z Ollinger

-

Upload

masteriraga -

Category

Documents

-

view

224 -

download

0

Transcript of z Ollinger

-

8/13/2019 z Ollinger

1/50

Evaluation of Concrete Curing

Effectiveness

Muhammad Ehsanul Bari

Dan Zollinger, Phd, PEPeizhi Sun

Zachry Department of Civil Engineering

Texas A&M University

14 April, 2013

1

-

8/13/2019 z Ollinger

2/50

OUTLINE Present Technology

ASTM C 156 New Approach

Curing Indexing Index Validation and Testing

Conclusions

2

-

8/13/2019 z Ollinger

3/50

Present Testing Technology Time of Curing

Low surface concrete strength Delamination and spalling

Duration (rate) of Curing Set Gradient

Liquid membrane-forming curing compounds Only represented by total moisture loss

No attention paid to a design rate of application

3

-

8/13/2019 z Ollinger

4/50

-

8/13/2019 z Ollinger

5/50

New Approach Laboratory Test for Evaluating Curing

Compound

Relative humidity (RH) measurement

Moisture loss measurement Concrete surface abrasion test

Propose an Evaluation Index

Relate Index to Performance

5

-

8/13/2019 z Ollinger

6/50

Relative Humidity Measurement ACMM device to collect RH data

RH data Ambient temperature

Wind speed

Solar radiation

6

-

8/13/2019 z Ollinger

7/50

Relative Humidity Measurement Sealed chamber

Collect RH data near perfect curing conditions Filtered chamber

Collect RH data just below the concrete curing surface

7Top ViewSide View

-

8/13/2019 z Ollinger

8/50

Relative Humidity Measurement screen is place over a plate for the filter

chamber thin mortar layer on the screen

curing compound is applied on the mortar

8

-

8/13/2019 z Ollinger

9/50

After placing curing compound , place the ACMM device on the housings inthe plate

Relative Humidity Measurement

-

8/13/2019 z Ollinger

10/50

Relative Humidity Measurement

10

same procedure is applicable for field condition to

collect RH data

-

8/13/2019 z Ollinger

11/50

Relative Humidity Measurement

11

Example of RH Data Curing compound 1600

225 ft2/gal application rate

-

8/13/2019 z Ollinger

12/50

Indexes for Evaluating Curing Evaluation Index

based on maturity or equivalent age of concrete

Curing Index

through modeling curing as moisture diffusion

process

based on time dependent diffusion coefficient

12

-

8/13/2019 z Ollinger

13/50

Evaluation Index (EI) Equivalent Age (t) of Concrete

13

( ) ( )4

0 00 0

1

1 (7.5 7.5 )

t to o

i H

rm rm

T T T T t t t

T T RH T T

= =

+

[ ] 14)5.75.7(+1= HH

where

H = the moisture modification factorRH = the humidity of concrete

ti = equivalent age of concrete

i = sealed, filtered, and ambient conditions

T = the average temperature of the concrete during time interval t

T0 = the datum temperature with a value of -10 C

Trm

= room temperature 21C

-

8/13/2019 z Ollinger

14/50

Evaluation Index (EI) EI is defined as:

14

as

af

tt

ttEI

=

where

tf= the equivalent age of the filtered curing condition

ts = the equivalent age of the sealed curing conditionta = the equivalent age of the ambient curing condition

-

8/13/2019 z Ollinger

15/50

0 0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

00.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9 1

10/11/12 12:00 PM

10/12/12 12:00 AM

10/12/12 12:00 PM

10/13/12 12:00 AM

10/13/12 12:00 PM

10/14/12 12:00 AM

10/14/12 12:00 PM

10/15/12 12:00 AM

Evaluation Index

Relative Humidity, %/100

Date-

Time

Re

sinCure

sealedrh

filter

edrh

AmRH

EI

0 0 0 0 0 1 1

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

Relative Humidity, %/100

Date-Time

LithiumCure

Exam

ples(

-

8/13/2019 z Ollinger

16/50

Curing Index

16

Curing process can be represented by the following

differential equation:

2

2

u u

t z

=

where

u = suction in concrete (pF)

= Diffusion coefficient (cm2/sec)

t = time (sec)

Suction in pF = log (capillary pressure)

-

8/13/2019 z Ollinger

17/50

Curing Index

17

c

b

w

where

current diffusion coefficient

best possible diffusion coefficient

worst possible diffusion coefficient

=

=

=

, w c

w b

Curing Index CI

=

Diffusion Coefficient Curing Index

exp( )cCI a b t = Modeled CI with with R2 = 0.92

-

8/13/2019 z Ollinger

18/50

Dielectric Constant (DC) Apply a thin layer of concrete mortar on top of the cap and spray curing

compound on it

Take off the cap and insert the probe into the cylinder when measuringthe DC readings

Let the bottom surface of the probe

fully contact with the concrete surface and read the reading

18

-

8/13/2019 z Ollinger

19/50

( )

=t

et ,,,

is related to the curing compound application rate. The higher is, better the

curing quality is.

is related to curing compound quality. The higher is, it is more likely that

curing compounds would diminish more quickly.

is related to the effective duration of the curing compound.

Dielectric Constant (DC)

-

8/13/2019 z Ollinger

20/50

Concrete Surface Abrasion Test Test concrete surface abrasion resistance based on ASTM

C944

By measuring the amount of concrete abraded by a rotating

cutter in a given time period (10 min, under 22 lb. of load inthis study)

20

-

8/13/2019 z Ollinger

21/50

0

2

4

6

8

10

12

14

16

18

20

84 85 86 87 88 89 90

DepthfromSurface(in)

RH (%)

Int 0 Int 5 Int 10 Int 15 Int 20

No Curing Curing

0

2

4

6

8

10

12

14

16

18

20

70 75 80 85 90 95 100

DepthfromSurface(in)

RH (%)

Int 0 Int 5 Int 10 Int 15 Int 20

Set Gradient

-

8/13/2019 z Ollinger

22/50

( )L , D-Days l

( )-

1 1

2 2

3 3

C = e

Site

1

2

3

N

Field Performance Calibration

-

8/13/2019 z Ollinger

23/50

-

8/13/2019 z Ollinger

24/50

Performance vs. Climatic

Conditions

-

8/13/2019 z Ollinger

25/50

Cracking Calibration

maxC

C

2 2, C

1 1,N C

cfN

( ){ }1 211

10 %k k r

fN Ln C

+= = c

( )3

1 1

cfTo tLog N C

r oR C C

= =

c

-

8/13/2019 z Ollinger

26/50

Damage Coefficients (C4, C5)

{ } ( ) ( )

( ) ( ) { }{ } ( ) ( ){ }

( ) { } ( ){ }

5 5

5

5 5

1

4

4

4

5 4 5

4 5 4 5

4 5 5

1% 1

1

11

%1

1%

11

%

11

%

11%

c

c

c

C C

fC

C C

f

f

f

f

C C N N C D

N C N

C

Ln C Ln N Ln C C Ln NC

n Ln C C Ln N Ln N Ln C C Ln DC

Ln Ln C C Ln N C Ln NC

y b mx

y Ln C

= = + +

=

+ = +

= + = +

= +

= +

=

( )

( ) { } { }

5

4 4;fb mLn N

f

x Ln N

m C

b Ln C mLn N C e

+

=

=

= =

-

8/13/2019 z Ollinger

27/50

Design Stress Ratio

2

1

3

1 1

10

10

i

Ci

i

ci c i built in C

built in ci C

N

Log D Cr

C C

r r r r r

r r r

=

= =

= +

c

-

8/13/2019 z Ollinger

28/50

Built-In Gradient

28

{ }&cbuilt in c w set r r r = +

{ }design

Totwls envr r r

MoR

= = +

{ } { }& & &i

i i i c

env

env c w built in c w c w set r r r r r r MoR

= = + = + +

-

8/13/2019 z Ollinger

29/50

Curing and Fatigue Damage Therefore, evaluation index or curing index

can be tied to the calibration of cracking andallowable wheel load calculation.

This can help to better predict theperformance of the pavement.

29

-

8/13/2019 z Ollinger

30/50

Test ProgramMaterial and Mixture Design

30

Curing Compound

-

8/13/2019 z Ollinger

31/50

Test Program (Contd)Experimental Design

31

Environmental Condition

Variable Unit Low Level Medium Level High Level

Curing compound A Lithium B

Application Rate Ft2/gallon 220 120

w/c of mixture 0.4 0.43

Wind Speed mph 0 5

-

8/13/2019 z Ollinger

32/50

Validation Checking Evaluation of Curing effectiveness between

different curing compounds

Evaluation of Curing effectiveness under

different ambient conditions

w/c ratio = 0.43 for all the results shown inthe presentation

32

-

8/13/2019 z Ollinger

33/50

Lithium/120 Lithium/220 A/120 A/220 B/120 B/220

Moisture loss

Validation Checking

-

8/13/2019 z Ollinger

34/50

Lithium A B

EI at 72 hours

-

8/13/2019 z Ollinger

35/50

Lithium A B

Weight,lb.

3-day Abrasion weight loss

Sands used in this section are 100% passing through #4

sieve, some of the large variance may due to the

influence of large aggregate particles retaining on #8

sieve.

-

8/13/2019 z Ollinger

36/50

Circle----- Curing compound B

Line------ Curing compound ATriangle---- Lithium

Red----120 AR

Green ----220 AR

(some tests were conducted by a few people, lack of consistency)

-

8/13/2019 z Ollinger

37/50

Dielectric constant & Water content

Two same mixes applied with high (120 ft2/gal ) and low (220 ft2/gal ) rate of curing compound

Sample with higher application rate (120 ft2/gal ) shows higher DC and water content over time

Water content is predicted using a self consistent model developed by Dr. Sang Ick Lee

w/c Curing compound Type Application rate Fixed ambient condition

0.43 2250 120 ft2/gal & 220 ft2/gal 32C, 50% RH, 5 mph wind

0

0.05

0.1

0.15

0.2

0.25

8.00

9.00

10.00

11.00

12.00

13.00

14.00

15.00

16.00

17.00

18.00

0.00 10.00 20.00 30.00 40.00 50.00 60.00

VolumetricWaterContent

DielectricConstant

Time, hours

Variation of Volumetric Water Content by D.C.

Dielectric constant (120 ft2/gal) Dielectric constant (220 ft2/gal)

water content (120 ft2/gal) water content (220 ft2/gal)

3 51 2 4

1 2 3 4 5

02 2 2 2 2

Aggw h cp uc Air

+ + + + =

+ + + + +

-

8/13/2019 z Ollinger

38/50

Model for Comparison of Dielectric constant

0.00

2.00

4.006.00

8.00

10.00

12.00

14.00

16.00

18.00

0.00 10.00 20.00 30.00 40.00 50.00 60.00DielectricC

onstant

Time, hours

Variation of Volumetric Water Content by D.C.

Dielectric constant (120 ft2/gal) Dielectric constant (220 ft2/gal)

Pridicted model (120 ft2/gal) Pridicted model (220 ft2/gal)

y1 = 16.778*(1-exp(-(1/(t*0.013))^0.417)

y2 = 16.47*(1-exp(-(1/(t*0.0171))^0.446)

Weibull accumulative distribution:

where,

= amplifying parameter

= scaling parameter, and

= shift parameter.

( , , , ) . 1

t

W t e

=

1/

120 ft2/gal 16.778 76.923 0.417

220 ft2/gal 16.47 5.848 0.446

Higher 1/ Lower rate of reduction of

moisture Better curing

-

8/13/2019 z Ollinger

39/50

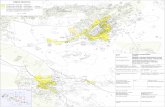

Victoria, Tx

-

8/13/2019 z Ollinger

40/50

3/26/2013

100 Ft Test SectionSurface

Treatment (1)Lithium Cure (2)

Shrinkage

Reduction (3)Resin Cure (13=4) Notes

1 + NO - Tr - None 200 ft2/galFirst half sprayed with Dayton resin, rest

sprayed with city resin

2 - SB - None + With 200 ft2/gal manually sprayed with city resin

3 - SB - Tr - None 150 ft2/gal manually sprayed with city resin

3/28/2013

100 Ft Test

Section

Surface Treatment

(1)Lithium Cure (2)

Shrinkage

Reduction (3)Resin Cure (13=4) Note

1 + NO + Si + With 150 ft2/gal All the Lithium are sprayed

manually at 200 ft2/gal.

The City Resin cure are sprayed

by using the machine. 150 ft2/gal

goes two passes, 200 ft2/gal goes

one pass.

No City Resin was sprayed on

Section 4, 6, 8, since the Sinak

Lithium sprayed on this section is

already mixed with resin

2 - SB - Tr plus + With 200 ft2/gal

3 + NO + Si + With 200 ft2/gal

4 - SB + Si mix + With

5 + NO - Tr plus + With 150 ft2/gal

6 + SB + Si mix - None

7 + SB + Si - None 150 ft2/gal

8 - NO + Si mix - None

9 - SB - Tr - None 150 ft2/gal

Victoria Test Plan

-

8/13/2019 z Ollinger

41/50

Effectiveness Index (EI)

0

0.1

0.2

0.30.4

0.5

0.6

0.7

0.8

0.9

1

Mar 26 (Section

1)

Mar 26 (Section

3)

Mar 28 (Section

3)

Mar 28 (Section

8)

EI

EI at 72 hours Date100 Ft

TestSection

Lithium Cure (200ft2/gal)

Resin Cure

March 26 1 - Transil 200 ft2/gal

March 26 3 - Transil 150 ft2/gal

March 28 3 + Sinak 200 ft2/gal

March 28 8 + Resin-mixedSinak None

Dayton Resin cure were unevenly sprayed on

March 26 Section#1because the thick compound

clogged the spray gun.

The other sections are sprayed with City Resin

cure (except for March 28 Section#8)

0.01

0.1

1

10

100

1/

-

8/13/2019 z Ollinger

42/50

42

Evaluation Index (EI)Test Section 8 at Victoria

-

8/13/2019 z Ollinger

43/50

Curing IndexSection 3 and Section 8, Victoria

43

-

8/13/2019 z Ollinger

44/50

T and RH Gradient set gradient around maturity 200 deg C-hr

leads to curled up position

set gradient strain was 510-4

44

T and RH gradient of Section 8 at 8.75 hr

0

2

4

6

8

10

12

0 5 10 15 20 25

S

labThicknessfromB

ot

tom(

in)

Temperature (Deg C)

0

2

4

6

8

10

12

0.88 0.9 0.92 0.94 0.96 0.98 1

S

labThicknessfromB

ot

tom(

in)

Relative Humidity (%)

-

8/13/2019 z Ollinger

45/50

Curing Effectiveness Can be monitored in laboratory and the field

Can be indexed to strength and setting Moisture Modeling (routinely done)

Examine the factors affect set gradient of concrete

Improved calibration of cracking models

Improved concrete pavement design and

performance prediction

45

CODE BRIGHT Computational

-

8/13/2019 z Ollinger

46/50

mat1

mat4

mat5

mat3

mat6

mat2

N

M

J

K

L

P O

I

CODE_BRIGHT Computational

Code Coupled analysis in porous media Interaction with the atmosphere(Olivella, 1995;Guimares, 2002; Snchez, 2004)

Finite element in space 1D, 2D and 3D elements

Monolithic coupling

Full Newton-Raphson

Finite difference in time Implicit time discretisation scheme

Automatic time advance

Mass conservative approach for mass

balance equations User-friendly pre/post processing of data

-

8/13/2019 z Ollinger

47/50

Date EI %Cracking Cure

Mar 5th 0.814 5.6% WMR

Jun 26th 0.785 WMR- 1g/150 ft2

Jun 15-16 0.734 Lithium Relay 1g/188 ft2

0.971 Lithium Relay 1g/94ft2

-

8/13/2019 z Ollinger

48/50

-

8/13/2019 z Ollinger

49/50

Evaluation of Curing EffectivenessCuring Compound A

49

NW: No wind W: With wind NC: No Curing

-

8/13/2019 z Ollinger

50/50

Evaluation of Curing Effectiveness

50

NW: No wind

W: With wind

NC: No curing

Large aggregate particles

retaining on #8 sieve were

eliminated

all sands used are 100% passing

through #8 sieve

Curing compound A