Yardlines, August 2013

-

Upload

newport-news-shipbuilding -

Category

Documents

-

view

215 -

download

1

description

Transcript of Yardlines, August 2013

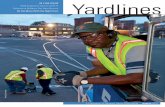

Yardlines

A Publication of Newport News Shipbuilding August 2013

IN THIS ISSUE

Career Pathways Earns High Praise

Tool Rooms at the Heart of the Shipyard

Honoring President Ford’s 100th Birthday

Phot

o by

Ric

ky T

hom

pson

Shipbuilders building Gerald R. Ford (CVN 78) – the most advanced nuclear-powered aircraft carrier – participated in a series of events July 14 to honor what would have been the 38th president’s 100th birthday.

Two ceremonies, hosted by the Gerald R. Ford Presidential Museum, were held in Ford’s hometown, Grand Rapids, Michigan.

The first included a wreath-laying ceremony in which four wreaths were placed over President Ford’s gravesite from President Barack Obama, the Ford family, the officers and crew of Gerald R. Ford, and CVN 78 shipbuilders.

CVN 78 Electrical Foreman Wilson Woods Jr. was among the small group who represented NNS shipbuilders in

Michigan for the centennial events.

“I was proud to represent our shipbuilders who are constructing the first ship in a new class of aircraft carriers that will bear President Ford’s name,” said Woods. “When we reflect on the president’s legacy as a man, father and grandfather, we are reminded that integrity goes a long way.”

Following the wreath-laying ceremony, a scale model of the CVN 78 aircraft carrier was unveiled inside the atrium of the Ford Museum.

“We are proud to be building CVN 78 – named for a man who embodied integrity, honor and courage,” NNS President Matt Mulherin said. “We are building his ship

Honoring President Ford’s

Birthdayth★★★★

★★★★★★★

★★★★★★★

★★★★★★★

★★★

★

with the same pride, quality and dedication that we have built ships with for more than a century. We take great pride in this responsibility and feel a tremendous sense of ownership in the role we play to build upon President Ford’s legacy.”

Mulherin also presented a copy of an ad featuring an illustration of President Ford that was framed in steel from the CVN 78 ship. The steel frame was handcrafted by shipbuilders David Batdorf, Steve Cannard, James “Bones” Jones, Christine Mitchell, Michael Shultz and Linwood Walker. The ad appeared in the July 14 edition of The Grand Rapids Press and will be displayed alongside the model in the museum.

Thanking NNS shipbuilders for their kindness, support and friendship through the years, Ship’s Sponsor and Ford’s daughter Susan Ford Bales said, “I have welded with you on the carrier. I have punched holes. I have turned wrenches and gone up in the shipyard’s crane. So to be called a shipbuilder makes me prouder than you’ll ever know.”

The Gerald R. Ford will be christened Nov. 9. To see video of the Ford centennial ceremonies and learn more about the Ford christening, visit thefordclass.com. | By Gina Chew-Holman

Shipbuilders join the Ford family and Navy personnel at the July 14 wreath-laying ceremony to honor Gerald R. Ford’s 100th birthday in Grand Rapids, Michigan.Photo by Ricky Thompson

Apprentice Geoffrey Monson gets a tool from one of the 12 new ergonomically-friendly toolboxes that were recommended by apprentices working in Lane 3 of the Detail Pipe Shop. Photo by Ricky Thompson

Traditionally, the Detail Pipe Shop’s Lane 3 has been a new apprentice’s introduction to the shipyard’s production and manufacturing work environment.

“Being the first stop on an apprentice’s manufacturing schedule is exciting and stressful at the same time,” said Craft Instructor Rob Teel. “It’s our responsibility to ensure that each apprentice remains safe and learns correct ways of working with and around machinery.”

Teel’s effort to keep apprentices safe is shown through results – the lane has been accident-free for the past five years. “I attribute our success to safety being part of the lane’s culture,” said Teel. “Another contributing factor is our belief that there’s always more that can be done to improve ourselves, our team and our product.”

So when apprentices came to Teel with a list of potential lane improvements, he welcomed them. “Our recommendations included ways to rearrange our lane to make it safer, more ergonomically pleasing and efficient,” said William Harris.

Teel reviewed the list with his leadership and within a week came back to the apprentices with good news. “When we found out that the majority of our recommendations were approved, we were all excited,” said Joel Prichard.

The apprentices began implementing

the changes right away. “The first change we made was replacing old welding machines with new thermal arc machines,” said Harris. “The old machines were loud and took up a lot of space. With the new machines, we gained 5 feet of additional real estate!”

Apprentice Josh King added, “We also rerouted the air, Tig and argon lines and the power cables. This change not only eliminated tripping hazards, but also made the lines more easily accessible.”

Twelve new toolboxes were added to the lane. “The updated new toolboxes are placed on stands to make them more ergonomic,” said King. “Now, we don’t have to lean down or squat to get the tools we need to complete our job.”

Other changes included replacing floor-standing fans with new overhead fans to open up floor space, adding brazing reels to allow lines to be neatly coiled, and furnishing two new material lay-down tables so pipe and fittings could be staged off the ground, preventing leg and back injuries.

“We’re still thinking of other ways to improve our lane,” said Harris. “But for now, these improvements have made our lane safer, improved our workflow and organization, and given us extra space. It’s always a good feeling when your opinions are considered and become a reality.” I By Lauren Ward

OpinionsMaking

Count

Talyr Janus easily locates tools in one of the shipyard’s 18 tool rooms. The tool room’s 60-member team services more than 2,000 employees daily and maintains an inventory of nearly 210,000 tools. Photo by John Whalen

Building ships would be impossible without having the right tools for the job. At Newport News Shipbuilding (NNS), the tool rooms provide employees with everything they need for construction, from hard hats to heavy-duty machinery. But managing a huge assortment of equipment is no small task.

“There’s a new challenge every day,” said Warren Doyle, general foreman of the tool rooms. “It’s not only about providing what shipbuilders need, but also providing the right tool for the right guy and making sure it’s safe when it goes out.”

The 18 tool rooms spread throughout the shipyard currently maintain 23,565 calibrated tools; 173,688 serialized, unique tools; and 11,923 different hand tools.

To help keep track of everything, the tool room’s 60-member team uses a database management system.

Master Shipbuilder Judy Weatherly oversees the database system and has seen firsthand how technology has improved tool room operations. “It tracks inventory, helps us with orders and recalls, and keeps us organized,” explained Weatherly.

With so many different types of tools, learning the best use, location and safety precautions of each one could be a daunting process but Talyr Janus has it down to a science. “I used to waitress and work in retail, so both have helped me with memorization,” said Janus, “I just keep organized, and if you try to memorize something every day it will click.”

Janus also credits her father for her tool-savvy ways. “I would help him fix cars when I was younger, so I already knew some tools before coming to NNS.”

Marcus Amerson, who came to the shipyard a little less than a year after serving in the U.S. Navy for four years, enjoys the tool room environment. “After serving on two carriers, knowing that I have a helping hand in building one along with the submarines is amazing,” said Amerson.

Denise Peoples agrees that building Navy ships is a huge accomplishment. She works in the tool room next to Ford and estimates that she interacts with more than 250 people each day. Peoples has been working in the tool room for 33 years. “From the keel-laying to the end, I have seen what men and women can do with their hands and it’s amazing,” said Peoples. “And I feel joy knowing our team has helped take part in that.”

Roy McCullen, a 46-year Master Shipbuilder, has worked in every NNS tool room. He’s proud to have trained generations of shipbuilders to learn the right tools for the right job. “If you don’t train, you can’t get the job done and, in return, you can’t build the ship. To me, it’s one of the biggest assets,” said McCullen, whose favorite part is helping people do the right job safely and efficiently.

To all the men and women of the tool rooms, it’s more than just a job. They are providing a vital line to the heart of the shipyard. At the end of the day, running the tool room is really all about the shipbuilders.

“We’re a customer service, customer-oriented business,” said Doyle “We pretty much interact with everyone in the yard. If you have a hard hat on, you’ve come in contact with one of our people.” | By Rehn West

TheToolB

usiness

PerfectPracticemakes

Working in accordance with the Detail Pipe Shop’s hard-hat safety variance, Top Gun Welder Mark Paine uses a fixed head automatic tig welding machine to create flawless welds. Photo by Rick Thompson

In the middle of the night, while most people are fast asleep, shipbuilder Mark Paine is busy performing some of the most complex welds in the business – and welding them quickly and perfectly.

Paine is currently one of a small group of automated radiographic testing (RT) pipe welders at Newport News Shipbuilding (NNS). As an RT welder, virtually every weld Paine completes is required to be inspected through RT – a nondestructive testing method used to inspect materials for flaws the human eye cannot see.

“It’s important that the details I weld are flawless,” said Paine, who had zero rejected RT welds last year. “Most of the pipes I work on will eventually have chemicals and gases running through them that could potentially be harmful to the sailors on the boat if the pipe were to leak. To prevent that from happening, the pipes are sent through an X-ray machine for inspection.”

Paine is a strong believer in the old phrase, “practice makes perfect,” and has been perfecting his welding skills for the past 37 years. “I started my career at the shipyard as a hand welder working on new carrier construction, then moved to the Detail Pipe Shop to work on pipes – and I have been there ever since,” he said.

“Most people are surprised to find out I use a machine to weld,” he said. “I can guarantee you it’s a lot harder than it looks. The machine I work on is called a fixed head automatic tig welding machine. To get it to weld the way I want, the wire-feed, voltage, amps, temperature and pipe must all be precise.”

Throughout Paine’s time in the Detail Pipe Shop, he has worked on every submarine since the mid-1960s and has gained membership into the “Top Gun Welders,” the Component Fabrication and Assembly’s most elite club of welders. During his eight-year tenure as a “Top Gun Welder,” he has produced the most satisfactory RT welds of any welder at NNS.

Paine has also taken his skill a step further with several inventions to positively impact the welding community. “My first invention was a small ‘turning roller’ used to turn small pipes,” said Paine. “And my second was an ‘adjustable arm jig’ that is mounted to the turn table of my machine. Its main purpose is to allow us to be able to automatically weld pipes with awkward bends in them. Without this tool, most pipe joints with awkward bends would have to be hand-welded.”

The “Top Gun Welder” vows to continue leading the RT welding community. He says, “As long as I’m making my job and the job of other welders around me more convenient and efficient – I’m happy.” | By Lauren Ward

What began as a pilot initiative with Newport News City schools has spread throughout the Peninsula and the south side of Hampton Roads. In just four years, Newport News Shipbuilding’s (NNS) Career Pathways program has engaged with more than 26,000 Hampton Roads students, teachers and parents.

“In 2009, Newport News City schools approached area businesses to establish a Career Pathways chapter for the city to help students learn about different career paths, six initiatives were highlighted: internships, work-site opportunities, job-shadowing, middle school partnerships, club activities and guest speaking,” said John Shifflett, director of Leadership, Professional and Technical Development.

“NNS was the only business to sign up for all six initiatives,” Shifflett added. “Different departments throughout the yard took on the initiatives and, after a year, we decided to formalize the Career Pathways activities under a single office, assign a dedicated staff and grow the program.”

Since this shift, Career Pathways has grown exponentially in both the number of students and NNS volunteers involved – more than 300 volunteers in 2013 so far – because of the program’s active presence from Virginia Beach to Chesapeake to Gloucester.

Stressing career readiness skills, these volunteers dedicate time to career fairs, guest speaking events and club activities like boat-building contests and egg-drop competitions. The events focus on STEM (science, technology, engineering and math) fields that high school and even middle school students can set their sights on. The partnerships help students learn about shipbuilding and, in turn, provide NNS with a wider talent pool for potential job applicants.

“Career Pathways is helping reshape misconceptions about the shipyard,” said Sherri Thompson, manager of Career Pathways. “We’re showing teachers and students throughout Hampton Roads what the shipbuilding industry is all about to help them understand and get them excited about new career opportunities here.”

Shauntel Foster, a Career Pathways lead who began

as a volunteer, said, “Newport News City schools want students to be college-, citizen- and career-ready, so Career Pathways offers a number of different opportunities to meet this goal. In the last year, we’ve hired students who first came to NNS through our job-shadowing programs.”

Career Pathways’ partnership with Heritage High School has received particularly high praise, winning several awards, including Virginia’s statewide Creating Excellence Award.

“In the coming school year, we plan to utilize the new Career Pathways office at Heritage High as a permanent resource center to conduct mock interviews, review résumés and get students in touch with NNS recruiters

FROM Schoolyard

TO Shipyard

Paving the Way

and mentors,” said Thompson. “It’s a great link between the school and the shipyard.”

Speaking at the 2013 Career Pathways Volunteer Recognition Luncheon, Toinette Outland, program administrator of Heritage High School Governor’s STEM Academy, said, “NNS’ Career Pathways has done so much for our local schools. NNS mentors have helped students learn about future careers; they’ve volunteered as judges during our science fairs, acted as guest speakers, and have even served on our curriculum-writing teams.”

Career Pathways Lead Gordon Sproat said, “In this summer alone, Career Pathways has supported an internship for local teachers at the yard, treated local

clubs to egg-drop and boat-building contests, and supported a summer camp for 7th-, 8th- and 9th-graders dedicated to STEM. We’re always looking to expand and help out the community, from doing more events to visiting more schools.”

Any NNS employee interested in volunteering at a Career Pathways event can contact the Career Pathways team at [email protected]. | By Phoebe Doty

Designer Christopher Bryans challenges Hampton Roads area high school students’ skills in a duct tape boat-building contest, one of several special events sponsored by the Newport News Shipbuilding Career Pathways program to educate students about engineering as a career. Photo by Ricky Thompson

TIME CAPSULE

NNS welder Shaun Woroneski welds a time capsule containing commemorative items into the island of the aircraft carrier Gerald R. Ford (CVN 78). Photo by John Whalen

More than 25 shipbuilders and Navy personnel gathered July 11 in the flight deck control room of the nuclear-powered aircraft carrier Gerald R. Ford (CVN 78) to witness the welding of a time capsule. It contained special coins, official seals representing President Ford’s service to the nation, and a sandstone piece cut from the same stone used in the construction of the White House and the United States Capitol. The items had been previously placed under the 555-metric-ton island during a ceremony in January by Susan Ford Bales, the ship’s sponsor, as well as shipyard and Navy leadership.

Rolf Bartschi, vice president of carrier construction, said, “I would like to recognize the shipbuilders who have been working day and night to get Gerald R. Ford 100 percent structurally complete. I couldn’t be more proud.”

Capt. John F. Meier assumed command of the ship July 8. “Gerald R. Ford was first and foremost a man of integrity, and he was also a man of humility,” he said at the event. “What a great ideal for today’s sailor and today’s shipbuilder and, truly, for all of us as a nation.”

Welders Shaun Woroneski and Jerry Womack welded the time capsule shut. “I was honored to be a part of this event,” said Woroneski.

Womack agreed. “It was very exciting. Everything went smoothly and according to plan.”

The time capsule will stay sealed for the next 25 years, until the ship returns for its refueling and complex overhaul. | By Rehn West

Art and music are really important to Newport News Shipbuilding Electrical Designer Monica Clark. “Everyone is talented in some form of art,” said Clark. “We just have to find it within ourselves.”

Clark has been playing the clarinet with the all-volunteer Hampton Roads Metro Band (HRMB) for eight years. Her daughter Alicia, one of the younger members of the band, enjoys sharing the stage with her mother when she is in town. ”Volunteering for the band allows me to use my talent to touch other people,” explained Clark. “Our music can lift the spirits of everyone, especially those who don’t usually have those types of musical opportunities.”

Since 1934, HRMB has been entertaining audiences at special events, assisted-living facilities, retirement homes, charitable organizations, churches and synagogues. The more than 90 members of the band perform a diverse repertoire of music, from patriotic

selections, Broadway musicals, Big Band, and easy-listening genres.

NNS Communications Technician Wiley Williams leads HRMB’s trombone section. He has been playing music since he was 3 years old, and has mastered several instruments, including saxophone, trombone, guitar and piano. As a professional musician, he has played with Sheila Ray, the Virginia Symphony Orchestra, and Bones Apart, one of the most renowned brass groups in the world.

“I love music, but what I love more is when I see the lights in people’s eyes. Then I know we’ve had a positive impact and made a difference in that person’s life, “said Williams. | By Jeremy Bustin

Music of the Heart

Making a Difference

Shipbuilders Monica Clark and Wiley Williams, members of the all-volunteer Hampton Roads Metro Band, prepare for a concert at Virginia Beach Town Center.Photo by Dar Deerfield-Mook

Donald Cherry

40 years

Phillip Eley

40 years

Earl Long

40 years

Willard Hunt

40 years

Jackie Newby

40 years

Darrell Bergeron

40 years

Gus Johnson

40 years

Dave Brookman

40 years

Michael King

40 years

Jim Leber

40 years

Warner Parker

40 years

Long ServiceMASTER SHIPBUILDERS

“Willie D” Crandell

40 years

Michael “Huckabuck” Hucks

40 yearsStanley Jackson

40 years

Frank Cherry

40 years

Willie “Baseball” Turner

40 years

Linwood “Big Man” Gorham

40 years

Arthur Lewis

40 years

Sylvester “Sly” Cooper

40 years

Darrell Harrison

45 years

Willie Jenkins

40 years

James Cheek

40 years

Mike Carr

40 years

JULY

Dan Brookman

40 years

Ella Yarborough

40 years

Long ServiceJULY

45 YEARSWilliam R. Colligan O68Darrell Harrison X88

40 YEARSDarrell J. Bergeron O15Daniel L. Brookman O22David L. Brookman X88Michael L. Carr X75James E. Cheek O43Donald G. Cherry X33James F. Cherry X33Phil P. Clarke X67Sylvester Cooper Jr. X33Willie Crandell X33Phillip R. Eley X33Linwood E. Gorham X33

Patrick H. Haynes III O87Michael E. Hucks X33Willard M. Hunt Jr. X33Stanley A. Jackson X88Willie A. Jenkins Jr. X33Gustavus Johnson II X33Michael W. King X70James B. Leber X87Arthur L. Lewis X36Earl Long X88Jackie R. Newby X33Steve T. Oliver X36Warner L. Parker Jr. X82John W. Savage X82Willie L. Turner X33Ella B. Yarborough T54

35 YEARSTimothy L. Bean X58Johnny N. Chappell M53James P. Connolly X89William R. Fralich X73Karen D. Kennedy O20Richard M. Snow E72

30 YEARSWilliam L. Bassett X71James E. Cecelic E84Timothy H. Christian X33Robert L. Corbin O15William L. Dunbar E14Richard K. Gregory X88David A. Haskiell O83Todd J. Krenzer E17

Robert B. Rhodes E22Donna Shannon AMSECMichael A. Via E83James R. Wei E74

25 YEARSVirginia Alexander-Scheiderer K74Leroy L. Bossetti E71Douglas M. Brown E51James E. Bullock X33Christopher E. Casper X32Sharon L. Christensen X72Jonathan S. Dansereau O87Robert S. Diggs T53Caffee A. First X33Willie C. Gilbert AMSEC

Thominice Hargett E88Cary L. Harris O54Steven A. Hoagland E83Christopher A. Holloway X18Joseph A. Kimbel E17Charles F. Lewis X18Robin D. Malarkey O51Thomas S. Mason E17Robert. F. McClaren AMSECHildrew L. McNair X33Leon McWilliams X33Joseph C. Murdock E80John R. Natterer K81Garry F. Parks O19Gayneal D. Parris T56William A. Rhodes X42

Demond D. Shepard X33Milton L. Slade X33Jenifer L. Solomon E80Timothy B. Stull X15Jeffrey C. Tatum E84James T. Tunstall O68Tommy D. Worthington X58Dennis S. Yeldell E84

20 YEARSVictor R. Albea E82Andrew W. Eshelman A572Jesse C. Johnson X88William Jones X10

RetirementsJUNE

Thomas R. Adair O15Maurice M. Adams M53

Junie J. Bell X31Clarence J. Bishop X11

Robert A. Goodwin E41Terry W. Lapoint N206

Genard I. Patrick E86Patricia J. Stewart E88

Phillip H. Thomas O53Clinton M. Turner X11

Donald T. Wallace O37

Yardlines is published 10 times a year for the employees of Newport News Shipbuilding.

This issue of Yardlines was produced by: Jeremy Bustin, Gina Chew-Holman, Troy Cooper, Mike Dillard, Phoebe Doty, Christie Miller, Eugene Phillips, LaMar Smith, Peter Stern, Susan Sumner, Lauren Ward and Rehn West. Photographs by: Chris Oxley, Ricky Thompson and John Whalen.

Send comments, questions and story ideas to Yardlines editor: [email protected] or call 757-380-2627.

To stop receiving Yardlines, go to nns.huntingtoningalls.com/Yardlines to unsubscribe.

Look for more news at nns.huntingtoningalls.com.

CRAFTSMAN • Crane Operators• Fitters• Insulators• Machinists• Marine Electricians• Marine Painters

• Pipe Fitters• Pipe Welders• Refuelers• Riggers• Stage Builders• Sheet Metal Workers

ENGINEERING • Electrical• Manufacturing• Material Process/Welding • Mechanical • Nuclear, Quality, Structural,

and Systems Engineering

Some IT and engineering positions are eligible for referral bonuses from $1,000 to $3,000.For more information about the Employee Referral Program,

visit the HII Careers site at www.huntingtoningalls.com/careers/refer.

HELP WANTEDYOUR help is needed to fill several hundred craftsman, information technology (IT) and engineering positions available at Newport News Shipbuilding. If you know someone who would be a great fit, encourage them to

apply at www.huntingtoningalls.com/careers. Employee referrals can also be sent to [email protected].

August 2013

4101 Washington Ave.

Newport News, VA 23607

PRST STD U.S. POSTAGE

PAID EAU CLAIRE WI PERMIT NO. 366

Yardlines is printed on recycled paper with vegetable-based inks.

Dribble-drilling basketball campers work under the eyes of Apprentice School Basketball Coach Dickran Parunak during a July 12 one-day camp held for children of Newport News Shipbuilding employees. The free camp was led by coaches Parunak and Franklin Chatman and featured members of the Apprentice School’s men’s and women’s basketball teams. More than 70 particpants received hands on instruction, lunch and a camp T-shirt. Photo by Chris Oxley.

Teaching the Art of Basketball