zipro zirconium oxychloride 拷貝 2 · 2020. 2. 18. · Oxychloride, Stabilized Zirconia,...

Transcript of zipro zirconium oxychloride 拷貝 2 · 2020. 2. 18. · Oxychloride, Stabilized Zirconia,...

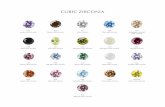

-

ZIPRO GROUP Zirconia Resources Vertical Integrator

ZIPRO TECHNOLOGY CORPORATION is a leading international advanced zirconium material solution provider, including zirconium material application, manufacturing, and supply. We offer a wide range of high quality products along with implementing vertical integration of zirconium related resources, to meet the various requirements application as high-speed 5G ceramic housing applications, zirconium 3D printing technology, and SOFC, etc. Through an effective manufacturing process, optimized design, and the unique properties of zirconium, we are able to achieve core competitiveness with our services and products.

Zipro is a subsidiary of VESTPRO INTERNATIONAL LTD., one of the largest shareholders of IMAGE RESOURCES (ASX listed: IMA ) and one of the major shareholders of“THE WIM150 MINERAL SANDS PROJECT”, a zircon mineral development project in Australia.

Zipro is also global agent of GUANGDONG ORIENT ZIRCONIC IND SCI & TECH CO., LTD. “ OZC”(Code:002167). Our vision is to reach a common success and a sustainable future by leveraging the power of long term partnerships with IMA , WIM 150 Project and OZC – built on integrity, reliability, and innovative solution thinking.

Zipro / ADVANCED ZIRCONIA MATERIAL

-

Advanced Mineral Sands : One stop Service Provider of Global Zirconium Resources

Zipro’s strategic partnership with Image Resources ( ASX: IMA ) allows for high-quality supply and distribution of zirconium resources. IMA, based in West Australia, is an emerging Mineral Sands producer focus on the development of its Boonanarring project in the North Perth Basin, and continues to expand its resources and reserves with high grade Zirconium sand amongst other heavy metals.

Zipro / ADVANCED ZIRCONIA MATERIAL

-

Organization

Zipro Sales and R&D department are based in Taiwan and provides you with all kinds of zirconia products services.

Guangdong, China - Powders Factory

Fujian, China - CNC / Ceramic Factory

Shenzhen, China - Electronics ODM/OEM Factory

Perth, Australia - IMA Zirconia Mine Concession

Zipro Taiwan - Sales / RD Department Fine Ceramic Factory

Zipro / ADVANCED ZIRCONIA MATERIAL

-

Business Main Groups

Zircon Sand/Powder Ceramic Grinding Media

Zircon sand, ilmenite, rutile, zirconia powders and grinding media.

Zirconia Industrial Products Zirconia Consumer Products Customized industrial/consumer

zircon related structural ceramic units.

Zirconia 3D Slurry Powders for 3D ceramic printing

slurry with complex ceramic products.

Zirconia R&D Development Focus on bioscience material develop and analyze especially at dental and

bone composite material.

Zipro / ADVANCED ZIRCONIA MATERIAL

-

GUANGDONG ORIENT ZIRCONIC IND SCI & TECH CO., LTD

GUANGDONG ORIENT ZIRCONIC IND SCI & TECH CO., Ltd(OZ) (Code:002167) was found in 1995 and is a key high tech enterprise specialized in the development, production and operation of zircon and zircon related products. It produces over 90 products in eight main categories, including Zirconium Ores, Zirconium Dioxide, Zirconium Oxychloride, Stabilized Zirconia, Zirconium silicate, Fused Zirconia, Zirconium Sponge and structural ceramic.

POWDERS

POWDERS WORKSHOP

Zipro / ADVANCED ZIRCONIA MATERIAL

-

APPLICATION

Powders General Properties

Product Code

Chemical Formula

Analytical Value Typical Specifications

ZrO2+HfO2 (Min%)

SiO2 (Max%)

Fe2O3 (Max%)

TiO2 (Max%)

Na2O (Max%)

Form & Appearance Remarks Applications

OZ-2-1 ZrOCI2 · 8H2O 36.0 0.002 0.001 0.001 0.001 White Powder High-purityTextile, Leather, Rubber additive, Metal Surface

Treating Agent, Coating Drying Agent, Ceramic Colored Glaze

Catalyst, Water-proof AgentOZ-2-2 ZrOCI2 · 8H2O 35.0 0.004 0.002 0.002 0.003White

Powder High-purity

Product Code

Chemical Formula

Analytical Value Typical Specifications

ZrO2+HfO2 (Min%)

SiO2 (Max%)

Fe2O3 (Max%)

TiO2 (Max%)

Na2O (Max%)

Average Particle Size

D50 (μm)

B.E.T (m2/g)

Ig.Loss (Max%)

Form & Appearance Applications

OZ-B-1 ZrO2 99.9 0.01 0.005 0.001 0.001 —— 1-4 0.2 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-B-2 ZrO2 99.5 0.01 0.002 0.002 0.002 —— 1-4 0.3 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-R-1 ZrO2 99.9 0.001 0.001 0.002 0.001 3~6 3~7 0.4 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-R-2 ZrO2 99.5 0.001 0.001 0.002 0.003 3.4 3~7 0.4 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-R-3 ZrO2 99.5 0.01 0.002 0.003 0.004 6.1 3~7 0.4 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-R-4 ZrO2 99.5 0.020 0.005 0.005 0.005 —— 2~6 0.5 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-R-5 ZrO2 99.5 0.020 0.005 0.005 0.005 —— 2~6 0.5 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-R-6 ZrO2 99.9 0.010 0.001 0.002 0.002 1 5 0.3 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

OZ-R-7 ZrO2 99.9 0.010 0.001 0.001 0.002 0.6 5.2 0.5 White Powder

Plezoelectric ceramic, Ceramic capacitor, Other Ceramic catalyst

Zirconium Oxychloride

Zirconium Dioxide

Zipro / ADVANCED ZIRCONIA MATERIAL

-

Stabilized Zirconia

Product Code

Chemical Formula

Analytical Value Typical Specifications

ZrO2+HfO2 (Min%)

Y2O3 (Max%)

Al2O3 (Max%)

SiO2 (Max%)

Fe2O3 (Max%)

TiO2 (Max%)

Na2O (Max%)

Average Particle Size

D50 (μm)

B.E.T (m2/g)

Ig.Loss (Max%)

Form & Appearance

OZ-3YG-4 (Y2O3)x(ZrO2)1-x 94.0 5.40±0.25 0.229 0.008 0.001 0.001 0.005 1.000 8.200 2.35 White Powder

OZ-3Y-6 (Y2O3)x(ZrO2)1-x 94.0 5.30±0.25 0.231 0.013 0.002 0.001 0.005 0.409 11.6 0.96 White Powder

OZ-3YG-6 (Y2O3)x(ZrO2)1-x 94.0 5.35±0.25 0.235 0.007 0.001 0.001 0.005 1.000 8.100 2.73 White Powder

OZ-3Y-7 (Y2O3)x(ZrO2)1-x 94.0 5.25±0.25 0.231 0.001 0.001 0.001 0.005 0.709 8.5 0.83 White Powder

OZ-3YAZr-7 (Y2O3)x(ZrO2)1-x 94.0 5.30±0.25 0.233 0.001 0.001 0.001 0.005 0.708 6.7 0.38 White Powder

OZ-4Y (Y2O3)x(ZrO2)1-x 92.0 7.2±0.25 —— 0.020 0.003 0.002 0.005 1.0 —— 1.0 White Powder

OZ-8Y (Y2O3)x(ZrO2)1-x 86.0 13.5±0.25 —— 0.020 0.003 0.002 0.005 1.0 —— 1.0 White Powder

3Y : It means 3 mol% Y2O3 ll G : It means powder with binder.

3YG-4 : Apply in big special-shaped structure parts ll 3YG-6 : Apply in small special-shaped structure parts

3Y-7 / 3YAZr-7 : Apply in small casting and injection mould parts

Application : Advanced Ceramic, Structural Ceramic Parts, Grinding Ball and Solid Fuel Cell.

(a) SEM photograph (Before sintering)

(b) SEM photograph (After sintering)

Transformation of Zirconium Oxide

0 1000 2000 3000

TetragonalMonoclinicAmorphous Cubic Liquid

Temperature(oC)

This transformation can be stabilized by doping with Y2O3, CaO, MgO etc.,for the stabilization of the crystalized isometric and tetragonal structure.

Monoclinic Tetragonal Cubic

Zipro / ADVANCED ZIRCONIA MATERIAL

-

Product Code

Chemical Formula

Analytical Value Typical Specifications

ZrO2+HfO2 (Min%)

SiO2 (Max%)

Fe2O3 (Max%)

TiO2 (Max%)

Al2O3 (Max%)

Average Particle Size D50(μm)

Form & Appearance Applications

ZCO-GF-1 ZrO2 98.50 0.40 0.04 0.25 0.35 14~16 Light yellow Ceramic pigment, Glass additive, Refractory material, Nuclear power

ZCO-GF-3 ZrO2 98.50 0.40 0.04 0.25 0.35 5~6 Light yellow Ceramic pigment, Glass additive, Refractory material, Nuclear power

Fused Zirconia

Zirconium Sponge

Product Code

Chemical Formula

Chemical Composition(%)

Zr+Hf Hf Ni Cr Al Mg Mn Pb Ti

HZr-1 Zr >99.4

-

Y/ Ce-TZP Material Properties

Ceramic Grinding Media

Items Unis Typical Values Typical ValuesComposition wt% 94.8%ZrO2, 5.2%Y2O3 ZrO2+CeO2

Hardness(HV) GPa >10 12

Thermal Expansion Coefficient 10-6/K 9.6 ——

Modulus of Elasticity GPa 205 ——

Fracture Toughness MPa·m1/2 7-10 7-10

Bending Strength MPa 1150 1150

Density g/cm3 6.0 ——

Grain Size μm

-

Features of the Structural Ceramics

Excellent strength , hardness, and fracture toughness. High temperature resistance. Coefficient similar to steel.

Ultra-smooth surface low friction. Superior stability, corrosion resistance, no oxidation and rustiness.

P.S. According to customer requirement, we can provide a complete set of zirconia accessory, such as: dispersing disk, impeller, rotor, lining, gland, end cover, space sleeve, etc.

Zipro / ADVANCED ZIRCONIA MATERIAL

-

ZIPRO GROUP Zipro Technology International Limited Zipro Technology Corporation www.ziprotech.com

[email protected] +886-2-2627-5586 +886-2-2627-5608

http://www.ziprotech.commailto:[email protected]

![Analysis of oxide layers on zirconium alloys by Raman ...eurocorr.efcweb.org/2018/abstracts/4/110072.pdf · ) molecular weightof zirconia.[4] The Raman spectra were measured by Thermo](https://static.fdocuments.net/doc/165x107/6061dfaf4c83696a5e551e52/analysis-of-oxide-layers-on-zirconium-alloys-by-raman-molecular-weightof-zirconia4.jpg)