ZZ Series Heavy-Duty Robots

Transcript of ZZ Series Heavy-Duty Robots

ZZ Series Heavy-Duty RobotsThe ZZ Series Robots are the work horses of the Kawasaki Robotics product line.

Automation applications around the world utilize Kawasaki Heavy-Duty Robots for

spot welding, material handling, sealing, die and investment casting, material

removal, machine tending, as well as numerous other demanding tasks.

The ZZ Series of Robots consist of eight models with payload capabilities up

to 300 kg (660 lbs.). The ZZX models are designed to be floor or pedestal

mounted while the unique ZZT Robots, with their work range envelope

being primarily below the base, are ideally suited for shelf

mount applications. All of the ZZ Robots can be

utilized with a Kawasaki 7th Axis

Traversing unit, allowing for a

flexible and expandable work range.

Protection from Harsh Environments The ZZ Robots can operate in some of the harshest environments due to the Kawasaki sealed arm design. The wrist portion of the robot has an Ingress Protection rating

of IP67. The other areas of the arm are rated at IP65.

1

2

3

4

5

6

Cycle Time AdvantageThe ZZ Robots can achieve higher operating speeds, as compared to previous models, due to a reduction in overall mass and the ultra high processing speed capabilities of the Kawasaki D Controller. The fasterspeeds of the ZZ Robots translate to shorter cycle times, resulting in increased production efficiencies.

1

2

3

4

5

6

Wide Work EnvelopeThe Kawasaki ZZ Robot combines a long reach arm with a minimal amount of dead space for the widest work envelope in its class. In addition, the patented Kawasaki Hybrid Link Configuration enables the arm to rotate back over itself without having to rotate the major axis, thereby improving efficiency and reducing power consumption.

1

2

3

4

5

6

Space Saving Design with Integrated Features The small footprint of these high payload long reach robots allow for installations in confined areas. The ZZ Robots are available with integrated pneumatic piping, wiring, and fork lift pockets, limiting the

amount of required space.

1

2

3

4

5

6

1

2

3

4

5

6

Arm ID Memory Kawasaki’s Arm ID board enables the robot arm to be interchanged with any D Controller. The ID board stores the necessary servo encoder data. In the event of a production emergency, the controller can quickly and easily be replaced to allow for any service and/or maintenance procedures to be performed. This feature

limits potential system downtime.

1

2

3

4

5

6 Upgradeable The ZZ Series Robots are constructed utilizing modular components and common software. This flexible design allows some models to be upgraded to alter reach, payload capacities and/or speed. Modifications can beperformed in the field via a hardware and/or software alteration. The ability to change the robot characteristics provide for greater flexibility to accommodate production and/or system changes.

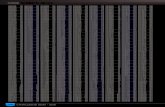

ZZX130L

ZZX130U · ZZX165U · ZZX200S

ZZX300S

2,265 2,951

4,01

53,64

0

210 600.5

1,199

270

1,10

067

0

120°

70°

75°60°JT2

JT3

JT2

JT3

JT1±180°

288 1,600 228

A

1,49

0

30°

30°

6–M10 Depth 12

Depth 8X Y X

XY

1,22

5210 600.5

1,199

270

1,10

067

0

2,6511,965

3,41

53,

340

120°

70°

75°60°

JT2

JT3

JT2

JT3

JT1±180°

ZZX200S

1,300288 231

A

A

228

1,49

0

30°

30°

6–M10 Depth 12

Depth 8X Y X

XY

30°30°

YY X

X

X

6–M10 Depth 12

1,22

5

210 600.5

670

1,10

027

0

3,11

5

1,815

60° 75°

120°

70°

3,19

0

2,501

288

1,199

JT3

JT2

JT3

JT2

A

JT1±180°

30°30°

YY X

X

X

6–M10 Depth 12

1,49

0

1,150 231

1,22

5

View A

View A

View A

2,265 2,951

4,01

53,64

0

210 600.5

1,199

270

1,10

067

0

120°

70°

75°60°JT2

JT3

JT2

JT3

JT1±180°

288 1,600 228

A

1,49

0

30°

30°

6–M10 Depth 12

Depth 8X Y X

XY

1,22

5

2,265 2,951

4,01

53,64

0

210 600.5

1,199

270

1,10

067

0

120°

70°

75°60°JT2

JT3

JT2

JT3

JT1±180°

288 1,600 228

A1,

490

30°

30°

6–M10 Depth 12

Depth 8X Y X

XY

1,22

5

210 600.5

1,199

270

1,10

067

0

2,6511,965

3,41

53,

340

120°

70°

75°60°

JT2

JT3

JT2

JT3

JT1±180°

ZZX200S

1,300288 231

A

A

228

1,49

0

30°

30°

6–M10 Depth 12

Depth 8X Y X

XY

30°30°

YY X

X

X

6–M10 Depth 12

1,22

5210 600.5

1,199

270

1,10

067

0

2,6511,965

3,41

53,

340

120°

70°

75°60°

JT2

JT3

JT2

JT3

JT1±180°

ZZX200S

1,300288 231

A

A

228

1,49

0

30°

30°

6–M10 Depth 12

Depth 8X Y X

XY

30°30°

YY X

X

X

6–M10 Depth 12

1,22

5

210 600.5

670

1,10

027

0

3,11

5

1,815

60° 75°

120°

70°

3,19

0

2,501

288

1,199

JT3

JT2

JT3

JT2

A

JT1±180°

30°30°

YY X

X

X

6–M10 Depth 12

1,49

0

1,150 231

1,22

5

210 600.5

670

1,10

027

0

3,11

5

1,815

60° 75°

120°

70°

3,19

0

2,501

288

1,199

JT3

JT2

JT3

JT2

A

JT1±180°

30°30°

YY X

X

X

6–M10 Depth 12

1,49

0

1,150 231

1,22

5

Standard Features (Apply to ZZX and ZZT) • Six-Axis Articulated Arm• Payload Capacity 130-300 kg (286-660 lbs)• Electric AC Servo Drive Motors/Encoders• Common D Controller • Large Working Envelope• High Payload · High Wrist Torque and Inertia Capacity · Maximum Payload Capacity Rated at Full Speed and Full Reach• Tool Mounting Flange: ISO 9409-1• Space Saving Design · Small Footprint · Kawasaki Hybrid Link Configuration · Minimal Dead Zones• Production Advantages · Modular Arm Design · High Speed Operation · Rapid and Adaptive Acceleration and Deceleration Rates

• Low-Cost Maintenance · Greater than 80,000 Hours MTBF · 10,000 Hour Maintenance Intervals · Fittings for Easy Lubrication (one grease type) · Modular Components for Quick Repairs• Programming · Simplified “Block Step” Teaching · Advanced Kawasaki “AS Programming Language” · RS-232 Port for PC Communication · Menu Driven Software · On-Screen Diagnostics• Safety · Three-Position Teach Pendant Safety Switch · Rotational Hard Stops and Software Limits · Collision Detection Software · UL Approved

(See D Controller Brochure or visit www.kawasakirobotics.comfor Controller Features and Specifications)

ZZX Series Specifications Type

Arm Type

Degrees of Freedom

Axis Work Envelopeand Max. Speed

Position Repeatability

Max. Payload

Moment

Moment of Inertia

Vertical Reach

Horizontal Reach Front

Horizontal Reach Back

Weight

Installation

Environmental Conditions

Integrated Features

Options

Color

Axis

JT1 : Arm rotation

JT2 : Arm out-in

JT3 : Arm up-down

JT4 : Wrist swivel

JT5 : Wrist bend

JT6 : Wrist twist

JT7 : Arm traverse

JT4 : Wrist swivel

JT5 : Wrist bend

JT6 : Wrist twist

JT4 : Wrist swivel

JT5 : Wrist bend

JT6 : Wrist twist

ZZX130U ZZX130L ZZX165U ZZX200S ZZX300S

Articulated Type

6 Axes (7 Axes : Option)

Max. Stroke Max. Speed Max. Stroke Max. Speed Max. Stroke Max. Speed Max. Stroke Max. Speed Max. Stroke Max. Speed

±180° 110°/s ±180° 110°/s ±180° 110°/s ±180° 100°/s ±180° 100°/s

+75°~-60° 110°/s +75°~-60° 110°/s +75°~-60° 110°/s +75°~-60° 100°/s +75°~-60° 85°/s

+250°~-120° 110°/s +250°~-120° 110°/s +250°~-120° 110°/s +250°~-120° 95°/s +250°~-120° 85°/s

±360° 140°/s ±360° 140°/s ±360° 135°/s ±360° 120°/s ±360° 90°/s

±130° 135°/s ±130° 135°/s ±130° 135°/s ±120° 115°/s ±120° 90°/s

±360° 230°/s ±360° 230°/s ±360° 210°/s ±360° 180°/s ±360° 150°/s standard standard standard standard standard 2,000mm 1,000mm/s 2,000mm 1,000mm/s 2,000mm 1,000mm/s 2,000mm 1,000mm/s 2,000mm 1,000mm/s

±0.3 mm

130 kg 130 kg 165 kg 200 kg 300 kg

735 N·m 735 N·m 911.4 N·m 1,274 N·m 1,470 N·m

735 N·m 735 N·m 911.4 N·m 1,274 N·m 1,470 N·m

421.4 N·m 421.4 N·m 451 N·m 686 N·m 705.6 N·m

107.8 kg·m2 107.8 kg·m2 165.5 kg·m2 199.8 kg·m2 274.5 kg·m2

107.8 kg·m2 107.8 kg·m2 165.5 kg·m2 199.8 kg·m2 274.5 kg·m2

45.9 kg·m2 45.9 kg·m2 46.9 kg·m2 154.9 kg·m2 155.9 kg·m2

3568 mm 3868 mm 3568 mm 3571 mm 3421 mm

2879 mm 3179 mm 2879 mm 2882 mm 2732 mm

2193 mm 2493 mm 2193 mm 2196 mm 2046 mm

1,350 kg 1,400 kg 1,350 kg 1,400 kg 1,400 kg

Floor Mounted

0~45°C, 35-85% Relative Humidity without Condensation, IP67 Wrist (IP65 Arm)

Air Piping (12mm dia. x 2), Solenoid Valve Wiring for Grippers (24 VDC )

Mechanical Hard Stop JT1/JT2/JT3, End Stroke Limit Switch JT1/JT2/JT3, Special Color, Traversing Track, Internal Wiring for End Effector

Internal Hoses – Cooling Water for Welding Gun, Arm I/O Option, (other options available upon request)

Kawasaki Standard1 N·m = 0.102 kgf·m 1 kg·m2 = 0.102 kgf·m·s2 1 kgf = 2.2 lbf 1 m = 3.28 ft.

���

����

���

���

���±

���°

����

���±

����

°

���±���°

����

±���

°°

��°

���°

��°

����

���

���

����

�

���

�������

���

���

���

������

��°

��°

��°

� �������������

�������� � �

��

��°��°

�� �

�

�

� ������������

���

���

� �

�

��� ����� ���

���±���°

ZZT130U, ZZT165U, ZZT200S

View A View B

Type

Arm Type

Degrees of Freedom

Axis Work Envelopeand Max. Speed

Position Repeatability

Max. Payload

Moment

Moment of Inertia

Vertical Reach

Horizontal Reach

Weight

Installation

Environmental Conditions

Integrated Features

Options

Color

ZZT130U ZZT165U ZZT200S

Articulated Type

6 Axes (7 Axes : Option)

Max. Stroke Max. Speed Max. Stroke Max. Speed Max. Stroke Max. Speed

±180° 105°/s ±180° 105°/s ±180° 100°/s

+60°~-75° 105°/s +60°~-75° 105°/s +60°~-75° 100°/s

+165°~-95° 105°/s +165°~-95° 105°/s +165°~-95° 90°/s

±360° 140°/s ±360° 135°/s ±360° 120°/s

±130° 135°/s ±130° 135°/s ±120° 115°/s

±360° 230°/s ±360° 210°/s ±360° 180°/s

standard 2,000 mm 1,000 mm/s standard 2,000 mm 1,000 mm/s standard 2,000 mm 1,000 mm/s

±0.3 mm

130 kg 165 kg 200 kg

735 N·m 911.4 N·m 1,274 N·m

735 N·m 911.4 N·m 1,274 N·m

421.4 N·m 451 N·m 686 N·m

107.8 kg·m2 165.5 kg·m2 199.8 kg·m2

107.8 kg·m2 165.5 kg·m2 199.8 kg·m2

45.9 kg·m2 46.9 kg·m2 154.9 kg·m2

5027 mm 5027 mm 5027 mm

3458 mm 3458 mm 3461 mm

1,550 kg 1,550 kg 1,600 kg

Shelf Mounted

0~45°C, 35-85% Relative Humidity without Condensation, IP67 Wrist (IP65 Arm)

Air Piping (12mm dia. x 2), Solenoid Valve Wiring for Grippers (24VDC)

Mechanical Hard Stop JT1/JT2/JT3, End Stroke Limit Switch JT1/JT2/JT3, Special Color, Traversing Track, Internal Wiring for End Effector

Internal Hoses – Cooling Water for Welding Gun, (other options available upon request)

Kawasaki Standard

Axis

JT1 : Arm rotation

JT2 : Arm out-in

JT3 : Arm up-down

JT4 : Wrist swivel

JT5 : Wrist bend

JT6 : Wrist twist

JT7 : Arm traverse

JT4 : Wrist swivel

JT5 : Wrist bend

JT6 : Wrist twist

JT4 : Wrist swivel

JT5 : Wrist bend

JT6 : Wrist twist

ZZT Series Specifications

1 N·m = 0.102 kgf·m 1 kg·m2 = 0.102 kgf·m·s2 1 kgf = 2.2 lbf 1 m = 3.28 ft.

Kawasaki Robotics (USA), Inc.28140 Lakeview DriveWixom, Michigan 48393Phone: (248) 446-4100Fax: (248) 446-4200

Canada1155 North Service Road West, Suite #4Oakville, Ontario L6M 3E3Phone: (905) 465-0880Fax: (905) 465-1221

Louisville, Kentucky2726 River Green CircleLouisville, Kentucky 40206Phone: (502) 893-3889Fax: (502) 893-3830

MexicoAv. Vallarta #6503 Local B 9Concentro Zapopan, Jalisco45010, MexicoPhone: (52) 33 3110-1895Fax: (52) 33 3110-1897

www.kawasakirobotics.com

ZZSeries - REV06/0606/06 - 1M - EGD

San Jose, California3081 North First StreetSan Jose, California 95134Phone: (408) 432-0990Fax: (408) 432-0996