Architectural Precast Concrete Presentation May 2009 · Architectural Precast Concrete Presentation...

Transcript of Architectural Precast Concrete Presentation May 2009 · Architectural Precast Concrete Presentation...

Architectural Precast Concrete PresentationMay 2009

1

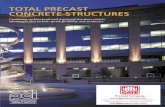

Presented by

Martin Newland B.E. M.I.E. Aust CP Eng

SA Precast Pty. Ltd.72 Days Road

CROYDON PARK SA 5008

PHONE: 8346 1771

FAX: 8340 1645

email: [email protected]

Web Page: www.saprecast.com.au

ArchitecturalPrecast Concrete

Nomenclature

Ferrule

Dowel

Grout tube

Packers

Clutch

Lifter Shutter (Mould sides)

Cast in plates

Tilt - up Concrete(A brief overview)

It is NOT to be confused with Precast Concrete

Tilt - up concrete is manufacured onsite and thenthe panels are lifted into final position

Architectural Precast Concrete PresentationMay 2009

2

In all construction work safety is paramount. Precast concreteand tilt up panels are heavy and dangerous if mishandled.

Panels onsite should be securely propped.

An accident involving 6 tonne panels, only material damage, luckily there were no lives lost

Architectural Precast Concrete PresentationMay 2009

3

Large open siteSimple low rise designLarge panelsHigh quality finish is not paramount as high a build painthas been used on exterior to cover imperfections

Precast Concrete Panels

Precast Concrete Tilt-up Concrete

Factory made and taken to site Made on site and lifted into positionFactory controlled quality Site controlled qualityLarge variety of colours Limited range of natural coloursLarger variety of finishes Limited finishes available

Restricted size & weight Extremely large panels can be made

Best used for

Multistorey buildings where spaceis restricted during construction.The panels are made off site &ahead of time and where a highquality finish is required.

Ideal for warehouses, factorybuildings where there is space tomake the panels and where quality &finish are not paramount

Relatively expensive Relatively inexpensive

Variety of shapes Limited Shapes

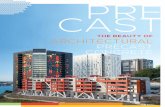

versus Architectural Precast Concrete Convention Centre Hyatt Hotel Westpac

House

CommonwealthOffices

Origin BuildingKPMG HouseDavidJones

EmbassyApartments

HorizonApartments

Education Department Bldg

Flinders Street

Westpac House

King William Street KPMG House, Grenfell Street

Architectural Precast Concrete PresentationMay 2009

4

David Jones, North TerraceHorizon Apartments

North Terrace

Embassy Apartments

North Terrace

SA Water Building

Grenfell Street

BHP-Billiton House

Grenfell Street

Architectural Precast Concrete

SGIC Building, Victoria Square

Price Waterhouse Centre, Hindmarsh Square Adelaide Bank Building, Hindmarsh Square

Architectural Precast Concrete PresentationMay 2009

5

Stamford Grand

GlenelgStamford Grand

Glenelg

Origin Building, North Terrace The Hawke Building, Campus West UniSA, North Terrace

How are Architectural Precast Concrete panels made?

Shop DrawingsShop drawings are made using AutoCAD.They contain theinformation gathered from the Design Engineer’s drawings, theArchitect’s Drawings and the specifications for the project.

Each panel has its own shop drawing & must contain all therelevant information for the moulds and the panel to bemanufactured. This information includes:-

· all dimensions required to make the mould· the location and type of fittings to be cast into the panel· how the panel is to be lifted & the capacity of the lifters· the reinforcement to be used and the cover to the surfaces· the type and colour of concrete to be used· the surface finish to be achieved

Elevations & Plans must be drawn showing the location of eachpanel on the building.

Architectural Precast Concrete PresentationMay 2009

6

MouldsMoulds are made using the information contained in the shop drawings.

Moulds can be made from concrete, timber, or steel or a combination ofall three.

Moulds must be made accurately and rigid enough to support theconcrete before it sets.

Moulds must be made so the precast panel can be easilyremoved once the concrete has set.

An advantage of precast concrete is that a well designedmould can be reused many times.

Excellent repetition ofthe panel moulds

Hooker Building

King William Street

Mould bases can be flat and made of steel or concrete

Mould bases can be curved & complex in shape Moulds can be used to make complex panel finishes

Architectural Precast Concrete PresentationMay 2009

7

The mould sides (shutters) and “block outs” for windowpenetrations are fixed to the mould base, and the and themould size is checked.

Fittings and lifting devices are placed and secured.

The mould is cleaned of debris & the location of fittings ischecked against the shop drawings

The Batch Plant

The concrete is placed and vibrated in the mould The concrete is screeded and finished as the concrete castingproceeds

Architectural Precast Concrete PresentationMay 2009

8

The next day the shutters are removed & the panel isprepared for lifting.

The panel is lifted using a special spreader bar and a gantry crane andtaken to the storage area or taken for further processing

The panels are stored on edge in “pin racks.” Storing on edgeminimises any warping and twisting Concrete does not have to be a cold grey material. Apart from painting

the surface there are a number of common finish treatments available.

These are:-

Acid washing. Removes the cement skin and gives a sandstonefinish to the concrete.

Sandblasting. Removes the cement skin but exposes the aggregatebeneath.

Polishing. The milling process removes the top 5mm on concretefrom the panel face. The milled face is then polished with a seriesof polishing stones until all the scratches on the aggregates havebeen removed and a high gloss is achieved.

Acid washing Sandblasting

Architectural Precast Concrete PresentationMay 2009

9

Polishing Brick tile facing & Mould liners

Relative Precast Concrete PricesPrice Per Square Metre On Truck On Site

$400

$300

$200

$100

Plain offform

Acid Washed & Sandblasted

Polished, Brick facing & Mould Liners$500

$400

$300

$200

Delivery to site Delivery to site

Architectural Precast Concrete PresentationMay 2009

10

Lifting into position on site

Favco STD 1500 cranewith 61m boom

5 tonnes @ 55 metres10 tonnes @ 30 metres

140Tonne Liebherr mobile cranewith 45m boom

5 tonnes @ 34 metres10 tonnes @ 26 metres

Environmental considerations. Use electric cranes in residential areasLifting into position on site

Architectural Precast Concrete PresentationMay 2009

11

Fixing precast panels to the building

The structure is constructed ahead of the Precast Panels beingdelivered to site

These panels are not load bearing

Panels may be incorporated in the structureThese panels are load bearing

These precast concrete panels arestored on there sides in a “pinrack” in the precast yard

The “Grout tubes” can be seen inthe base of the outer two panels

These precast concrete panels arestored on there sides in a “pinrack” in the precast yard

The “Grout tubes” can be seen inthe base of the outer two panels

The three dowels in the top of thecentre panel match the grout tubesin the bases of the other panels.

Architectural Precast Concrete PresentationMay 2009

12

These precast concrete panels arestored on there sides in a “pinrack” in the precast yard

The “Grout tubes” can be seen inthe base of the outer two panels

The three dowels in the top of thecentre panel match the grout tubesin the bases of the other panels.

Lifting points can be seen inthe top edge of the centre panel

Fixing sequence on site

This is how the building looks today

Pacific Apartments, Hindmarsh Square

Sealing the joints of the façade to make it watertight

Help is available. Seek out this book in your library

www.npcaa.com.au

Architectural Precast Concrete PresentationMay 2009

13

Precast concrete can be simple or ornatePrecast concrete can be simple or ornate

Precast concrete can be simple or ornateArchitectural

Precast Concrete

email: [email protected]

Web Page: www.saprecast.com.au