11000 Ty-Mawr Glaster Presentation.indd

Transcript of 11000 Ty-Mawr Glaster Presentation.indd

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

1/10

T y-Mawrecological building productsdeunyddiau adeiladu ecolegol

lime plaster made with recycled glass for external & internal use

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

2/10

T y-Mawr2

BackgroundIn 1993 Nigel and Joyce Gervis, founders

and directors of T y-Mawr Lime, purchased

T y-Mawr, a run-down farm in the heart of

the Brecon Beacons National Park. As wellas becoming the couples family home (and

a life-times restoration project!), this listed

property also proved to be the inspiration

for their business T y-Mawr Lime Ltd. The

reason for this is simple. On purchasing the

property, it was Nigel and Joyces intention

to restore the building sympathetically and

in-line with their architectural heritage.

But the couple faced one key problem

they couldnt source appropriate lime

mortars and plasters! The initial solution was

straightforward, using Nigels experience,

they began making their own.

TY-MAWR GRANARIES 1993

A business is bornThe potential for expansion was obvious

and what started off as a temporary solution

for a one off renovation project soon

germinated into a business plan. UtilisingNigels background where he had gained

valuable experience of using lime in the

eighties with Capps and Capps on projects

in London and then Wales and Joyces

experience in IT, project management and

rural development, the couple established

their own business. In 1995, T y-Mawr Lime

Ltd was born.

Originally, the primary focus was the

manufacture of lime-based building

materials for the conservation of old and

historic buildings. Lime mortars, plasters &paints have subsequently been supplied to

some of the most prestigious conservation,

restoration and, more laterally new

construction projects throughout the UK.

Buildings, organisations and projects that

have benefited from T y-Mawr products and

expertise include Aberglasney House, the

National Botanical Gardens, The Landmark

Trust, Dolbelydr, St Teilos Church,

National Museum of Wales and Worcester

Cathedral. T y-Mawr Lime Ltd is still the only

manufacturer of lime based products inWales and this remains the companys core

area of business.

Skills & specificationWhat soon became apparent to Joyce and

Nigel was that, just as UK lime production

had diminished to almost nothing in the

past fifty years, so had the skills andknowledge base required to use such

products.

With calls coming in on almost a daily

basis, asking for advice on product usage

and application techniques, T y-Mawr Lime

Ltd established an education arm and in

1996 began offering courses in the use of

traditional building materials. These courses

have proved to be extremely popular and

now attract delegates from all over the

world.

Tailor-made courses have been designed

and run for a wide range of organisations

including Local Authorities, British

Waterways, the Canals Trust, the National

Trust, and Townscape Heritage Initiatives.

For two years, they hosted and organised

the prestigious Summer School for the

Princes Foundation for the Building

Community with participants from all overthe world.

As well as concentrating on getting the

practical skills right, T y-Mawr Ltd has also

focused heavily on the specification of

traditional building products, so much so

that the company is certified to deliver RIBA

accredited CPD seminars on using lime as a

sustainable material appropriate to todays

world. Such seminars have benefited

private architect practices, Building Control

and other professional groups country-

wide. They have also drafted a wide range

of NBS clauses.

The Company

SUMMER SCHOOL 2010 AT TY-MAWR THE PRINCES FOUNDATION FOR THE BUILDING COMMUNITY

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

3/10

T y-Mawr3 The Company

Supporting theenvironmentConcern for the environment, particularly

with regards to minimising the impact

of buildings on the environment, quicklybecame an important focus for Nigel and

Joyce. It remains one of T y-Mawr Lime

Ltds core business principles today.

This philosophy is at the heart of the

companys development of a unique range

of environmentally-friendly building materials

compatible with breathing building

principles. The range includes paints

and finishes, building boards including

woodfibre boards, wood wool boards, reed

mats and reed boards, as well as insulation

products made from Welsh sheeps wool,hemp and cellulose (recycled newspaper).

NEW BUILD WITH PIGMENTED GLASTER SITS ALONGSIDE

GRADE II* LISTED BUILDINGS

This dedication to the environment hasmotivated the company to develop

greener alternatives to mainstream

building products. Examples of this are

glaster - a lime plaster made with recycled

glass instead of sand; Lime hemp Plaster,

which uses hemp fibres instead of sand,

and Limecrete, an environmentally-friendly

alternative to concrete.

In 2009, Nigel and Joyce were thrilled

to be named as one of 52 sustainable

development champions on the first

Welsh Green List - a list recognising the

commitment and contribution of individuals

in Wales to the environment!

Back to the buildingT y-Mawr itself is an on-going restoration

project, and provides an excellent example

of how Joyce and Nigel practice what they

preach. As well as being the couples home

and business base, the building is also now

used extensively as a venue for visits from

all sorts of groups concerned with building

and the environment.

As well as demonstrating examples of

T y-Mawr products, the building itself also

incorporates environmental technologies

such as solar thermal, rain-water harvesting

and biomass heating. This has helped

reduce T y-Mawrs carbon dioxide

emissions by up to 40 tonnes per year,

demonstrating that Joyce and Nigel are

just as passionate about minimising their

own impact on the environment as they are

about developing greener building solutions.

Be The Change.... -From Nigel & Joyce Gervis

The lime industry has changed enormously

over the last 18 years. At T y-Mawr, we

have watched, contributed and adapted

to the changes that now sees lime as an

appropriate building material not only for

traditional buildings but also new ecologicalbuildings.

The business has invested heavily in

product development, research, testing,

product accreditation, quality standards,

and custom built computer-controlled,

highly energy efficient manufacturing

machinery, the company has expanded to

a purpose built distribution warehouse and

has built up a team of some 20 members

of skilled staff to ensure the excellent quality

of products and services, that T y-Mawr has

become renowned for, continues as the

business grows.

Building and buildings are one of the

greatest polluters on the planet, one of the

quotes we have used a lot as a business

is that you must be the change you want

to see in the world, we are slowly realising

some of the change we would wish to

see at T y-Mawr and through our work

and product manufacture, feel proud that

we have now supplied over 17,000 other

projects over the last 18 years, hopefully

helping others be the change they wish to

see as well!

TY-MAWRS DISTRIBUTION CENTRE

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

4/10

T y-Mawr4 Product Development

Product backgroundLime plasters have been used for over

12,000 years; no plaster has performed

better in old, solid wall construction

buildings. Our concern for the environmenthowever, led us to look at improving the

green credentials of this ancient material,

the resulting product was glaster.

GLASTER IS AN EXCITING BLEND OF LIME (BINDER) AND

RECYCLED GLASS (AGGREGATE) TO MAKE PLASTERS,

RENDERS, MORTARS AND SCREEDING FOR FLOORS.

Why Lime?Products are made with lime ideal for use in old buildings as the use of the traditional lime

binder means that they benefit from being vapour permeable (to manage moisture and

hence regulate humidity), are relatively soft allowing the building to continue to move and

flex (which they are designed to do) and can be recycled at the end of their useful life.

A breathing building

SOLID WALL CONSTRUCTION BUILDING - MAINTAINED WITH

SOFT, TRADITIONAL, VAPOUR PERMEABLE MATERIALS.

Sick building

SOLID WALL CONSTRUCTION - REPAIRED WITH HARD,

MODERN IMPERVIOUS MATERIALS POTENTIALLY TRAPPING

MOISTURE AND LEADING TO PROBLEMS SUCH AS DAMP,

CONDENSATION, MOULD GROWTH, WET/DRY ROT ETC.

It is also a perfect choice in more

sustainable new builds where low impact

materials are demanded. It is greener

because it uses a binder that absorbs

carbon dioxide when curing and is burnt at

a lower temperature than cement.

RISING DAMP

DENSE CONCRETE FLOOR

IMPERVIOUS

PLASTER AND OR

IMPERVIOUS PAINT

(TRAPS MOISTURE)

POORLY

MAINTAINED

RAINWATER

GOODS

HARD IMPERVIOUS

RENDER AND OR

PAINT (TRAPS MOISTURE)

RAIN

WATER PENETRATION

THROUGH CRACKS

PAVING

TIMBER LINTEL - WET ROT

POTENTIALLY LEADS

TO CONDENSATION,

MOULD GROWTH

BLOCKED LAND DRAIN

RISING DAMP

VAPOUR PERMEABLEFLOOR

LAND DRAIN

EVAPORATIONOF MOISTURE

GOOD EAVESAND WELLMAINTAINEDRAINWATERGOODS

EVAPORATIONOF MOISTURE

RAIN

LIME MORTARPOINTING

(or lime render withvapour permeablepaint)

EVAPORATIONOF MOISTURE

TIMBER LINTEL

INTERNAL LIME PLASTERWITH VAPOUR PERMEABLE

PAINT

= EQUILIBRIUM

Slaking burnt lime in either:

Heat

i) an excess of water

to produce a putty

or ii) a shortfall of water to

produce a powder (hydrate)

or iii) in damp sand

to produce a hot mix

Slaked lime (putty)

is mixed with selected sands to

produce mortars and plasters, or

with water to produce limewash

Water-born Carbon Dioxide (CO 2) is absorbed

over time to form Calcium Carbonate (CaCO 3)

Limestone from the quarry

Burning limestone in a kiln drives off

CarbonDioxide (CO2)and water(H 2O)

Burnt lime is also known

as quicklime or lumplime

CARBON

AT

ION B

URN

ING

SLAKING

Limestone

Calcium Carbonate

(CaCO3)

Slaking Lime

Calcium Hydroxide

(Ca(OH)2

Burnt Lime

Calcium Oxide

(CaO)

The Lime Cycle

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

5/10

T y-Mawr5 Product Range

Why Recycled Glass?We chose to use recycled glass because

of the wide environmental benefits of using

it as opposed to sand, benefits include

reducing the extraction of a virgin rawmaterial (160.5 million tonnes are extracted

annually in the UK for construction

purposes, 14.5 million tonnes are marine

dredged) with environmental implications,

it also reduces the volume of waste sent

to landfill and saves the energy and natural

resources required to make new glass.

For every tonne of glass recycled, 30

gallons of oil is saved.

glaster can be used on> most conventional backgrounds including

stone, brick, block, wood wool and

woodfibre boards.

> as a mortar for building or pointing up

stonework, brickwork or blocks.

> externally as a render with a flat or

roughcast finish.

> internally as a plaster which can be

painted, trowelled to a smooth finish or

etched to reveal more glass or as a self

coloured finish.

> as a floor screed.

glaster productsare available in twopremixed ranges> traditional ready-to-use wet premix

manufactured using traditional fat lime putty

and recycled crushed glass.

This product range is ideal for plastering

internally or repairing old buildings where

it is important to maintain the flexibility and

vapour permeability of the building.

It requires mixing, prior to application and is

best used within a month of purchase.

> dry hydraulic premix manufactured

using a moderately hydraulic lime and

recycled glass which is suitable in most

usual conditions e.g. for stone, brick orblock work as a render, plaster or mortar.

This range is supplied as a dry premix to

which water must be added on-site and

then mixed in a mill/site mixer. Silos are also

now available.

glaster plasterIt is available in a coloured range see

page 6 which can be trowelled smooth

or etched to reveal more of the glass

aggregate. Alternatively, it can be paintedwith a vapour permeable paint.

We are also able to tailor-mix specific

colours.

glaster externalroughcastUsing a coarser grade of crushed glass

and by spray applying the product a

unique render finish can quickly be applied

to blockwork, masonry, brick and building

boards. The increased surface area of such

a finish helps the evaporation of moisture,it is therefore an extremely effective finish for

very exposed elevations.

glaster mortarThis mortar is ideal for building or pointing

blockwork, masonry and brick. It is available

as a dry premixed to which water must be

carefully gauged on site.

APPLYING GLASTER TO WOOD WOOL BOARDS.COURTESY: WWW.CO2DL.CO.UK

JOHN CHRISTOPHERS CODE LEVEL 6 HOUSE

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

6/10

T y-Mawr6 Product Range

glaster screedThis product is perfect for use with our

insulated limecrete floors, compatible with

underfloor heating onto which flagstones,

timber floors (ventilated) or unsealed tilescan be laid. It can be polished to give a

decorative finish.

Coloured range

glaster Plaster Product Selection

Building Material Site Type Suggested Base Coats Suggested Suggested Top Coat -please note the top coat Suggested

Build-up should be softer and thinner than previous coats Build-up

Cob, Rammed Earth, Internal glaster Fat Lime (haired) Plaster 2 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 6mm

Strawbale or glaster Dry Hydraulic Lime Plaster 2 x 9mm(haired base coats) External glaster Dry Hydraulic Lime Plaster 2 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 6mm

Reed Mat, Reed Board Internal glaster Fat Lime (haired) Plaster 2 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 6mm

(haired base coats) or glaster Dry Hydraulic Lime Plaster 2 x 9mm

External n/a n/a

Celenit Wood Wool Internal glaster Fat Lime (unhaired) Plaster 1 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 9mm

Boards or glaster Dry Hydraulic Lime Plaster 1 x 9mm

(mesh base coat) External glaster Dry Hydraulic Lime Plaster 1 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 9mm

Woodfibre Board Internal glaster Fat Lime (unhaired) Plaster 1 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 9mm

(mesh base coat) or glasterDry Hydraulic Lime Plaster 1 x 9mm

External glaster Dry Hydraulic Lime Plaster 1 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 9mm

Lath (internal only), Internal glaster Fat Lime (haired) Plaster 2 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 6mm

Soft Stone External glaster Fat Lime (haired) Plaster 2 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 6mm

or glaster Dry Hydraulic Lime Plaster 2 x 9mm or glaster Dry Hydraulic Lime Plaster 1 x 6mm

Soft Brick Internal glaster

Fat Lime (unhaired) Plaster 2 x 9mm glaster

Fat Lime (unhaired) Plaster 1 x 6mm(mesh base coat) or glaster Dry Hydraulic Lime Plaster 2 x 9mm

External glaster Fat Lime (unhaired) Plaster 2 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 6mm

or glaster Dry Hydraulic Lime Plaster 2 x 9mm or glaster Dry Hydraulic Lime Plaster 1 x 6mm

Hard Stone Internal glaster Dry Hydraulic Lime Plaster 2 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 6mm

(haired base coats) External glaster Dry Hydraulic Lime Plaster 2 x 9mm glaster Fat Lime (unhaired) Plaster 1 x 6mm

Hard Engineering Brick, Internal glaster Dry Hydraulic Lime Plaster 2 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 6mm

Concrete Blocks External glaster Dry Hydraulic Lime Plaster 2 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 6mm

(mesh base coat)

Insulation Blocks* Internal glaster Dry Hydraulic Lime Plaster 1 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 9mm

(haired base coat) External glaster Dry Hydraulic Lime Plaster 1 x 9mm glaster Dry Hydraulic Lime Plaster 1 x 9mm

Dub out uneven surfaces prior to applying first coat. May require more coats due to waviness of bales.*Insulation blocks have very high suction, be careful to control suction.

Available in a coloured range and with different coloured glass, when available.or for a fine finish add Fat Lime Internal Top Coat Plaster, 1 x 3mm coat

CREAM PALE GREY DEEP GREY NATURAL BURNT UMBER YELLOW OCHRESTONE GREEN BRICK PINK DEEP ORANGE

POLISHED GLASTER FLOOR

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

7/10

T y-Mawr7 Benefits

Health benefitsIt is a highly technical finish, helping to

regulate humidity within the building and

therefore keeping it healthy for those living

and/or working inside the building. We

currently spend approximately 90% of

time indoors, the quality of the air and the

internal environment in paramount in terms

of our health and happiness. This chart

shows the humidity levels at which the listed

microbes and health problems are likely to

flourish. As the width of the bar increases,

indoor air quality diminishes and potential

health problems increase. For example,

virus growth is unsupported at humidity

levels of 50% to 70%, glaster helps to

maintain this optimum, but its growth rates

steadily increase above and below this

range with maximum growth at 0% and

100% relative humidity.

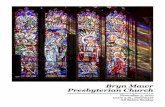

Aesthetics

COURTESY: WWW.PRINTSOFWALES.BIZ

glaster offers a genuinely sustainable

plaster/render that produces a surface

that is unique, giving all sorts of aesthetic

potential by varying pigment colours as

well as aggregate type and colours. It is

also highly suitable for pargetting see

example above.

COURTESY FACIT HOMES

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

8/10

T y-Mawr8 Case Studies

Flint HouseFamily house in Blackheath, London.

Construction and detail design by Modernarc

Nick Willson Architects

Materials Supplied: Hydraulic glaster render

Photos courtesy Gareth Gardner

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

9/10

T y-Mawr9 Case Studies

COURTESY: AUSTIN SMITH LORD ARCHITECTS,

A.J.PHILIP PLASTERING

Severn Theatre, ShrewsburyClient: Wilmott Dixon Construction Ltd, A J Phillips Plastering

Materials Supplied: Pigments glaster Yellow Ochre

glaster was chosen to give a durable finish in the foyer at the Severn Theatre, Shrewsbury. The through

colour meant that the plaster did not require painting and gave a lively finish for visitors.glaster is just as suitable for high traffic, commercial environments as well as domestic situations.

NBS Clause

EXTRACT FROM ARCHITECTS DRAWINGS

COURTESY: UPTON CASTLE ESTATE

-

7/29/2019 11000 Ty-Mawr Glaster Presentation.indd

10/10

T y-Mawr10 Training and Support

To support the products, we spend a great

deal of time raising awareness and assisting

architects in specifying this innovative

material by delivering RIBA accredited

CPDs across the UK. Nigel Gervis, inventor

and Technical Director delivers some 60 ofthese technical seminars per annum to help

build the confidence in the product in order

to encourage architects to specify it for

commercial as well as domestic projects.

NIGEL GERVIS, INVENTOR, DELIVERING CPDS

SPRAY APPLYING GLASTER

We have also developed RIBA approvedNBS (National Building Specification)

clauses to assist architects with choosing

the right products and build-up for the

different substrates based on the table on

page 6.

Practical application of the product requires

some understanding of how it carbonates.

We therefore run practical training day for

contractors at our dedicated training centre

as well as their site when required. For

example, we advised and provided on-site

training for the rendering at The Lime Housein Ebbw Vale, Mission Hall, West Sussex

and John Weavers contractors at Elliott

Colliery and for the Duchy of Cornwall.

LIME HOUSE, EBBW VALE, COURTESY BERE ARCHITECTS

THE TRAINING CENTRE, TY-MAWR, LLANGASTY

COURTESY DUCHY OF CORNWALL