5. Optimum Fleet Recommendation_AED UT

-

Upload

yuan-jaya-pratama -

Category

Documents

-

view

219 -

download

3

Transcript of 5. Optimum Fleet Recommendation_AED UT

-

Advanced SeriesTeam AED

-

CUSTOMER BOUGHT THE MACHINES

COMPLAINS ON PERFORMANCE

OFR DONE

EXISTING PROJECT

CUSTOMER

CONSIDERING TO BUY

OFR DONE

FLEET DEMAND NEW

PROJECT

-

Proses OFR

Data Proyek & faktor pembatas pemilihan alat berat

Pemilihan Type dan model alat berat

Perhitungan jumlah armada alat berat

Check pencapaian produksi armada vs target produksi

Perhitungan biaya produksi dan investasi

Check sensitivitas terhadap hari kerja

-

DATA-DATA YANG DIPERLUKAN

Data Proyek : Target Produksi, striping ratio,

Karateristik material (Density bank/loose,

Swell factor, kekerasan)

Lay out penambangan Lay out penambangan

Jadwal Kerja

Process sequent

Other (regulasi, curah hujan, ketinggian, dll)

-

Condition checkCondition check

Job Site VisitJob Site VisitJob Site VisitJob Site VisitDiscuss with customerDiscuss with customer

OFR MAKING

Current operation checkCurrent operation checkJob site measurementJob site measurement

-

Actual dataActual dataMaterial, Haul road, mapMaterial, Haul road, map

Cycle time, data proyek,Cycle time, data proyek,

dlldll

Actual dataActual dataMaterial, Haul road, mapMaterial, Haul road, map

Cycle time, data proyek,Cycle time, data proyek,

dlldll

Data ReviewData ReviewData ReviewData ReviewOFR MAKING

-

AnalysisAnalysisAnalysisAnalysisOFROFR

OFR MAKING

Fleet Production Cost

-

ReportingReportingReportingReportingReportingReportingReportingReportingOFR MAKING

Presentation

to customer

Presentation

to customer

-

OFR Tambang BatubaraData-data proyek :- Customer : PT Angkasa Megah- Bidang usaha : Kontraktor tambang batubara- Pemilik KP : PT Satya Nugraha- Area kerja : Batulicin- Jenis kontrak : Double rit- Target produksi : 50,000 ton/bulan- Stripping ratio : Rata-rata 1:5 - Tidak memerlukan land clearing

Jarak angkut :Jarak angkut :- Overburden : 1.5 km- Coal : 2 km (pit-stockpile)

10 km (stockpile-port)- Profil jalan : OB : rata-rata uphill 5%, max 10%

Coal : Pit-stockpile : rata-rata uphill 4%, max 10%Stockpile-port : rata-rata flat, max 2%

Material- Jenis material OB : soil & sandstone- Densitas : OB : 2.4 t/bcm; 1.7 t/lcm

Coal : 1.3 t/bcm; 0.9 t/lcm- Jumlah seam : 1 seam- Tebal minimum : 1 meter

-

OFR Tambang Batubara

Sistem Penambangan- Penggalian : OB : 50% ripping minta UT melakukan test seismic

50% direct excavatingCoal : direct excavating

- Pemuatan : OB : track tipe loaderCoal : Pit: track tipe loader

Stockpile : Wheel tipe loader- Pengangkutan : dump truck

Jadwal kerja- Jam kerja efektif : 18 jam/hari- Jam kerja efektif : 18 jam/hari- Hari kerja rata-rata : 25 hari/bulan

300 hari/tahun- Hari kerja hujan : 20 hari/bulan- Hari kerja kering : 30 hari/bulan- Target time efficiency : 90%- Target availability alat : 90%

Pricing- OB removal : USD 2.4 /bcm- Coal getting&loading : USD 1 /ton- Coal hauling : USD 0.1 /ton.kmHarga diatas sudah termasuk road maintenance dan kegiatan mining supporting lainnya

-

Lay out tambang

Port

Ponton

Jalan Raya

Simpang km 5Hauling Road 5 km

PitStockpile & Crushing plant

Hauling Road 5 km

2 km

Desa Domba

Desa Biribiri

Disposalarea

1.5 km

-

OFR Tambang Batubara

Regulasi setempat- Tidak boleh ada peledakan/blasting di pit dekat kampung- Trailer tidak boleh menyeberangi jalan raya umum, panjang kendaraan max 12 m, axle yang dibolehkan 8x4

- Tidak diperkenankan membuat bypass atau flyover- Berat max kendaraan & muatan yang lewat jalan raya 50 ton

Financing- Pembiayaan alat berat : 20% dari perusahaan 80% dari bank/leasing company- Alat 100% baru

Local Cost- Fuel Price :Rp.5,000.-- Oil Cost :Rp.12,000.-- Grease :Rp.20,000.-- Kurs :Rp.9,3000.- / US$- Operator :1 US$/jam

-

Penentuan Tahapan Kegiatan Penambangan

Overburden Removal Digging/Ripping Bulldozer Pemuatan Excavator Hauling Dumptruck Spreading at disposal Bulldozer

Coal Production Digging-loading Excavator Digging-loading Excavator Hauling to stockpile Dump truck Crushing Coal crusher Loading to truck Wheel Loader Hauling to port Dump truck Loading to ponton Hoper & Belt Conveyor

Perawatan Jalan Grading Motor Grader Dust suppression Water truck

-

Pembagian Kerja Alat Berat

Produksi

Langsung melakukan kegiatan produksi alat gali, muat, angkut

Support

Membantu kelancaran proses produksi road maintenance, ditching, dll

-

Bulldozer for Ripping

-

Bulldozer for RippingHasil tes seismik :Cepat rambat max 2,635 m/s

2,635

2,635

Bulldozer yang paling tepat adalah D375A-5

-

Excavator for Loading - Overburden

Faktor pembatas :

- Kedalaman ripping bulldozer, D375A-5 : 1.44 m

- Ketinggian tumpukan material hasil gusuran D375A-5 : 2.26 m

Alternatifnya : Alternatifnya :

PC800-7, PC1250-7

-

Faktor yang mempengaruhi pemilihan :

- Seam minimum : 1 m

- Tinggi bucket

PC400LCSE-7 : 1.58 m

PC300-7 : 1.49 m

Excavating & Loading - Batubara

PC300-7 : 1.49 m

PC200-7 : 1.17 m

-

Dump truck - overburden

Faktor yang mempengaruhi pemilihan :

Kesesuaian dengan alat muat

Ukuran bucket ukuran vessel

Jumlah bucket per trip 3 7 kali

Alternatif :

PC800 HM400

PC1250 HD465-7 or HD785-5

-

Dump truck batubara

(Pit Stockpile)

Faktor yang mempengaruhi pemilihan :

Kesesuaian dengan alat muat (excavator)

Dimensi Hoper 2 x 3 m

-

Dump truck batubara

(Stockpile Port)

Faktor yang mempengaruhi pemilihan :

Regulasi :

Maksimum 8x4

Berat bermuatan maksimum 50 ton Berat bermuatan maksimum 50 ton

Tidak boleh mengoperasikan trailer

Dimensi Hoper : 10 x 5 m

Nissan CWB520LDN 20 tScania P124CA 6x4 360 28 t

Scania P124CA 8x4 420 33 t

-

Loading Batubara di stockpile

Faktor yang mempengaruhi pemilihan :

- Kesesuaian dengan truck batubara- Batubara di stockpile bersifat lepas dan ringan, - Area kerja cukup luas, butuh mobilitas tinggi

Wheel Loader

dengan coal bucket

-

Kesesuaian dimensi wheel loader coal bucket dump truck coal body

-

Feeding batubara ke hoper di port

- Batubara termasuk material ringan - Bandingkan lebar blade dengan lebar hoper

Bulldozer dengan coal bladeBulldozer dengan coal blade

Lebar BladeD155A-2 : 5.3 mD275A-5 : 6.27 mD375A-5 : 7.64 m

-

Pemilihan Alat pendukung

Motor GraderTergantung dump truck yang bekerja

Up to HD325 : GD600 seriesHD465 series : GD700 seriesHD785 series & up : GD800 series

-

Manpower yang berkaitan dengan

operasional alat berat di tambang

1. OperatorJumlahnya menggunakan rumus : Jumlah alat berat x jumlah shift kerja x 1.2Jumlah alat berat untuk proyek ini adalah 26 unitJumlah shift kerja adalah 2 shift panjangMaka jumlah operator yang perlu disiapkan adalah 63 orang operator

2. Foreman2. Foreman- 1 armada 1 foreman ada 2 armada overburden dan 1 armada coal- 1 disposal area 1 foremanTotal ada 4 foreman yang perlu disiapkan

3. Checker- 1 hauling road overburden 1 checker- 1 hauling road coal 1 checkerTotal ada 2 orang checker

-

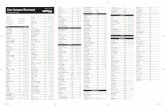

Penentuan alternatif alat berat

Alt - 1 Alt - 2 Alt - 3

- Ripping-dozing Bulldozer D375A-5 D375A-5 D375A-5

- Loading Hydraulic Excavator PC750SE-7 PC1250-6 PC1250-6- Hauling to Disposal Dump Truck HD325-6 HD465-7 HD785-5

- Dozing and Spreading Bulldozer D85ESS-2 D85ESS-2 D85ESS-2

Digging-loading Excavator PC200-7 PC300SE-7 PC400LCE-7Hauling to stockpile Dump truck CWB520LDN CWB520LDN CWB520LDN

OVERBURDEN REMOVAL

COAL PRODUCTION

Working Type Machine TypeMachine Model

Hauling to stockpile Dump truck CWB520LDN CWB520LDN CWB520LDN

Crushing Coal crusher

Loading to truck Wheel Loader WA320-3 WA320-3 WA320-3Hauling to port Dump truck P124 8x4 P124 8x4 P124 8x4Loading to ponton Belt Conveyor

- Grading and Leveling Motor Grader GD621R-1 GD705A-4 GD825A-2- Dust Suppression Water Truck CWB520LDN CWB520LDN CWB520LDN

ROAD MAINTENANCE

-

Jumlah alat berat

Productivity

Jam kerja efektif

Target produksi

Jumlah alat berat

-

Jumlah Kebutuhan Alat OverburdenEffective Working hours 450 hrs/month

bcm/hour bcm/month unit bcm/monthAlternative 1

- Ripping-dozing D375A-5 348.09 125,000 1 156,642

- Loading PC750SE-7 342.22 250,000 2 307,994

- Hauling to Disposal HD325-6 57.38 250,000 10 258,227

- Dozing and Spreading D85ESS-2 687.01 125,000 1 309,153

Road Maintenance

- Grading and Leveling GD621R-1 1

- Dust Suppression CWB520LDN 1

Alternative 2

AchievementWorking TypeMachine

Model

Production

CapacityNo. of Unit

Production

Target

Alternative 2

- Ripping-dozing D375A-5 348.09 125,000 1 156,642

- Loading PC1250-6 487.37 250,000 2 438,631

- Hauling to Disposal HD465-7 89.85 250,000 7 283,012

- Dozing and Spreading D85ESS-2 687.01 125,000 1 309,153

Road Maintenance

- Grading and Leveling GD705A-4 1

- Dust Suppression CWB520LDN 1

Alternative 3

- Ripping-dozing D375A-5 348.09 125,000 1 156,642

- Loading PC1250-6 487.37 250,000 2 438,631

- Hauling to Disposal HD785-5 132.65 250,000 5 298,456

- Dozing and Spreading D85ESS-2 687.01 125,000 1 309,153

Road Maintenance

- Grading and Leveling GD825A-2 1

- Dust Suppression CWB520LDN 1

-

Jumlah Kebutuhan Alat BatubaraEffective w orking hours 450 hrs/month

ton/hour ton/month unit ton/month

Alternative 1

Digging-loading PC200-7 65.90 50,000 2 59,309

Hauling to stockpile CWB520LDN 41.75 50,000 3 56,369

Loading to truck WA320-3 181.24 50,000 1 81,557

Hauling to port P124 8x4 35.11 50,000 4 63,205

Production

Target

No. of

UnitAchievementWorking Type

Machine

Model

Production

Capacity

Hauling to port P124 8x4 35.11 50,000 4 63,205

Alternative 2

Digging-loading PC300SE-7 194.02 50,000 1 87,308

Hauling to stockpile CWB520LDN 61.14 50,000 2 55,023

Loading to truck WA320-3 181.24 50,000 1 81,557

Hauling to port P124 8x4 35.11 50,000 4 63,205

Alternative 3

Digging-loading PC400LCE-7 246.47 50,000 1 110,909

Hauling to stockpile CWB520LDN 67.08 50,000 2 60,374

Loading to truck WA320-3 181.24 50,000 1 81,557

Hauling to port P124 8x4 35.11 50,000 4 63,205

-

Biaya Produksi

Total biaya produksi alat berat

Total pencapaian produksi alat berat

Biaya produksi alat berat

-

Unit US$/hr US$/month bcm/month US$/bcm

Alternative 1

- Ripping-dozing D375A-5 1 91.7 338,483 250,000 1.35

- Loading PC750SE-7 2 61.2

- Hauling to Disposal HD325-6 10 46.4

- Dozing and Spreading D85ESS-2 1 29.1

Road Maintenance

- Grading and Leveling GD621R-1 1 24.4

- Dust Suppression CWB520LDN 1 20.4

Alternative 2

Production

Target

Production

Cost

Owning and

Operating CostTotal CostWorking Type

Machine

Model

No. of

Unit

Biaya Produksi Alat Berat Overburden

Alternative 2

- Ripping-dozing D375A-5 1 91.7 362,626 250,000 1.45

- Loading PC1250-6 2 81.5

- Hauling to Disposal HD465-7 7 66.5

- Dozing and Spreading D85ESS-2 1 29.1

Road Maintenance

- Grading and Leveling GD705A-4 1 35.9

- Dust Suppression CWB520LDN 1 20.4

Alternative 3

- Ripping-dozing D375A-5 1 91.7 367,359 250,000 1.47

- Loading PC1250-6 2 81.5

- Hauling to Disposal HD785-5 5 90.0

- Dozing and Spreading D85ESS-2 1 29.1

Road Maintenance

- Grading and Leveling GD825A-2 1 62.1

- Dust Suppression CWB520LDN 1 20.4

-

Effective working hours 450 hrs/month

Unit US$/hr US$/month ton/month US$/Ton

Alternative 1

Digging-loading PC200-7 2 15.94 90675 50,000 1.81

Hauling to stockpile CWB520LDN 3 20.64

Loading to truck WA320-3 1 24.11

Hauling to port P124 8x4 4 20.90

Production

CostWorking Type

Machine

Model

No. of

Unit

Owning and

Operating Cost

Production

TargetTotal Cost

Biaya Produksi Alat Berat Batubara

Hauling to port P124 8x4 4 20.90

Alternative 2

Digging-loading PC300SE-7 1 26.69 79053 50,000 1.58

Hauling to stockpile CWB520LDN 2 20.64

Loading to truck WA320-3 1 24.11

Hauling to port P124 8x4 4 20.90

Alternative 3

Digging-loading PC400LCE-7 1 41.96 85926 50,000 1.72

Hauling to stockpile CWB520LDN 2 20.64

Loading to truck WA320-3 1 24.11

Hauling to port P124 8x4 4 20.90

-

CRITERIA DRY SEASON NORMAL RAINY SEASON

Working Hours (hrs/month) 540 450 360

Overburden (bcm/month) 309,872 258,227 206,581

Coal (ton/month) 66,028 55,023 44,019all currency in US$

Overburden Removal ?? ?? ??

Coal Getting ?? ?? ??

Coal Hauling ?? ?? ??

Total Cash In ?? ?? ??

Production

CASH IN

Sensitivitas terhadap jam kerja efektif

Total Cash In ?? ?? ??

Salary ?? ?? ??

Fuel & Consumable ?? ?? ??

Operating cost ?? ?? ??

Owning cost ?? ?? ??

Bank Loan ?? ?? ??

Insurance ?? ?? ??

Total Cash Out ?? ?? ??

Tax 3% ?? ?? ??Surplus/Deficit per month ?? ?? ??

CASH OUT

-

Data

Pricing OB : $ 2.4 /bcm- Coal getting & loading: $ 1 /ton- Coal hauling : $ 0.1 /ton.km

Employee Operator : $ 54 /month.operator Operator : $ 54 /month.operator Foreman : $ 97/month/foreman Supervisor : $ 151 /month.supervisor

Fuel Qty : 613 liter/jam Price : Rp.5,000/liter

Consumable good : $ 185 /jam Bank Loan : $ 6,003,800 dengan rate 9% Insurance : 0.5%

-

Sensitivitas terhadap jam kerja efektifCRITERIA DRY SEASON NORMAL RAINY SEASON

Working Hours (hrs/month) 540 450 360

Overburden (bcm/month) 309,872 258,227 206,581

Coal (ton/month) 66,028 55,023 44,019

CASH IN all currency in US$

Overburden Removal 743,693 619,744 495,796

Coal Getting 83,430 69,525 55,620

Coal Hauling 91,015 75,846 60,676

Operation 918,138 765,115 612,092

Other Income - - -

Production

Other Income - - -

Total Cash In 918,138 765,115 612,092

120% 100% 80%

Salary 12,215 12,215 12,215

Fuel & Consumable 421,682 351,402 281,121

Operating cost 433,897 363,617 293,336

119% 100% 81%

Owning cost 209,180 209,180 209,180

Bank Loan 206,053 206,053 206,053

Insurance 3,127 3,127 3,127

Total Cash Out 643,077 572,797 502,517

Tax 3% 8,252 5,770 3,287

Surplus/Deficit per month 266,809 186,548 106,288

143% 100% 57%

CASH OUT