3-Isentropic Flow with Area...

Transcript of 3-Isentropic Flow with Area...

Gas Dynamics

Isentropic Mach number relations

3

⎥⎦⎤

⎢⎣⎡ −+= 20

211 M

TT γ

120

211

−

⎥⎦⎤

⎢⎣⎡ −+=

γγ

γ MPP

11

20

211

−

⎥⎦⎤

⎢⎣⎡ −+=

γγρρ M

( )121

2

2* 1

11

21 −+

⎟⎟⎠

⎞⎜⎜⎝

⎛+−+

+=

γγ

γγ

γM

MAA

21

20

211 ⎥⎦

⎤⎢⎣⎡ −+= M

aa γ

Gas Dynamics 7

The maximum velocity is found by converting all the thermal energy to kinetic energy. Takingzero thermal energy to correspond to absolute zero (despite the fact that air would not be a gas atthis point) one could estimate

Gas Dynamics

Effect of Area Change

9

In the isentropic limit the mass, momentum, and energy equation for a compressible ideal gas reduce to:

Gas Dynamics 11

equation singular when M2 = 1

if M2 = 1, one needs dA = 0

area minimum necessary to transition from subsonic to supersonic flow!!

can be shown area maximum not relevant

Gas Dynamics

Choking

15

Consider mass flow rate variation with pressure difference• small pressure difference gives small velocity, small mass flow• as pressure difference grows, velocity and mass flow rate grow• velocity is limited to sonic at a particular duct location• this provides fundamental restriction on mass flow rate• can be proven rigorously that sonic condition gives maximum mass flow

rate

A flow which has a maximum mass flow rate is known as choked flow. Flows will choke at area minima in a duct.

Gas Dynamics 17

1. Pb = Po, Pb /Po = 1. No flow occurs. Pe = Pb, Me=0.

2. Pb > P* or P*/Po < Pb /Po < 1. Flow begins to increase as the back pressure is lowered. Pe = Pb, Me < 1.

3. Pb = P* or P*/Po = Pb /Po < 1. Flow increases to the choked flow limit as the back pressure is lowered to the critical pressure. Pe = Pb, Me=1.

4. Pb < P* or Pb /Po < P*/Po < 1. Flow is still choked and does not increase as the back pressure is lowered below the critical pressure, pressure drop from Pe to Pb occurs outside the nozzle. Pe = P*, Me=1.

5. Pb = 0. Results are the same as for item 4.

Gas Dynamics

Choking Example

18

Given: Air with stagnation conditions Po = 200 kPa To = 500 K flows through athroat to an exit with Mach number of 2.5. The desired mass flow is 3.0 kg/s,Find: a) throat area, b) exit pressure, c) exit temperature, d) exit velocity, and e)exit area.

Gas Dynamics 25

•PA = Po, or PA/Po = 1. No flow occurs. Pe = Pb, Me = 0.

•Po > PB > PC > P* or P*/Po < PC/Po < PB/Po < 1. Flow beginsto increase as the back pressure is lowered. The velocityincreases in the converging section but M < 1 at the throat; thus,the diverging section acts as a diffuser with the velocitydecreasing and pressure increasing. The flow remains subsonicthrough the nozzle. Pe = Pb and Me < 1.

•Pb = PC = P* or P*/Po = Pb/Po = PC/Po and Pb is adjusted sothat M=1 at the throat. Flow increases to its maximum value atchoked conditions; velocity increases to the speed of sound atthe throat, but the converging section acts as a diffuser withvelocity decreasing and pressure increasing. Pe = Pb, Me < 1.

Gas Dynamics 26

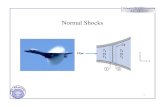

•PC > Pb > PE or PE/Po < Pb/Po < PC/Po < 1. The fluid that achieved sonic velocityat the throat continues to accelerate to supersonic velocities in the diverging sectionas the pressure drops. This acceleration comes to a sudden stop, however, as anormal shock develops at a section between the throat and the exit plane. The flowacross the shock is highly irreversible. The normal shock moves downstream awayfrom the throat as Pb is decreased and approaches the nozzle exit plane as Pbapproaches PE. When Pb = PE, the normal shock forms at the exit plane of thenozzle. The flow is supersonic through the entire diverging section in this case,and it can be approximated as isentropic. However, the fluid velocity drops tosubsonic levels just before leaving the nozzle as it crosses the normal shock.

•PE > Pb > 0 or 0 < Pb/Po < PE/Po < 1. The flow in the diverging section issupersonic, and the fluids expand to PF at the nozzle exit with no normal shockforming within the nozzle. Thus the flow through the nozzle can be approximatedas isentropic. When Pb = PF, no shocks occur within or outside the nozzle. WhenPb < PF, irreversible mixing and expansion waves occur downstream of the exitplane or the nozzle. When Pb > PF, however, the pressure of the fluid increasesfrom PF to Pb irreversibly in the wake or the nozzle exit, creating what are calledoblique shocks.

Gas Dynamics

Example : Converging-Diverging Area

27

A converging-diverging nozzle has an exit-area-to-throat area ratio of 2.Air enters this nozzle with a stagnation pressure of 1000 kPa and astagnation temperature of 500 K. The throat area is 8 cm2. Determine themass flow rate, exit pressure, exit temperature, exit Mach number, and exitvelocity for the following conditions:

•Sonic velocity at the throat, diverging section acting as a nozzle.•Sonic velocity at the throat, diverging section acting as a diffuser.

Gas Dynamics 28

For A/A* = 2, Table A-32 yields two Mach numbers, one > 1 and one < 1.When the diverging section acts as a supersonic nozzle, we use the value for M > 1. Then, for AE/A* = 2.0, ME = 2.197, PE/Po = 0.0939, and TE/To = 0.5089,

P P kPa kPaT T K KE o

E o

= = == = =

0 0939 0 0939 1000 93908333 05089 254 5

. . ( ) .. . (500 ) .

C kRT

kJkg K

K

ms

kJkg

ms

E E=

=⋅

=

14 0 287 254 51000

319 7

2

2. ( . )( . )

.

Analysis:

rV M C m

smsE E E= = =2 197 319 7 702 5. ( . ) .

Gas Dynamics

The mass flow rate can be calculated at any known cross-sectional area where the properties are known. It normally is best to use the throat conditions. Since the flow has sonic conditions at the throat, Mt = 1, and

*0.8333

0.8333 0.8333(500 ) 416.6

T TtT To oT T K Kt o

= =

= = =

21000 2

1.4(0.287 )(416.6 )

409.2

V C kRTt t t

mkJ sK kJkg K

kgms

= =

=⋅

=

r

*0.528

0.528 0.528(1000 ) 528

P PtP Po oP P kPa kPat o

= =

= = =

ρ ρtPRT

kPakJ

kg KK

kJm kPa

kgm

= = =

⋅

=

**

*(528 )

( . )( . )

.

0 287 416 6

4 416

3

3

Gas Dynamics

&

. (8 )( . )( )

.

m AVkgm

cm ms

mcm

kgs

t t t=

=

=

ρr

4 416 409 2100

1446

32

2

2

When the diverging section acts as a diffuser, we use M < 1. Then, forAE /A* = 2.0, ME = 0.308, PE /Po = 0.936, and TE /To = 0.9812,

P P kPa kPaT T K KE o

E o

= = == = =

0 0939 0 936 1000 93608333 0 9812 490 6

. . ( ). . (500 ) .

C kRT

kJkg K

K

ms

kJkg

ms

E E=

=⋅

=

14 0 287 490 61000

444 0

2

2. ( . )( . )

.

Since M = 1 at the throat, the mass flow rate is the same as that in the first part because the nozzle is choked.

rV M C m

smsE E E= = =0 308 444 0 136 7. ( . ) .