Artificial Lift - ESP Thrust

-

Upload

ashish-kumar -

Category

Documents

-

view

214 -

download

10

Transcript of Artificial Lift - ESP Thrust

Runtime performance

Preventing early pulls

Copyright 2009 All Rights Reserved ESPLIFT.com

Objectives:

You’ll recognize importance of ESP thrust design as a function of ESP performance and reliability.

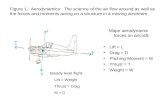

Overview of thrust and how it occurs. Upthrust and downthrust – the real story with

ESPs How to stay away from trouble. ***Participation and sharing knowledge - Question

time is anytime

VALUE PROPOSITIONRecap the obvious:

$$$ - > reliability & performance

OPEX & PRODUCTION REVENUE The early stage of field development - which form of artificial lift?

The ultimate operator measure of how a lift technology and vendor performs

Reduces operator cost of equipment replacement

Reduces your workover cost (can be as much as $500k - $2M per workover)

Reduces the cost of lost production (@2000 BOPD = $80K/day, , $2.4 MM/month ) assuming $40 / b

Short runs are bad for your stress level, trust me!

Some Factors that Influence ESP Runlife& where THRUST fits into the equation

Well conditions - temperature, viscosity, gas, abrasives, corrosion, solids, scale etc.

***The Product Design - Engineering Quality of manufacture and testing - Manufacturing ***The right product for each application - Applications Quality of installation - Field Service ***The operator - it is actually very easy to destroy an ESP

through improper operation ***Mechanical and electrical stress ***Lack of down hole knowledge - Monitoring Systems ***Pulling and failure analysis - Reliability Engineering

SOME BASICS 1-2-3:

All ESPs are designed to operate in DOWNTHRUST.

UPTHRUST IS TO BE AVOIDED ! Pearl of Wisdom – if operating near the

extreme – know your limits and monitor!

Pumps are designed to operate in downthrust.

In a fixed stage pump the thrust is handled by the thrust chamber bearings

In a floater style pump the hydraulic thrust is controlled by the individual stage diffuser

Various manufacturers have different technologies –examples Centrilift Abrasion Resistant Technology -Tungsten Carbide bearing support (1:1 AR and Modular) and Reda - Ceramic Bearing Support.

14

•In a gassy well,

what’s the longest

duration your ESP has

operated in upthrust?

•What does your O&M

manual tell you about

length of time and

cycles allowed in

upthrust ---

SPECIFICS !

•Affects of sand and

gas on operating into

upthrust.

Do your homework

Get your operations people trained and updated!

If in doubt, consider obtaining unbiased non vendor help to ask the right questions and steer you away from trouble

Design the right applications – great performance and economical solution

KEEP YOUR OPERATION UP AND RUNNING – CAPEX AND OPEX TOPS.

Questions.

Credits: SLB Reda, BHI Centrilift, Canadian Advanced, Wood Group ESPI.

15