Yarn Manufacturing BUTex

-

Upload

saad589 -

Category

Engineering

-

view

269 -

download

18

Transcript of Yarn Manufacturing BUTex

INDUSTRIAL ATTACHMENT

Welcome to OurPresentation

on

TECHNO TEXTILE &

SPINNING MILLS

Supervised byMd. Sultan Mahmud

Assistant ProfessorDept. of Yarn Manufacturing Engineering

CONTENTSCompany Profile

Blow Room

Carding

Drawing

Lap former

Comber

Simplex

Ring frame

Auto Coner M/C

CompliancePackaging

UtilityQuality Assurance

: TECHNO TEXTILES &SPINNING MILLS LTD: Spinning Mill: Private Limited Company: 100% export Oriented Company: June, 2007: Different count (18-40 Ne) cotton yarn: 8640 tons/year: Around 3.0 Billion Taka Carded Yarn Combed Yarn: 28,224: 25 tons/day : 100% Yarn Manufacturer

Company Name Type Nature of the Company Nature of the Project Year of Establishment Range of Count Annual Production

Capacity Project Cost Product Mix

Total no. of Spindle Production Capacity Type of Manufacturer Factory Location Corporate Office

87, New Eskaton 10th floor, Dhaka – 1000, Bangladesh Factory Location

Uttar Dariapur, Kaliakoir, Gazipur, Bangladesh

COMPANY AT A GLANCE

PRODUCT MIX

RING YARN

CARDED YARN

COMBED YARN

MAIN BUYERS

Jinnat Apparels.Beximco Knitting LtdUttara Knitting and dyeing LtdNew Delta Knitting LtdKnit Asia LtdRobintex Ltd. Square textile

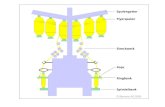

ADMINISTRATIVE STRUCTURE ChairmanDirector

GMAGMAssistant Manager

Shift Incharge

SPO

Others

Manager (maintenance)

Assistant Manager

Maintenance Engineer

Assistant Engineer

Others

Manager (quality)

Assistant Manager

Quality Officer

Assistant Quality Officer

Others

MANPOWER MANAGEMRNTDesignation Approved setup Present

status Difference

General service 72 55 17

Production 394 389 5

Quality 17 14 3

Maintenance 67 55 12

Utility 51 43 8

Total 601 556 45

SHIFT CLASSIFICATIONA-shift 6 am to 2

pm

B-shift 2 pm to 10

pm

C-shift 10 pm to 6am

DIFFERENT DEPARTMENTS

PRODUCTION DEPARTMENT

QUALITY CONTROL

AND ASSURANCE DEPARTMENT

MAINTANANCE

DEPARTMENT UTILITY

DEPARTMENT

PRODUCTION MACHINAERIES IN BLOWROOM SECTION

Capacity : 1500 kg/hourFunctions : To plucking raw material

Fig: Blendomat

PRODUCTION MACHINAERIES IN BLOWROOM SECTION

(CONTINUED)

Fig: CL-P

Capacity : 700 kg/hourFunctions : To remove dust and trash particle

PRODUCTION MACHINAERIES IN BLOWROOM SECTION

(CONTINUED)

Fig: SP-EM

Functions : To detect fire & metal

PRODUCTION MACHINAERIES IN BLOWROOM SECTION

(CONTINUED)

Fig: MX-U

Functions : To blend fiber

PRODUCTION MACHINAERIES IN BLOWROOM SECTION

(CONTINUED)

Fig: CL-C3

Functions : To remove micro dust

PRODUCTION MACHINAERIES IN BLOWROOM SECTION

(CONTINUED)

Fig: SP-F

Functions : To detect contamination

CARDING M/C

Fig: Truitzschler card

DFK opening roll : 830 rpmCard Feed roll : 6.2 – 6.8 rpmCylinder speed: 565 rpmWeb speed open : 80 rpmBlade cleaning : 20 minLicker-in speed: 1st Licker in – 1240 rpm2nd Licker in – 1935 rpm3rd Licker in – 2545 rpmFlat speed : 332 mm/minDoffer speed : 45 rpmStippling r/r speed : 225 rpmSquizing r/r speed :548 rpm

DRAWING FRAME

Manufacturer: Toyoda, Japan.No of doubling : Breaker-5 or 6 and Finisher-8Delivery speed : 300-1000 m/minGrain/Yards : 81Can size : 1000m

Fig: Toyoda D/F

TYPES OF DRAWING FRAME

MODEL NO. OF

MACHINE

DRAFTING SYSTEM

NAME OF DRAW FRAME

DX-8 3 5/4 Breaker D/F

DX-8 LT 3 5/4 Finisher D/F

LAP FORMER

Fig: Toyoda D/F

No. of machine :1Make: TOYODA, JAPANModel : SL-100No of doubling:28(max)Delivery speed: 120m/minDrafting system: 3 over 3Front roller dia: 39 mmBack roller dia: 32 mmLap dia: 650mm

COMBER

Fig: Toyoda Comber

No. of machine : 5Manufacturer: TOYODA, JAPAN.No of head: 8Delivery speed:(230-240) nips/min

Drafting system: 2 OVER 2Can size: (25mmX600mm1200mm)Can capacity : 3500 mFeed/nip: 4.9mmNoil%: (8-25)Machine rpm : 230-240 m/minTime : 1 hr per can

SIMPLEX

Fig: Simplex

No. of machine :6Manufacturer: TOYOTA, JAPANModel : FL100No of Spindle: 120Spindle speed: 1200 rpmRoller gauge : 37.5 X 49.5 X 48.5(For medium staple)Drafting system : 4 over 4Spindle gauge : 130 mmWaste % :1

RINGFRAME

Fig: Ringframe

No. of machine : 28Manufacturer: SHANGHAI ERFANGJI CO. LTD. (CHINA)Model : EGM-168No of Spindle: 1008Spindle speed: Up to 18000 rpmDrafting system : 3 over 3, PK 2025Spindle gauge : 75 mmRing dia: 38 & 40 mmLift : 7 inchMaximum draft : 60

AUTOCONER

Fig: Autoconer

Machine name : PROCESS CONERNo. of machine : 9Manufacturer: MURATEC, JAPAN.Model : 21CNO of drum : 60Delivery speed : 2000 m/minPackage weight : 2140gmPackage length : 122493mBobbin yarn length : 2863m

PACKAGING

Net wt. : 50 kgGross wt: 51.26 kg

W.P.P. :180 gm Cone wt. :40 gm with sticker Poly bag :4 gm W.P.P bag size:40” X 47” Poly bag size :16” X 16” Package wt.:2.14 kg

PRODUCTION PARAMETERS CL-P:

Waste rate- 8%Cleaning intensity- .4%

MX-U:Degree of opening- 3Production level- 100

CL-C3:Waste rate- 5%Cleaning intensity- .3%

Carding:Hank- .093Speed-116-144m/minNRE%- 52%U%- 3.3%

PRODUCTION PARAMETERS (CONTINUED)

Draw frame:Speed- 500-700m/minWaste- 0.50%Gr/ yds- 78-81

Lapformer:Speed- 115m/minWaste- 0.50%Lap wt- 78-82gm/m

Comber:Nips/min- 4230-240Feed/nip- 4.9mmNoil%- 3.5-17%

PRODUCTION PARAMETERS (CONTINUED)

Simplex:Flyer Speed- 1050-1200 rpmTPI- 0.96-1.003Hank- 0.83 neWaste- 0.50%

Ring frame:Speed- 10000-18500 rpmTPI- 19.41Count- (18-40) neWaste- 1.5-2%

Winding:Speed- 1450m/minWaste- 0.5%

PRODUCT QUALITY PARAMETERS

Carding chute:Neps/gm-575Waste%-2.0%

Carding sliver:

Neps/gm-274Waste%-52.0%

RAW MATERIALS

The factory has used the following cottons in the past years:

Cotton price:

Serial no Country of origin Micronaire01 Australia 4.5802 USA 4.6303 ZIMBABWE 4.1804 UGANDA 4.105 INDIA 4.806 UZBEKISTAN 4.5

Name Price(Rate $ per Lbs)Australia 1.5India .75CIS .90Uganda 1

BALE MANAGEMENT SYSTEM

• Way to call bales of a particular country.Growth Area Definition

• A data file is converted to .dat format to use with Uster Bale Manager.Data Import

• Imported data is observed to select usable property range & to find out highest value & lowest value of selected property

Observation• Depending upon the target QAM defines

important properties. Common choices are mic, SCI.

Defining Mix Criteria

• Catagory is the group of bales having a specific property value within a defined range.Defining Category

• Histogram displays the distribution of bales in different catagories according to the property and values set in "Catagory Definition". It is a general practice to equalize these columns as nearly as possible.

Equalizing Histogram

• This steps shoe which bales from store are to taken out and how to arrange them in the bale lay down.

Making a Mix

• Informing UBM the ID of bales which are using today.Acceptance

QUALITY ASSURANCE

USTER HVI Spectrum

USTER Tester 4

USTER AFIS Pro

Wrap Reel

Lea Strength Tester

Machineries used in QC lab:

QUALITY ASSURANCE M/C

Fig: USTER HVI

Name of the equipment:Uster High Volume Instrument (Version : Spectrum)

Measuring Modules: Length & Strength module Micronaire module Color & Trash module

QUALITY ASSURANCE M/C (CONTINUED)

Fig. USTER AFIS-PRO

Name of the Equipment:USTER ADVANCED FIBRE INFORMATION SYSTEM (AFIS)

Measurements: Neps Length & Maturity

QUALITY ASSURANCE M/C (CONTINUED)

Fig. USTER TESTER-4

Name of the Equipment : Uster tester-4 (UT-4)

Testing results: Mass variation (U%, CV%) Imperfections (Thin/km, Thick/km,

Neps/km)

Hairiness Mass Diagram Periodic faults of machine parts

STANDARD WASTE%

Blow room 3.5Cardin 6-6.5Draw frame 0.5Comber 3.5-17Simplex 0.5Ring frame 1.5-2Autoconer 1.5

UTILITY

• Manufacturer: LTG (Germany) • No of plant: 5• RH in different section:

• Blow room: 50-53%• Carding to Simplex section: 50-55% • Ring section: 50-54%• Finishing section: 55-60%

•

• Rotor: 55-60%

Humidification plant

• Manufacturer: Atlas Copco ; Model no: GA37• No of compressor: 3• Minimum air pressure: 7 Bar• Dryer: Atlas Copco FD110

Compressor

• Manufacturer: York-Shipley (U.S.A.)• Model no: 400 SPR-40-NS 93940• Steam pressure: 50 PSI• Function: Supply steam for heat setting

machine.

Boiler

• Engine: CATERPILLER • No of generators: 6• Power requirement: 4.5 MW• Type: Gas Generator

Generator

MAINTENANCE• General cleaning • Oil change in gear motors• Checking of bearings & motor shafts

BLOWROOM Once in

every 7 days

• General cleaning • Full setting / re-setting• Checking of doffer to cylinder driving gears,

bearings & motor shaft

CARDING Once in every 7

days

• General cleaning • Checking of machine gears• Roller gauge & Pressure checking / re-setting

DRAW FRAME Once in every

14 days

• General cleaning• Checking and tightening of nuts, bolt etc• Gauge checking / resetting• Top roller cot treatment / greasing

LAP FORMER

Once in every 14 days

• General cleaning • Top roller cots treatment greasing• Gauge checking / re-setting• Change of lubricating oil

COMBER Once in every 14

days

MAINTENANCE (CONTINUED)• General cleaning • Building motion setting• lubricating oil change• Top roller cot treatment • Roller gauge Pressure checking / re-setting

SPEED FRAME Once in every 14

days

• General cleaning • Inverter checking A/C (Input & Output), D.0

voltage, ring data motor• Checking of oil pump

RING FRAME Once in every 30 days

• General cleaning • Checking of cone sensor• Drum checking• Checking of drum bearing, splicing bearing,

blower shaft bearing

WINDING MACHINE Once in every 30 days

• General cleaning • Checking gearing, shaft bearing etc.

Rotor Spg. m/c Once in every 30

days

COST ANALYSIS

According to production cost:Raw material cost (30/k) ---69% of total cost

31% conversion costRaw material cost (30/c) ---58% of total cost

42% conversion cost

Export Ne Per Kg 20 Card 2.40$ 26 Card 2.50$ 28 Card 2.55$ 30 Card 2.63$ 34 Card 2.75$ 18 Combed 2.8$ 20 Combed 2.84$ 26 Combed 2.95$ 30 Combed 2.95$ 32 Combed 3.00$ 34 Combed 3.25$

COST ANALYSIS (CONTINUED)Costing of product.

Today Yarn export compliance is an unavoidable issue Compliance subjects :

Safety and health Child labors Harassment Discrimination Working hours Wage and benefits Freedom of association Environmental compliance Notice and record keeping

COMPLIANCE

THANKS

TO

ALL