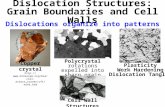

AREA DEFECTS: GRAIN BOUNDARIES

description

Transcript of AREA DEFECTS: GRAIN BOUNDARIES

Chapter 4-15

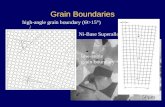

Grain boundaries: • are boundaries between crystals. • are produced by the solidification process, for example. • have a change in crystal orientation across them. • impede dislocation motion.

grain boundaries

Schematic

Adapted from Fig. 4.7, Callister 6e.

AREA DEFECTS: GRAIN BOUNDARIES

Low-angle or tilt grain boundary

Burgers vector

Chapter 4-15

• External surfaces of a material (where bonds are not complete for atoms).• Stacking faults in FCC materials (i.e. a loss or interruption in the ABCABC… sequence)• Bulk or Volume Defects: like cracks, voids or pores, foreign relatively- large inclusions, other material phases (to be studied more later).• Atomic Vibrations: a function of temperature T (actually define it). Typically 1013 vibrations/second.

OTHER DEFECTS:

Chapter 4-16

• Useful up to 2000X magnification.• Polishing removes surface features (e.g., scratches)• Etching changes reflectance, depending on crystal orientation.

microscope

close-packed planes

micrograph ofBrass (Cu and Zn)

Adapted from Fig. 4.11(b) and (c), Callister 6e. (Fig. 4.11(c) is courtesyof J.E. Burke, General Electric Co.

0.75mm

OPTICAL MICROSCOPY (1)

Chapter 4-

Fe-Cr alloy

microscope

grain boundarysurface groove

polished surface

17

Grain boundaries...• are imperfections,• are more susceptible to etching,• may be revealed as dark lines,• change direction in a polycrystal.

Adapted from Fig. 4.12(a) and (b), Callister 6e.(Fig. 4.12(b) is courtesyof L.C. Smith and C. Brady, the National Bureau of Standards, Washington, DC [now the National Institute of Standards and Technology, Gaithersburg, MD].)

ASTM grain size number

N = 2n-1

no. grains/in2 at 100x magnification

OPTICAL MICROSCOPY (2)

Or use line method: measure grain numbers intersecting several (5-10) lines drawn on a photomicrograph. Divide line length by average grain number by magnification.

Chapter 4-16

• magnification > 2000X.• Examples: Transmission Electron Microscope (TEM) Scanning Electron Microscope (SEM)• TEM and SEM use electron beams instead of light beams• SEM pictures a top view of a sample (needs to be electrically conductive but no need for polishing and etching)• TEM “sees” through a thin foil of a specimen. Magnification up to 1,000,000X. Used frequently to study dislocations.• SEM has a great depth of field. Magnification from 10X-50,000X.

ELECTRON MICROSCOPY

Real dislocationsusing TEM

Chapter 4-16

• resolution in the nanometer range (mags. up to 109X)• Examples: Scanning Tunneling Microscope (STM), and Atomic Force Microscope (AFM)• SPMs give three-dimensional images with surface topography information.

SCANNING PROBE MICROSCOPY (SPM)

An AFM image of (111) atoms in gold

Chapter 4-18

• Point, Line, and Area defects arise in solids.

• The number and type of defects can be varied and controlled (e.g., T controls vacancy conc.)

• Defects affect material properties (e.g., grain boundaries control crystal slip).

• Defects may be desirable or undesirable (e.g., dislocations may be good or bad, depending on whether plastic deformation is desirable or not.)

SUMMARY