1 Pumping 101. 2 Learning Outcomes Upon completion of this training one should be able to: Know what...

-

Upload

brooke-amberlynn-matthews -

Category

Documents

-

view

220 -

download

1

Transcript of 1 Pumping 101. 2 Learning Outcomes Upon completion of this training one should be able to: Know what...

1

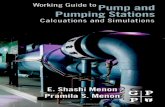

Pumping 101

2

Learning OutcomesUpon completion of this training one should be able to:

•Know what are the key pump components and how they impact pump performance.

•Know what the impact of pump efficiency is on annual operating cost.

•Know what TDH is and how to calculate it.

•Define the three Pump Affinity Laws.

•Know the difference between NPSHR and NPSHA.

•Describe the difference between series and parallel pumping.

•Know what WWE is.

•Know the difference between a dry running and wet running pump.

3

Unit 1Pump Mechanics

4

What is a pump?

5

What is a Pump?

• A pump is a machine which adds energy to a fluid for the purpose of increasing the pressure or moving it along a pipeline.

• Pumps don’t make water.• Pumps don’t make pressure, it just operates

against the pressure.

6

Basic Types of Pumps

• Positive displacement pumps, add energy directly to a movable boundary, which imparts the energy to the fluid.– Examples include screw pumps, piston

pumps, gear pumps.• Roto-dynamic pumps, add the energy

indirectly through a rotating part in the form of velocity, and subsequently converts the velocity to pressure.– These pumps are commonly referred to as

centrifugal pumps.

7

Basic Impeller Types

OPEN SEMI-OPEN CLOSED

8

Impeller Discharge Configurations

9

Centrifugal Impellers

A. Width = Flow

B. Diameter = Head

C. Vane Design = BEP / Efficiency

B

AC

10

Impeller Direction of Rotation

11

The fluid enters the pump through the inlet (suction eye) where the impeller adds energy (in the form of velocity) through centrifugal force.

When the fluid leaves the impeller, there is a decrease in velocity.

Velocity and pressure are inversely proportional.

The decrease in velocity results in an increase in pressure as the fluid leaves the pump.

Centrifugal Action

12

Other Pump Parts

• Coupling: Connects motor to shaft.

• Shaft: Mount for impeller.

• Bearings: Keeps shaft aligned.

• Mechanical Seal: No leak at shaft.

• Nameplate: Data about pump.

13

Dry Running (Three-Piece)

• Requires shaft seal.• Can change the size of motors.• Repairable.

Shaft Seal

14

Dry Running (Three-Piece)

Shaft Seal

• Requires shaft seal.• Can change the size of motors.• Repairable.

15

Wet Running (Wet Rotor)

• Does not require shaft seal.• Cannot oversize motors.• Not repairable.

16

Wet Running (Wet Rotor)

• Does not require shaft seal.• Cannot oversize motors.• Not repairable.

Water Cooled Areas

17

Questions on Wet Runners

• Can you mount a wet running pump in a vertical position with the bearing facing up? – No, airlock can occur. Also, the bearings may not be

lubricated which could cause bearing failure.

• Can you pump syrup with a wet running pump? – No, the “fluid” lubricates the pump and pumping syrup

would generally gum up the pump.

18

Unit 2Pump Curves, Affinity

Laws, and System Curves

19

A TypicalPump Curve

Format

Performance Curve

Efficiency ( or eta) Curve

BHP Curve

NPSHr Curve

20

A Typical Catalog Performance Curve

21

Head, H

• Centrifugal pump curves are generally not rated in psi.

• Rating is in feet of head.• Total Dynamic Head (TDH) is found by adding:

1. Elevation (He) – rated in feet.2. Pressure (Hp or ∆P) – rated in psi.3. Friction loss (Hf) – usually rated in feet.

22

Determining Elevation Head (He)

What is the total elevation head of the above system?200 ft

200 ft

S

D

23

2.311 psi = _______ Feet of Water*

2.31 feet

Converting Between Head and Pressure

*Water @ 32°F ~ 60°F

1 psi

24

Converting between Hp & ∆P

..

31.2)()(

gs

psiPftH

31.2

..)()(

gsftHpsiP

Pg. 8 HVAC Technical Guide

25

What is 2.31?

31.24.62

144 3

2

2

2

lb

ftX

ft

inX

in

lb

Where:62.4 = specific weight of water @ 32°F ~

60°F

26

100 ft

23 ft

80 ft

43.29 psi 34.6 psi 9.956709957 psi

Head and Pressure Based on Water

27Gasoline Salt Water Sugar Water0.70 s.g. 1.03 s.g. 1.30 s.g.

165 ft 165 ft165 ft

50 psi 50 psi93 psi74 psi50

psi

Effect of s.g. on Pressure and Head

28

Determining Friction Head

29

Friction of WaterAsphalt-dipped Cast Iron and New Steel Pipe

(Based on Darcy’s Formula) 8 Inch

Note: No allowance has been made for age, difference in diameter, or any abnormal condition of interior surface., Any factor of safety must be estimated from the local conditions and the requirement of each particular installation. It is recommended that for most commercial design purposes a safety factor of 15 to 20% be added to the values in the tables.

Asphalt-dipped Std. wt. steel Extra strong steel cast iron sch 80 Schedule 160 steel

8.0" inside dia. 7.981" inside dia. 7.625" inside dia. 6.813" inside dia.Flow Ve- Ve- Head Ve- Ve- Head Ve- Ve- Head Ve- Ve- HeadU.S. locity locity loss locity locity loss locity locity loss locity locity lossgal. ft. per head ft. per ft. per head ft. per ft. per head ft. per ft. per head ft. per

per min. sec. ft. 100 ft. sec. ft. 100 ft. sec. ft. 100 ft. sec. ft. 100 ft.130 .83 .011 .037 .83 .011 .036 .91 .01 .046 1.14 020 .079140 .89 .012 .042 .90 .013 .042 .98 .01 .052 1.33 024 .090150 .96 .014 .048 .96 .014 .047 1.05 .02 .059 1.32 027 .102160 1.02 .016 .054 1.03 .016 .053 1.12 .02 .066 1.41 031 .115170 1.08 .0187 .060 1.09 .018 .059 1.19 .02 .074 1.50 035 .128180 1.15 .021 .067 1.15 .021 .066 1.26 .02 .082 1.58 039 .142190 1.21 .023 .067 1.22 .023 .073 1.33 .03 .091 1.67 043 .157200 1.28 .025 .082 1.28 .026 080 1.41 .03 .099 1.76 048 .172220 1.40 .031 .098 1.41 .031 .095 1.55 .04 .118 1.94 058 .205240 1.53 .037 .115 1.54 .037 .111 1.69 .04 .139 2.11 069 .241

30

Friction in Fittings

The friction loss through one 1¼ inch standard

90° elbow is equal to the friction loss through

how many feet of straight 1¼ inch pipe?

3.6 ft

These are NOT friction

values!!!

31

Friction Head

10 gpm thru 250 ft – 1” Sched. 40 steel pipe

1. What is the friction head in feet? _______________

2. What is the pressure head in feet? _______________

3. What is the elevation head in feet? _______________4. What is the total head? (4 = 1+2+3) _______________

0 ft

0 ft

17 ft

17 ft

S D

Total Length Per

100’ Friction Factor Total Friction Loss

250 ÷ 100 X 6.81 = 17

32

Calculating Horsepower

3 9 6 0

s .g .T D Hgp mW H P (P 3 )

p u mpp u mp η3 9 6 0

s .g.T D Hgp m

η

W H PB H P (P 2 )

mo t o rp u mpmo t o rp u mpmo t o r ηη3 9 6 0

s .g.T D Hgp m

ηη

W H P

η

B H PE H P (P 1 )

33

Where do we get “3960” ?

1HP = 550 Foot Pounds per SecondX 60 Seconds per Minute33,000 Foot Pounds per Minute÷ 8.333 Pounds per Gallon of Water3960

34

Practice Problems

• What is WHP(P3) for a pump moving 200 gpm of 60°F water against a TDH of 500’?

(200 gpm X 500 feet) ÷ 3960 = 25.25 WHP

35

Practice Problems

• What is BHP(P2) if the efficiency of the pump is 83%?

25.25 WHP ÷ 0.83 = 30.42 BHP

36

Practice Problems

• What is EHP(P1) if the efficiency of the motor is 90%?

30.42 BHP ÷ 0.90 = 33.81 EHP

37

Convert EHP to Kilowatts

33.81 EHP X 0.746 = 25.21 kW

• What is kW value if the EHP of the pump is 33.81?

38

Calculate Energy Cost

25.21 kW

X 1000 hours per year

25,210 kW/hrs per year

X $0.10 per kWh

$2,521.00 cost per year

39

An Important Point!!!!!

• At a given speed, with a given impeller diameter:the pump will perform along its characteristic curve, from run out to shut off.

40

Pump Affinity Laws

41

FLOW changes DIRECTLY as a change in speed or diameter*

HEAD changes as the SQUARE of a change in speed or diameter*

HORSEPOWER changes as the CUBE of a change in speed or diameter*

FLOW changes DIRECTLY as a change in speed or diameter*

HEAD changes as the SQUARE of a change in speed or diameter*

HORSEPOWER changes as the CUBE of a change in speed or diameter*

Pump Affinity Laws

* May not be true for higher specific speeds

42

3

2

1

2

1

*

2

1

2

1

2

2

1

2

1

*

2

1

2

1

2

1

2

1

*

2

1

2

1

N

N

BHP

BHPOR

D

D

BHP

BHP

N

N

H

HOR

D

D

H

H

N

N

Q

QOR

D

D

Q

Q

Important...Remember these:

Pump Affinity Laws

Pg. 14 HVAC Technical Guide

43

What are the affects of the Affinity Laws?

%SPEED

POWER

PG: 113PG: 113

HEAD

FLOW

44

As we trim, we would expect the efficiency to stay the same, but remember the internal losses!

What are the affects of the Affinity Laws?

ACTUAL PUMP CURVE

HH

THEORETICAL PUMP CURVE

LOSSES DUE TO SHOCK, TURBULENCE, RECIRCULATION AND FRICTION

45

Catalog Pump Curve

46

System Curves

47

Creating a System Curve

48

Graph the head required through point for 100’ Equivalent Length of 2” Type L Copper Tubing for the following flows:

GPM 10 20 30 40 50

TDH .29

•

.98

•

2.01

•

3.36

•

5.01

•

•

Creating a System Curve

49

Graph the head required through point for 200’ Equivalent Length of 2” Type L Copper Tubing for the following flows:

GPM 10 20 30 40 50

TDH

•

.58

• ••

•

•

•

1.96

•

4.02

•

6.72

•

10.02

•

•

Creating a System Curve

50

System Curve

51

Operating Point

Duty Point

System and Pump Curves

52

System CurvesOpen System w/ Static Head

53

System CurvesOpen System w/ Static Head

54

Overlaying the pump curve and the system curve for systems with static head

Operating Point

Duty Point

System Curves

55

Unit 3 NPSH &

Multiple Pump Operation

56

NPSH

Net Positive Suction Head

57

Why Worry About NPSH ?

• Pumps Don’t Suck.

58

• The fluid needs to enter the impeller before the impeller can begin adding energy.

• NPSH defines the energy available to the fluid above it’s vapor pressure.

Remember Pump Basics

59

Two “Types” of NPSH

• NPSHR is the NPSH required by the pump.– It is a function of the pump design. (This is the NPSH shown on

the pump curve.)

• NPSHA is the NPSH available to the pump. – It is a function of the system design.

60

NPSH is Like a Checkbook

• NPSHR is like the money needed to pay your bills

• NPSHA is income.

• You need much more income than bills!

61

The “Rule”:

For practical purposes, forget the equal sign:NPSH Available must be GREATER than theNPSH Required.

NPSHA NPSHR

62

Take This Note!!!!

• Add minimum 2 foot safety factor to NPSHR!

63

NPSHR

• Chief factors influencing NPSHR include:– impeller eye area– vane inlet design– the relationship with the casing.

• NPSHR is determined by factory testing.

64

NPSHA

• The NPSHA is influenced by several factors, many of which are controllable or modifiable.

• These factors include:– Absolute pressure– Vapor pressure– Suction pressure– Friction loses– Highly aerated water (as seen in cooling towers)

65

NPSHA Formula

• NPSHA = HA + HS - HVPA - HF

• Where:

• HA = Absolute pressure

• HS = Suction pressure (head)

• HVPA = Vapor pressure

• HF = suction piping Friction head

66

In Suction Lift Example B, HS will be a Negative

Number

67

Question:

• What is difference between PSI, PSIA and PSIG?

– PSI is a unit of measurement.

– PSIG is Gauge pressure, and is relative to atmospheric pressure (reads 0 psi on the bench).

– PSIA is Absolute pressure, and includes atmospheric pressure (reads about 14.7 psi on the bench at sea level).

68

Absolute Pressure

• The absolute pressure is the pressure (energy) added to the fluid by an outside source.

• In an open system, this is the atmospheric pressure.

69

Atmospheric Pressure• 1 PSI = 2.31 ft H20 @ 70OF

= 2.0438 inches of mercury (hg).• 14.7 PSI = 33.9 ft = 30 inches of mercury (hg).• (Watch the weather report!)

70

Atmospheric Pressure vs. AltitudeAtmospheric Pressure Pg. 31 HVAC

Technical Guide

71

Vapor Pressure of Water

Pg. 30 HVAC Technical Guide

72

Vapor Pressure Curve

73

Multiple Pump Operation

74

Pumping in Series

75

Pumping in Parallel

76

Unit 4The Cost of Pumping

77

Cost Per Hour of Pumping

$ /k W H.7 4 6 (k W ) W W E3 9 6 0

s .g .T D Hg p mC P H

$ /k W H.7 4 6 (k W ) ηη3 9 6 0

s .g.T D Hgp mC P H

mo t o rp u mp

WWE = Wire To Water EfficiencyFixed Speed WWE = (PE) (ME)Variable speed WWE = (PE) (ME) (DE)

OR

78

Calculating Operating CostsDESIGN POINT: 3200GPM @ 160’TDH

(PUMP “A”)

79

Calculating Operating Costs Assume $0.10 /kWH Assume 92% Motor Efficiency Assume 84.5% Pump Efficiency Assume 1 Pump Assume 24 Hrs / Day Assume 365 Days / Yr Assume 60°F Water (s.g. = 1)

80

Calculating Operating Costs

≈ $108,711 / YEAR

1 0..7 4 6 9 2.8 4 5.3 9 6 0

11 6 02 0 03C P H

1 0.7 4 6.5.0 7 8,3

0 0 0,5 1 2C P H

4 1.1 2$C P H

Y e a r/D a y s3 6 5D a y/H r s2 4C P H

81

Calculating Operating Costs

Assume $0.10 /kWH Assume 92% Motor Efficiency Assume 90.5% Pump Efficiency Assume 1 Pump Assume 24 Hrs / Day Assume 365 Days / Yr Assume 60°F Water (s.g. = 1)

82

Calculating Operating Costs

DESIGN POINT: 3200GPM @ 160’TDH(PUMP “B”)

83

Calculating Operating Costs

≈ $102,054 / YEAR

1 0..7 4 6 9 2.09.3 9 6 0

11 6 02 0 03C P H

1 0.7 4 6.8 8.2 7 8,3

0 0 0,5 1 2C P H

6 5.1 1$C P H

Y e a r/D a y s3 6 5D a y/H r s2 4C P H

84

The Difference is Savings

The difference in PUMP EFFICIENCY between the 84.5% Efficient Pump “A” and the 90% Efficient Pump “B” Results in Real Operating Cost Savings

Pump “A” Operating Cost ≈ $108,711 / YearPump “B” Operating Cost ≈ $102,054 / Year

$Operating Cost Savings = $6,657 / Year

85

What Questions Do you Have?