April 29, 2019 From: Project: MTOID Office Copies: Dean ...

Transcript of April 29, 2019 From: Project: MTOID Office Copies: Dean ...

ADDENDUM 01

To: Bidders Subject: Addendum 01 Date: April 29, 2019

From: Jesse Allen, GSBS Architects

Project: MTOID Office Remodel

Copies: Dean Ayala, MTOID

Construction Documents dated 04/18/2019 were posted on Mt. Olympus Improvement District’s website

on Friday, 04/19/2019. Items in this addendum apply to all drawings and specification sections whether

referenced or not involving the portion of the work added, deleted, modified, or otherwise addressed in

this addendum.

Receipt of this addendum shall be acknowledged by inserting its number and date on the bid form.

This addendum consists of the following:

1) Revised Mechanical Drawings:

a. Updated floorplan consistent with the rest of the Construction Documents. Including the

walls in the central restroom area on the Plumbing Plan.

b. Engineer’s stamp

c. Updated title block indicating “Construction Documents” instead of “Schematic Design”

d. Updated issue date of 04/18/2019.

SECTION 230080 - SELECTIVE MECHANICAL DEMOLITION

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and other Division 01 Specification Sections, apply to this Section.

1.2 SUMMARY

A. This Section includes the following:

1. Demolition and removal of selected portions of building or mechanical systems.

2. Salvage of existing items to be reused or recycled.

1.3 DEFINITIONS

A. Remove: Detach items from existing construction and legally dispose of them off-site, unless

indicated to be removed and reinstalled.

B. Remove and Reinstall: Detach items from existing construction, prepare them for reuse, and

reinstall them where indicated.

C. Existing to Remain: Existing items of construction that are not to be removed and that are not

otherwise indicated to be removed or removed and reinstalled.

1.4 PROJECT CONDITIONS

A. Hazardous Materials: It is not expected that hazardous materials will be encountered in the

Work.

1. If materials suspected of containing hazardous materials are encountered, do not

disturb; immediately notify Architect and Owner.

B. Utility Service: Maintain existing utilities in service and protect them against damage during

selective demolition operations.

PART 2 - EXECUTION

2.1 EXAMINATION

A. Survey existing conditions and correlate with requirements indicated to determine extent of

selective demolition required.

B. When unanticipated mechanical, electrical, or structural elements that conflict with intended

function or design are encountered, investigate and measure the nature and extent of conflict.

Promptly submit a written report to Architect.

2.2 UTILITY SERVICES AND MECHANICAL SYSTEMS

A. Existing Services/Systems: Maintain all services and systems and protect them against

damage during selective demolition operations.

2.3 PREPARATION

A. Site Access and Temporary Controls: Conduct selective demolition and debris-removal

operations to ensure minimum interference with roads, streets, walks, walkways, and other

adjacent occupied and used facilities.

1. Comply with requirements for access and protection specified in Section 015000 -

Temporary Facilities and Controls.

B. Temporary Facilities: Provide temporary barricades and other protection required to prevent

injury to people.

2.4 SELECTIVE DEMOLITION, GENERAL

A. General: Remove existing mechanical systems only to the extent required and as indicated.

Use methods required to complete the Work within limitations of governing regulations.

B. Removed and Reinstalled Items:

1. Clean items to functional condition adequate for intended reuse.

2. Protect items from damage during transport and storage.

3. Reinstall items in locations indicated. Comply with installation requirements for new

materials and equipment. Provide connections, supports, and miscellaneous materials

necessary to make item functional for use indicated.

C. Existing Items to Remain: Protect construction to remain against damage and soiling during

selective demolition.

2.5 SELECTIVE DEMOLITION PROCEDURES FOR SPECIFIC SYSTEMS

A. Piping includes: Pipe, fittings, valves, accessories, hangers and insulation.

1. Where existing piping is to be removed:

a. Piping shall be drained, disconnected, removed and capped at an active main.

b. Piping not to remain in use shall be removed completely.

B. Ductwork includes: Ductwork, fittings, dampers, registers, grilles, diffusers, accessories,

hangers and insulation:

2. Where existing ductwork is to be removed:

a. Ductwork shall be disconnected, removed and capped at an active main.

b. Ductwork not to remain in use shall be removed completely.

2. Where existing ductwork is to be relocated:

a. Ductwork shall be disconnected and removed as shown.

b. Hangers may remain if they are to be reused for reinstallation.

c. Ductwork shall be stored for reinstallation.

C. Where piping or ductwork to be removed is concealed in construction it may be abandoned in

place if capped at both ends and approved by the Owner and the Architect.

2.6 DISPOSAL OF DEMOLISHED MATERIALS

A. General: Except for items or materials indicated to be reused, reinstalled, or otherwise

indicated to remain Owner's property, remove demolished materials from Project site and

legally dispose of them in an EPA-approved landfill.

1. Do not allow demolished materials to accumulate on-site.

2. Remove and transport debris in a manner that will prevent spillage.

B. Burning: Do not burn demolished materials.

C. Disposal: Transport demolished materials off Owner's property and legally dispose of them.

2.7 CUTTING AND PATCHING

A. All necessary cutting and patching shall be done by the General Contractor.

B. Removal and replacement of suspended ceilings necessary for selective demolition of

mechanical systems shall be done under this section.

END OF SECTION 230080

B

A

GENERAL NOTES

C

D

E

F

G

H

I

J

K

L

M

N

MODIFY EXISTING FIRE SPRINKLER SYSTEM TO PROTECT ALL

REMODEL AREAS. NEW SPRINKLER HEADS TO BE "RELIABLE" F1 OR FR.

CONTRACTOR SHALL COORDINATE ALL SPRINKLER WORK WITH THE

ONSITE BUILDING ENGINEER. CONTRACTOR SHALL NOTIFY BUILDING

ENGINEER 24 HRS. PRIOR TO NEEDED DRAIN DOWN. ALL SPRINKLER

DRAIN DOWNS AND REFILLS SHALL BE DONE BY THE ON-SITE

BUILDING ENGINEER. FIRE SYSTEM SHALL BE FULLY FUNCTIONAL

OVER NIGHTS AND WEEKENDS.

CONTRACTOR SHALL COORDINATE ALL SPRINKLER WORK WITH THE

ONSITE BUILDING ENGINEER 24 HOUR ADVANCE NOTICE IS REQUIRED

FOR SPRINKLER DRAIN DOWNS. ALL SPRINKLER DRAIN DOWNS AND

REFILLS SHALL BE PERFORMED BY THE ON-SITE BUILDING ENGINEER.

ALL SPRINKLER WORK MUST BE COMPLETED ON THE SAME DAY AND

THE SYSTEM REFILLED NO LATER THAN 4:PM MON-FRI.

HAMILTON PARTNERS ENGINEERING TO WITNESS FIRE ALARM TEST,

DOOR RELEASE TEST AT PROJECT COMPLETION.

CONTRACTOR SHALL ENSURE THAT ALL SMOKE DETECTION DEVICES

ARE COVERED PRIOR TO AND DURING CONSTRUCTION.

A

FIRE PROTECTION NOTES

O

P

CONTROL CONTRACTOR SHALL SET UP TREND LOGS ON EACH FANPOWERED VAV BOX AT THE FOLLOWING POINTS: SUPPLY AIR TEMP,OCCUPIED TEMP SET POINT, SPACE TEMP, OCCUPIED/UNOCCUPIED,FAN SPEED. EACH TREND LOG SHALL BE LABELED IN THE FOLLOWINGMANNER: FLOOR#, TENANT NAME, BOX NUMBER, LOG NAME I.E.;“SUPPLY AIR TEMP”. CONTRACTOR SHALL COORDINATE AND FOLLOWEXISTING BUILDING SPECIFICATIONS AND MANUFACTURER.

A

CONTROLS NOTES

Q

R

S

T

U

B

C

D

E

F

DO NOT SCALE DRAWINGS. SEE ARCHITECTURAL DRAWINGS AND

REFLECTED CEILING PLAN FOR EXACT LOCATION OF DOORS,

WINDOWS, CEILING DIFFUSERS, ETC. CLOSELY COORDINATE NEW

MECHANICAL WITH ALL NEW AND EXISTING MECHANICAL, ELECTRICAL,

ARCHITECTURAL AND STRUCTURAL MEMBERS. DUCTWORK AND PIPE

ROUTING IS APPROXIMATE, DIAGRAMMATIC AND IS NOT TO BE SCALED.

PROVIDE ALTERNATE ROUTING, OFFSETS AND TRANSITIONS AS

REQUIRED FOR COORDINATION OF ALL WORK WITHOUT ADDITIONAL

COST TO THE OWNER.

FIELD VERIFY ALL MECHANICAL AND PLUMBING ITEMS PRIOR TO

COMMENCING NEW WORK. NO ADDITIONAL PAYMENT WILL BE

ALLOWED FOR CONTRACTOR'S FAILURE TO BECOME FAMILIAR WITH

EXISTING CONDITIONS.

ALL MECHANICAL WORK SHALL BE COORDINATED WITH THE WORK

PERFORMED UNDER OTHER DIVISIONS TO AVOID INTERFERENCE.

HVAC CONTRACTOR SHALL REPAIR, REPLACE AND REPAINT TO MATCH

EXISTING SURFACES DAMAGED BY THE HVAC CONTRACTOR DURING

INSTALLATION OF MECHANICAL EQUIPMENT.

HVAC CONTRACTOR SHALL REMOVE FROM THE JOBSITE ANY

MATERIALS PRODUCED DURING DEMOLITION AND NOT IDENTIFIED TO

BE REUSED OR RETURNED TO OWNER.

DO NOT SHUT-OFF/PUT OUT SERVICE ANY SYSTEMS/SERVICES

WITHOUT FIRST COORDINATING ALL DOWNTIME WITH THE OWNER'S

PERSONNEL.

INSTALL ALL EQUIPMENT PER MANUFACTURERS RECOMMENDATIONS

AND INSTRUCTIONS.

DUCT DIMENSIONS SHOWN ARE INSIDE CLEAR DIMENSIONS.

COORDINATE ALL FIRE SPRINKLER, DIFFUSER AND GRILLE LOCATIONS

WITH REFLECTED CEILING PLAN AND ELECTRICAL DRAWINGS.

ALL PIPING SHALL BE SUPPORTED ADJACENT TO EQUIPMENT, TO

PREVENT WEIGHT OF PIPING BEING PLACED ON EQUIPMENT.

FURNISH AND INSTALL ALL SUPPORTING ANGLES AND EXTRA SUPPORT

BEAMS FOR A.C. UNITS, EXHAUST FANS, ETC.

HVAC CONTRACTOR SHALL CHANGE OUT THE EQUIPMENT FILTERS AT

THE TIME OF POSSESSION OF THE PROJECT BY THE OWNER, USING

ONLY NEW FILTERS OF THE PROPER SIZE AND TYPE.

DUCT INTERIORS VISIBLE THROUGH REGISTERS, GRILLES, AND

DIFFUSERS SHALL BE FLAT BLACK.

PROVIDE ISOLATION VALVES ON ALL PIPING TO EQUIPMENT.

PROVIDE SERVICES OF A TEST & BALANCE AGENCY TO BALANCE ALL

AIRFLOWS. THE ONLY APPROVED T&B AGENCIES ARE CTB AND BTC.

ALL CONTROLS WORK TO BE PERFORMED BY D&L CONTROLS.

CONTROL CONTRACTOR SHALL SET UP TREND LOGS ON EACH FPB AT

THE FOLLOWING POINTS: SUPPLY AIR TEMP, OCCUPIED TEMP SET

POINT, SPACE TEMP, OCCUPIED/UNOCCUPIED, FAN SPEED. EACH

TREND LOG SHALL BE LABELED IN THE FOLLOWING MANNER: FLOOR#,

TENANT NAME, BOX NUMBER, LOG NAME I.E.; “SUPPLY AIR TEMP”

ALL WORK THAT REQUIRES OPEN FLAME OR PRODUCES ANY SPARK

SUCH AS SOLDERING OF PIPE JOINTS, WELDING, CUTTING OF METAL

STUDS WILL REQUIRE A “HOT WORK PERMIT” PRIOR TO COMMENCING

WITH ANY SUCH WORK, CONTRACTOR SHALL CONTACT THE BUILDING

ENGINEER FOR A “HOT WORK PERMIT”

IN RESTROOMS, KITCHEN AND WET AREAS THAT CONTAIN: SINKS,

FLOOR SINKS, ICE MACHINES, SHOWERS/RESTROOMS ETC. THE

CONCRETE SLAB MUST BE SEALED WALL TO WALL WITH A WATER

PROOFING MEMBRANE PRIOR TO THE INSTALLATION OF FINISH

FLOORING.

ALL FLOOR PENETRATIONS MUST BE COORDINATED WITH BUILDING

MANAGEMENT 36 HOURS PRIOR TO THE WORK BEING PERFORMED.

CONTRACTOR SHALL BE AWARE THAT OFFICES ARE DIRECTLY BELOW

THE SPACE AND NO PENETRATION MAY BE LEFT OPEN AT ANY TIME.

LOCATE ALL MECHANICAL EQUIPMENT TO ALLOW SUFFICIENT ACCESS

TO SERVICE ALL COMPONENTS.

5954406

ROGER LEE

HAMLET JR.

ST

ATE

OFUT

AH

LICENSED

PROFE

SSIONAL

ENGINEER

COLVIN ENGINEERINGASSOCIATES

244 West 300 North, Suite 200 / Salt Lake City, Utah 84103Phone 801.322.2400 / colvinengineering.com

375 WEST 200 SOUTHSALT LAKE CITY, UT 84101

801.521.8600801.521.791

PF

www.gsbsarchitects.com

OWNER PROJECT NO.:

GSBS PROJECT NO.:

ISSUED DATE:

REVISIONS:

REV

Copyright (C) 2019 by Colvin Engineering Associates, Inc. Salt Lake C

ity, Utah. All rights reserved. U

nauthorized copying and/

or use is illegal and subject to prosecution.

1

04/18/2019

2018.082.00

MECHANICAL LEGEND,SYMBOLS & ABBREVIATIONS

MT. OLYMPUS IMPROVEMENTDISTRICT

MTOID OFFICEREMODEL

3932 500 EMillcreek, UT 84107

3932 500 EMillcreek, UT 84107

CONSTRUCTION DOCUMENTS

M001

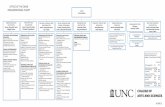

DRAWING INDEX# SHEET NAME

M001 MECHANICAL LEGEND, SYMBOLS & ABBREVIATIONS

MH100 BASEMENT MECHANICAL PLAN

MH101 LEVEL 1 MECHANICAL PLAN

MH601 MECHANICAL SCHEDULES

PL101 LEVEL 1 PLUMBING PLAN

ARGON

CARBON DIOXIDE

DEIONIZED WATER RETURN

DEIONIZED WATER SUPPLY

FUEL OIL RETURN

FUEL OIL SUPPLY

HELIUM

HYDROGEN

INDUSTRIAL WATER (NON-POTABLE)

MEDICAL AIR

NITROGEN

NITROUS OXIDE

OXYGEN

PROPANE

REVERSE OSMOSIS

VACUUM

WATER TREATMENT

ACCESS PANEL

CARBON DIOXIDE SENSOR

CARBON MONOXIDE SENSOR

HUMIDISTAT OR HUMIDITY SENSOR

NITROGEN DIOXIDE SENSOR

POINT OF CONNECTION TO EXISTING

POINT OF REMOVAL FROM EXISTING

AIR VENT (AUTOMATIC)

AUTOMATIC CONTROL VALVE (2-WAY)

AUTOMATIC CONTROL VALVE (3-WAY)

BALL VALVE

BUTTERFLY VALVE

CALIBRATED BALANCE VALVE

CHECK (SWING OR LIFT AS REQ'D) VALVE

CURB COCK

GAS COCK

GATE OS & Y PATTERN VALVE

GATE VALVE

MOTORIZED ACTUATOR

P&T RELIEF VALVE

PET COCK OR GAUGE COCK

PLUG VALVE

PRESSURE REDUCING VALVE

SOLENOID VALVE

THERMAL EXPANSION VALVE

CHILLED WATER SUPPLY

CONDENSER WATER RETURN

CONDENSER WATER SUPPLY

HEATING WATER RETURN

HEATING WATER SUPPLY

RADIANT FLOOR RETURN

RADIANT FLOOR SUPPLY

REFRIGERANT LIQUID

REFRIGERANT SUCTION

SNOWMELT RETURN

SNOWMELT SUPPLY

STEAM

STEAM CONDENSATE RETURN

GROUND LOOP RETURN

GROUND LOOP SUPPLY

HOT GAS

HOT GAS BYPASS

AQUASTAT

FLOW SWITCH

IN-LINE PUMP

PRESSURE GAUGE W/ GAUGE COCK

STRAINER

TEMPERATURE & PRESSURE TEST PLUG

TEMPERATURE SENSING WELL

THERMOMETER

VENTURI FLOW METER

DIRECTION OF FLOW

ELBOW DOWN

ELBOW UP

PIPE CAP

REDUCER

TEE DOWN

UNION

CONDENSATE DRAIN

DOMESTIC COLD WATER

DOMESTIC HOT WATER

DOMESTIC HOT WATER RECIRC.

FIRE SERVICE

GREASE WASTE ABOVE GRADE

GREASE WASTE BELOW GRADE

NATURAL GAS

OVERFLOW DRAIN

ROOF DRAIN

SANITARY (PLBG) VENT

SANITARY WASTE ABOVE GRADE

SANITARY WASTE BELOW GRADE

COMPRESSED AIR

TEMPERED WATER

BURIED OR UNDERFLOOR DUCT

DUCT SIZE (IN)FIRST FIGURE IS SIDE SHOWN

FLEXIBLE DUCT (HELICAL)

FLEXIBLE DUCT CONNECTION

SPIN-IN W/ MVD

AIR FLOW STATION

COMBINATION FIRE/SMOKE DAMPER

FIRE DAMPER SMOKE DAMPER

GRAVITY BACKDRAFT DAMPER

MANUAL VOLUME DAMPER

MOTORIZED DAMPER

SMOKE DAMPER

THERMOSTAT OR TEMP SENSOR W/ EQUIPMENT TAG

RADIAL SUPPLY DIFFUSERS

RETURN GRILLE

SUPPLY DIFFUSER

SUPPLY SLOT DIFFUSER

DUCT TRANSITION

ELBOW W/ TURNING VANES

TEE W/ 45° ENTRY

WYE W/ 45° ENTRY

EXHAUST AIR DUCT DOWN

EXHAUST AIR DUCT SECTION

EXHAUST AIR DUCT UP

RETURN AIR DUCT DOWN

RETURN AIR DUCT SECTION

RETURN AIR DUCT UP

SUPPLY AIR DUCT DOWN

SUPPLY AIR DUCT SECTION

SUPPLY AIR DUCT UP

FIRE DEPT. HORN & LIGHT

FIRE HOSE CABINET

POST TYPE FDC CONNECTION

WALL TYPE FDC CONNECTION

YARD HYDRANT

FLOOR DRAIN

FLOOR OR GRADE CLEANOUT

FLOOR SINK

GRADE CLEANOUT W/ CONCRETE PAD

HOSE BIBB OR SILLCOCK

MANHOLE

REDUCED PRESSURE BACKFLOW PREVENTOR

VENT THROUGH THE ROOF

WALL CLEANOUT

EXPANSION JOINT

FLEXIBLE PIPE CONNECTION

HEAT TRACING

CHILLED WATER RETURN

ABBREVIATIONSKey Name Comments

AD ACCESS DOOR

AF AIRFOIL

AFF ABOVE FINISHED FLOOR

ALT ALTERNATE

BI BACKWARD INCLINE

BOD BOTTOM OF DUCT

BOP BOTTOM OF PIPE

BTU/H BRITISH THERMAL UNITS PER HOUR

CAP CAPACITY

CBV CALIBRATED BALANCE VALVE

CFM CUBIC FEET PER MINUTE

CV CONSTANT VOLUME

CV CONTROL VALVE

DB DRY BULB

DCW DOMESTIC COLD WATER

DF DRINKING FOUNTAIN

DHW DOMESTIC HOT WATER

DHWR DOMESTIC HOT WATER RECIRC

DIA DIAMETER

DN DOWN

DSN DOWN SPOUT NOZZLE

DW DISHWASHER

E EXISTING

EA EACH OR EXHAUST AIR

EAT ENTERING AIR TEMPERATURE

EFF EFFICIENCY

ELEV ELEVATION

ENCL ENCLOSURE

ESP EXTERNAL STATIC PRESSURE

ET EXPANSION TANK

EWC ELECTRIC WATER COOLER

EWT ENTERING WATER TEMPERATURE

FCO FLOOR CLEAN OUT

FD FLOOR DRAIN

FO FLAT OVAL

FPM FEET PER MINUTE

FS FLOOR SINK

FT FEET

FV FACE VELOCITY

GA GAUGE

GAL GALLON

GD GARAGE DRAIN

GEA GREASE EXHAUST AIR

GPM GALLONS PER MINUTE

HP HORSE POWER

HR HOUR

HT HEIGHT

IN INCH

INWC INCHES OF WATER COLUMN

INWG INCHES OF WATER GAUGE

L LAVATORY OR LOUVER

LAT LEAVING AIR TEMPERATURE

LBS POUNDS

LWT LEAVING WATER TEMPERATURE

MAX MAXIMUM

MBH THOUSAND BRITISH THERMAL UNITS

MECH MECHANICAL

MIN MINIMUM

MPSA MEDUIM PRESSURE SUPPLY AIR

MUA MAKE-UP AIR

MVD MANUAL VOLUME DAMPER

NC NOISE CRITERIA OR NORMALLY CLOSED

NIC NOT IN CONTRACT

NO NUMBER

NOM NOMINAL

NTS NOT TO SCALE

OA OUTSIDE AIR

OBD OPPOSED BLADE DAMPER

OD OVERFLOW DRAIN

OFCI OWNER FURNISHED, CONTRACTOR INSTALLED

OFOI OWNER FURNISHED, OWNER INSTALLED

PD PRESSURE DROP

PG PROPYLENE GLYCOL

POC POINT OF CONNECTION

PRV PRESSURE REDUCING VALVE

PSI POUNDS PER SQUARE INCH

PSIG POUNDS PER SQUARE INCH GAUGE

RA RETURN AIR

RAD RADIUS

RD ROOF DRAIN

RLF RELIEF AIR

RPBP REDUCED PRESSURE BACKFLOW PREVENTOR

SA SUPPLY AIR OR SHOCK ARRESTOR

SEN SENSIBLE

SF SQUARE FEET

SIM SIMILAR

SL SEA LEVEL

SP STATIC PRESSURE

SS SERVICE SINK OR STAINLESS STEEL

TOD TOP OF DUCT

TSP TOTAL STATIC PRESSURE

TYP. TYPICAL

U URINAL

V VENT

VAV VARIABLE AIR VOLUME

VD VOLUME DAMPER

VFD VARIABLE FREQUENCY DRIVE

VOL VOLUME

VTR VENT THROUGH THE ROOF

W WASTE

W/ WITH

W/O WITHOUT

WB WET BULB

WC WATER CLOSET

WCO WALL CLEANOUT

WHA WATER HAMMER ARRESTOR

WPD WATER PRESSURE DROP

WT WEIGHT

Ø ROUND OR DIAMETER

MECHANICAL LEGEND

DETAIL TAG

KEYED NOTE

SECTION CUT LINE

PROJECT DESIGN TEAM

Designer: ADRIAN GARCIA , [email protected]

Project Manager: ROB VAN , [email protected]

BIM Modeler: ADRIAN GARCIA , [email protected]

1 04-22-19 ADD#1

1

B

B

C

C

2

MH301

(E)VAV-15

(E)VAV-14

(E)VAV-13

(E)VAV-11

(E)VAV-10

(E) VAV-9(E) VAV-8

(E) VAV-5(E) VAV-6

(E) VAV-7

(E) VAV-4

(E) VAV-3(E) VAV-2

(E) VAV-1

(E)VAV-12

(E)48/12 SA

(E)20/12 SA

(E)22/12 SA

(E)18/

12 SA

(E)18/10 SA

(E)16/12 SA

(E)8/8 SA (E)6/8 SA (E)6/6 SA

(E)6/8 SA

(E)8/8 SA

(E)10/8 SA

(E)10/8 SA

(E)10/8 SA (E)10/8 SA

(E)10/6 SA

(E)14/12 SA

(E)16/8 SA

(E)16/8 SA

(E)10/8 SA

(E)12/8 SA

(E)12/8 SA(E)10/8 SA

(E)10/6 SA

(E)14/12 SA

1

B

B

C

C

2

MH301

3

MH301

1

MH301

(E)VAV-15

(E)VAV-14

(E)VAV-13

(E)VAV-11

(E)VAV-10

(E) VAV-9

(E) VAV-8

(E) VAV-5(E) VAV-6

(E) VAV-7

(E) VAV-4

(E) VAV-3(E) VAV-2

(E) VAV-1

(E)VAV-12

(E)48/12 SA

(E)20/12 SA

(E)22/12 SA

(E)18/

12 SA

(E)18/10 SA

(E)16/12 SA

(E)8/8 SA (E)6/8 SA (E)6/6 SA

(E)6/8 SA(E)8/8 SA

(E)10/8 SA

(E)10/8 SA

(E)10/8 SA (E)10/8 SA

(E)10/6 SA

(E)14/12 SA

(E)16/8 SA

(E)10/8 SA

(E)12/8 SA

(E)12/8 SA

(E)10/8 SA

(E)10/6 SA

(E)14/12 SA

8R2 1360 125

8ø SA

8ø SA

12/12 SA

8ø SA

1/2"

HW

S

1/2"

HW

R

(E) 1

1/2

"(E

) 1 1

/2"

(E) 1 1/4"

(E) 1 1/4" (E) 1 1/4"

(E) 1 1/4"

(E) 3/4"(E) 1 1/4"

(E) 3

/4"

(E) 1

1/4

"

(E) 3/4"

(E) 1 1/2"

(E) 1/2"

(E) 1 1/2"

12/12 SA12/12 SA

12/12 SA

5954406

ROGER LEE

HAMLET JR.

ST

ATE

OFUT

AH

LICENSED

PROFE

SSIONAL

ENGINEER

COLVIN ENGINEERINGASSOCIATES

244 West 300 North, Suite 200 / Salt Lake City, Utah 84103Phone 801.322.2400 / colvinengineering.com

375 WEST 200 SOUTHSALT LAKE CITY, UT 84101

801.521.8600801.521.791

PF

www.gsbsarchitects.com

OWNER PROJECT NO.:

GSBS PROJECT NO.:

ISSUED DATE:

REVISIONS:

REV

Copyright (C) 2019 by Colvin Engineering Associates, Inc. Salt Lake C

ity, Utah. All rights reserved. U

nauthorized copying and/

or use is illegal and subject to prosecution.

1

04/18/2019

2018.082.00

BASEMENT MECHANICALPLAN

MT. OLYMPUS IMPROVEMENTDISTRICT

MTOID OFFICEREMODEL

3932 500 EMillcreek, UT 84107

3932 500 EMillcreek, UT 84107

CONSTRUCTION DOCUMENTS

MH100

0' 4' 8' 16'6'SCALE: 1/8" = 1'-0"1

BASEMENT MECH DEMO. PLAN

0' 4' 8' 16'6'SCALE: 1/8" = 1'-0"2

BASEMENT MECH FLOOR PLAN

GENERAL NOTES

KEYED NOTES1 DEMOLISH DUCT. CAP AND SEAL AS REQUIRED.

A. ALL ITEMS SHOWN LIGHT ARE EXISTING.B. ALL ITEMS SHOWN DARK AND SOLID ARE NEW.C. OFFSET NEW DUCT AS REQUIRED TO AVOID EXISTING CONDITIONS.D. DUCTWORK ABOVE GYP. BOARD CEILINGS SHALL BE HARD DUCTED.E. CONTRACTOR SHALL PROVIDE ALL INCIDENTAL OFFSETS REQUIRED

FOR COMPLETE OPERATIONAL MECHANICAL SYSTEMS.F. A YOUNG TYPE GEAR REGULATOR SHALL BE USED ON ALL DAMPERS

LOCATED ABOVE GYP. BOARD CEILINGS.G. OFFICES WITH WALLS EXTENDING TO ABOVE CEILING TO BOTTOM OF

DECK ARE REQUIRED TO HAVE 14/12 TRANSFER AIR (TYPICAL).H. COORDINATE MOUNTING HEIGHT OF AIR DEVICE GRILLS WITH

EXPOSED CEILINGS WITH ARCHITECT AND OWNER.I. BRANCH SIZE TO MATCH DIFFUSER NECK SIZE UNLESS NOTED

OTHERWISE.J. ALL DUCT TRANSITIONS FROM ROOF TOP UNIT DROPS TO BE PER

MANUFACTURER DRAWING SIZE.K. DUCT DIMENSIONS SHOWN ARE INSIDE CLEAR DIMENSIONS.

1 04-22-19 ADD#1

1

LOBBY

101

RECEPTION

102

CONFERENCE

103

BOARD ROOM

115

GM OFFICE

116

ENGINEER OFFICE

117

FINANCE OFFICE

128

OFFICE

122BREAKROOM

121

STORAGE

104

VAULT

105

WOMENS

106

PUBLIC R.R.

107

MENS

108

STORAGE

109

JANITOR

110

OUTDOOR STORAGE

111

COPY/PRINT

124

WORKSTATION 1

127

WORKSTATION 2

126OFFICE

123

WORKSTATION 3

125

A

A

B

B

C

C

D

D

E

E

F

F

G

G

1 1

2 2

3 3

4 4

5 5

6 6

2

MH301

3

MH301

1

MH301

50120

50125

EF-1(ON ROOF)

E100

TYP. 3

E120

TYP. 2

E200

TYP. 2

4995

TYP. 8

E110

TYP. 3

E550

E195

E375

E375

E130

TYP. 7

E90

TYP. 4

E90

TYP. 2

E100

TYP. 4

T

4

T

4

T

4

5

1375

E75

E75

TYP. 3 TYP. 4

A

A

B

B

C

C

D

D

E

E

F

F

G

G

1 1

2 2

3 3

4 4

5 5

6 6

T T T

T T T

T T

T

T

TTTT

1 1 1 1 1 1 1 1

2

1

1

3

3

2

1

6

5954406

ROGER LEE

HAMLET JR.

ST

ATE

OFUT

AH

LICENSED

PROFE

SSIONAL

ENGINEER

COLVIN ENGINEERINGASSOCIATES

244 West 300 North, Suite 200 / Salt Lake City, Utah 84103Phone 801.322.2400 / colvinengineering.com

375 WEST 200 SOUTHSALT LAKE CITY, UT 84101

801.521.8600801.521.791

PF

www.gsbsarchitects.com

OWNER PROJECT NO.:

GSBS PROJECT NO.:

ISSUED DATE:

REVISIONS:

REV

Copyright (C) 2019 by Colvin Engineering Associates, Inc. Salt Lake C

ity, Utah. All rights reserved. U

nauthorized copying and/

or use is illegal and subject to prosecution.

1

04/18/2019

2018.082.00

LEVEL 1 MECHANICAL PLAN

MT. OLYMPUS IMPROVEMENTDISTRICT

MTOID OFFICEREMODEL

3932 500 EMillcreek, UT 84107

3932 500 EMillcreek, UT 84107

CONSTRUCTION DOCUMENTS

MH101

GENERAL NOTES

KEYED NOTES1 REMOVE EXISTING FLOOR GRILLES AS SHOWN.

2 REMOVE EXISTING THERMOSTAT AS SHOWN.

3 NEW LOCATION FOR EXISTING THERMOSTAT.

4 EXISTING THERMOSTAT TO BE LOCATED IN THIS LOCATION.THERMOSTAT TO CONTROL TO EXISTING VAV BOXES.

5 DUCT FROM BELOW AND THROUGH KICK SPACE GRILLE TO BE IN THEKICKSPACE.

6 REMOVE EXISTING EXHAUST DUCT AS SHOWN. SEE MH101 FOR NEWDUCT DROP FROM EF-1.

A. ALL ITEMS SHOWN LIGHT ARE EXISTING.B. ALL ITEMS SHOWN DARK AND SOLID ARE NEW.C. OFFSET NEW DUCT AS REQUIRED TO AVOID EXISTING CONDITIONS.D. DUCTWORK ABOVE GYP. BOARD CEILINGS SHALL BE HARD DUCTED.E. CONTRACTOR SHALL PROVIDE ALL INCIDENTAL OFFSETS REQUIRED

FOR COMPLETE OPERATIONAL MECHANICAL SYSTEMS.F. A YOUNG TYPE GEAR REGULATOR SHALL BE USED ON ALL DAMPERS

LOCATED ABOVE GYP. BOARD CEILINGS.G. OFFICES WITH WALLS EXTENDING TO ABOVE CEILING TO BOTTOM OF

DECK ARE REQUIRED TO HAVE 14/12 TRANSFER AIR (TYPICAL).H. COORDINATE MOUNTING HEIGHT OF AIR DEVICE GRILLS WITH

EXPOSED CEILINGS WITH ARCHITECT AND OWNER.I. BRANCH SIZE TO MATCH DIFFUSER NECK SIZE UNLESS NOTED

OTHERWISE.J. ALL DUCT TRANSITIONS FROM ROOF TOP UNIT DROPS TO BE PER

MANUFACTURER DRAWING SIZE.K. DUCT DIMENSIONS SHOWN ARE INSIDE CLEAR DIMENSIONS.

0' 4' 8' 16'6'SCALE: 1/8" = 1'-0"2

LEVEL 1 MECHANICAL PLAN

0' 4' 8' 16'6'SCALE: 1/8" = 1'-0"1

LEVEL 1 MECHANICAL DEMO. PLAN

1 04-22-19 ADD#1

1

Level 1100' - 0"

1

4995

1

4/10

SA

(E)6ø SA

2

WORKSTATION AREA

Level 1100' - 0"

BASEMENT88' - 0"

23

2

MH301

50125

50120

12/4

SA

12/4

SA

12/4

SA

12/4

SA

12/4

SA

12/4

SA

12/4

SA

(E)22/12 SA

8ø SA8ø SA

12/4 SA 8ø SA 8ø SA 8ø SA

50125

50120

50125

50125

50120

Level 1100' - 0"

BASEMENT88' - 0"

B C1

MH301

CONFERENCE 103 RECEPTION 1024/12 SA

8ø SA(E) VAV-8 12/12 SA

5954406

ROGER LEE

HAMLET JR.

ST

ATE

OFUT

AH

LICENSED

PROFE

SSIONAL

ENGINEER

COLVIN ENGINEERINGASSOCIATES

244 West 300 North, Suite 200 / Salt Lake City, Utah 84103Phone 801.322.2400 / colvinengineering.com

375 WEST 200 SOUTHSALT LAKE CITY, UT 84101

801.521.8600801.521.791

PF

www.gsbsarchitects.com

OWNER PROJECT NO.:

GSBS PROJECT NO.:

ISSUED DATE:

REVISIONS:

REV

Copyright (C) 2019 by Colvin Engineering Associates, Inc. Salt Lake C

ity, Utah. All rights reserved. U

nauthorized copying and/

or use is illegal and subject to prosecution.

1

04/18/2019

2018.082.00

MECHANICAL SECTIONS

MT. OLYMPUS IMPROVEMENTDISTRICT

MTOID OFFICEREMODEL

3932 500 EMillcreek, UT 84107

3932 500 EMillcreek, UT 84107

CONSTRUCTION DOCUMENTS

MH301

SCALE: NONE3

KICKSPACE GRILLE SECTION

SCALE: NONE1

CONF. 103/ RECEPTION 102 SIDEWALL GRILLES SECTION

GENERAL NOTES

KEYED NOTES1 CONNECT TO EXISTING AT THIS APPROXIMATE LOCATION. FIELD

VERIFY EXISTING CONDITIONS.

2 DUCT FROM BELOW AND THROUGH KICK SPACE GRILLE TO BE IN THEKICKSPACE.

A. ALL ITEMS SHOWN LIGHT ARE EXISTING.B. ALL ITEMS SHOWN DARK AND SOLID ARE NEW.C. OFFSET NEW DUCT AS REQUIRED TO AVOID EXISTING CONDITIONS.D. DUCTWORK ABOVE GYP. BOARD CEILINGS SHALL BE HARD DUCTED.E. CONTRACTOR SHALL PROVIDE ALL INCIDENTAL OFFSETS REQUIRED

FOR COMPLETE OPERATIONAL MECHANICAL SYSTEMS.F. A YOUNG TYPE GEAR REGULATOR SHALL BE USED ON ALL DAMPERS

LOCATED ABOVE GYP. BOARD CEILINGS.G. OFFICES WITH WALLS EXTENDING TO ABOVE CEILING TO BOTTOM OF

DECK ARE REQUIRED TO HAVE 14/12 TRANSFER AIR (TYPICAL).H. COORDINATE MOUNTING HEIGHT OF AIR DEVICE GRILLS WITH

EXPOSED CEILINGS WITH ARCHITECT AND OWNER.I. BRANCH SIZE TO MATCH DIFFUSER NECK SIZE UNLESS NOTED

OTHERWISE.J. ALL DUCT TRANSITIONS FROM ROOF TOP UNIT DROPS TO BE PER

MANUFACTURER DRAWING SIZE.K. DUCT DIMENSIONS SHOWN ARE INSIDE CLEAR DIMENSIONS.

SCALE: NONE2

SIDEWALL GRILLE SECTION VIEW 2

1 04-22-19 ADD#1

1

RECOMMENDED MINIMUM DISTANCE BETWEEN DIFFUSERS IN 9' CEILING. PLANCODE

CFMGRILLEVERIFY FRAME TYPE OF ALL AIR DEVICES WITH ARCHITECTURAL REFLECTED CEILING PLAN BEFORE ORDERING.

1

2

NOTE:

1. ALL SCREWS AND FASTENERS

ARE TO BE PER SMACNA AND CBC

STANDARDS.

2. CURB TO SLOPE PER EXISTING

ROOF SLOPE.

EXHAUST FAN, RELIEF FAN AND CURB DETAIL VAV REHEAT TERMINAL PIPING DETAILTYPICAL MANUAL VOLUME DAMPER DETAIL

A

STRAINER

TWO WAY MODULATING

1/2" DRAIN VALVE W/HOSE END

CONTROL VALVE

PRIMARY AIR

HWR

HWS

CFM @

ELEV.

AREA

SERVED

PLAN

CODETYPE

DAMPER

(GRAVITY OR MOTOR)

ESP

(S.L.) H.P.

MOTOR

SONESVOLTAGE

& PHASE

METHOD OF

CONTROL

OPENING

SIZE

OPERATING

WT. (LBS.)MANUFACTURER / MODEL REMARKS

ROOF CENT.BCRD 085D

TWIN CITY10014/14120/1 8.90.250.5 GRAVITYRESTROOMS 500

(IN.)

EF-1THERMOSTAT

WITH MANUFACTURER CRUBDDC

EXHAUST FAN SCHEDULE

PLUMBING FIXTURE SCHEDULE

MIXING VALVE SCHEDULE (MV)

AIR DEVICE SCHEDULE

CIRCUIT SETTER

UNION

MANUAL AIR VENT

P & T TEST PLUG

ISOLATION VALVE

IF REQUIRED.

ACESSIBLE POSITION - MOUNT REMOTELY

BOX CONTROLLER MAINTAIN IN READILY

VAV

REHEAT

CLEARANCE

3' SERVICE

SEEPLANS

12"

SEEPLANS

SHEET METAL DUCT

CAULKING

ATTACH TOCURB

ANCHOR CABLEWITH EYELETS

TO CURB PER CBC

SEAL ROOFPENETRATIONWITH FLEXIBLE

SCREW DUCT

ATTACH TOFAN

FULL WIDTH ANDLENGTH OF CURB

ELASTOMERICFOAM INSULATION

PREFABRICATED AND

WHERE NOTED ONSCHEDULE, PROVIDE

ATTENUATING CURB

SEE SCHEDULE)

INSULATED CURB BY MC.

12" MINIMUM ABOVEFINISHED ROOF

BACK DRAFT DAMPER -(GRAVITY OR MOTORIZED -

FLASHING BY G.C.FLASHING AND COUNTER

EXHAUST OR RELIEF FAN

PLANCODE

DESCRIPTION

ROUGH IN SIZE

MANUFACTURER& MODEL NO.

REMARKSCW HW TEMPERED WASTE VENT

WC-1AWATER CLOSET, ADA COMPLIANT, FLOOR MOUNT, FLUSHTANK, ELONGATED BOWL, VITREOUS CHINA 1.6 GPF

1/2 - - 3 2AMERICAN STANDARD 215AA.104.020SEAT: BEMIS 1955CT

COLOR WHITESEE ARCH DRAWINGS FOR MOUNTING HEIGHT

WC-2WATER CLOSET, WALL MOUNT, BATTERYPOWERED SENSOR FLUSH VALVE, SIPHONJET, VITREOUS CHINA 1.28 GPF

1 - - 4 2KOHLER "KINGSTON" K-4325SEAT: OLSONITE #10CC/SSFLUSH VALVE: SLOAN ECOS 8111-1.28

COLOR WHITESEE ARCH DRAWINGS FOR MOUNTING HEIGHT

L-1UNDERCOUNTER SINK, COORDINATE COUNTERDIMENSIONS W/ ARCH, 4" CENTERSET, CHROME BATTERYSENSOR FAUCET WITH GRID DRAIN, 0.5 GPM FLOW

- - 1/2" 1 1/2" 1 1/2"SINK: AMERICAN STANDARD 0496.300FAUCET: MOEN 9482W/ MOUNTING KIT (047194-0070A)

COORDINATE COUNTER DIMENSIONS W/ARCH

S-1DOUBLE COMPARTMENT, RECTANGULAR STAINLESSSTEEL, COUNTER MOUNT SINK, GOOSENECK SWINGSPOUT WITH WING HANDLES, 0.5 GPM 18 GA, TAIL-PIECE.

1/2 1/2 - 1 1/2" 1 1/2"

BOWL: ELKAY LR 3321

FAUCET: KOHLER "TRITON" K-7305

STRAINER: ELKAY LK-35 . OR EQUAL

FOOD WASTE DISPOSER: INSINKERATOR

"BADGER 5" 1/2 HP 120/1 PH

-

EWC-1SINGLE LEVEL, SURFACE MOUNT ELECTRIC WATERCOOLER WITH 1.5 GPM BOTTLE FILLER, ADA COMPLIANT

3/8" - - 1 1/4" 1 1/4"

HALSEY TAYLOR "HYDROBOOST"HTHB-HAC8PV-WF 8 GPH, F.L.A. = 6.0,115 V/1 PH/ 60 HZ. PROVIDE WITHACCESSORY APRONS MODEL 98312C

-

FD-1 FLOOR DRAIN - - - 2 1 1/2J.R. SMITH MANUFACTURING COMPANYFIG. 2005Y-NB-U-M.DUCO CAST IRON FLOOR DRAIN

SEE PLANS FOR OUTLET SIZE. STRAINER GRATE MUST BE HEEL PROOF. PROVIDE WITHDEEP SEAL TRAP GUARD, OR EQUAL.

SA-1 SHOCK ARRESTOR 3/4 3/4 - - -PRECISION PLUMBING PRODUCTSSC-750

VANDAL PROOF OR EQUAL.

FS-1 FLOOR SINK - -- - SEE PLANS 1 1/2J.R. SMITH MANUFACTURING COMPANYFIG. 3150-Y-ASB SQUARE FLOOR SINK

FLOOR SINK SHALL BE OF CAST IRON CONSTRUCTION WITH ENAMEL INTERIOR FINISH,MINIMUM INTERIOR DIMENSIONS OF 12"x12"x8"D. PROVIDE WITH NICKEL BRONZEGRATE AND DEEP SEAL P-TRAP. SEE FOOD SERVICE EQUIPMENT PLANS FOR GRATEREQUIRED IN KITCHEN. OR EQUAL.

TP-1 TRAP PRIMER 1 / 2 - - - -

PRECISION PLUMBING PRODUCTS#PR-500WITH TRAP PRIMER AIR GAP PPP #AG-500

-

SS-1SERVICE SINK, 28" X 28" X 8" CORNER MOUNTCAST IRON, 3" GRID DRAIN AND FAUCET WITHVACUUM BREAKER, STOPS, TOP BRACE, CHROME FINISH

3 / 4 3 / 4 - 3 2SINK: KOHLER "WHITBY" K-6710FAUCET: KOHLER "KINLOCK" K-8907

-

PLANCODE

AREA SERVEDINLETSIZE

OUTLETSIZE

MINIMUM FLOWGPM

MAXIMUM FLOWGPM

MANUFACTURER& MODEL NO.

MV-1RESTROOMLAVATORIES

1/2" 1/2" 0.5 12LEANARD

MODEL 170-LF

1. ASSE 1070 2. PIPING METHOD W

1

PLANCODE

TYPE & DUTY FACE SIZE NECK SIZECEILING

TYPE(NOTE 2)

MAXCFM

MAX TP(IN WC)

NCLEVELMAX

MIN THROWT50 (FT)

4-WAYMIN THROW

(T50)

2-WAYMIN THROW

(T50)

MANUFACTURER &MODEL NO.

REMARKS

13PERFORATED

EXHAUST GRILLE8" x 8" 6" x 6"

MATCHCEILING

120 0.12 10 - - - TITUS 8F -

14PERFORATED

EXHAUST GRILLE10" x 10" 8" x 8"

MATCHCEILING

100 0.12 12 - - - TITUS 8F -

49SIDEWALL

SUPPLY GRILLE12" x 4" 12" x 3.5"

MATCHWALL

100 0.07 20 27 - - TITUS CT-PP-0PROVIDE WITH FRAME AND BORDER

TYPE 3, AND OBD

50SIDEWALL

SUPPLY GRILLE14" x 8" 12" x 6"

MATCHWALL

265 0.07 20 30 - - TITUS 300RL PROVIDE WITH OBD

3NO SCALE

2NO SCALE

1NO SCALE

5954406

ROGER LEE

HAMLET JR.

ST

ATE

OFUT

AH

LICENSED

PROFE

SSIONAL

ENGINEER

COLVIN ENGINEERINGASSOCIATES

244 West 300 North, Suite 200 / Salt Lake City, Utah 84103Phone 801.322.2400 / colvinengineering.com

375 WEST 200 SOUTHSALT LAKE CITY, UT 84101

801.521.8600801.521.791

PF

www.gsbsarchitects.com

OWNER PROJECT NO.:

GSBS PROJECT NO.:

ISSUED DATE:

REVISIONS:

REV

Copyright (C) 2019 by Colvin Engineering Associates, Inc. Salt Lake C

ity, Utah. All rights reserved. U

nauthorized copying and/

or use is illegal and subject to prosecution.

1

04/18/2019

2018.082.00

MECHANICAL SCHEDULES

MT. OLYMPUS IMPROVEMENTDISTRICT

MTOID OFFICEREMODEL

3932 500 EMillcreek, UT 84107

3932 500 EMillcreek, UT 84107

CONSTRUCTION DOCUMENTS

MH601

1 04-22-19 ADD#1

1

LOBBY

101

RECEPTION

102

CONFERENCE

103

BOARD ROOM

115

GM OFFICE

116

ENGINEER OFFICE

117

FINANCE OFFICE

128

OFFICE

122BREAKROOM

121

STORAGE

104

VAULT

105

WOMENS

106

PUBLIC R.R.

107

MENS

108

STORAGE

109

JANITOR

110

OUTDOOR STORAGE

111

COPY/PRINT

124

WORKSTATION 1

127

WORKSTATION 2

126OFFICE

123

WORKSTATION 3

125

A

A

B

B

C

C

D

D

E

E

F

F

G

G

1 1

2 2

3 3

4 4

5 5

6 6

2

2"FD-12"FD-1

WC-1A

5 6

1 1/2" DCW

1" DCW

4" W

2" W

4" W

2" W

L-1

88

1 1/

2" D

CW

1/2"

DH

W

(E) 2" V

99

2" D

CW

WC-1A

L-1

L-1

WC-1A

(E) 2"

10

4" W 1" DCW

EWC-1

A

A

B

B

C

C

D

D

E

E

F

F

G

G

1 1

2 2

3 3

4 4

5 5

6 6

(E) 3/4" G

(E) 1/2" DCW

(E) 1/2" DHW

(E) 3" W

(E) 1/2" DHW

(E) 2" V

(E) 4

"

(E) 1

/2"(E

) 2"

V

(E) 4" V UP

(E) 1 1/4" DHW UP

(E) 1 1/2" DCW UP

(E) 2"(E) 1/2"

1

(E) 1/2"

(E) 1/2"

34

7

5954406

ROGER LEE

HAMLET JR.

ST

ATE

OFUT

AH

LICENSED

PROFE

SSIONAL

ENGINEER

COLVIN ENGINEERINGASSOCIATES

244 West 300 North, Suite 200 / Salt Lake City, Utah 84103Phone 801.322.2400 / colvinengineering.com

375 WEST 200 SOUTHSALT LAKE CITY, UT 84101

801.521.8600801.521.791

PF

www.gsbsarchitects.com

OWNER PROJECT NO.:

GSBS PROJECT NO.:

ISSUED DATE:

REVISIONS:

REV

Copyright (C) 2019 by Colvin Engineering Associates, Inc. Salt Lake C

ity, Utah. All rights reserved. U

nauthorized copying and/

or use is illegal and subject to prosecution.

1

04/18/2019

2018.082.00

LEVEL 1 PLUMBING PLAN

MT. OLYMPUS IMPROVEMENTDISTRICT

MTOID OFFICEREMODEL

3932 500 EMillcreek, UT 84107

3932 500 EMillcreek, UT 84107

CONSTRUCTION DOCUMENTS

PL101

GENERAL NOTES

1 DEMOLISH EXISTING WASTE AND ALL ASSOCIATED PIPINGCONNECTED TO EXISTING PLUMBING FIXTURES STARTING FROM THISAPPROXIMATE LOCATION BACK TO 4" DROP IN RESTROOM CHASE.CAP ALL ABANDONED VENT LINES NOT USED AS REQUIRED.

2 CONNECT TO EXISTING 4" WASTE RISER AS SHOWN.

3 DEMOLISH EXISTING WASTE AND ASSOCIATED PIPING TO ELECTRICWATER COOLER. CAP WASTE BELOW FLOOR AND VENT, COLD WATERIN CEILING.

4 DEMOLISH EXISTING 1-1/2" DOMESTIC COLD WATER SUPPLY BACK TOMAIN 2" MAIN ON LOWER LEVEL REPLACE AS SHOWN ON 2/PL101.LEAVE 1-1/2" RISE SERVING BOILER ON LEVEL ABOVE,

5 REPLACE 1-1/2" DCW GOING TO 2" MAIN ON LOWER LEVEL WITH A NEW2" DCW. ROUTE NEW SUPPLY AS SHOWN.

6 RECONNECT EXISTING 1-1/2" COLD WATER SUPPLY BRANCH SERVINGTHE BOILER ON LEVEL ABOVE AT THIS APPROXIMATE LOCATION.

7 DEMOLISH EXISTING DOMESTIC HOT WATER SERVING EXISTINGRESTROOMS DOWNSTREAM OF THIS APPROXIMATE LOCATION.

8 CONNECT EXISTING DHW AND DCW TO NEW FIXTURE AS REQUIRED.

9 ROUTE AND CONNECT TO EXISTING 2" VENT PIPE.

10 CONNECT TO EXISTING AT THIS APPROXIMATE LOCATION. ROUTEDCW TO ICE MAKER PER MANUFACTURERS INSTALLATION MANUAL.

KEYED NOTES

A. ALL ITEMS SHOWN LIGHT ARE EXISTING.B. ALL ITEMS SHOWN DARK AND SOLID ARE NEW.C. ALL FLOOR DRAINS AND FLOOR SINKS SHALL BE PROVIDED WITH TRAP

PRIMERS.D. ALL VALVES SHALL BE LOCATED ABOVE ACCESSIBLE CEILINGS.E. PROVIDE ACCESS PANELS AS REQUIRED.F. EACH FIXTURE SHALL HAVE SEPARATE ISOLATIONS VALVES FOR HOT

AND COLD WATER.G. CONTRACTOR TO COORDINATE WITH ELECTRICAL AND DO NOT ROUTE

PIPING OVER ELECTRICAL EQUIPMENT.H. ALL PIPING SHALL BE HELD TIGHT TO BOTTOM OF STRUCTURE.I. OFFSET AND TRANSITION PIPING AS REQUIRED.J. CONTRACTOR TO COORDINATE ALL INSTALLATIONS WITH OTHER

TRADES.K. ALL FIRE PROTECTION PIPING SHALL BE SIZED BY FIRE PROTECTION

CONTRACTOR.L. ALL WASTE, ROOF DRAINS AND OVERFLOW DRIANS TO BE SLOPED AT

AN 1/8” PER FOOT SLOPE UNLESS NOTED OTHERWISE.M. WHERE INDIVIDUAL OUTLET PIPING SIZE IS NOT SHOWN, SEE

PLUMBING SCHEDULE SIZE.N. DO NOT ROUTE OR LOCATE ANY PLUMBING PIPE OR EQUIPMENT OVER

ANY ELECTRICAL EQUIPMENT.O. NO PIPE TO BE RUN OVER ANY ELECTRICAL OR COMMUNICATION

ROOMS.P. CONTRACTOR SHALL PROVIDE ALL INCIDENTAL OFFSETS REQUIRED

FOR COMPLETE OPERATIONAL MECHANICAL SYSTEM.Q. ALL WATER CONNECTIONS TO SINKS, LAVS AND CLOSETS SHALL BE

MADE WITH A ½” CONNECTION UNLESS OTHERWISE NOTED.

0' 4' 8' 16'6'SCALE: 1/8" = 1'-0"2

LEVEL 1 PLUMBING PLAN

0' 4' 8' 16'6'SCALE: 1/8" = 1'-0"1

LEVEL 1 PLUMBING DEMO. PLAN

1 04-22-19 ADD#1

1