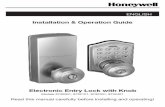

AM3 Installation & Operation Manual

Transcript of AM3 Installation & Operation Manual

AM3 Dishwasher installation and operation manual

Hobart Food Equipment Co., Ltd.

FORM 743423-2E

TABLE OF CONTENTS

GENERAL……………………………………………………………1

INSTALLATION……………………………………………………2

Location……………………………………………………………………………2

Convert from straight-through to corner operation………………………3

Electrical connections……………………………………………………………4

Plumbing connections……………………………………………………………6

OPERATION………………………………………………………7

Controls……………………………………………………………………………7

Preparation…………………………………………………………………………7

Dishwashing………………………………………………………………………8

MAINTENANCE……………………………………………………9

MACHINE CLEANING……………………………………………9

TROUBLESHOOTING……………………………………………10

Appendix 1: Circuit Diagram

Appendix 2: Electrical Wiring Connection Layout

Appendix3: Installation guide

Appendix4: Control board chart

AM3 Dishwasher Installation & Operation Manual

Installation, Operation, and Maintenance of

AM3 DISHWASHERS SAVE THESE INSTRUCTIONS

GENERAL

The AM3 dishwashers are semi-automatic rack-type machines. Three doors open at the same time to allow the rack to be pushed in or out. After filling, an automatic wash and rinse cycle begins when the door is lowered.

Dish table heights may be specified at time of order for 800mm (31.5 inches) or 860mm (33.875 inches).

Electric booster heat options (7kW or 14kW) include an open vented booster tank supplied with a solenoid valve, line strainer, rinse pump and type “A” air gap. Low water protection is provided in the boosters. No booster versions are also available for connection to external heating.

1

AM3 Dishwasher Installation & operation Manual

INSTALLATION Before installing, check the electrical service to be sure it agrees with the electrical specifications on the data plate located on the right side of machines.

Immediately after unpacking, check for possible shipping damage. If the dishwasher is found to be damaged, save the packaging material and contact the carrier or supplier within 15 days of delivery.

LOCATION

Place the dishwasher in its operating location. Before finalizing the location, make sure that consideration has been given for the electrical conduit, water supply, drain connection, gas booster location (if applicable), tabling, chemical feeder replenishment (if applicable), daily cleaning, maintenance and adequate clearance for opening the doors (Fig. 1).

E BETWEEN WALL AND MACHINE IS AT LEAST 100 MM

H TABLE

DRAIN

FILL HOSE

WALL

WALL

THE SPAC

DIS

Fig12

AM3 Dishwasher Installation & Operation Manual

The dishwasher must be level before any connections are made. Turn the leveling feet as required to level the machine and adjust to the desired height.

Dish table should be turned down and fitted into the dishwasher (Fig.2). Use a suitable sealer between table and tank lip to prevent leakage.

A hood or vent may be required in order to meet local codes. The ventilation volume should be more than 2.8m3/min t (supplied by others).

TO PREVENTAGE

CONVERT FROM ST

For corner operation, guide on the side and

STRAIGHT-TH

in case of using hood or ven

SEALLEAK

DISH TABLE

Fig. 2

RAIGHT-THROUGH TO CORNER OPERATION

remove the rack guide and baffle (Fig.3) from the front, assemble the rack use screws to re-install the baffle in the front.

ROUGH CORNER

RE-INSTALL BAFFLE HERE

RACK GUIDE

Fig. 3

3

AM3 Dishwasher Installation & operation Manual

ELECTRICAL CONNECTIONS WARNING:ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

Refer to the electrical diagram on the inside of side panel. Connect the electrical supply wires with different colors to terminal block (Fig. 4).

No Booste

Min. CircuAmpacity / M

Protective De

Volts / Hz / Ph

AMPS 100/50/1 60

100/60/1 60

220/50/1 25

220/60/1 25

240/50/1 25

200/50/3 15

200/60/3 15

220/60/3 15

380/60/3 15

380~415/50/3 15

RPS1

RPS2

DPS1

DPS2

2FU1FU

3FU L1L3N L2

Fig. 4

Electrical Data

r 7KW Electrical Booster

14KW Electrical Booster

it ax. vice

Min. Circuit Ampacity / Max.

Protective Device

Min. Circuit Ampacity / Max.

Protective Device

AMPS AMPS

30 50

30 50

40 60 25 40

25 40

4

AM3 Dishwasher Installation & Operation Manual

CHECK ROTATION (Three-Phase Machines Only) Three phase motors must rotate in the direction of the arrow on the pump housing (counterclockwise). If the rotation is incorrect, DISCONNECT ELECTRICAL POWER SUPPLY and interchange any two of the incoming power supply leads. Re-energize the dishwasher and verify correct rotation.

Warning: The rotation of motors must be checked again before the first operation. In-correct rotation could cause improperly operation of dishwasher and damage of wash pump even in short period of time.

Power Supply for Detergent Dispenser and/or Rinse/Sanitizer Feeder (by others)

Terminals DPS1 and DPS2 in the control box allow connection of a detergent dispenser (by others). RPS1 and RPS2 terminals allow connection of a rinse/sanitizer feeder (by others) with maximum current of 3 Amps (Fig. 4). DPS1-DPS2 is powered during the wash cycle; RPS1-RPS2 is powered during the rinse cycle. Refer to the electrical diagram on the inside of side panel.

Note 1: All connecting wires must accommodate the movement of the control box as it slides out for service.

Note 2:All wires must be 600 volts insulation cable; do not use normal low voltage cable.

Cycle Timing Data

Whole Cycle(s) 60 90 120

Wash(s) 44/47 74/77 104/107

Dwell(s) 4 4 4

Rinse(s) 12/9 12/9 12/9

5

AM3 Dishwasher Installation & operation Manual

PLUMBING CONNECTIONS WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY, AND PLUMBING CODES.

WATER SUPPLY Connect the water pipe to the incoming water supply (3/4” NPT internal threads)

With 7KW ElecWith 14KW Elec

Note: In caseinstalled (by reducer mus

DRAIN

Connect the 11/4” NPrequired by code, it sminute).

RINSE AGENT CON

Remove front panepoints. Two connprovided. One is locaand allows rinse agAnother is located upump outlet and allopipe. Select a suitarequirement. Use aconnect rinse agent (Fig. 5).

INCOMING WATER SUPPLY REQUIREMENTS TEMPERATURE PRESSURE (Dynamic) 0C 0F KPa kg/cm2

trical Booster 50~60 122~140 29.4~490 0.3~5 trical Booster 10~60 50~140 29.4~490 0.3~5

of line dynamic pressure is less than 0.3kg/cm2,a booster-pump must be others); in case of line static pressure is more than 5kg/cm2,a pressure t be installed (by others).

T drain connector under the wash tank to a suitable drain. If a grease trap is hould have a minimum flow capacity of 95.5 liters per minute (21 gallons per

NECTION

l to locate rinse agent connection ecting points for rinse agent are ted at the upper right side of booster ent to inject into the booster tank. nder the booster tank near the rinse ws rinse agent to inject into the rinse ble point according to the chemical spanner to loosen the plug and pipe with a suitable sealing material

G1/8" INTRERNALTHREADS

G1/8" INTERNALTHREADS

Fig. 5

6

AM3 Dishwasher Installation & Operation Manual

OPERATION

CONTROLS

Power Switch (below )

“Faucet” – power is on

“O” – power is off

Power Indicator (above )

Light on – machine power is on

Light off – machine power is off

Cycle Selector (below )

“I” – 60s wash cycle

“II” – 90s wash cycle

Working Indicator (above )

Light on – machine is working

Light off – wash cycle is finished

Temperature Display the left display indicates wash water temperature

the right display indicates rinse water temperature

Automatic Start closing the doors will automatically start a timed cycle or filling cycle.

Drain lift the standpipe to drain the wash tank

W

R

65

50

4045

5560

7085

70

6065

7580

90I

II O

Recommended Operating Temperatures

ash Water 60 – 65oC(140 – 149oF)

o o

inse Water 8 2 – 90 C(181 – 194 F)7

AM3 Dishwasher Installation & operation Manual

PREPARATION

Place the strainer basket in its proper location in the corner of the wash tank and insert the stand drain pipe (Fig. 6)

Close the doors.

Turn the power switch on, the machine will fill automatically.

Open the door and make sure the wash tank is full of water after fill cycle is complete. Scatter the initial amount of detergent on the strainer basket. Replenish as needed. If an automatic detergent dispenser has been installed, follow supplier’s instruction.

Strainer BasketDrain Pipe

Fig. 6

Close the door and the wash and rinse cycle will begin automatically.

Wait for the wash and rinse tank thermometer to reach the proper temperature.

DISHWASHING

Scrape the dishes to remove large particles of food and debris.

Select suitable 60 or 90 second wash cycle according to dish size and food soil.

Stack the dishes in a rack. Do not stack dishes one on top of another as water must have free access to all sides of every dish. Stand plates and dishes up edgewise in a peg-type rack. Cups, glasses and bowls should be inverted in an open-type or compartment type rack (Fig. 7). Silverware and other small pieces may be scattered loosely over the bottom of a flat bottom rack or in a basket type rack.

Fig. 7

After filling a rack, open the doors, slide the rack into the dishwasher, and close the doors. The wash and rinse cycle will begin when the doors are closed.

When the wash and rinse cycle is finished, open the doors and remove the rack of clean dishes. Continue by sliding in the next rack of dishes and close the doors.

If you want to add a dish after the wash cycle has started, before opening the doors, turn off the power switch and wait 10 seconds to allow the wash arm to stop rotation to avoid hot water splashing out on the operators.

8

AM3 Dishwasher Installation & Operation Manual

CLEANING

It is recommended that the machine be thoroughly cleaned at the end of each working shift or at least daily.

The procedures of machine cleaning as follow: 1 Turn of the power switch 2 Open the doors 3 Clean off the dish table into the dishwasher 4 Drain the machine by pulling out the drain stand pipe 5 Remove and empty the strainer basket and pump intake screen. Wash and rinse them

thoroughly. 6 Thoroughly clean and flush the dishwasher interior 7 Replace intake screen and strainer basket 8 Leave the doors open to allow the interior to dry 9 Check the wash and rinse arms rotate freely and are free of any obstructions 10 Check rinse nozzles to make sure they are free of any lime or obstruction

MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT SWITCH INDICATING THAT THE CIRCUIT IS BEING WORKED ON BEFORE BEGINNING ANY MAINTENANCE PRECEDURE.

WASHARMS

Upper and lower wash and rinse arms should turn freely and continue turning for a few seconds after being whirled by hand. To check arms, DISCONNECT ELECTRICAL POWER SUPPLY, rotate arms, and remove any obstructions causing improper operation.

Fig.8

Knurled Disk

Rinse Arm

Wash Arm

If the strainer basket or pump intake screen is not properly in place, obstructions (such as food particles or bones) may clog the wash arm nozzles. The wash arms are easily removed for cleaning.

To remove the wash and rinse arms, unscrew the knurled disk between the rinse and wash arms and take them out (Fig. 8).

NOTE: 1 It is not necessary to remove the spacer located on

the lower wash arm shaft. 2 During upper wash and rinse arms removal, be careful not to drop these arms. 3 Upper and lower wash arms and rinse arms are interchangeable.

9

AM3 Dishwasher Installation & operation Manual

TROUBLESHOOTING This section may help you avoid a service call. However, if a symptom persists after the possible causes have been checked, please contact HOBART local service departments.

SYMPTOM POSSIBLE CAUSES/SUGGESTED ACTIONS

No machine operation

1 Open doors and hold for 2 seconds, close it again 2 Blown fuse or tripped circuit breaker at power supply 3 Blown fuse FU3 at control circuit

Long wash cycle

1 Water temperature in booster is too low, fill water temperature is too low.

2 Water in booster is below high level sensor; please examine line strainer and solenoid valve.

Dishes not clean

1 Wash pump rotating in wrong direction. 2 Insufficient wash water due to drain obstruction preventing proper

drain closing. 3 Insufficient water circulation due to obstruction at pump intake screen.

Disconnect power supply, drain wash tank and check. 4 Incorrect water temperature. Insufficient warm-up time. Check circuit

breaker, thermostat and heater. 5 Incorrect detergent dispensing. Contact your detergent

representative. 6 Excessive mineral deposits through wash and rinse system. Deliming

may be necessary.

Spotting silverware, glasses, and dishes

1 Improperly loaded racks. 2 Incorrect rinse water temperature. 3 Loss of water pressure due to pump obstruction. 4 Excessively hardness of water. 5 Incorrect detergent for water type. 6 Incorrect rinse additive for water type. 7 Incorrect concentration of detergent, rinse additive and/or sanitizer.

Inadequate rinse

1 Dirty line strainer causing reduced water flow. Turn off water supply, disconnect water supply pipe and solenoid valve, withdraw and clean screen. Reassemble.

Leaking valve

1 Foreign material preventing proper valve operation. Note: a critical period is soon after installation when pipe compound or metal shavings may lodge at the valve seat. Shut off supply line. Unscrew and lift bonnet from valve body. Clean valve and reassemble

2 If a solenoid valve is malfunctioning, it is recommended that you contact Service

No or slow fill

1 Dirty line strainer causing reduced water flow. Turn off water supply, disconnect water supply pipe and solenoid valve, withdraw and clean screen. Reassemble

2 Low supply line pressure

10

AM3 Dishwasher Installation & Operation Manual

11

SERVICE Contact your local Hobart-authorized service office for any repairs or adjustments needed on this equipment.

INC

OM

ING

WA

TE

R:C

on

ne

ctw

ate

rlin

eto

the

su

pp

lied

wa

ter

ho

se

on

the

ba

ck

ofth

em

ach

ine

.

2.1

Th

eH

ob

art

su

pp

lied

inco

min

gw

ate

rh

ose

is1

.5m

lon

g,G

3/4

"

inte

rna

lth

rea

ds.

2.2

Flo

win

gw

ate

rp

ressu

reshoukd

be

0.3

-5.0

kg/c

m2.

2.3

Inco

min

gw

ate

rte

mp

era

ture

sh

ou

db

e1

0-6

0C

.

No

te:W

ate

rp

ressu

reo

uts

ide

the

ab

ove

ran

ge

will

resu

ltin

ine

ffe

ctive

rin

se

resu

lts.

PO

WE

R:M

ake

ele

ctr

ica

lco

nn

ectio

nto

the

ma

ch

ine

with

the

Ho

ba

rtsu

pp

lied

co

rdlo

ca

ted

atth

eba

ck

ofth

em

ach

ine

.

3.1

Co

nfirm

tha

tm

ach

ine

ele

ctr

ica

lsp

ecific

atio

na

rerig

htfo

rth

e

insta

llatio

nlo

ca

tio

n.

3.2

Ye

llow

/gre

en

wir

es

are

Gro

un

d,th

eb

lue

wir

ein

Na

nd

the

oth

er

wire

sa

reL

.

No

te:

Ele

ctr

ica

la

nd

gro

un

dco

nn

ectio

ns

mu

st

co

mp

lyw

ith

all

na

tio

na

la

nd

loca

lco

de

s.

CH

EC

KR

OT

AT

ION

OF

WA

SH

PU

MP

:

4.1

Ve

rify

co

un

terc

lockw

ise

rota

tio

no

fp

um

pa

fte

re

lectr

ica

l

co

nn

ectio

nis

co

mp

lete

d.

4.2

Ifro

tatio

nis

inco

rre

ctd

isco

nn

ectp

ow

er

su

pp

lya

nd

inte

rch

an

ge

an

ytw

ole

ad

s.

4.3

Re-e

nerg

ize

the

machin

ea

nd

verify

counte

rclo

ckw

ise

pum

p

rota

tio

n.

RIN

SE

AG

EN

TD

ISP

EN

SE

RC

ON

NE

CT

ION

:(u

su

ally

co

nn

ecte

db

ych

em

ica

lco

mp

an

y)

5.1

Co

nn

ectto

eith

er

po

int(1

)o

rp

oin

t(2

).

5.2

Co

nn

ectio

ns

po

ints

are

G1

/8"

inte

rna

lth

rea

ds.

CO

NN

EC

TR

INS

EA

GE

NT

AN

DD

ET

ER

GE

NG

PO

WE

RS

UP

PL

Y:

(usu

ally

co

nn

ecte

db

ych

em

ica

l

com

pany)

6.1

Slid

eo

utco

ntr

olb

ox

an

dre

mo

ve

co

ve

r.

6.2

Co

nn

ectd

ete

rge

ntd

isp

en

ser

wires

tote

rmin

als

DS

P1

and

DS

P2

.T

he

se

term

ina

lsa

rep

ow

ere

dd

urin

gth

ew

ash

cycle

an

dsu

pp

lya

ma

xim

um

cu

rre

nto

f3

am

ps.

6.3

Co

nn

ectrin

se

ag

en

td

isp

en

se

sw

ire

sto

term

ina

lsR

PS

1

an

dR

PS

2.T

he

se

term

ina

lsa

rep

ow

ere

dd

uri

ng

the

rin

se

cycle

an

dsu

pp

lya

ma

xim

um

cu

rre

nto

f3

am

ps.

No

te:

De

terg

en

ta

nd

rin

se

ag

en

td

isp

en

se

rsca

no

nly

be

co

nn

ecte

dto

the

term

ina

lslis

ted

ab

ove

.

DR

AIN

:C

on

ne

ctd

rain

toth

eG

1-1

/4"

exte

rna

l

thre

ad

dra

ino

pe

nin

go

nth

eb

ott

om

of

the

ma

ch

ine

.

TH

ISC

AR

DIS

AB

RIE

FS

TE

P-B

YS

TE

PG

UID

EF

OR

INS

TA

LL

ING

HO

BA

RT

MO

DE

LA

M3

.

FO

RM

OR

EIN

FO

RM

AT

ION

PL

EA

SE

RE

FE

RT

OT

HE

AM

3O

PE

RA

TO

RM

AN

UA

LIN

CL

UD

ED

WIT

HY

OU

RM

AC

HIN

EO

R

CO

NT

AC

TY

OU

RLO

CA

LH

OB

AR

TS

ER

VIC

EO

FF

ICE

,D

EA

LE

RO

RS

ER

VIC

EA

GE

NT

.

1

2 3 4

5 6

AM

3D

ish

wa

sh

er

Ins

tall

ati

on

Gu

ide

7

DIS

HT

AB

LE

S:

Dis

hta

ble

ed

ge

sh

ou

ldtu

rnd

ow

n

into

the

dis

hw

ash

er.

Dis

hta

ble

dim

en

sio

ns

are

de

taile

do

nth

ep

rod

uctb

roch

ure

an

din

the

op

era

tor

ma

nu

al.

Use

asu

ita

ble

se

ale

rb

etw

ee

n

tab

les

an

dta

nk

top

reve

ntle

aka

ge

.

F-74

3441

E

AM

3 C

ON

TRO

L B

OA

RD

CH

AR

T

Desc

riptio

n Ind

icatio

n Po

wer

Light

mean

s elec

tricity

turn

ed on

60

sec.

Light

mean

s 60 s

ec. w

orkin

g cyc

le se

lected

90

sec.

Light

mean

s 90 s

ec. w

orkin

g cyc

le se

lected

12

0 sec

. Lig

ht me

ans 1

20 se

c. wo

rking

cycle

selec

ted

Door

switc

h Lig

ht me

ans d

oor c

losed

Ta

nk lo

w lev

el Lig

ht me

ans w

ater in

tank

abov

e low

leve

l sen

sor

Tank

high

leve

l Lig

ht me

ans w

ater in

tank

abov

e high

leve

l sen

sor

Boos

ter te

mper

ature

Lig

ht me

ans w

ater t

empe

ratur

e in b

ooste

r too

low

Boos

ter lo

w lev

el Lig

ht me

ans w

ater in

boos

ter ab

ove l

ow le

vel s

enso

r Bo

oster

high

leve

l Lig

ht me

ans w

ater in

boos

ter ab

ove h

igh le

vel s

enso

r W

ash p

ump

Light

mean

s was

h pum

p run

ning

Rins

e Pum

p Lig

ht me

ans r

inse p

ump r

unnin

g Fil

l Lig

ht me

ans f

ill va

lve op

en

Tank

heate

r Lig

ht me

ans w

ater le

vel a

bove

low

water

sens

or

Boos

ter he

ater

Light

mean

s wate

r leve

l abo

ve lo

w wa

ter se

nsor

Ind

icator

Lig

ht me

ans w

ash i

n pro

gres

s

OSw

itch

1 O O

Switc

h 2

O

60' LN

100~

220V

DC

5V

- ++-0'

60'

Rin

sepu

mp

J503

Was

hpu

mp

J502

J504Fill

J505

Tank

heat

er

J506

Boo

ster

heat

er

J501

Indi

cato

r

Boo

ster

tem

pera

ture

120'

90'

Pow

er

90'

120'

off

on

21

J107

Boo

ster

hi

gh le

vel

J106

Boo

ster

low

leve

l

J102

low

leve

lhi

gh le

vel

J103

Tank

J105

Tank

J101

Doo

r sw

ith

Pin

switc

h

Stat

e of

indi

cato

rs

Fill c

ycle

Was

h cyc

le Dw

ell cy

cle

Rins

e cyc

le Re

set

ON

ON

ON

ON

ON

Only

and m

ust o

ne of

the t

hree

indic

ator is

ON

ON

ON

ON

ON

ON/O

FF

OFF

ON

ONON

ONON

/OFF

OFF

ON

ON/O

FFON

/OFF

ON/O

FFON

/OFF

ON

ON/O

FF

OFF

OFF

ON/O

FF

ONOF

F

ON

ONON

ONON

OFF

OFF

ONON

ONOF

FON

OFF

ON

OFF

OFF

OFF

ONOF

F

OF

FOF

FON

OFF

ON

ONOF

F

OFF

OFF

OFF

OFF

ON

ONON

ONON

/OFF

ONOF

F

ON

ONON

ONFla

sh

ON

ON

ON

OFF

NO

TE:

This

cha

rt is

for

the

use

of

HO

BA

RT

serv

ice

tech

nici

ans

and

serv

ice

agen

ts.

Con

tact

yo

ur

loca

l H

OB

AR

T-au

thor

ized

serv

ice

offic

e fo

r an

y re

pairs

or

adju

stm

ents

need

ed o

n th

is e

quip

men

t.

Pin

switc

h fu

nctio

ns

N

12

sec

. rin

se ti

me

FF

9 se

c. ri

nse

time

N

Ther

mo-

stop

feat

ure

is O

N

FF

Ther

mo-

stop

feat

ure

is O

FF