An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain...

Transcript of An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain...

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

1/125

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

2/125

UNIVERSITY STUTTGART

DEPARTMENT OF

STRUCTURAL MECHANICS

The undersigned hereby certify that they have read and recommend

to the Faculty of Civil and Environmental Engineering for acceptance a

thesis entitled An Arbitrary Lagrangian-Eulerian Finite Element

Formulation for Dynamics and Finite Strain Plasticity Models

by Dipl.-Ing. Christian Linderin partial fulfillment of the requirements

for the degree ofMaster of Science.

Dated: April 2003

Supervisor:Prof. Dr.-Ing. Ekkehard Ramm

Readers:Dr.-Ing. Wolfgang Wall

Dipl.-Ing. Tobias Erhart

ii

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

3/125

UNIVERSITY STUTTGART

Date: April 2003

Author: Dipl.-Ing. Christian Linder

Title: An Arbitrary Lagrangian-Eulerian Finite Element

Formulation for Dynamics and Finite Strain

Plasticity Models

Department: Structural Mechanics

Degree: M.Sc.

Permission is herewith granted to University Stuttgart to circulate and to

have copied for non-commercial purposes, at its discretion, the above title upon

the request of individuals or institutions.

Signature of Author

THE AUTHOR ASSURES THAT THE WORK WAS PRODUCEDINDEPENDENTLY AND NO SOURCES OR ASSISTANCE OTHER THAN THOSEINDICATED WERE USED.

THE AUTHOR RESERVES OTHER PUBLICATION RIGHTS, ANDNEITHER THE THESIS NOR EXTENSIVE EXTRACTS FROM IT MAYBE PRINTED OR OTHERWISE REPRODUCED WITHOUT THE AUTHORS

WRITTEN PERMISSION.THE AUTHOR ATTESTS THAT PERMISSION HAS BEEN OBTAINED

FOR THE USE OF ANY COPYRIGHTED MATERIAL APPEARING IN THISTHESIS (OTHER THAN BRIEF EXCERPTS REQUIRING ONLY PROPERACKNOWLEDGEMENT IN SCHOLARLY WRITING) AND THAT ALL SUCH USEIS CLEARLY ACKNOWLEDGED.

iii

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

4/125

University StuttgartInstitute of Structural Mechanics

Prof. Dr.-Ing. E. Ramm

Masters Thesis

An Arbitrary Lagrangian-EulerianFinite Element Formulation for Dynamics

and Finite Strain Plasticity Models

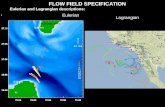

The Arbitrary Lagrangian-Eulerian (ALE) formulation was developed to overcomethe limitations of pure Lagrangian and pure Eulerian formulations. Recently, the ALEtechnique has been extended from fluid dynamics to non-linear solid mechanics, where

finite strain plasticity based material models are involved. One major aspect for imple-mentation is the correct treatment of the convective terms in the constitutive equationsby adequate stress update procedures.

B S

m

Bt St

M

t

t t

materialconfiguration

spatialconfiguration

reference configuration

X x

X

X

X

X

x

x

Cp1 be

G

F

FT

Fp Fe

FpT FeT

TXB

TXB

TXB

TX

B

TxS

TxS

ALE-kinematics Multiplicative Decomposition ofF

Lagrange ALE

Numerical Simulation - Coining Test

iv

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

5/125

To my late grandfather.

v

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

6/125

Table of Contents

Table of Contents vi

Abstract ix

Acknowledgements x

1 Introduction 11.1 Motivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Motion of a Material Body . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 Arbitrary Lagrangian-Eulerian description . . . . . . . . . . . . 3

1.1.3 Lagrangian description . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.4 Eulerian description . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.5 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Development of ALE formulations . . . . . . . . . . . . . . . . . . . . . 9

1.3 Overview of the work . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Basics of Continuum Mechanics 122.1 Basic Kinematics of Finite Strain Deformations . . . . . . . . . . . . . 12

2.1.1 Material Body, Configurations and Motion of the Body . . . . . 13

2.1.2 Displacement-, Velocity- and Acceleration Fields . . . . . . . . . 16

2.1.3 The Deformation Gradient . . . . . . . . . . . . . . . . . . . . . 21

2.1.4 Metric- and Strain Tensors . . . . . . . . . . . . . . . . . . . . . 23

2.2 The Concept of Stress . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2.1 Eulers Cut Principle . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2.2 Stress Tensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.3 Balance Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3.1 Master Balance Principle . . . . . . . . . . . . . . . . . . . . . . 28

2.3.2 Balance of Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.3.3 Balance of Linear Momentum . . . . . . . . . . . . . . . . . . . 30

2.3.4 Balance of Angular Momentum . . . . . . . . . . . . . . . . . . 31

2.3.5 Balance of Energy . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3.6 Balance of Entropy . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.7 Influence of the ALE formulation . . . . . . . . . . . . . . . . . 35

vi

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

7/125

Table of Contents vii

3 Constitutive Model: Finite Strain Plasticity 373.1 Kinematic relations for the Multiplicative Decomposition . . . . . . . . 37

3.2 Free Energy and Local Dissipation . . . . . . . . . . . . . . . . . . . . 39

3.3 Principle of Maximum Dissipation . . . . . . . . . . . . . . . . . . . . . 40

3.4 Summary: Finite Strain Plasticity in Tensor Notation . . . . . . . . . . 42

3.5 Numerical Implementation . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5.1 Integration of the Flow Rules . . . . . . . . . . . . . . . . . . . 42

3.5.2 The Elastic Predictor . . . . . . . . . . . . . . . . . . . . . . . . 43

3.5.3 The Plastic Corrector . . . . . . . . . . . . . . . . . . . . . . . . 46

3.6 Spectral Decomposition . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.7 Summary: Finite Strain Plasticity in Spectral Decomposition . . . . . . 48

3.8 Influence of the ALE formulation . . . . . . . . . . . . . . . . . . . . . 49

4 Initial Boundary Value Problem 514.1 Problem Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.2 Strong Form of the IBVP . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.3 Weak Form of the IBVP . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3.1 Weak Form of the balance of mass . . . . . . . . . . . . . . . . 53

4.3.2 Weak Form of the balance of linear momentum . . . . . . . . . 53

4.3.3 Weak Form of the constitutive equation . . . . . . . . . . . . . . 54

4.4 Finite Element Discretization . . . . . . . . . . . . . . . . . . . . . . . 54

4.4.1 FE-matrix equations for the balance of mass . . . . . . . . . . . 57

4.4.2 FE-matrix equations for the balance of linear momentum . . . . 574.4.3 FE-matrix equations for the constitutive equation . . . . . . . . 57

4.4.4 Summary of the ALE-matrix equations . . . . . . . . . . . . . . 58

4.4.5 Special Case: Eulerian Formulation . . . . . . . . . . . . . . . . 59

4.4.6 Special Case: Lagrangian Formulation . . . . . . . . . . . . . . . 60

4.5 Solution Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.5.1 Fully Coupled Solution . . . . . . . . . . . . . . . . . . . . . . . 61

4.5.2 Uncoupled Solution . . . . . . . . . . . . . . . . . . . . . . . . . 61

5 Uncoupled ALE Formulation 64

5.1 The Operator Split . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 645.1.1 Lagrangian Phase . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1.2 Smoothing Phase . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.3 Eulerian Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.4 Application to the ALE formulation . . . . . . . . . . . . . . . . 67

5.2 The Lagrangian Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.2.1 Lagrangian solution of the velocities . . . . . . . . . . . . . . . . 72

5.2.2 Lagrangian solution of the internal variables . . . . . . . . . . . 72

5.2.3 Summary of the Lagrangian Phase . . . . . . . . . . . . . . . . 73

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

8/125

Table of Contents viii

5.3 The Smoothing Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.3.1 Laplacian Based Approach . . . . . . . . . . . . . . . . . . . . . 74

5.3.2 Element Area Based Approach . . . . . . . . . . . . . . . . . . 75

5.3.3 Application to the ALE formulation . . . . . . . . . . . . . . . . 76

5.4 The Eulerian Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4.1 Final solution of the velocities . . . . . . . . . . . . . . . . . . . 76

5.4.2 Final solution of the internal variables . . . . . . . . . . . . . . 77

5.5 Numerical Implementation . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.5.1 Flowchart of the Numerical Implementation . . . . . . . . . . . 87

5.5.2 Additional Remarks on the Numerical Implementation . . . . . 91

6 Numerical Simulations 926.1 Impact of a Circular Bar . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.2 Necking of a Circular Bar . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.3 Coining Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7 Closure 1067.1 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.2 Future Directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Bibliography 107

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

9/125

Abstract

Non-linear finite element analysis is an essential component of todays computationalmechanics. Whereas no difference between the material and the spatial configurati-on of a solid must be considered in a small deformation analysis the selection of an

appropriate configuration for the finite element mesh is important for many of thelarge deformation problems. The configuration where the finite element mesh is loca-ted will be denoted as reference configuration throughout this work. The choice of thematerial-, spatial- or any arbitrary configuration as this reference configuration thenyields to a Lagrangian, Eulerianor Arbitrary Lagrangian-Eulerian (ALE) description,respectively.

Since mesh points are attached to material points in the Lagrangian description,elements deform with the material and therefore can become severely distorted. Thisis commonly observed in plastic models where large plastic strains appear. On theother hand boundary nodes remain on the boundary which simplifies the imposition of

boundary conditions. In the Eulerian description boundary nodes do not remain coinci-dent with the boundary which engenders significant complications in multi-dimensionalproblems. This work pays attention on the ALE description, which combines the ad-vantages of both, Lagrangian and Eulerian descriptions.

The ALE description in non-linear solid mechanics is nowadays standard for hypo-elastic-plastic models. Extensions to hyperelastic-plastic models were presented by Ar-mero & Love [1, 2] and Rodriguez-Ferran et al [74]. An extension to soliddynamics and hyperelastic material models is also presented in this work.

Two different approaches to solve the resulting equations of the ALE method are

possible. Consideration is given to the so called Uncoupled ALE formulation in thiswork, where the relevant equations are decoupled into its Lagrangian and Euleriancounterparts based on an operator splitting technique. This uncoupled approach makesthe extension of a pure Lagrangian finite element programme to the ALE case easy andallows the use of the original programme to solve the relevant Lagrangian equations.After a smoothing phase only the Eulerian equations must be solved additionally.

In this work it will be shown how a Lagrangian finite element programme can beupgraded to the ALE case. The fully transient dynamic range will be considered basedon an explicit time integration scheme and the influence of the ALE formulation onthe finite strain plasticity model will be outlined.

ix

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

10/125

Acknowledgements

First of all I would like to thank Professor Ekkehard Ramm. From the early days of theCOMMAS course on he supported me. The many interesting talks on computationalmechanics and especially on our favorite kind of structures, namely shell structures,

motivated me in a very strong format. He expressed his interest also in my work on theArbitrary Lagrangian-Eulerian finite element formulation and gave me the opportunityto work at his institute during the last year. Additionally I thank Professor Ramm foroffering me support concerning the application for my further graduate studies.

I would like to thank Dr.-Ing. Wolfgang Wall for his constant support and guidanceduring this interesting research. I am also thankful to Dipl.-Ing. Tobias Erhart andDipl.-Ing. Michael Gee for the introduction to the finite element programs used at theInstitute of Structural Mechanics. Thanks also to all other colleagues at the institutefor the pleasant working atmosphere.

Furthermore I would like to thank Professor Werner Guggenberger. He gave me theopportunity to take part on the Euromech Colloquium 444 at Bremen. Together withProfessor Gerhard A. Holzapfel, to whom I am also very grateful, he made my parti-cipation in the COMMAS-programme possible. I am thankful to Professor FranciscoArmero for providing me with his actual research paper on the ALE formulation beforeit was published - see Armero & Love [2].

I should also mention that my studies in Germany were supported in part bythe German Academic Exchange Service (Deutscher Akademischer Austauschdienst- DAAD).

Of course, I am thankful to my family in Austria for their patience and love. Without

them this work would never have come into existence. Grandpa I wish you all the beston your last journey.

Finally, I wish to thank Sandra for her unconditionally source of motivation andsupport during the last three semesters. Thank you for all the good times and the manybeautiful days we spent here together in Stuttgart.

StuttgartApril, 2003 Christian Linder

x

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

11/125

Chapter 1

Introduction

1.1 Motivation

Two different approaches to describe the motion of a continuum are common. The La-grangianor materialdescription is faced with the Eulerianor spatialone. To overcomethe drawbacks of pure Lagrangian and pure Eulerian descriptions a third approach hasbeen proposed, namely the Arbitrary Lagrangian-Eulerian (ALE) description. Sincemesh points remain coincident with material points in the Lagrangian description, ele-ments deform with the material and therefore can become severely distorted, which iscommonly observed in plastic models where large plastic strains appear. On the otherhand boundary nodes remain on the boundary which simplifies the imposition of boun-

dary conditions. In the Eulerian description boundary nodes do not remain coincidentwith the boundary which engenders significant complications in multi-dimensional pro-blems. The ALE description combines the advantages of both, Lagrangian and Euleriandescriptions. It will be shown that they only differ from each other by the location ofthe finite element mesh used to describe the motion of the material body.

Irrespectively of the description of the motion of a material body we shall distin-guish between different configurations of this material body. In the following we willdistinguish between amaterial- and aspatialconfiguration. All of the above mentioneddescriptions (Lagrangian, Eulerian and ALE) can now be described in terms of theseconfigurations. This means that the related measures of strains and stresses are used.

Furthermore derivatives are taken with respect to the related configurations and theweak form involves integrals over the related domains.

Because of the same notation of the description of the motion and the configurationof a material body confusion is artificially introduced in the literature. Always remem-ber that the description itself has nothing to do with the configuration in which it isdescribed. InSteinmann[84] the author established a formalistic framework that hel-ps to eliminate this confusion for the Lagrangian and Eulerian description, highlightsthe intriguing duality and provides the necessary tools for an elegant transition bet-ween them. More background on geometrically nonlinear kinematics, especially of theLagrangian description, may be found in Marsden & Hughes[59] or Hughes[44].

1

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

12/125

Chapter 1 Introduction 2

1.1.1 Motion of a Material Body

To outline the differences between the different formulations we have to introduce the

motion of a material body. This chapter serves only as an introduction and will betreated more precisely in Chapter 2.

A material body is a physical object equipped with some physical properties, liketexture, color, density and so on. Mathematically the body Bis defined as an open setof infinitely many material points P B. The placement of the body B in R3 will bedenoted as a configuration of the body and can be mathematically described with therelationship : B B R3. The motion of the material body is a one parameterfamily of configurations indexed by time. Then for each t [0, T], where [0, T] R+ is the time interval of interest, the mapping t : B Bt R

3 is a mappingwhich maps B onto Bt R

3 at time t. In a motion the body occupies a sequence

of configurations Bt in space. From this sequence we pick out two configurations attime tn and tn+1 := tn + t. We denote the first one as material configuration B,the second one as spatial configuration S and the related mappings of the body Binto R3 as n and n+1, respectively. These relationships are shown in Figure (1.1).It is now convenient to label the material point Pby its position X in the materialconfiguration. Its spatial position is then denoted as x. It is important to realize thatwe picked out two arbitrary configurations of the motion of the material body. We donot demand the material configuration to be identical to the initial configuration attime t= t0 of the material body, although this is often used, since it is the real initialstress free configuration at time t = 0.

P

X B x S

B

B S

R3

t

n n+1

material configuration spatial configuration

Figure 1.1: Motion of a material body

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

13/125

Chapter 1 Introduction 3

With these definitions in hand and by the use of the illustration in Figure (1.1) itis now possible to describe the physical motion of the material point P between thematerial configurationBand the spatial configuration Sof the material body by themapping

t :

B S

X x= t(X) =(X, t).

We can now describe this physical motion of the continuum body with the abovementioned Lagrangian, Eulerian and ALE descriptions. For this purpose we introduceadditionally to the material and spatial configuration a third one, namely the referenceconfiguration M, where our finite element mesh with the position of the node m islocated. The physical motion of the body from its material to its spatial configurationis now described proceeding from this introduced domain M.

The location of this reference configuration makes now the difference between theabove mentioned descriptions, namely the Lagrangian, Eulerian and ALE description.To outline these differences a brief introduction follows now.

1.1.2 Arbitrary Lagrangian-Eulerian description

We start with the ALE description since this is the most general case and the Lagran-gian as well as the Eulerian descriptions can be defined as special cases of the ALE

description.In the ALE description the introduced fixed reference configuration M is, as the

name of the description suggests, completely arbitrary. It is neither labelled with thematerial nor with the spatial configuration of the material body. We are now interestedin describing the physical motion between the material configurationBand the spatialconfiguration Sof the body. That means we want to solve for the deformation mappingt : B S (physical motion) for each time t [0, T]. To this purpose we considerthe two additional mappings t : M Bt (material motion) and t : M St(mesh motion), which relate the material and spatial parameterization Bt and St ofthe material and spatial configuration Band Sof the material body to the reference

domain, respectively. We have then t =t 1t by construction. These relationshipsare shown in Figure (1.2).

Since the choice of the reference configuration is arbitrary one tries to capturethe advantages of both Lagrangian and Eulerian descriptions while minimizing theirdisadvantages. Of course a judicious choice of the reference domain is required if severemesh distortions should be eliminated, which often imposes a substantial burden onthe user.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

14/125

Chapter 1 Introduction 4

X x

B S

m

Bt St

M

t

t t

materialconfiguration

spatialconfiguration

reference configuration

Figure 1.2: The ALE-kinematics

In Figure (1.2) the physical motion t does not coincide with the mesh motion t.So material convects through the finite element mesh defined by the material motion t.

One could imagine that difficulties arise when dealing with history dependent materials.Consider all history variables are stored at the position of the material point P in thematerial configuration X, which is equal to the position of the mesh point m at thebeginning of the time step. During the computation material convects through thefinite element mesh and the position of the material point Xno longer coincides withthe position of the mesh point m. Thus these history variables must be convectedin the ALE formulation, which makes the handling of history dependent materialschallenging. These types of material models will be considered in this work.

1.1.3 Lagrangian description

The Lagrangian description can be defined as a special case of the ALE descriptionby setting the reference configuration Mequal to the material configuration B, whichthen yields to a material parameterization Bt independent in time t. Mathematicallythis can be obtained by the particular choice t = id, so that the physical motionis equal to the mesh motion, that means t = t. These relationships are shown inFigure (1.3).

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

15/125

Chapter 1 Introduction 5

X=mx

B S

Bt=M St

t = t

material configuration(=reference configuration)

spatial configuration

Figure 1.3: The Lagrangian-kinematics

Since the physical motion t is equal to the mesh motion t no material convectsthrough the finite element mesh defined by t = id. Therefore the difficulties of theALE formulation when dealing with history dependent materials do not occur in theLagrangian description. The mesh point mcoincides with the position of the materialpoint P in the material configuration denoted by X, where the history variables arestored. Thus no convective effects must be considered here.

In solid mechanics the Lagrangian description is most popular. Its attractivenessstems from the ease with which it handles complicated boundaries and its ability tofollow material points, so that history dependent materials can be treated accurately.

The disadvantage stems from the fact that the material points remain coincident withmesh points, elements deform with the material and can become severely distorted,which is commonly observed in plastic models where large plastic strains appear. Theapproximation accuracy of the elements then deteriorates, particularly for higher orderelements.

1.1.4 Eulerian description

Also the Eulerian description can be defined as a special case of the ALE description.By setting the reference configuration M equal to the spatial configuration Swe obtainthe Eulerian description, which then yields a spatial parameterization St independentin time t. Mathematically this can be described by setting t = id, which leads tot =

1t . These relationships are shown in Figure (1.4).

Since the mesh is labelled with the spatial configuration of the body during thewhole deformation, the mesh motion t = id. Thus the physical motion t and themesh motion t do not coincide. The same difficulties as in the ALE formulationarise when dealing with history dependent material models. History variables must beagain convected, since the position of the material point Xdoes not coincide with theposition of the mesh point m.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

16/125

Chapter 1 Introduction 6

Xx=m

B S

Bt St=M

t = 1t

material configuration spatial configuration(=reference configuration)

Figure 1.4: The Eulerian-kinematics

Since the Eulerian description is mostly used in fluid mechanics where often nohistory dependent materials are used, these difficulties are circumvented. Until recentlyEulerian meshes have not been used much in solid mechanics. Eulerian meshes aremost appealing in problems with very large deformations. Their advantage in theseproblems is a consequence of the fact that Eulerian elements do not deform with thematerial. Therefore, regardless of the magnitudes of the deformation in a process,Eulerian elements retain their original shape. Eulerian elements are particularly usefulin modelling many manufacturing processes, where very large deformations are oftenencountered.

1.1.5 Summary

In the previous chapters we have shown the connection between the Lagrangian, Eu-lerian and ALE description of the motion of a material body. We have seen that thedifference lies in the location of the reference configuration M, from where the physicalmotion of the material body is described. In the Lagrangian approach M is labelledwith the material configuration B, whereas in the Eulerian approach it is identical tothe spatial configuration S. Only in the ALE approach the reference configuration ischosen arbitrary, that means it differs from the material configuration as well as fromthe spatial configuration.

Finally an example is presented in Figure (1.5) to illustrate the differences betweenthese descriptions. A circular plate is pulled horizontally, which then becomes elliptical.This deformation is now described with the Lagrangian, Eulerian and ALE description.

In the Lagrangian description, shown in Figure (1.5a), the reference configurationis equal to the material configuration. The finite element mesh (contiguous lines inFigure (1.5)) is therefore located in the material configuration and the mesh point mis identical to the position of the material point Pin the material configuration, denotedbyX. Now lets assume to draw material lines (dashed lines in Figure (1.5)) onto thematerial body, which are identical to the finite element mesh located in the material

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

17/125

Chapter 1 Introduction 7

X

X

x

x

m

Bt

Bt

St

St

M

t

t t

X =m

x=m

Bt=M

St=M

t=t

t=1t

a) Lagrangian description

b) Eulerian description

c) ALE description

Figure 1.5: An illustrative example to show the difference between thea) Lagrangian description, b) Eulerian description and thec) ALE des-cription

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

18/125

Chapter 1 Introduction 8

configuration. Since the circular plate deforms into an elliptical one, also these materiallines deform and the spatial position xof the material point is obtained. It can be seenthat large deformations of the material lines occur. Since the mesh motion is identical tothe physical motion, which leads to the deformed material lines, also distorted elementsoccur. This is the main drawback of the Lagrangian formulation. It should be notedthat of course the center of the circular plate in the material configuration and thecenter of the elliptical plate in the spatial configuration lie above each other. They areonly drawn apart from each other to make the example more illustrative.

On the other hand in the Eulerian description, shown in Figure (1.5b), the referenceconfiguration is labelled with the spatial configuration. So the finite element mesh islocated in the spatial configuration and the mesh point mis equal to the position of thematerial point P in the spatial configuration, denoted by x. Again we draw material

lines onto the material body, but now in the spatial configuration. These material linescoincide with the finite element mesh in the spatial configuration. To obtain exactlythese lines in the spatial configuration one can expect that these lines must be locatedin the material configuration as it is shown in the left hand side of Figure (1.5b). Onecould observe that the well distributed elements chosen as our reference configurationremain in its position since the finite element mesh is fixed in space. The drawback liesin the fact that boundary nodes will not remain on the boundary if the plate is furtherpulled, since for the next time step the same reference configuration is used, whereasthe plate deforms and becomes more elliptical.

In the ALE description, shown in Figure (1.5c), the reference configuration is neit-

her labelled with the material nor with the spatial one. It could be observed that themotion of the finite element mesh t differs now from the physical motion t. As onecould recognize in Figure (1.5c) a good choice of the reference configuration leads toless distorted elements in the spatial configuration as compared to the Lagrangian de-scription. So the ALE formulation minimizes the disadvantages of both, Lagrangianand Eulerian descriptions, while capturing their advantages, which are that boundarynodes remain on the boundary like in the Lagrangian description and that the elementsare better distributed in the spatial configuration like this is the case in the Euleriandescription.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

19/125

Chapter 1 Introduction 9

1.2 Development of ALE formulations

The formulation of ALE methods closely parallels that of Eulerian methods. Withinthe context of finite difference methods Noh [65] and Hirt et al [35] talked aboutQuasi-Eulerian and Coupled Eulerian-Lagrangianmethods. First ALE formulationsdate from Donea et al[21],Belytschko & Kennedy[7],Belytschko et al[8]and Hughes et al [47]. In Hughes et al [47] the first ALE finite element formulationfor incompressible, viscous flow was presented. Further research on the ALE approachwithin the context of fluid mechanics was done by Huerta & Liu [41], Chippadaet al [17] and Venkatasubban [94]. Nomura & Hughes [67], Nomura [66] andSarrate et al[76] worked on fluid structure interaction. The ALE formulation hasobvious appeal in these classes of problems. Two review papers which discuss thegeneral notion of ALE formulations are Benson[10, 11].

Within the context of non-linear solid mechanics considerable amount of work hasbeen done by Liu et al [54, 55, 56], Hu & Liu [37, 38], Gosh & Kikuchi [30, 31],Gosh [29] and Pijaudier-Cabot et al [69]. A good review of ALE formulationsin solid mechanics is given in the papers of Huerta & Casadei [39] and Wang& Gadala [98]. The main difficulty in extending the ALE formulation from fluidto solid mechanics was the path dependent behavior of material models used in solidmechanics. It will be shown in this work that the constitutive equation of ALE nonlinearmechanics contains a convective term which reflects the relative motion between thephysical motion and the mesh motion. In fluid mechanics these convective effects onlyoccur in the mass balance, momentum balance and energy balance, but not in theconstitutive equation. The correct treatment of this convective term in the constitutiveequation is the key point in ALE nonlinear solid mechanics. The most popular approachto deal with this convective term is the use of an operator-split method. Each time-stepis divided into a Lagrangian phase and an Eulerian phase. Convection is neglected inthe Lagrangian phase, which is thus identical to a time-step in a standard Lagrangiananalysis. After that the solution of the Lagrangian phase is transported to account forthe relative mesh-material motion in the Eulerian phase.

An example for a path dependent material model is the hypoelastic-plastic mo-del described in Simo & Hughes [82], Bonet & Wood [12], Stoker [85] or Be-lytschko et al[9]. In this material model the evolution of stresses is expressed inrate format relating an objective stress rate with a rate of deformation. Various formu-lations for large strain solid mechanics which combine an ALE kinematic descriptionand hypoelastic-plastic models can be found in the literature, e.g. Liu et al [54],Benson[10],Huetnik et al[43],Gosh & Kikuchi[31],Huerta & Casadei[39]or Rodriguez-Ferran et al[72].

An extension of the hypoelastic-plastic model to finite strain plasticity models ba-sed on the multiplicative decomposition of the deformation gradient in an elastic and aplastic part (F=FeFp) with the stresses given by a hyperelastic relation was develo-ped by Simo[78, 79, 80, 81], Simo & Hughes[82], Simo & Miehe [83], Miehe[61],

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

20/125

Chapter 1 Introduction 10

Bonet & Wood [12] or Belytschko et al [9]. This plasticity model is nowadaysstandard in Lagrangian formulations but not in ALE formulations. Instead of com-puting the stresses by its rate equation as in the hypoelastic-plastic model, here thedeformation gradient in combination with the free energy is used. However the plasticresponse is still described in rate form involving the Lie derivative.

In the work of Rodriguez-Ferran et al [74] an ALE formulation for this hy-perelastoplastic material model was developed. It is very similar to the formulationswhich are standard for hypoelastic-plastic models. The hyperelastic part of the responseis described as in standard hyperelastic-plastic algorithms by means of the incremen-tal deformation gradient, where the material configuration is set equal to the spatialconfiguration of the last time step, rather than the initial undeformed configuration isused as the material configuration during the whole deformation process. In the ALE

formulation the parameterization of the spatial configuration of the last time step issmoothed during a smoothing phase which then yields to a well distributed spatialparameterization which is finally used as the material configuration in the next timestep. This approach let us forget about any distortions before the actual time step.Thus the full potential of the ALE formulation as an r-adaptive technique (that is anadaptive technique based onrelocating the nodes of a given mesh without changing itstopology, see Huerta et al [42]) can be exploited.

A different ALE formulation for hyperelastoplasticity was developed in Love [57]and Armero & Love [1, 2]. This work is an extension of the work of Yamada &Kikuchi [102], where a fully coupled solution for an ALE formulation for elasticity

was developed. In Love [57] and Armero & Love [1, 2] the material model wasextended for hyperelastoplasticity and an uncoupled solution procedure was derivedfor the fully dynamic range. Instead of the incremental deformation gradient, used inRodriguez-Ferran et al[74], the total deformation gradient is used. This leadsto a formulation where no elastic variables must be convected, since the strains can becomputed by the use of the total deformation gradient and the plastic metric of the lasttime step which of course only occurs if the material becomes plastic. In Rodriguez-Ferran et al [74] the strains are computed by the use of the incremental deformationgradient and the elastic metric of the last time step which leads to a formulation wherethe elastic metric must be stored from the very first time step on, no matter if thematerial is still elastic or already plastic. However convection of plastic variables isstill needed in Armero & Love [1, 2]. The proposed method is based on a directinterpolation of the material and mesh motion, separate of the physical motion of thematerial body compared to typical ALE formulations of finite strain plasticity basedon the solution of the spatial domain together with the mesh velocity.

In this work we will follow the work of Rodriguez-Ferran et al [74] and willshow the relevant steps to upgrade a standard Lagrangian Finite Element programmeinto an ALE formulation for solid dynamics using the finite strain plasticity modelsbased on the multiplicative decomposition of the deformation gradient.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

21/125

Chapter 1 Introduction 11

1.3 Overview of the work

The outline of the work is as follows:

Chapter 2: Basics of Continuum Mechanics. A presentation of the funda-mental continuum equations is given. Due to the formalistic framework used in thischapter, the theory of the ALE formulation can be embedded easily. The kinematicsand definitions of stresses and strains are presented. Finally the fundamental balanceprinciples are discussed. The discussion here is fundamental to the understanding ofthe ALE formulation presented in the subsequent chapters.

Chapter 3: Constitutive Model: Finite Strain Plasticity. In this chapter aformulation for isotropic plasticity at finite strains based on the multiplicative decompo-

sition of the deformation gradient into its elastic and plastic contribution is presented.The numerical implementation as well as the influence of the ALE formulation on thismaterial model is shown.

Chapter 4: Initial Boundary Value Problem. The Initial Boundary ValueProblem (IBVP) which we want to solve by the use of the ALE formulation is presentedin this chapter. The relevant finite element matrix equations are computed based onthe strong and the weak form of the problem. Two solution procedures are shown,where we will restrict ourself to the so called uncoupled solution strategy, where thewhole problem is decoupled based on an operator splitting technique.

Chapter 5: Uncoupled ALE formulation. This chapter presents the UncoupledALE formulation for finite strain plasticity. The relevant equations will be decoupledbased on an operator splitting technique, which breaks the whole problem into a Lag-rangian phase and an Eulerian phase combined with a smoothing phase. These phasesare described in detail. For the update of the internal variables in the Eulerian phasethe Lax Wendroff scheme and the Godunov scheme are presented. Finally the numericalimplementation of the ALE formulation for finite strain plasticity in the fully transientdynamic range is shown.

Chapter 6: Numerical Simulations. Three representative numerical simulations

are shown to illustrate the performance of the proposed Uncoupled ALE formulationfor finite strain plasticity. The Impact of a Circular Bar, the Necking of a CircularBar and a Coining Test are shown. By the use of these examples the ALE methodis compared with the Lagrangian method. Furthermore the differences between theLax Wendroff- and the Godunov scheme for the update of the internal variables arepresented.

Chapter 7: Closure. The final chapter summarizes the work and addresses areasof future research concerning the Arbitrary Lagrangian-Eulerian Finite Element for-mulation.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

22/125

Chapter 2

Basics of Continuum Mechanics

This chapter reviews some basic results of continuum mechanics needed for the subse-quent development and understanding of the ALE formulation. It is a brief overviewof the relevant aspects of the theory and should, by no means, be considered exhau-stive. The notation of modern differential-geometry used in the following chapter isbased on lectures of Miehe [62] and subsequent applications in Lambrecht [50] orVelasco [93]. Detailed expositions of the subject are found in the classical treatiseof Trusdell & Noll [90], Gurtin [32], Marsden & Hughes [59], Ogden [68],Hughes[44], Holzapfel[36] or Belytschko et al [9].

The method of continuum mechanics is a powerful and effective tool to explainvarious physical phenomena without detailed knowledge of the complexity of their in-

ternal microstructure. In an approximation the distribution of a few physical quantitiesas the density, temperature, velocity and so on are considered as continuous and smoothover the whole domain. This approximation ignores inhomogeneities and replaces thevery large number of particles with independent and smooth fields of these quantities.

First the basic kinematics of finite strain deformations is presented. Then the con-cept of stress is defined and finally the mathematical description of the fundamentalbalance laws of physics governing the motion of a continuum are discussed in thischapter.

2.1 Basic Kinematics of Finite Strain DeformationsIn continuum mechanics, kinematics refer to the mathematical description of the de-formation and motion of a material body, which can be either a solid, a fluid or a gas.The different configurations will be shown, and their influence on the description ofthe motion and the different strain- and stress measures will be outlined. Due to theformalistic framework used here, the theory of the ALE formulation can be embeddedeasily.

12

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

23/125

Chapter 2 Basics of Continuum Mechanics 13

2.1.1 Material Body, Configurations and Motion of the Body

This chapter concerns the description of material bodies, their motions, and their

configurations within the continuum theory. Such a material bodyis a physical objectequipped with some physical properties, like texture, density, color and so on, whichare assumed to be contiguous. The body Btakes a place Bin the Euclidean space R3,which can be denoted as the placement ofB in R3. Mathematically the body B is anopen set of infinitely many material points P B, which is a one-to-one relationshipto a subset B R3 of the Euclidean space. This context is shown in Figure (2.1).

P B x B

B B

R3

Figure 2.1: Placement ofB in R3

The placement of the body Bin R3

, which will be denoted as a configurationof thebody, can be mathematically described with the bijective relationship

:

B B R3

P x =(P) B.(2.1)

The place x Bis the place, which the material point Poccupies in space. Themotionof a material body is a one-parameter family of configurations indexed by time.Explicitly, let [0, T] R+ be the time interval of interest. Then, for each t [0, T], themapping

t :

B Bt R

3

P x=t(P) =(P, t) Bt(2.2)

is a mapping which maps Bonto Bt R3 at time t. In a motion the particle P

occupies a sequence of places in space, which is shown in Figure (2.2). This sequenceof configurations will be denoted as path L of the material point P in the Euclideanspace R3.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

24/125

Chapter 2 Basics of Continuum Mechanics 14

P

B

x

x x

x

Bt1

Bt2 Bt3

Bt4

R3

t1

t2 t3

t4

L

Figure 2.2: Family of configurations of the material body

From this sequence we pick out two neighboring configurations. We denote the first

one asmaterialconfiguration Band the second one asspatialconfiguration S. It is nowconvenient to label the material point Pby its position X in the material configurationB, i.e.

0 :

B B R3

P X = 0(P) =(P, t0) B.(2.3)

Inversion of Equation (2.3)2 and insertion into Equation (2.2)2 leads to the map-ping t, which states the current position x of the material point P in the spatialconfiguration S, relating to its position X in the material configuration B.

x = t(P) =t(10 (X))

= t 10 =:t(X) (2.4)

Then the mapping t between the material configuration Band the spatial confi-guration Stakes the form

t :

B S

X x =t(X) =(X, t).(2.5)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

25/125

Chapter 2 Basics of Continuum Mechanics 15

P B

B0

X B

B

x S

St

material configuration spatial configuration

R3

Figure 2.3: Motion of a material body

The motion t is assumed to be uniquely invertible. With the inverse motion,denoted by 1t , the position X in the material configuration Bcan be defined by

X =1t (x) = 1(x, t). (2.6)

The aim is now to describe the motion t of the material body between these twoconfigurations. That is, we want to solve for the deformation mapping t, for each timet [0, T]. Therefore we introduce a fixed reference configuration M, independent ofany placement of the material body. Furthermore we consider two additional mappingst and t, which relate the material and spatial parameterizations Bt and St of thematerial and spatial configurations B and S of the material body to the referenceconfiguration, respectively, i.e

t :

M Bt

m X =t(m) = (m, t)

t :

M St

m x =t(m) = (m, t).

(2.7)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

26/125

Chapter 2 Basics of Continuum Mechanics 16

Here we have denoted the reference points by m M, the material points byX Bt and their spatial position with x St. We have then t = t

1t by

construction, where stands for a composition of mappings. Figure (2.4) depicts theseconsiderations. We will call it the reference description of the motion of a material body.In particular, the reference configuration is understood as defined by a fixed mesh inthe context of the finite element formulation to be developed in this work. In this finiteelement context the material and the spatial domains Band Sof the material body areparameterized in timet. Contrary to the time independent physical configuration Bitsparameterization Bt is now time-dependent. It could be observed that the particularchoice oft = id, so that t = t, leads to the Lagrangian description, whereas thechoicet=id, so that t =

1t reduces the problem to its Eulerian form.

X x

B S

m

Bt St

M

t

t t

materialconfiguration

spatialconfiguration

reference configuration

Figure 2.4: Reference description of the motion of a material body

2.1.2 Displacement-, Velocity- and Acceleration Fields

With the basic definitions of the motion of a material body it is now possible to definedisplacement-, velocity and acceleration fields of a typical material point Xand a meshpoint m.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

27/125

Chapter 2 Basics of Continuum Mechanics 17

Displacement Fields

In particular, we have the physical displacement u of a particle, which relates the

position of a material point Xin the material configuration and its spatial position x.This is illustrated in Figure (2.5) . Since we introduced the reference configuration todescribe the motion of the material body, we can compute this physical displacementin terms of this reference configuration, i.e.

u(m, t) :=(m, t) (m, t) =x(m, t) X(m, t). (2.8)

u, v

um, vm

X x

m

B S

M

materialconfiguration

spatialconfiguration

reference configuration

Figure 2.5: Displacement- and Velocity Fields

Again it could be observed that the particular choice of= id, so that m = X,leads to the physical displacement in terms of the material configuration, known asmaterial displacement U(X, t) whereas the choice = id, so that m = x leadsto the physical displacement in terms of the spatial configuration, known as spatialdisplacement u(x, t), i.e.

U(X, t) :=x(X, t) X(X, t) = x(X, t) X

u(x, t) :=x(x, t) X(x, t) = x X(x, t).

(2.9)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

28/125

Chapter 2 Basics of Continuum Mechanics 18

In the mathematics and continuum mechanics literature, see e.g. Marsden &Hughes[59], different symbols are often used for the same field when it is expressedin terms of different configurations. A common notation uses capital letters for a fielddescribed in the material configuration, like U(X, t), and small letters for a field de-scribed in the spatial configuration, like u(x, t). Since the referential configuration iseither identical to the material or spatial one in a Lagrangian or Eulerian formulation,respectively, no further notation is used for fields described in the referential configu-ration. To avoid further confusion we will not introduce a further notation here in thedevelopment of the ALE formulation. We will use small letters for a field when it isexpressed in terms of the referential configuration, like u(m, t).

Similarly to the physical displacement we can define the displacement of the meshpoint m, which relates its position in the reference configuration m to its spatialposition x as

um(m, t) :=(m, t) m(m, t) =x(m, t) m. (2.10)

Velocity Fields

Similar to the displacement fields, we have now the physical velocity v(m, t) of aparticle in terms of the reference configuration, given by

v(m, t) := d(1(X, t), t)

dt

= (m, t)

t +

(m, t)1(X, t)

1(X, t)t

= x(m, t)

t +

x(m, t)

m(X, t)

m(X, t)

t

= x

t

m

+ gradmxm

t

X

,

(2.11)

where [ ]|mand [ ]|Xmeans holding mand Xfixed, respectively. The abbreviationgradm[ ] stands for [ ]/m. Again it could be observed that the particular choiceof = id, so that m = X, leads to the physical velocity in terms of the material

configuration, known as material velocity V(X, t) whereas the choice = id, so thatm = x leads to the physical velocity in terms of the spatial configuration, known asspatial velocity v(x, t), i.e.

V(X, t) :=(X, t)

t =

x(X, t)

t =

x

t

X

v(x, t) :=1(X, t)

t =1 V(X, t).

(2.12)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

29/125

Chapter 2 Basics of Continuum Mechanics 19

Similarly to the physical velocity v(m, t) we can define the velocity of the meshpoint vm(m, t) in terms of the reference configuration as

vm(m, t) :=(m, t)

t =

x(m, t)

t =

x

t

m

. (2.13)

With these definitions in hand we can now introduce the so called convective ve-locity c(m, t) as the difference of the physical velocity v(m, t) and the mesh velocityvm(m, t). Insertion of Equation (2.13) into Equation (2.11)4 yields

c(m, t) :=v(m, t) vm(m, t) = gradmxm

t X . (2.14)Acceleration Fields

Similar to the velocity fields, we have now the physical acceleration a(m, t) of a particlein terms of the reference configuration, given by

a(m, t) :=d2(1(X, t), t)

dt2 =

2x

t2

m

+ gradmx2m

t2

X

. (2.15)

Again it could be observed that the particular choice of= id, so that m = X,

leads to the physical acceleration in terms of the material configuration, known asmaterial accelerationA(X, t) whereas the choice =id, so that m= x leads to thephysical acceleration in terms of the spatial configuration, known as spatial accelerationa(x, t), i.e.

A(X, t) :=2(X, t)

t2 =

2x(X, t)

t2 =

2x

t2

X

a(x, t) :=12(X, t)

t2

=1 A(X, t).

(2.16)

Similarly to the physical acceleration a(m, t) we can define the acceleration of themesh point am(m, t) in terms of the reference configuration as

am(m, t) :=2(m, t)

t2 =

2x(m, t)

t2 =

2x

t2

m

. (2.17)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

30/125

Chapter 2 Basics of Continuum Mechanics 20

On the other hand it is also possible to compute the physical acceleration a(m, t),given in Equation (2.15), from the derivative of the physical velocity v(m, t) withrespect to time without any knowledge of the material configuration by the use of thereferential gradient gradm[ ]. This is denoted as the material (total) time derivative ofthe referential velocity field v(m, t) and looks like

a(m, t) := dv(m, t)

dt

= v(m, t)

t +

v(m, t)

m(X, t)

m(X, t)

t

= v

t

m

+ gradmv m

t

X

.

(2.18)

It is also possible to use the spatial gradient gradx[ ] = [ ]/x instead of thereferential gradient gradm[ ], which will become important for the development of theALE formulation. By the use of the chain rule in Equation (2.18)2 and insertion of theconvective velocity from Equation (2.14) we obtain

a(m, t) := v(m, t)

t +

v(m, t)

x(m, t)

x(m, t)

m(X, t)

m(X, t)

t

= v

t

m

+ gradxv c =: v(m, t).(2.19)

The first term in the middle of Equation (2.19)2, namely v/t, describes thelocal acceleration (local rate of change of the velocity field). The second term, namelygradxv c is quadratically nonlinear in the velocity field and describes the convectiveacceleration field (convective rate of change of the velocity field).

For the development of the ALE formulation this equation will become very import-ant, since it describes the material time derivative in terms of the local time derivativein the referential configuration and the spatial gradient. Since this relationship holdsfor all functions f(m, t) we can write

f(m, t) := ft

m

+ gradxf c. (2.20)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

31/125

Chapter 2 Basics of Continuum Mechanics 21

2.1.3 The Deformation Gradient

The deformation gradient plays a fundamental role in the theory of continuum me-

chanics. It is used to study the deformation (i.e. the changes of size and shape) of acontinuum body occurring when moved from the material configuration Bto the spa-tial configuration S. Places X and x in these configurations contain tangent spacesTXB,TxSand cotangent spaces T

XB,T

xS. Contravariant vectors are elements of thetangent spaces and covariant vectors are elements of the cotangent spaces. In the fol-lowing, based on the notation of Miehe [62], three fundamental maps, namely theTangent Map, the Normal Map and the Jacobian Map are derived.

The Tangent Map

In the last chapter we have shown that the position of a material point Pin the materialconfiguration Bis labelled by X. This position is mapped into the spatial configurationSby the mapping t, shown in Equation (2.5). The spatial position is then labelled byx. The deformation gradient Fcan be defined as the Frechet-derivative of the mappingt(X), resulting in

F :=tX

. (2.21)

A graphical interpretation of what the deformation gradient is doing can be doneby considering a material curve C() in the material configuration. This curve, where denotes a parameterization, transforms into the spatial curve c() in the spatialconfiguration, when the physical mapping t is applied to B. This is illustrated inFigure (2.6).

c() = t(C()) (2.22)

X

dX

dA C()

B

xdx

da

c()

S

F

TXB TxS

Figure 2.6: Mapping of points, tangent vectors and normal vectors

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

32/125

Chapter 2 Basics of Continuum Mechanics 22

The tangent vector dx to the spatial curve c() is obtained by deriving c() withrespect to its parameter , resulting in the expression

dx=dc()

d =

tX

C()

. (2.23)

Insertion of Equation (2.21) into the last expression leads to the following relation-ship between the tangent vector dx to the curve c() in the spatial configuration andthe tangent vector dX to the curve C() in the material configuration:

dx =FdX (2.24)

Therefore Fcan be interpreted as a linear mapping of contravariant vectors of the

tangent space in the material configuration TXB to the tangent space in the spatialconfiguration TxS, i.e.

F:

TXB TxS

dX dx= FdX.(2.25)

In the same way we can introduce the tangent maps F and F used for the

derivation of the ALE formulation by

F :=tm

and F:= t

m (2.26)

as a linear mapping of contravariant vectors of the tangent space in the referenceconfiguration TmM to the tangent space in the spatial configuration TxS and to thetangent space in the material configuration TXB, i.e.

F :

TmM TxS

dm dx=Fdmand F :

TmM TXB

dm dX = Fdm.(2.27)

The Normal Map

In analogy to the mapping of tangent vectors through F, the tensor cof[F] =det[F]FT

maps the normalsdAand dato the curveC() andc() at the placeX andx, shownin Figure (2.6), from the cotangent spaces of the material T XBto the cotangent spacesof the spatial configuration TxS, i.e.

cof[F] :

TXB T

xS

dAda=cof[F]dA.(2.28)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

33/125

Chapter 2 Basics of Continuum Mechanics 23

Since the normal vectors dAand daare defined as a cross product of two tangentvectors dX1, dX2 and dx1, dx2, and since the length of the normals are equal tothe area spanned by the related tangent vectors, this normal map is also called areamapping.

The Jacobi Map

The relationship between the volume dV and dv of the material and the spatial confi-guration can be defined by the Jacobi map, also denoted as volume mapping,

J:

R R

dV dv = JdV,(2.29)

where J is equal to the determinant of the deformation gradient F. Since themapping t has to be bijective and no penetration of material is allowed a Jacobiangreater than zero is implied, reading

J :=detF>0. (2.30)

2.1.4 Metric- and Strain Tensors

The aim of this chapter is to derive strain measures to measure the relative change ofthe length of the tangent vectorsdXanddx. To this end, we need to introduce an innerproduct associated with spaces (TXB,T

XB) and (TxS,T

xS). This is done by definingnatural metric tensorson the material and the spatial configuration, respectively.

Metric Tensors

To compute the length of a vector we introduce vector norms with the help of thematerial or spatial metric tensor Gand g. These metric tensors describe the mappingfrom the contravariant vectorsdX and dxof the tangent spaces to the dual covariantvectorsdAanddaof the cotangent spaces. The inner product [ a ] [ b ] is only defined

as an operation between different spaces, i.e. [ a ] TXBand [ b ] TXBor [ a ] TxSand [ b ] TxS. It is obvious that the pairs (dX, dA) and (dx, da) define differentgeometrical objects. But in classical terminologies they are defined as the contravariantand covariant representation of the same vector.

G:

TXB T

XB

dX dA= GdXand g:

TxS T

xS

dx da=gdx(2.31)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

34/125

Chapter 2 Basics of Continuum Mechanics 24

The metric tensors G and gare positive definite symmetric second order tensors.With these definitions it is now possible to measure the lengthdSanddsof the tangentvectorsdX and dx, respectively.

dS=dX

G=

dX (GdX) and ds=dx

g=

dx (gdx) (2.32)

The index shows, which metric tensor was used to determine the length of thevector. Insertion of Equation (2.24) yields

dS=dx

c=

dx (cdx) and ds=dX

C =

dX (CdX). (2.33)

In Equation (2.33) the positive definite symmetric right Cauchy-Green tensor C

and the inverse left Cauchy-Green tensor or inverse finger tensor c (do not confuseyourself by the same notation as the convective velocity) have been introduced:

C :=FTgF and c :=FTGF1 (2.34)

These deformation dependent metric tensors allow the computation of the spatiallength ds proceeding from the material tangent vector dX and the computation ofthe material length dSproceeding from the spatial tangent vector dx. The relatedmappings are shown in Figure (2.7) and can be defined as

C:

TXB T

XB

dX dA= CdXand c :

TxS T

xS

dx da=cdx.(2.35)

It is obvious, that the inversion of the inverse finger tensor c results in the so calledfinger tensor, sometimes referred as left Cauchy-Green tensor, which will be denotedbyb, i.e.

b :=c1 =FG1FT. (2.36)

Strain Tensors

Unlike displacements, which are measurable quantities, strains are based on a conceptthat is introduced to simplify analysis. Therefore numerous definitions and names ofstrain tensorshave been proposed in the literature. All of them have in common, thatstrain measures always compare the two metric tensors in a chosen geometrical setting,e.g.

E=f(C,G) and e =f(c, g) . (2.37)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

35/125

Chapter 2 Basics of Continuum Mechanics 25

X

X

x

x

G cC g

F

FT

TXB

TXB

TxS

TxS

Figure 2.7: Metric Tensors

E.g. the well known Green-Lagrange strain tensorEand the Almansi strain tensore are defined by

E :=1

2(C G) and e :=

1

2(g c) . (2.38)

2.2 The Concept of Stress

In the previous chapter some kinematic aspects of the motion and deformation of acontinuum body have been discussed. The deformation causes interactions between thematerial and the neighboring material in the interior part of the body. One consequenceof these interactions is stress. The concept of stress will be discussed in this chapter.

2.2.1 Eulers Cut Principle

The mapping tmaps the material configuration Bto the spatial configuration S. Lets

now cut out a part of the body. This remaining part is denoted by BP and SP in thematerial and the spatial configuration, respectively. The quantitiesx, da and nwhichare associated with the part of the body in the spatial configuration are denoted by X,dAand Nwhen they are referred to the part of the body in the material configuration,which is shown in Figure (2.8).

To describe the relationship between the two parts of the body the Cauchy (ortrue) traction vector t(x, t,n) is introduced in the spatial configuration. A physicalinterpretation of this traction vector could be observed by the example of a neckingbar. Here trepresents the stress vector which can be computed by dividing the forcedfacting on the bar by the deformed area da. In reality often the actual force is divided by

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

36/125

Chapter 2 Basics of Continuum Mechanics 26

xXT

Ntt

dA

B

BP

t

nda

S

SPF

Figure 2.8: Eulers Cut Principle

the initial areadA, which would lead to the first Piola-Kirchhoff (or nominal) traction

vector t(X, t,N), which lives in the spatial configuration and points in the samedirection as the true traction vector t. For every surface element the infinitesimal forcevector can be defined as

df = tda = tdA. (2.39)

2.2.2 Stress Tensors

Cauchys stress theorem defines the Cauchy stress tensor and postulates the linear

dependency between the traction vector tand the normal nin the spatial configurationby

t(x, t,n) =:(x, t)n. (2.40)

The symmetric Cauchy stress tensor maps the spatial covariant normal vector nfrom the cotangent space TxSto the tangent space TxS:

: TxS TxS

n t=n(2.41)

The Cauchy stress tensor relates the local force df in the cut plane to the de-formed area da. That is why this stress is also called true stress. On the other handtheKirchhoff stress tensoris defined by multiplying the Cauchy stress tensor by theJacobian J:

=J :

TxS TxS

n Jt= n(2.42)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

37/125

Chapter 2 Basics of Continuum Mechanics 27

Applying Cauchys stress theorem onto the traction vector t, which can be derivedby the relationshipt = tda/dA observed from Equation (2.39), and onto the normalN

in the material configuration B leads to the non-symmetric first Piola Kirchhoffstress tensorP, i.e.

t(X, t,N) =:P(X, t)N. (2.43)

The first Piola Kirchhoff stress tensor P, a two-field tensor, maps the materialcovariant normal vector Nfrom the cotangent space TXBto the tangent space TxS inthe spatial configuration:

P: TXB TxS

N t=PN

(2.44)

The first Piola Kirchhoff stress tensor relates the local force df in the spatial cutplane to the undeformed area dA. Pcan be related to the Cauchy stress tensor by

P=JFT. (2.45)

In the last step we construct a pure material stress tensor, the so called secondPiola Kirchhoff stress tensor, denoted by S. Therefore the nominal traction vector tis transformed back to the material configuration, i.e.

T =F1t. (2.46)

In analogy to Equations (2.40) and (2.43) this leads to the pure material stresstensor S, i.e.

T(X, t,N) =:S(X, t)N. (2.47)

The symmetric second Piola Kirchhoff stress tensor maps the material covariantnormal vector N from the cotangent space TXB to the tangent space TXB in thematerial configuration:

S:

TXB TXB

N T =SN(2.48)

The second Piola Kirchhoff stress tensor can be related to the Cauchy stress tensor, the Kirchhoff stress tensor and the first Piola Kirchhoff stress tensor P by

S=JF1FT =F1FT =F1P. (2.49)

In Figure (2.9) a graphical interpretation of the relationship between all these stresstensors is given.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

38/125

Chapter 2 Basics of Continuum Mechanics 28

X

X

x

x

S =JP PT

F

FT

TXB

TXB

TxS

TxS

Figure 2.9: Stress Tensors

2.3 Balance Principles

The fundamental balance principles, i.e. conservation of mass, the momentum balanceprinciples and the balance of energy and entropy are discussed in this chapter. Theyare applicable to any particular material and must be satisfied for all times. The phy-sical balance principles are defined global as integrals over the whole material body.

These global balance laws can be transformed into local balance laws. In general, lo-cal forms are ideally suited for approximation techniques such as the finite differencemethod while global forms are the best to start with when the finite element methodis employed.

2.3.1 Master Balance Principle

The master balance principle provides the frame of all balances in continuum mecha-nics. The present status of a set of material points Poccupying an arbitrary region SP,obtained by application of Eulers cut principle, with boundary surface SP at timet may be characterized by a tensor valued function I(t) =

SP

f dv. In the following

let f = f(x, t) be a smooth spatial tensor field per unit current volume, which maycharacterize some physical scalar, vector or tensor quantity, like density, linear- andangular momentum, total energy or entropy, which has to be balanced.

A change of these quantities may now be expressed as the following master balanceprinciple here presented in the global spatial form, i.e.

d

dt

SP

f(x, t) dv=

SP

(x, t,n) da+

SP

(x, t) dv+

SP

f(x, t) dv. (2.50)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

39/125

Chapter 2 Basics of Continuum Mechanics 29

As stated abovef=f(x, t) is the volume specific mechanical quantity which has tobe balanced. The field function = (x, t,n) is the efflux of the mechanical quantitythrough the surface SP. Note that depends not only on the position x and timet, but also on the orientation of the infinitesimal spatial surface element ds SPcharacterized by the unit vector field nnormal to SP at x. = (x, t) is the supplyof the mechanical quantity and f= f(x, t) represents the production of the mechanicalquantity.

The goal is now to transform the global master balance principle of Equation (2.50),valid in the domain SP to a local form valid for each material point P. This can be doneby insertion of Cauchys stress theorem in a more general setting leading to(x, t,n) =(x, t)n. Then the surface integral is transformed into a volume integral by Gauss-typetheorem, i.e.

SP[ ]nda = SP

div[ ] dv. Finally the localization theorem is appliedsince the domain S

P is arbitrary. This leads to the result, that an expression in the

formSP

[ ] dv states the same as [ ] = 0, which then leads to the local representationof the master balance law, i.e.

f+fdivxx= divx + + f . (2.51)

All specific balance relations of mechanics have to be introduced as an axiom andfit into the global master balance principle, shown in Equation (2.50). Then it is easyto obtain the local balance law from the local master balance law, shown in Equation(2.51).

2.3.2 Balance of Mass

A closed system consists of a fixed amount of massM. No mass can enter or leave theboundary of the system. The mass is a fundamental scalar property independent of themotion. It is a measure of material in the body B. We consider a closed system witha given motion x = (X, t), the material mass density 0(X) and the spatial massdensity(x, t).

Axiom 2.1. In a closed system, the massMof a body is constant.

Thus,

M=

SP

(x, t) dv = const d

dtM= 0.

In comparison with the global master balance principle, see Equation (2.50), oneconcludes to

f=, = 0, = 0, f= 0. (2.52)

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

40/125

Chapter 2 Basics of Continuum Mechanics 30

Thus in comparison with the local master balance principle, see Equation (2.51),the local mass balance in the spatial framework has the form

(x, t) +(x, t)divxx(x, t) = 0. (2.53)

Transferring the axiom of mass balance into the framework of the material confi-guration and comparing it with the local master balance principle leads to the localbalance of mass in the material framework, which has the obvious form

0(X) = 0. (2.54)

2.3.3 Balance of Linear MomentumAgain we consider a closed system with a given motion x=(X, t), the material massdensity 0(X), the spatial mass density (x, t) and the spatial velocity field v(x, t).We define the total linear momentum L by the vector valued function

L(t) =

SP

(x, t)v(x, t) dv. (2.55)

x

bu

tS

SPu

SPt

Figure 2.10: Forces acting on a continuum body

To define the balance of linear momentum we need to define the structure of forcesacting on a continuum body, shown in Figure (2.10). Consider a boundary surfaceSP, subdivided into a part SPt, which is subjected to the Cauchy traction vectort(x, t,n) =t, defined in Equation (2.40), and into a partSPu, where the displacementu(x, t) = u is prescribed, with SPt SPu = SP and SPt SPu = 0. The unitvector field n is the outward normal to the infinitesimal surface element da SP.Furthermore let b=b(x, t) denote a spatial vector field, called body force defined perunit spatial mass.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

41/125

Chapter 2 Basics of Continuum Mechanics 31

Axiom 2.2. The temporal change of the linear momentumL equalsthe sum of the forces acting onSP. Thus,

d

dt

SP

(x, t)v(x, t) dv=

SP

t(x, t,n) da+

SP

(x, t)b(x, t) dv.

In comparison with the global master balance principle, see Equation (2.50), oneconcludes to

f=v, = t= n, =b, f= 0. (2.56)

Thus in comparison with the local master balance principle, see Equation (2.51), andafter some calculations, the local balance of linear momentum in the spatial frameworkhas the form

(x, t)v(x, t) = divx(x, t) +(x, t)b(x, t). (2.57)

Transferring the axiom of the balance of linear momentum into the framework ofthe material configuration and comparing it with the local master balance principleleads to the local balance of linear momentum in the material framework, which hasthe form

0(X) V(X, t) = divXP(X, t) +0(X)B(X, t). (2.58)

2.3.4 Balance of Angular Momentum

In addition to the linear momentum, we define the total angular momentum Jby thevector valued function

J(t) =

SPx (x, t)v(x, t) dv. (2.59)

Axiom 2.3. The temporal change of the angular momentum Jequals the sum of the moments of all forces acting onSP. Thus,

d

dt

SP

x (x, t)v(x, t) dv=SP

x t(x, t,n) da+

SP

x (x, t)b(x, t) dv.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

42/125

Chapter 2 Basics of Continuum Mechanics 32

In comparison with the global master balance principle, see Equation (2.50), oneconcludes to

f= x (v), = x t, =x (b), f= 0. (2.60)

Thus in comparison with the local master balance principle, see Equation (2.51),and after some calculations, the local balance of angular momentum in the spatialframework states the symmetry of the Cauchy stress tensor, i.e.

= T. (2.61)

From this result the symmetry conditions for all other stress tensors which have

been determined in Chapter (2.2) follow as

= T, PFT =FPT and S=ST. (2.62)

2.3.5 Balance of Energy

To determine the balance of energy we have to introduce the kinetic energy K(SP, t)of the body and the internal energyU(SP, t). The internal energy depends on the massspecific scalar fieldu(x, t), which describes the locally stored energy at the spatial pointx SP.

K :=

SP

1

2v (gv) dv and U :=

SP

udv (2.63)

We used the spatial metric g to determine the scalar product. Furthermore themechanical powerPext(SP, t) and the thermal powerQ(SP, t) must be introduced. Thethermal power depends on a heat influx h(x, t,n) = q(x, t) nand a volume specificexternal heat supply r(x, t).

Pext=SP v (gb) dv+

SP v (gt) da and Q=

SP rdv

SP h da (2.64)

Axiom 2.4. The sum of the temporal changes of kinetic and in-ternal energy equals the sum of the mechanical and thermal power.Thus,

d

dt[K+ U] =Pext+Q.

-

8/13/2019 An Arbitrary Lagrangian Eulerian Finite Element Formulation for Dynamics and Finite Strain Plasticity Models

43/125

Chapter 2 Basics of Continuum Mechanics 33

Insertion of the specific terms into the global balance of energy equation and incomparison with the global master balance principle, see Equation (2.50), one concludesto

f=[u+1