c)

TyvekR lid outside after transfer into smallbatch isolator

Separate study in qualified laboratoryisolator contact plate inside TyvekR lid

Separate study in qualifiedlaboratory isolator contact plateinside TyvekR lid on container linerover open containers

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 97

98 BENGT LJUNGQVIST, BERIT REINMÜLLER, CORINNAMAIER, ANN-CATHERINE ROTH

6. Incubation of contact plates for 36 hours then a further7 days, which gives the best chance ofdetecting/visualising a range of microorganisms atformation growth states. The CFU were counted andrecorded at these two timepoints3,11.

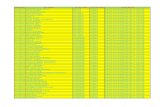

Results L-R methodThe challenge test (see step 2 in Experiment 1 method),was performed first with no activity in the preparationarea or in the RABS de-bagger (Table 1), and then with abag in the transfer opening (Table 2). After that, thechallenge test was carried out during simulated activity(Table 3). From the measurements taken during thesesimulated situations, the third step – calculation of the riskfactor – was performed. The results and calculated riskfactors are shown in Tables 1 to 3.

When the risk factor is less than 10-4 (0.01%) duringthe challenge test, it is assumed there are no risks ofairborne microbiological contamination during normaloperational conditions according to experimentalfindings from more than 30 studied aseptic productionlines16. The evaluation of NTT undertaken here with theL-R method demonstrated that the risk factors are low,thus there was no airborne microbial contaminationduring the tested activities.

Analysis of the L-R method highlighted that thefollowing points should be considered. Firstly, in the tubloading preparation area, bags should not be stored alongthe inner wall of this zone and only on the pathway to‘mouse-hole’ entry to the RABS–NTT zone as this wasshown to disrupt airflow. Secondly, at entry to the RABS–NTT zone, a further NTT technique (using double bags)would provide a more controlled tub entry not onlyreducing risk of contamination transfer but also preventpossible adverse airflow movements at operatorintervention process points.

Results of Experiment 2: Contamination transferstudiesExperiment 2 results are shown in Tables 4 and 5. Adeviation from an expected result was that the initialbioburden at the cutting knife (before inoculation) was 1CFU, but the plate growth was outside the streak line ofthe swab indicating a false-positive. However, false-positive or not, the 1 CFU was still below the 5 CFU not toexceed level of the de-bagging RABS–NTT zone so doesnot influence results. The results per sample type forcontact plates are shown in Table 6.

Even with this worst case challenge, no contaminationwas detected in the Grade A area on tub surfaces.

The most probable root cause for the high counts atouter bag in bioburden studies (marked as red) is fingercontact of contact plate edge due to operator error.

Table 1. L-R method – results from tests without activity and no bag in the transfer area.

Challenge region Probe position Particles per ft3 Risk factor

Inside preparation area (II) P2 In de-bagger 52 1.7 x 10-4

Outside, in front of de-bagger (III) P4 In de-bagger 19 < 10-4

Inside de-bagger, on table P4 In de-bagger 7192 2.4∙10-2

Inside de-bagger, on table P6 In de-bagger 5 < 10-4

Table 2. L-R method – results from tests without activity and with one bag in the transfer area.

Challenge region Probe position Particles per ft3 Risk factor Comments

Outside, in front of P1 In preparation area 11 < 10-4 Bag in transfer areapreparation area (I)

Inside preparation area (II) P2 In de-bagger 27 10-4 Bag in transfer area

Outside, in front of P4 In de-bagger 22 10-4 Bag in transfer areade-bagger (III)

Outside, in front of P6 In de-bagger 0 < 10-4 Bag in transfer areade-bagger (III)

Inside de-bagger, P4 In de-bagger 11,585 3.9 x 10-2 Bag in transfer areaon table

Inside de-bagger, P6 In de-bagger 0 < 10-4 Bag in transfer areaon table

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 98

PRE-STERILISED CONTAINER NO-TOUCH-TRANSFER (NTT) PROOF OF CONCEPT 99

Table 4. Environmental monitoring results per sample type.

Active air Swab Contact plates Laboratory isolator settleplates

Only sampled during Swab of the cutting knife Contact plates were taken before and after Only sampled duringqualification for before and after deliberate NTT from tub surfaces. The steri-bag outer qualification forclassification of controlled contamination to confirm was sampled before and after deliberate classification of controlledareas the bioburden inoculation to confirm bioburden. After the areas.

(see Table 5) steri-bag is removed by NTT the tub outerIsolator: 0 CFU surfaces were plated in the test isolator. Settle plate positioning is

The tub inner surfaces with the TyvekR lid shown in Figure 6.RABS: 1 CFU removed were recovered from the test All settle plates showed

equipment and tested in a laboratory 0 CFU recovery in criticalisolator to confirm sterility was not test areas.compromised during NTT as an independent confirmation study (see Table 6 for results).

Table 5. Confirmation of bioburden after inoculation.

Position Plate 1 (CFU)

Knife bioburden in Grade B before inoculation 1

Knife after inoculation (positive control) 59

Table 6. Results per sample type: contact plates.

Position/tub sample number 1 2 3 4 5 6 7 8 9 10

Outer bag bioburden 0 0 0 0 0 29 0 0 0 8

Outer bag after inoculation 9 27 12 11 11 10 15 9 83 34

TyvekR outside, inside study isolator 0 0 0 0 0 0 0 0 0 0

TyvekR inside laboratory isolator 0 0 0 0 0 0 0 0 0 0

Inner lid, laboratory isolator 0 0 0 0 0 0 0 0 0 0

Table 3. L-R method – results from tests with simulated activity, transfer and opening of bags.

Challenge region Probe position Particles per ft3 Risk factor Response to activity

Inside preparation area (II) P2 In de-bagger 53 1.8 x 10-4 Low

Outside, in front of P4 In de-bagger 8 < 10-4 Lowde-bagger (III)

Outside, in front of P7 In de-bagger at 15 < 10-4 Lowde-bagger (III) working height

Inside de-bagger, in front P8 In isolator, close to 0 < 10-4 Lowof opening to isolator opening to de-bagger

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 99

100 BENGT LJUNGQVIST, BERIT REINMÜLLER, CORINNAMAIER, ANN-CATHERINE ROTH

Growth round the edge of the plate is a possible samplingerror and this was evident when investigated. Fortunately,these errors did not occur on the critical Grade A samples,i.e. those testing if the process is successful. Also higherbioburden on the outer bag at starting may be due to use ofthe ‘worst case’ challenge single steri-bagged tub passingthrough the lower class cleanroom. Usually the processwould use double steri-bagged tubs at this stage andbioburden would be extremely low.

− For the outer bag No. 6, the CFU count of 29 washigher than the positive control (10).

− For the outer bag No. 10, it was visible that someonehad touched the agar surface.

Discussion and conclusionAlthough the sample size is small, the high level of ‘worstcase’ challenge conditions make for compelling data tosupport the concept of NTT. No surface or airbornecontamination was found in the Grade A zone after NTT.Visualisation of air movements alone provides anunderstanding of the situation but does not assure ormeasure the degree of microbiological safety of asepticprocesses. Taken together, both the risk assessment withthe L-R method and contamination transfer study are agood test of the NTT method and concept.

L-R method demonstrates NTT is a robustprocessThis study had some limitations, one of which is the factthat the experimental set up was a simulation of a real lifemedicinal product aseptic manufacturing filling line withthe preparation area for initial tub loading limited for thestudy as a loading table and not having a raised conveyoras the final design for actual processing. The airflowmovement in the experimental RABS–NTT with airflowprotection (high-efficiency particulate air filters) suggestthat the RABS–NTT barrier could be improved at thepreparation entry. As this was a mock-up, it was useful tounderstand the impact of having a less well engineered tubentry zone on airflow movement in the RABS–NTT entrypoint as turbulence was found that should be avoided in areal world scenario to maintain good aerodynamicprotection.

Classical microbiological sampling methodsprovide further evidence for methodDespite the high chance of contamination, these NTTstudies show that the NTT process for tub transfer via adebagger unit complies with the stringent regulatoryrequirements for maintained sterility. Even with worstcase situations (single packed tubs, transfer of humancommensals, sub-standard gowning of operators, Grade Denvironmental surround), no contamination transferoccurred. Although the study was limited in challengesample size and study runs, the significant worst case andcompromised contamination conditions increased theconfidence in the results.

To provide a high level of assurance that tub sterility is

not compromised in transfer into filling lines, it isrecommended that sterile tubs are double bagged ondelivery. For an isolator filling line, as used in studies, thefirst bag is typically removed under UDF together with anNTT technique on entry to the RABS–NTT de-baggingsystem. The second (final) steri-bag would typically remainsterile on the outside or only have very low bioburdenbefore the final bag is removed with the semi-automatedNTT de-bagging system at entry into the Grade A fillingzone. In the case of the research study, only a single steri-bag was used and there was no disinfection step for theouter bag surfaces, so the outer bag was contaminatedbefore it passed into the RABS–NTT de-bagging zonepresenting a further contamination challenge.

Next steps to further interrogate NTTThese experiments indicate that NTT is a secure processbut further studies would be optimal to fully test themethod. Furthermore, it may be appropriate to do case-by-case qualifications on site. Further studies could includeanalysis of a greater array of microbiological isolates, butin principal the most likely challenge from humancommensals (handling of tubs, i.e. by fingers) has beentested.

More studies are recommended to add assurance andreference data, including more extensive environmentalmonitoring sampling, and an increased number of tubtransfers to allow statistical analysis.

As the contamination control element of the NTTprocess relies on Grade A air supply, from down-flow airand out-coming air via the mouse-hole to the Grade Aisolator, it is recommended that this airflow is wellcharacterised with smoke studies and monitored (down-flow velocities) in process operations. As part ofoperational qualification, it is also recommended toinclude tub surface monitoring (to verify sterility and zeroCFU recovery) in conjunction with environmentalmonitoring sampling for the controlled zones (RABS andisolator).

Adoption of new technologies for a new marketAlternative technologies are now starting to be consideredfor many applications in GMP, and NTT offers asimplicity and cost saving with flexibility that is muchneeded as new product profiles are developed withvarying batch sizes and bio-compatibility requirements.Effectively the NTT process uses no decontaminationchemicals and has no process residuals that can cause bio-compatibility challenges to biological products soprovides added advantage at a cost saving.

This alternative process needs no bio-contaminationstep as tubs are assured as sterile in manufacture, throughthe supply chain to point of use and evidence is providedhere that the NTT process is robust to prevent compromiseof the tub sterility of Grade A filling environments.

The cost and expense of the existing tubdecontamination technologies used in productmanufacture such as eBeam do not necessarily suit smallbatch processing, e.g. clinical trial batches or small batchbiological products.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 100

PRE-STERILISED CONTAINER NO-TOUCH-TRANSFER (NTT) PROOF OF CONCEPT 101

Conclusions and recommendationsThese microbiological and airborne particulatecontamination studies were limited in study runs andrange of environmental monitoring sampling but thechallenge was considered greater than the asepticprocessing worst case providing confidence in the results.

This is a very positive indication that NTT with tubsthat start with sterile outer surfaces is a secure processwithout contamination transfer to the containers andfilling environment; and that it is a viable alternative totransfer processes that require a tub surfacedecontamination step, e.g. eBeam or VHPR/ vH202.

This is a contribution to knowledge and understandingand the indications are that NTT is a robust process andproves in principle the concept, but to ensure GMPcompliance individual sites should independentlyundertake contamination control qualification testing andprocess monitoring. These results should apply to anyisolator processing pre-sterilised containers but each siteshould conduct their own qualification studies andvalidation of all process steps, including NTT.

Following further research, microbiologicalcontamination challenge studies at user sites may not berequired with reference taken from peer-reviewed studies.User sites could benefit, however, from applying the L-Rmethod with its visualisation and particle challenge test inNTT process qualification together with environmentalmonitoring of the controlled environments.

References1. Shukla AA and Gottschalk U. Single-use disposable technologies

for biopharmaceutical manufacturing. Trends in Biotechnology2013;31(3):147–154.

2. Novak W. Developments in aseptic filling of parenterals.Presentation at Parenteral Manufacturing PDA Conference,Istanbul, Turkey; 23–27 June 2014.

3. European Commission. EudraLex. The Rules Governing MedicinalProducts in the European Union. Volume 4: EU Guidelines to GoodManufacturing Practice – Medicinal Products for Human andVeterinary Use. Annex 1 – Manufacture of Sterile MedicinalProducts. Brussels, Belgium: European Commission; 2008.

4. Food and Drug Administration. Sterile Drug Products Produced byAseptic Processing – Current Good Manufacturing Practice.Guidance for Industry. Rockville, MD, USA: FDA; August 2004.

5. International Organization for Standardization. ISO 14644-1:2015.Cleanrooms and Associated Controlled Environments – Part 1:Classification of Air Cleanliness by Particle Concentration.Geneva, Switzerland: ISO; 2015.

6. Denis B, Steves S, Semmler E, Bibinov N, Noval W and AwakowiczP. Plasma sterilization of pharmaceutical products: from basics toproduction Plasma Processes and Polymers 2012;9(6):619–629.

7. Vogt O. Case study: utilizing electron beam surface decontaminationto transfer sterile syringe barrels into an isolated aseptic syringefilling line. Pharmaceutical Engineering 2010;30(1):1–8.

8. Unger-Bimczoz B, Kottke V, Hertel C and Rauschnabel J. Theinfluence of humidity, hydrogen peroxide concentration andcondensation on the inactivation of Geobacillus stearothermophilusspores with hydrogen peroxide vapor. Journal of PharmaceuticalInnovation 2008;3:123–133.

9. Drinkwater JL, Novak W and Cecchetto A. Transfer of ready-to-usesterilised product primary packaging containers and single-usesystems into small batch filling systems in isolators. EuropeanJournal of Parenteral and Pharmaceutical Sciences 2015;20(1):23–31.

10. Drinkwater JL and Van Laere M. Risk-based environmental controland process monitoring in aseptic processing. European Journal ofParenteral and Pharmaceutical Sciences 2015;20(4):132–141.

11. Pharmaceutical and Healthcare Sciences Society Bio-contaminationSpecial Interest Group. Bio-contamination Technical MonographNo.20: Bio-contamination Characterisation, Control, Monitoringand Deviation Management in Controlled/GMP Classified Areas.Swindon, UK: PHSS; September 2014.

12. Ljungqvist B and Reinmüller B. Risk assessment with the LRmethod. European Journal of Parenteral Sciences 2002;7(4):105–109.

13. Ljungqvist B, Reinmuller B, Maier C and Roth A-C. Study ofairborne and surface contamination transfer through a process ofpre-sterilised container tub entry into a filling process inside isolatortechnology. Presentation at PHSS Conference: Challenges in SterileProduct Manufacture to Risk Based GMP, Manchester, UK; 9 June2016.

14. Ljungqvist B and Reinmüller B. Hazard analyses of airbornecontamination in clean rooms – application of a method forlimitation of risks. PDA Journal of Pharmaceutical Science andTechnology 1995;49:239–243.

15. Ljungqvist B and Reinmüller B. The LR method in critical areas –airflow patterns and the design of aseptic interventions.Pharmaceutical Technology 2004;28(7):46–54.

16. Thomasin C, Naeff R, Lieb S. et al. The challenge of sterile clinicalsupply manufacture. Proceedings of APV International Congress,Munich, Germany; 1997.

21-3 pp 90-101 Ljungqvist-12.qxp_EJPPS 25/08/2016 22:38 Page 101