XD Series - Air Atomising Nozzle - Spray Technologies · 2016. 12. 2. · 38 SECTION E - AIR...

Transcript of XD Series - Air Atomising Nozzle - Spray Technologies · 2016. 12. 2. · 38 SECTION E - AIR...

SECTION E - AIR ATOMISING NOZZLE 37

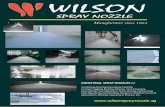

XD Series - Air Atomising NozzleNozzle Features

Design Options

XD series atomising nozzle are specially designed to evenly mix liquid and gas to generate fine, medium or large spray droplets. Each spray assembly consists of an air cap and fluid tip and are available in many flow and spray pattern combinations, including flat fan, full cone and hollow cone. All spray assemblies are interchangeable and therefore provide flexibility for your spray requirements.

STANDARD MODELXD series standard air atomising spray nozzle is designed with a hex plug. Inlet sizes available are 1/8” or 1/4” NPT or BSPT female.

XD SERIES - SHUT-OFFXD series shut-off air atomising spray nozzle is designed with an adjustable needle assembly to fine tune flow. Inlet sizes available are 1/8” or 1/4” NPT or BSPT female.

XD SERIES - CLEAN-OUTXD series clean-out air atomising spray nozzle is designed with a push button needle assembly to clear out debris build-up in fluid tip. Inlet sizes available are 1/8” or 1/4” NPT or BSPT female.

XD SERIES - SHUT-OFF / CLEAN-OUTXD series shut-off / clean-out air atomising spray nozzle is designed with both adjustable and push button needle assembly to fine tune flow and clear out debris build-up in fluid tip. Inlet sizes available are 1/8” or 1/4” NPT or BSPT female.

XD SERIES - THICK WALLXD series thick wall adapter air atomising spray nozzle is designed to allow nozzle to be held securely when fitted through a thick fixture. Inlet sizes available are 1/8” or 1/4” NPT or BSPT female.

XD SERIES - THIN WALLXD series thin wall adapter air atomising spray nozzle is designed to allow nozzle to be held securely when fitted through a thin fixture. Inlet sizes available are 1/8” or 1/4” NPT or BSPT female.

XDJ SERIES - AUTOMATIC XDJ series automatic air atomising nozzle is designed with an inner air cylinder allows the ‘on - off’ control operation which can cycle up to 180 times per minute.

XDJS SERIES - COMBINED XDJS series combined air atomising nozzle is designed with one air port to operate both cylinder air and nozzle air. XDJS series requires a minimum 2.0 BarG (30 psi) to open air cylinder and can cycle up to 180 times per minute.

XDJM SERIES - MINI XDJM series mini air atomising nozzle is designed with one air port to operate both cylinder air and nozzle air. XDJM series requires a minimum 2.0 BarG (30 psi). XDJM series mini is ideal for confined spaces.

Applicationsnn Static Control

nn Humidifying

nn Mould Lubrication

nn Deodorising

nn Air Disinfection

nn Sanitizer Sprays

SECTION E - AIR ATOMISING NOZZLE

38 SECTION E - AIR ATOMISING NOZZLE

XD Series - Air Atomising Nozzle

SPRAY ASM

FLUID TIP &

AIR CAP

FLOW RATE (l/ph) SPRAY COVERAGE

Water - 0.7 BarG Water - 1.5 BarG Water - 2.0 BarG Water - 3.0 BarG Water - 4.0 BarG Air

(BarG)Water (BarG)

X (mm)

Y (mm)

Z (mm)

L (mm)Air

(BarG)Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

SA-24BFT31

& AC439

0.7 5.5 1.44 1.3 9.1 1.86 2.0 8.6 2.52 2.7 11.2 3.12 3.9 12.0 4.14 1.1 0.7 250 360 460 2.60.9 4.7 1.62 1.5 7.7 2.16 2.2 7.5 2.82 3 10.1 3.36 4.6 9.7 4.86 2.1 1.5 360 480 660 3.01.0 4.1 1.86 1.8 6.5 2.52 2.5 6.2 3.12 3.2 9.1 3.72 5.3 7.5 5.58 2.8 2.0 380 530 760 3.21.1 3.5 2.04 2.1 5.4 2.82 2.8 5.2 3.42 3.5 8.1 3.96 6.0 5.3 6.24 3.5 3.0 470 610 860 3.41.3 3.0 2.22 2.4 4.3 3.12 3.1 4.2 3.78 4.2 5.4 4.74 6.3 4.3 6.6 6.0 4.0 560 740 940 4.01.4 2.5 2.4 2.7 3.3 3.42 3.2 3.7 3.9 4.6 4.2 5.1 6.7 3.3 6.96 - - - - - -1.5 2.0 2.64 2.8 2.8 3.6 3.4 3.2 4.08 4.9 3.1 5.46 7.0 2.4 7.32 - - - - - -

SA-24FT39

& AC439

0.9 8.2 1.2 1.4 14.4 1.62 2.1 13.5 2.16 2.7 19.1 2.52 4.6 16.1 4.141.0 6.8 1.38 1.7 11.9 1.92 2.4 11.4 2.52 3.0 17.1 2.76 4.9 13.8 4.56 1.1 0.7 360 460 710 2.11.1 5.5 1.62 2.0 9.5 2.22 2.7 9.2 2.82 3.2 15.1 3.12 5.3 11.5 4.98 2.1 1.5 430 610 810 2.41.3 4.1 1.8 2.1 8.3 2.4 3.0 7.1 3.18 3.5 13.1 3.42 5.6 9.3 5.4 3.0 2.0 510 660 890 2.61.4 2.9 2.04 2.2 7.1 2.58 3.2 5.0 3.54 4.2 8.1 4.32 6.0 7.3 5.82 3.5 3.0 580 760 970 2.7- - - 2.4 6.1 2.76 3.4 4.0 3.78 4.6 5.9 4.74 6.3 5.6 6.24 5.6 4.0 580 760 970 3.2- - - 2.5 5.1 2.94 3.5 3.3 3.96 4.9 4.0 5.16 6.7 4.3 6.72 - - - - - -

SA-O24FT39

& AC446

1.0 9.0 1.5 2.0 10.4 2.46 2.4 11.6 2.88 3.1 15.6 3.36 4.2 17.1 4.38 1.4 0.7 100 130 170 31.1 7.8 1.8 2.1 9.3 2.7 2.5 10.4 3.06 3.2 14.6 3.54 4.6 15.0 4.8 2.5 1.5 130 150 200 3.71.3 6.6 1.92 2.2 8.2 2.88 2.7 9.4 3.24 3.4 13.7 3.72 4.9 12.8 5.22 3.2 2.0 130 170 220 4.01.4 5.2 2.16 2.5 6.1 3.3 3.0 7.3 3.66 3.8 10.8 4.26 5.3 11.0 5.64 3.8 3.0 150 220 280 4.21.7 3.1 2.64 2.8 4.3 3.72 3.2 5.5 4.08 4.2 8.5 4.92 5.6 9.4 6.18 5.3 4.0 200 250 330 4.82.0 2.0 3.0 3.1 3.0 4.14 3.5 4.1 4.5 4.9 5.2 5.88 6.3 7.2 7.14 - - - - - -2.2 1.1 3.36 3.4 2 4.5 3.8 2.9 4.86 6.0 2.3 7.2 7.0 6.1 8.04 - - - - - -

SA-25FT39

& AC431

1.3 3.9 1.8 2.1 7.4 2.4 3 6.1 3.12 3.9 9.4 3.6 5.3 10.2 4.68 1.5 0.7 250 330 460 1.81.4 3.0 1.98 2.4 5.3 2.7 3.1 5.3 3.24 4.2 7.2 4.02 5.6 8.3 5.04 2.7 1.5 360 510 690 2.01.5 2.3 2.1 2.5 4.4 2.82 3.2 4.5 3.42 4.6 5.3 4.38 6.0 6.6 5.34 3.2 2.0 480 580 740 2.01.7 1.8 2.28 2.7 3.7 3.0 3.4 3.8 3.54 4.9 3.8 4.8 6.3 5.1 5.88 4.2 3.0 610 740 940 2.11.8 1.3 2.46 2.8 3.1 3.12 3.5 3.2 3.72 - - - - - - 5.6 4.0 640 760 970 2.32.0 1.0 2.64 3.0 2.6 3.3 3.9 1.8 4.08 - - - - - - - - - - - -- - - 3.1 2.1 3.42 - - - - - - - - - - - - - - -

SA-O34FT71

& AC6451

1.0 17 1.38 2.0 24 2.64 2.4 28.0 3.06 3.4 38.0 4.32 3.9 65 4.5 1.1 0.7 100 130 150 2.41.1 11 1.62 2.1 18.9 3.0 2.5 23.0 3.54 3.5 33.0 4.8 4.2 53 5.34 2.1 1.5 100 130 170 3.01.3 7.6 1.98 2.2 14.4 3.36 2.7 18.9 3.96 3.7 28.0 5.34 4.6 40.0 6.48 2.8 2.0 130 170 220 3.41.4 3.2 2.4 2.4 10.6 3.78 2.8 15.1 4.44 3.8 23.0 5.82 4.9 30.0 7.62 3.7 3.0 150 200 280 3.6- - - 2.5 7.2 4.26 3.0 11.7 4.74 3.9 19.7 6.3 5.3 21.0 8.94 4.9 4.0 200 250 350 4.0- - - - - - - - - 4.2 13.1 7.2 5.6 13.8 10.4 - - - - - -- - - - - - - - - 4.6 7.2 8.28 6.3 3.2 13.5 - - - - - -

SA-O34CFT51

& AC6439

1.1 11.2 3.24 2.1 18.0 4.74 2.7 19.6 5.58 3.5 27.0 6.72 4.6 33.0 8.22 1.4 0.7 150 180 200 31.3 8.5 3.6 2.2 15.8 5.04 2.8 17.3 5.88 3.7 25.0 6.96 4.9 28.0 8.94 2.4 1.5 230 280 330 3.21.4 6.5 3.9 2.4 13.6 5.34 3.0 15.2 6.18 3.8 23.0 7.26 5.3 24.0 9.66 3.0 2.0 250 330 400 3.41.5 5.0 4.26 2.5 11.6 5.7 3.1 13.2 6.54 3.9 21.0 7.56 5.6 19.7 10.4 3.7 3.0 300 380 460 3.51.7 3.8 4.62 - - - 3.2 11.4 6.84 4.1 18.9 7.92 6.0 15.7 11.2 5.3 4.0 330 410 480 4.0- - - - - - - - - 4.2 17.0 8.22 6.3 12.4 12.0 - - - - - -

SA-34FT71

& AC6439

0.9 27.0 1.98 1.8 38.0 3.3 2.4 39.0 4.02 3.2 58.0 4.56 4.6 59.0 6.36 1.1 0.7 180 230 300 3.41.0 20.0 2.28 2.1 28.0 3.96 2.7 30.0 4.62 3.5 47.0 5.22 5.3 40.0 7.92 2.4 1.5 230 300 410 3.51.1 15.9 2.7 2.2 24.0 4.26 3.0 24.0 5.22 3.8 38.0 5.82 5.6 32.0 8.7 3.2 2.0 250 330 430 3.71.3 12.5 2.88 2.4 21.0 4.56 3.2 17.8 5.88 3.9 34.0 6.18 6.0 26.0 9.48 3.9 3.0 300 380 480 3.81.4 10.2 3.36 2.5 17.8 4.92 3.4 15.1 6.18 4.2 27.0 6.78 6.3 20.0 10.3 6.0 4.0 330 410 510 4.41.5 7.6 3.72 2.7 15.1 5.22 3.5 12.9 6.54 4.6 20.0 7.56 6.7 15.9 11.1 - - - - - -- - - - - - 3.7 10.6 6.84 4.9 14.8 8.4 7.0 12.7 11.9 - - - - - -

SA-54FT211

& AC9462

1.0 29.0 5.4 1.8 56.0 7.02 2.1 100.0 7.14 3.0 126.0 8.4 4.1 140.0 10.9 1.0 0.7 180 200 250 3.41.1 18.9 6.48 2.0 40.0 7.98 2.2 79 7.98 3.1 110.0 9.06 4.2 125.0 11.6 1.8 1.5 250 300 430 3.8- - - - - - 2.4 62 8.82 3.2 95.0 9.78 4.6 89.0 13.5 2.4 2.0 250 300 460 4.3- - - - - - 2.5 48 9.72 3.4 78.0 11.0 4.9 58.0 15.9 3.4 3.0 330 410 530 4.6- - - - - - 2.7 36 10.6 3.5 62.0 11.6 5.3 34.0 18.3 4.9 4.0 360 430 580 5.2- - - - - - - - - 3.7 48.0 12.6 5.6 16.7 20.4 - - - - - -

Performance Data

XD-FP FLAT FAN SPRAY - PRESSURE METHOD

Flat Fan Spray Pattern

150mm250mm

400mm

Z Y

L

X

Nozzle Features

XD series flat fan internally mixed atomising nozzles produce fine spray particles in spray angles of approximately 75° to 90°. The pressure method system allows the supply of liquid to the fluid tip under pressure. The liquid is then mixed internally in chamber with compressed air to produce a flat fan spray pattern.

Ordering Example Available Materials1/4-XD-FP-SS-SA54 ENPB, 303ss, 316ss

* Other materials available on request

SECTION E - AIR ATOMISING NOZZLE 39

Full Cone Spray Pattern

LY

X

XD Series - Air Atomising Nozzle

Performance Data

XD-RP FULL CONE SPRAY - PRESSURE METHOD

SPRAY ASM

FLUID TIP &

AIR CAP

FLOW RATE (l/ph) SPRAY COVERAGE

Water - 0.7 BarG Water - 1.5 BarG Water - 2.0 BarG Water - 3.0 BarG Water - 4.0 BarG Air

(BarG)Water (BarG)

Spray Angle

X (deg)

Y (mm)

L (mm)Air

(BarG)Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

SA-22FT31

& AC258

0.7 2.5 0.96 1.1 6.4 0.72 1.4 6.4 0.84 2.7 6.2 1.38 3.5 7.8 1.68 - - - - -

0.9 1.8 1.14 1.4 5.0 0.9 1.7 5.5 1.02 2.8 5.7 1.5 3.7 7.3 1.74 0.9 0.7 13 300 3.0

1.0 1.4 1.32 1.7 4.1 1.14 2.0 4.5 1.2 3.0 5.2 1.62 3.9 6.4 1.98 1.7 1.5 13 330 3.0

- - - 1.8 3.4 1.2 2.2 3.4 1.44 3.1 4.7 1.74 4.2 5.5 2.28 2.5 2.0 13 360 3.0

- - - 2.0 3.0 1.38 2.4 3.0 1.56 3.2 4.3 1.86 4.5 4.5 2.58 3.1 3.0 14 390 4.0

- - - 2.1 2.6 1.5 2.5 2.5 1.68 3.4 3.9 1.98 4.6 4.1 2.7 4.5 4.0 15 440 4.0

- - - 2.2 2.0 1.62 2.7 2.3 1.86 3.7 3.0 2.28 4.8 3.7 2.82 - - - - -

SA-23BFT31

& AC271

0.7 2.5 1.14 1.4 5.7 1.62 1.7 6.7 1.74 2.2 9.2 2.04 2.8 11.9 2.34 - - - - -

0.9 2.0 1.32 1.5 5.2 1.74 1.8 6.4 1.86 2.5 8.2 2.34 3.1 11.0 2.58 0.9 0.7 12 430 4.0

1.0 1.6 1.56 1.7 4.8 1.92 2.0 5.9 2.04 2.8 7.2 2.64 3.4 10.1 2.82 1.5 1.5 13 460 4.0

- - - 1.8 4.3 2.1 2.1 5.2 2.22 3.0 6.7 2.82 3.7 9.2 3.12 2.4 2.0 13 480 4.0

- - - 2.0 3.9 2.22 2.2 4.8 2.4 3.1 6.3 2.94 3.9 8.4 3.48 3.0 3.0 13 510 5.0

- - - 2.1 3.4 2.4 2.4 4.3 2.58 3.2 5.9 3.12 4.2 7.6 3.72 3.9 4.0 15 560 5.0

- - - - - - 2.7 3.6 2.88 3.4 5.5 3.3 4.5 6.8 4.08 - - - - -

SA-23FT39

& AC271

0.9 4.8 1.26 1.7 8.4 1.86 2.0 10.7 1.98 2.7 16.5 2.22 3.4 20.0 2.58 - - - - -

1.1 4.1 1.62 1.8 7.5 2.1 2.1 9.8 2.22 2.8 15.4 2.28 3.7 18.4 2.82 1.5 0.7 12 480 4.0

1.4 3.4 1.98 2.0 7.0 2.22 2.4 8.2 2.52 3.1 13.6 2.58 3.9 16.8 3.0 2.5 1.5 13 510 4.0

1.5 3.1 2.1 2.2 5.7 2.64 2.7 6.8 2.88 3.4 11.8 2.94 4.2 15.2 3.3 3.0 2.0 13 530 5.0

1.7 3.0 2.34 2.5 4.8 2.94 3.0 5.9 3.3 3.7 10.4 3.3 4.5 13.8 3.6 3.4 3.0 14 560 5.0

1.8 2.9 2.46 2.8 4.1 3.24 3.2 5.0 3.54 3.9 9.1 3.66 4.8 12.4 3.9 4.2 4.0 15 600 5.0

2.0 2.8 2.64 3.1 3.6 3.54 3.5 4.1 3.9 4.2 7.9 3.9 4.9 11.8 4.08 - - - - -

SA-33BFT51

& AC2221

1.1 13 4.56 2.2 17.8 6.96 2.8 20 8.16 3.4 32 8.94 4.6 37 11.6 - - - - -

1.4 8.9 5.46 2.5 13.1 7.8 3.1 16.3 8.94 3.9 25 10.2 5.3 29.0 13.2 1.7 0.7 18 660 5.0

1.5 7.2 5.88 2.8 9.5 8.58 3.4 11.9 9.78 4.6 15.9 12.3 5.6 25.0 14.1 2.8 1.5 20 760 6.0

1.7 5.8 6.3 3.1 7.0 9.42 3.9 7.0 11.2 5.3 9.1 14.4 6.0 21.0 15.0 3.9 2.0 20 810 7.0

1.8 4.7 6.72 3.4 4.9 10.3 4.2 4.7 12.3 5.6 6.8 15.3 6.3 17.4 16.2 5.3 3.0 21 910 8.0

2.0 3.6 7.14 3.5 4.2 10.7 4.6 3.0 13.2 6.0 5.0 16.5 6.7 14 17.4 6.0 4.0 21 970 9.0

2.1 2.7 7.62 - - - - - - 6.3 3.6 17.4 7 11 18.3 - - - - -

SA-33FT71

& AC2221

0.9 31 3.42 1.4 61.0 4.14 2.1 53.0 5.76 2.7 80.0 6.18 3.8 88.0 8.1 - - - - -

1.0 25 3.96 1.5 54.0 4.56 2.4 41.0 6.72 3.0 69.0 7.02 4.2 73.0 9.36 1.0 0.7 17 610 5.0

1.1 18.5 4.5 1.7 48.0 5.1 2.7 31.0 7.62 3.2 59.0 7.8 4.6 61.0 10.6 1.8 1.5 18 690 6.0

1.3 12.9 5.1 1.8 41.0 5.58 2.8 26.0 8.16 3.5 49.0 8.76 4.9 48 11.8 2.8 2.0 20 760 7.0

- - - 2.0 35.0 6.12 3.0 22.0 8.64 3.7 44.0 9.24 5.3 39 12.9 3.5 3.0 20 790 7.0

- - - 2.1 30.0 6.6 - - - 3.8 37.0 9.66 5.6 31 14.4 4.9 4.0 21 910 9.0

- - - 2.2 25.0 7.14 - - - 3.9 35.0 10.2 6.0 23 15.6 - - - - -

SA-O34CFT51

& AC2236

1.0 44.0 5.16 1.4 125.0 4.74 2.0 123.0 6.48 2.2 199.0 5.28 3.0 250 5.94 - - - - -

1.1 32.0 6.12 1.5 106.0 5.46 2.1 108.0 7.14 2.5 174.0 6.6 3.2 225 7.2 1.0 0.7 19 890 6.0

- - - 1.7 87.0 6.3 2.2 95.0 7.8 2.8 146.0 7.98 3.5 205 8.46 1.7 1.5 20 990 7.0

- - - 1.8 70.0 7.08 2.4 79.0 8.58 3.1 121.0 9.24 3.8 182 9.78 2.4 2.0 21 1040 8.0

- - - 2.0 55.0 7.8 2.5 64.0 9.3 3.2 108.0 9.96 4.1 159 11.0 3.1 3.0 21 1070 8.0

- - - - - - 2.7 52.0 9.96 3.4 95.0 10.6 4.6 121 13.5 3.8 4.0 22 1170 9.0

- - - - - - 2.8 42.0 10.7 3.5 84.0 11.2 4.9 93 15.3 - - - - -

Nozzle Features

XD series full cone internally mixed atomising nozzles produce very fine spray particles in spray angles of approximately 10° to 20°. The pressure method system allows the supply of liquid to the fluid tip under pressure. The liquid is then mixed internally in chamber with compressed air to produce a full cone spray pattern.

Ordering Example Available Materials1/4-XD-RP-E-SA33 ENPB, 303ss, 316ss

* Other materials available on request

40 SECTION E - AIR ATOMISING NOZZLE

XD Series - Air Atomising Nozzle

Performance Data

Nozzle Features

XD series externally mixed flat fan atomising nozzles produce fine spray particles in spray angles of approximately 55° to 90°. The pressure method system supplies liquid to the fluid tip, liquid exits fluid tip, then mixes with compressed air externally of the nozzle air cap and forms a flat spray pattern.

Ordering Example Available Materials1/4-XD-FEP-316SS-SAF29C ENPB, 303ss, 316ss

* Other materials available on request

SPRAY ASM

FLUID TIP &

AIR CAP

FLOW RATE (l/ph) SPRAY COVERAGE

Water - 0.7 BarG Water - 1.5 BarG Water - 2.0 BarG Water - 3.0 BarG Water - 4.0 BarG Air

(BarG)Water (BarG)

X (mm)

Y (mm)

Z (mm)

L (mm)Air

(BarG)Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

SA-F29CFT27

& AC35171

0.4 - 1.32 0.4 - 1.32 0.4 - 1.5 0.6 - 1.68 0.7 - 2.04 0.6 0.7 230 300 400 1.8

0.4 - 1.5 0.4 - 1.5 0.6 1.68 0.7 - 2.04 1.1 - 2.7 0.6 1.5 280 350 460 1.8

- 3.0 - - 4.0 - - 5.0 - - 8.0 - - 11.0 - 1.1 1.5 280 330 430 2.4

0.5 - 1.62 0.6 - 1.68 0.7 - 2.04 1.1 - 2.7 1.8 - 3.72 1.4 1.5 250 300 410 2.7

0.6 - 1.68 0.7 - 2.04 0.9 - 2.4 1.4 - 3.24 2.5 - 4.74 1.1 2.0 280 350 480 2.6

- - - - - - - - - - - - - - - 1.4 3.0 300 380 510 2.7

SA-F26CFT27

& AC33956

0.2 - 1.51 0.4 - 1.58 0.7 - 1.87 1.4 - 2.72 2.8 - 4.38 0.2 0.2 90 150 230 0.9

0.4 - 1.58 0.7 - 1.87 1.1 - 2.38 1.8 - 3.23 3.5 - 5.1 1.1 0.2 90 150 230 1.2

0.7 - 1.87 1.1 - 2.38 1.4 - 2.72 2.1 - 3.57 4.2 - 6.12 1.4 0.4 100 150 230 1.2

1.1 3.0 2.38 1.4 4.0 2.72 1.8 5.0 3.23 2.8 8.0 4.42 4.9 11.0 7.14 1.4 1.4 120 180 250 1.5

1.4 - 2.72 1.8 - 3.23 2.1 - 3.56 3.5 - 5.1 5.3 - 7.65 1.8 0.7 120 150 240 1.5

1.8 - 3.23 2.1 - 3.56 2.8 - 4.42 4.2 - 6.12 5.6 - 8.34 2.8 1.4 130 180 280 1.8

2.1 - 3.56 2.8 - 4.42 3.5 - 5.1 5.6 - 8.34 6.3 - 9.54 4.9 2.8 150 180 240 2.4

- - - - - - - - - - - - - - - 0.7 0.3 280 330 400 1.5

SA-F29BFT31

& AC35171

0.4 - 1.32 0.4 - 1.32 0.6 - 1.68 0.7 - 2.04 1.1 - 2.7 1.1 0.7 300 380 480 2.1

0.6 - 1.68 0.7 - 2.04 0.7 - 2.04 1.4 - 3.24 1.4 - 3.24 0.7 1.5 380 460 580 1.8

- 5.0 - - 6.0 - - 8.0 - - 12.0 - - 17.0 -- 1.4 1.5 350 430 560 2.4

0.7 - 2.04 1.1 - 2.7 1.4 - 3.24 2.1 - 4.26 2.1 - 4.26 2.5 1.5 330 400 510 3.0

1.1 - 2.7 1.4 - 3.24 2.1 - 4.26 2.5 - 4.74 2.5 - 4.74 1.8 2.0 380 460 580 2.7

- - - - - - - - - - - - - - - 1.8 3.0 410 480 660 2.9

SA-F26BFT31

& AC33956

0.4 - 1.58 0.7 - 1.87 1.1 - 2.38 1.8 - 3.23 3.2 - 4.92 0.4 0.2 80.0 140 220 1.0

0.7 - 1.87 1.1 - 2.38 1.4 - 2.72 2.1 - 3.56 3.5 - 5.1 1.4 0.2 90.0 150 220 1.7

1.1 - 2.38 1.4 - 2.72 1.8 - 3.23 2.8 - 4.42 4.2 - 6.12 1.8 0.4 100 170 230 1.8

1.4 5.0 2.72 1.8 6.0 3.23 2.1 8.0 3.56 3.5 12.0 5.1 4.9 17.0 7.14 1.8 1.4 130 190 290 2.1

1.8 - 3.23 2.1 - 3.56 2.8 - 4.42 4.2 - 6.12 5.3 - 7.62 2.1 0.7 130 180 250 1.8

2.1 - 3.56 2.8 - 4.42 3.5 - 5.1 4.9 - 7.14 6.3 - 9.54 3.5 1.4 130 220 300 2.4

2.8 - 4.42 3.5 - 5.1 4.2 - 6.12 6.3 - 9.54 6.7 - 9.84 5.3 2.8 150 190 250 3.0

- - - - - - - - - - - - - - - 0.6 0.3 350 480 610 1.8

SA-F29FT39

& AC35171

0.4 - 1.5 0.4 - 1.5 0.4 - 1.5 0.7 - 2.04 1.4 - 3.24 0.6 0.7 350 480 630 1.5

0.5 - 1.65 0.6 - 1.68 0.6 - 1.68 0.9 - 2.4 1.8 - 3.72 0.7 1.5 380 480 630 1.8

- 9.0 - - 10.0 - - 16.0 - - 23.0 - - 33.0 - 1.1 1.5 410 510 660 2.1

0.6 - 1.68 0.7 - 1.86 0.7 - 2.04 1.1 - 2.7 2.1 - 4.26 1.4 1.5 430 530 660 2.4

0.7 - 2.04 0.7 - 2.04 0.9 - 2.4 1.4 - 3.24 2.5 - 4.74 1.8 2.0 410 510 690 2.7

- - - - - - - - - - - - - - - 2.1 3.0 410 510 690 2.9

SA-F26FT39

& AC33956

0.7 - 1.87 1.1 - 2.38 1.4 - 2.72 2.5 - 4.08 3.5 - 5.1 0.7 0.2 130 170 250 1.2

1.1 - 2.38 1.4 - 2.72 1.8 - 3.23 2.8 - 4.42 4.2 - 6.12 1.8 0.2 130 170 250 1.8

1.4 - 2.72 1.8 - 3.23 2.1 - 3.56 3.5 - 5.1 4.9 - 7.14 2.1 0.4 130 180 240 1.8

1.8 9.0 3.23 2.1 10.0 3.56 2.8 16.0 4.42 4.2 23.0 6.12 5.3 33.0 7.62 2.5 1.4 140 200 320 1.8

2.1 - 3.56 2.8 - 4.42 3.5 - 5.1 4.9 - 7.14 5.6 - 8.34 2.8 0.7 140 190 300 2.3

2.8 - 4.42 3.5 - 5.1 4.2 - 6.12 5.6 - 8.34 6.3 - 9.54 4.2 1.4 140 200 360 3.0

3.5 - 5.1 4.2 - 6.12 4.9 - 7.14 6.3 - 9.54 7.0 - 10.56 5.3 2.8 170 200 300 4.0

XD-FEP EXTERNAL MIX FLAT FAN - PRESSURE METHOD

Flat Fan Spray Pattern

150mm250mm

400mm

Z Y

L

X

SECTION E - AIR ATOMISING NOZZLE 41

XD Series - Air Atomising Nozzle

Ordering Example Available Materials1/4-XD-FEP-316SS-SAF39C ENPB, 303ss, 316ss

* Other materials available on request

SPRAY ASM

FLUID TIP &

AIR CAP

FLOW RATE (l/ph) SPRAY COVERAGE

Water - 0.7 BarG Water - 1.5 BarG Water - 2.0 BarG Water - 3.0 BarG Water - 4.0 BarG Air

(BarG)Water (BarG)

X (mm)

Y (mm)

Z (mm)

L (mm)Air

(BarG)Water (LPH)

Air (m³h)Air

(BarG)Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

SA-F39CFT35

& AC228160

- - - - - - - - - - - - - - - 1.4 0.3 330 380 480 3.80.6 - 5.46 0.7 - 6.12 1.4 - 9.36 2.1 12.6 3.2 - 17.1 2.1 0.7 330 400 560 4.30.7 - 6.12 1.1 - 7.8 2.1 - 12.6 2.8 15.6 4.2 - 21.6 2.1 1.5 350 460 580 4.0- 13.0 - - 16.0 - - 25.0 - - 37.0 - - 52.0 - 3.2 1.5 380 480 660 4.6

1.1 - 7.8 1.8 - 11.0 2.5 - 14.1 3.5 - 18.6 5.3 - 25.8 4.2 1.5 380 480 640 5.21.4 - 9.36 2.1 - 12.6 2.8 - 15.6 4.2 - 21.6 5.6 - 27.3 3.9 2.0 410 510 710 4.9

SA-F36CFT46

& AC536656

0.7 - 5.1 1.0 - 6.12 1.4 - 6.96 2.5 - 10.7 3.2 - 12.7 0.7 0.2 130 190 250 1.71.0 - 6.12 1.4 - 6.96 1.8 - 8.34 2.8 - 11.7 3.5 - 13.9 1.8 0.2 130 190 250 2.71.4 - 6.96 1.8 - 8.34 2.1 - 9.36 3.5 - 13.6 3.9 - 15.3 2.1 0.4 150 190 280 3.01.8 13.0 8.34 2.1 16.0 9.36 2.5 25.0 10.7 4.2 37.0 16.0 4.2 52.0 16.5 2.5 0.7 150 220 280 3.52.1 - 9.36 2.8 - 11.7 2.8 - 11.7 4.9 - 18.7 4.9 - 18.8 2.5 1.4 170 230 360 3.72.8 - 11.7 3.5 - 13.6 3.5 - 13.6 5.6 - 21.6 5.6 - 21.6 4.2 1.4 170 230 370 4.33.5 - 13.6 4.2 - 16.0 4.2 - 16.0 6.3 - 24.7 6.3 - 24.7 4.9 2.8 170 220 320 4.9

SA-F39BFT51

& AC339271

- - - - - - - - - - - - - - - 1.1 0.2 330 380 510 3.50.6 5.46 0.7 6.12 1.1 7.8 2.5 14.1 3.5 18.6 - - - - - 1.8 0.7 350 480 640 3.01.1 7.8 1.4 9.36 1.8 11.0 3.2 17.1 4.6 22.8 - - - - - 2.5 1.5 380 460 640 3.8- 18.0 - - 22.0 - - 33.0 - - 48.0 - - 68.0 - 3.2 1.5 330 430 610 4.3

1.4 9.36 1.8 11 2.5 14.1 3.9 19.8 6.0 28.5 - - - - - 4.2 1.5 300 430 580 4.91.8 11.0 2.1 12.6 2.8 15.6 4.2 21.6 6.7 31.5 - - - - - 4.2 2.0 330 430 610 5.2- - - - - - - - - - - - - - - 4.9 3.0 330 430 600 4.0

SA-F36BFT51

& AC536656

0.7 - 5.1 1.4 - 6.96 1.8 - 8.34 2.8 - 11.7 3.5 - 13.9 0.7 0.4 150 190 270 2.11.0 - 6.12 1.8 - 8.34 2.1 - 9.36 3.2 - 12.7 4.2 - 16.5 1.8 0.7 150 190 270 3.01.4 - 6.96 2.1 - 9.36 2.5 - 10.7 3.5 - 13.6 4.9 - 18.8 2.5 1.4 150 220 330 3.41.8 18.0 8.34 2.5 22.0 10.7 2.8 33.0 11.7 4.2 48.0 16.0 5.3 68.0 20.4 2.8 1.4 150 220 360 3.82.1 - 9.36 2.8 - 11.7 3.5 - 13.6 4.9 - 18.7 5.6 - 21.6 2.8 1.4 170 250 370 4.02.8 - 11.7 3.5 - 13.6 4.2 - 16.0 5.6 - 21.6 6.3 - 24.7 4.2 2.1 170 250 370 4.93.5 - 13.6 4.2 - 16.0 4.9 - 18.7 6.3 - 24.7 6.6 - 25.7 5.3 2.8 180 230 360 5.8

SA-F39FT71

& AC339271

- - - - - - - - - - - - - - - 2.1 0.3 400 560 760 3.00.7 - 6.12 1.1 - 7.8 1.8 - 11.0 3.2 - 17.1 5.3 - 25.8 2.8 0.7 460 580 810 4.01.1 - 7.8 1.4 - 9.36 2.1 - 12.6 3.5 - 18.6 6.0 - 28.5 3.2 1.5 480 580 790 4.3- 36.0 - - 45.0 - - 68.0 - - 100 - - 141 - 4.6 1.5 430 530 760 4.9

1.4 - 9.36 2.1 - 12.6 2.8 - 15.6 4.9 - 24.3 6.7 - 31.5 5.6 1.5 380 510 660 5.81.8 - 11.0 2.5 - 14.1 3.2 - 17.1 5.9 - 27.3 7.0 - 33 3.9 2.0 480 640 840 4.3- - - - - - - - - - - - - - - 6.3 3.0 410 560 790 5.8

SA-F36FT71

& AC536656

1.0 - 6.12 1.8 - 8.34 2.5 - 10.7 3.2 - 12.7 3.9 - 15.3 1.0 0.2 150 200 250 2.71.4 - 6.96 2.1 - 9.36 2.8 - 11.7 3.5 - 13.6 4.2 - 16.5 2.1 0.2 150 220 290 3.01.8 - 8.34 2.5 - 10.7 3.2 - 12.7 3.9 - 14.8 4.6 - 17.8 2.8 0.4 180 240 360 3.52.1 36.0 9.36 2.8 45.0 11.7 3.5 68.0 13.6 4.2 100 16.0 4.9 141 18.8 3.2 1.4 200 280 390 3.72.5 - 10.7 3.2 - 12.7 4.2 - 16 4.9 - 18.7 5.6 - 21.6 3.5 0.7 190 270 380 4.02.8 - 11.7 3.5 - 13.6 4.9 - 18.7 5.6 - 21.6 6.3 - 24.7 4.2 1.4 200 280 390 4.33.5 - 13.6 4.2 - 16.0 5.6 - 21.6 6.3 - 24.7 7 - 27.2 5.6 2.8 180 240 380 5.9

SA-F56CFT7126

& AC138956

1.8 - 14.1 1.8 - 14.1 2.5 - 18.0 3.9 - 24.6 - - - 1.8 0.2 150 200 290 3.02.1 - 15.6 2.1 - 15.6 2.8 - 19.8 4.2 - 26.7 - - - 2.8 0.2 150 200 300 3.42.5 - 18.0 2.5 - 18 3.2 - 21.3 4.6 - 28.8 - - - 2.8 0.3 150 200 300 4.02.8 36.0 19.8 2.8 45.0 19.8 3.5 68.0 22.8 4.9 100 31.2 - - - 3.5 0.7 170 220 320 4.33.2 - 21.3 3.2 - 21.3 3.9 - 24.6 5.3 - 33.9 - - - 3.9 1.5 170 220 340 4.63.5 - 22.8 3.5 - 22.8 4.2 - 26.7 5.6 - 36.0 - - - 4.2 1.0 170 230 330 4.74.2 - 26.7 4.2 - 26.7 4.9 - 31.2 6.3 - 41.1 - - - 4.9 1.5 170 230 340 5.5

SA-F56BFT9126

& AC138956

2.1 - 15.6 2.8 - 19.8 3.9 - 24.6 4.9 - 31.2 - - - 2.1 0.2 170 240 340 3.52.5 - 18.0 3.2 - 21.3 4.2 - 26.7 5.3 - 33.9 - - - 3.2 0.2 180 240 360 4.32.8 - 19.8 3.5 - 22.8 4.6 - 28.8 5.6 - 36.0 - - - 3.9 0.3 180 250 360 4.93.2 64.0 21.3 3.9 78.0 24.6 4.9 119 31.2 6.0 175 38.4 - - - 4.9 0.7 180 250 360 5.53.5 - 22.8 4.2 - 26.7 5.3 - 33.9 6.3 - 41.1 - - - 4.9 1.5 200 250 380 5.54.2 - 26.7 4.9 - 31.2 5.6 - 36.0 - - - - - 5.3 1.0 180 250 380 5.84.9 - 31.2 5.6 - 36.0 6.3 - 41.1 - - - - - 5.6 1.5 200 250 380 6.1

SA-F56FT211

& AC138956

2.8 - 19.8 3.5 - 22.8 4.6 - 28.8 5.6 - 36.0 - - - 2.8 0.2 190 250 360 4.63.2 - 21.3 3.9 - 24.6 4.9 - 31.2 6.0 - 38.4 - - - 3.9 0.2 200 250 370 4.93.5 - 22.8 4.2 - 26.7 5.3 - 33.9 6.3 - 41.1 - - - 4.6 0.3 200 250 370 5.23.9 102 24.6 4.6 125 28.8 5.6 192 36.0 280 - - - - - 5.3 0.7 220 270 380 5.54.2 - 26.7 4.9 - 31.2 6.0 - 38.4 - - - - - - 5.6 1.0 220 270 410 5.54.6 - 28.8 5.3 - 33.9 6.3 - 41.1 - - - - - - 5.6 1.5 220 270 410 5.84.9 - 31.2 5.6 - 36 - - - - - - - 6.0 1.5 220 270 410 6.1

Performance Data

EXTERNAL MIX FLAT FAN - PRESSURE METHOD

42 SECTION E - AIR ATOMISING NOZZLE

XD Series - Air Atomising Nozzle

Performance Data

Nozzle Features

XD series cone internally mixed atomising nozzles produce fine spray particles in spray angles of approximately 65° to 75°. The pressure method system allows the supply of liquid to the fluid tip under pressure. The liquid is then mixed internally in chamber with compressed air to produce a hollow cone spray pattern.

Ordering Example Available Materials1/4-XD-RWP-316SS-SA27 ENPB, 303ss, 316ss

* Other materials available on request

SPRAY ASM

FLUID TIP &

AIR CAP

FLOW RATE (l/ph) APPROX. SPRAY COVERAGE

Water - 0.7 BarG Water - 1.5 BarG Water - 2.0 BarG Water - 3.0 BarG Water - 4.0 BarG Air

(BarG)Water (BarG)

X (mm)

Y (mm)

Z (mm)

L (mm)Air

(BarG)Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

Air (BarG)

Water (LPH)

Air (m³h)

SA-27FT31

& AC73181

0.6 5.3 0.6 1.1 8.1 0.79 1.5 8.1 0.92 2.4 8.9 1.24 3.1 10.5 1.44 0.7 0.7 140 180 230 1.5

0.7 4.3 0.72 1.3 7.0 0.88 1.8 6.6 1.09 2.7 8.1 1.4 3.4 9.7 1.68 1.4 1.5 150 190 240 1.8

0.9 3.0 0.84 1.4 6.4 0.94 2.1 4.9 1.32 3.0 6.4 1.66 3.9 7.8 2.16 1.8 2.0 160 200 250 2.1

1.0 1.7 1.02 1.5 5.5 1.01 2.4 3.2 1.68 3.2 4.9 1.92 4.2 6.1 2.52 3.0 3.0 160 200 260 2.7

- - - 1.7 4.5 1.16 - - - 3.4 4.2 2.13 4.6 4.4 2.82 3.9 4.0 190 230 300 4.0

- - - 1.8 3.5 1.3 - - - 3.5 3.4 2.33 4.9 2.8 3.24 - - - - - -

SA-37BFT51

& AC74881

0.9 7.0 3.0 1.7 13.2 4.08 2.0 18.5 4.08 2.8 25.0 5.04 3.7 31.0 5.76 - - - - - -

1.0 2.1 3.72 1.8 9.8 4.74 2.1 15.1 4.56 3.0 22.0 5.52 3.8 28.0 6.3 - - - - - -

- - - - - - 2.2 11.7 5.1 3.1 18.5 6.06 3.9 26.0 6.78 0.9 0.7 180 240 310 1.8

- - - - - - - - - 3.2 15.1 6.54 4.1 23.0 7.32 1.7 1.5 190 250 330 2.4

- - - - - - - - - 3.4 12.1 7.14 4.2 20.0 7.8 2.1 2.0 190 250 330 3.2

- - - - - - - - - 3.5 9.1 7.8 4.6 13.6 9.18 3.2 3.0 200 260 340 4.1

- - - - - - - - - 3.7 6.1 8.52 4.9 6.8 11.0 4.1 4.0 210 280 370 5.9

SA-37FT71

& AC74881

1.1 12.3 2.4 2.2 16.3 3.72 2.7 21.0 4.14 4.2 19.3 6.0 5.6 22.0 7.8 - - - - - -

1.3 9.9 2.7 2.5 12.1 4.26 3.0 16.3 4.68 4.6 14.6 6.78 6.0 17.6 8.52 - - - - - -

1.4 7.9 3.0 2.8 8.9 4.74 3.2 12.3 5.16 4.9 10.8 7.44 6.3 14.0 9.12 1.5 0.7 150 190 230 2.7

1.5 6.1 3.24 3.0 7.6 4.98 3.4 10.7 5.46 5.3 8.1 8.1 6.7 11.4 9.78 3.0 1.5 160 200 240 4.6

1.7 4.9 3.48 3.1 6.4 5.22 3.5 9.3 5.64 5.6 6.2 8.76 7.0 9.1 10.4 3.4 2.0 160 200 240 5.5

1.8 3.9 3.72 3.2 5.5 5.46 3.9 6.4 6.3 6.0 4.9 9.42 - - - 5.3 3.0 180 220 250 7.3

2.0 3.1 4.02 3.4 4.7 5.7 4.2 4.7 6.9 6.3 4.0 10.0 - - - 6.3 4.0 190 240 280 9.4

SA-40FT71

& AC76381

0.7 24.0 1.92 1.4 43.0 2.22 2.1 33.0 3.96 2.8 52.0 3.9 3.7 63.0 4.08 - - - - - -

0.9 13.6 2.64 1.5 35.0 2.94 2.2 26.0 4.68 3.0 46.0 4.56 3.8 58.0 4.74 - - - - - -

1.0 7.6 3.42 1.7 28.0 3.66 2.4 18.9 5.34 3.1 39.0 5.22 4.0 52.0 6.06 0.9 0.7 190 250 360 2.1

- - - 1.8 21.0 4.26 2.5 11.7 6.0 3.2 33.0 5.94 4.2 41.0 6.66 1.5 1.5 200 270 370 3.2

- - - - - - - - - 3.4 26.0 6.6 4.6 27.0 8.28 2.4 2.0 200 270 370 4.1

- - - - - - - - - 3.5 19.5 7.32 4.9 15.9 9.96 3.2 3.0 200 280 380 5.0

- - - - - - - - - 3.7 13.2 7.98 - - - 3.9 4.0 200 280 390 6.8

SA-41FT51

& AC74671

1.3 36 5.1 2.1 57.0 6.96 3.1 53.0 9.36 4.2 64.0 11.8 5.6 74.0 14.7 - - - - - -

1.5 29.0 6.12 2.4 51.0 7.8 3.2 50.0 9.78 4.9 51.0 13.8 6.0 68.0 15.6 - - - - - -

1.8 23.0 7.02 2.7 45.0 8.58 3.4 47.0 10.2 5.6 40.0 15.9 6.3 62.0 16.8 2.0 0.7 200 250 330 5.5

2.0 19.7 7.5 3.0 39.0 9.42 3.5 45.0 10.6 6.0 34.0 17.1 6.7 56.0 17.7 3.0 1.5 200 270 340 6.4

2.1 16.7 7.98 3.2 33.0 10.2 3.9 38.0 11.6 6.3 28.0 18.0 7.0 51.0 18.9 3.9 2.0 220 280 370 8.2

2.3 14.0 8.52 3.5 28.0 11.1 4.6 25.0 13.8 6.7 22.0 19.2 - - - 6.0 3.0 230 290 380 9.1

2.4 11.4 8.94 4.2 13.6 13.2 4.9 18.5 14.7 7.0 17.8 20.1 - - - 6.3 4.0 240 320 400 10.4

SA-57FT211

&AC77381

2.0 15.1 10.7 3.2 27.0 15.3 3.7 41.0 16.5 5.3 36.0 22.5 6.7 62.0 27.6 3.2 1.5 250 340 470 6.4

2.1 11.4 11.6 3.4 23.0 15.9 3.9 27.0 18 5.6 26.0 24.3 7.0 52.0 29.7 3.9 2.0 280 370 510 7.3

2.3 7.6 12.3 3.5 18.5 16.8 4.1 23.0 18.6 6.0 18.9 26.1 - - - 5.3 3.0 290 380 530 7.9

- - - 3.7 14.8 17.4 4.2 18.9 19.2 6.3 13.6 27.6 - - - 6.3 4.0 330 420 580 9.8

- - - - - - 4.4 15.9 20.1 - - - - - - - - - - - -

XD-RWP SPRAY - PRESSURE METHOD

Cone Spray Pattern

150mm250mm

400mm

ZY

L

X

SECTION E - AIR ATOMISING NOZZLE 43

XD Series - Air Atomising Nozzle

siphon system

liquid

liquidgravity system

air

air

siphon system

liquid

liquidgravity system

air

air

siphon system

liquid

liquidgravity system

air

air

SPRAY ASM

FLUID TIP &

AIR CAP

Air (BarG)

Air Flow (m³h)

FLOW RATE (l/ph) Coverage @ 200mm Siphon Height

GRAVITY METHOD SIPHON METHOD Air (BarG)

Spray Angle

X (deg)

Y (mm)

L (mm)450mm 300mm 150mm 100mm 200mm 300mm 600mm 900mm

SA-2BFT27

& AC75

0.7 0.66 1.5 1.3 1.1 0.9 0.7 0.5 - - 0.7 18 280 1.81.5 1.02 1.8 1.7 1.5 1.3 1.2 1.1 0.6 - 1.5 18 280 1.93.0 1.68 2.1 1.9 1.7 1.5 1.4 1.3 1.1 0.8 3.0 18 300 2.34.0 2.16 2.2 2.0 1.8 1.6 1.5 1.4 1.2 0.9 4.0 18 360 2.6

SA-2FT31

& AC75

0.7 0.78 24 2.1 1.7 1.5 1.2 0.8 - - 0.7 18 300 2.11.5 1.2 2.8 2.6 2.4 2.1 1.9 1.6 0.9 - 1.5 18 330 2.33.0 1.92 3.4 3.1 2.9 2.8 2.6 2.4 1.7 1.1 3.0 18 380 2.64.0 2.46 3.7 3.4 3.3 3.1 2.9 2.7 2.1 1.5 4.0 19 430 3

SA-3BFT31

& AC81

0.7 1.38 2.5 2.3 2.0 1.6 1.4 1.1 - - 0.7 18 300 2.41.5 2.16 2.9 2.8 2.5 2.2 2.0 1.7 0.9 - 1.5 18 330 2.73.0 3.48 3.4 3.3 3.2 2.9 2.8 2.5 1.9 1.2 3.0 19 380 3.44.0 4.44 3.7 3.6 3.5 3.4 3.3 3.0 2.5 2.0 4.0 20 430 4

SA-3FT39

& AC81

0.7 1.14 4.5 4.0 3.4 21.0 1.8 1.4 - - 0.7 21 380 31.5 1.86 5.3 4.9 4.4 3.5 2.9 2.7 1.8 - 1.5 21 410 3.43.0 3.0 6.0 5.6 5.0 4.4 4.0 3.4 2.4 1.2 3.0 21 460 44.0 3.9 5.7 5.4 5.0 4.2 3.9 3.5 2.8 1.9 4.0 22 510 4.6

SA-5FT71

& AC231

1.5 3.48 22.0 19.9 16.3 12.3 10.5 8.3 2.8 - 1.5 17 460 3.73.0 5.28 25.0 23.0 19.5 16.7 14.2 11.5 6.4 2.8 3.0 18 510 4.34.0 6.66 26.0 24.0 21.0 18.4 15.7 12.9 7.9 4.5 4.0 18 530 4.95.6 8.82 26.0 24.0 22.0 19.7 17.0 14.6 9.8 6.1 5.6 19 580 5.5

SA-6FT211

& AC291

2.0 8.64 - - 27.0 22.0 16.8 - - 2.0 20 510 6.73.0 11.4 - - 30.0 26.0 21.0 - - 3.0 20 530 7- 14.4 - 43.0 40.0 31.0 28.0 23.0 11.0 - 4.0 21 580 7.6

5.6 18.9 44.0 42.0 39.0 31.0 28.0 24.0 16.7 8.3 5.6 22 630 8.2

SPRAY ASM

FLUID TIP &

AIR CAP

Air (BarG)

Air Flow (m³h)

FLOW RATE (l/ph) Coverage @ 200mm Siphon Height

GRAVITY METHOD SIPHON METHOD Air (BarG)

X (mm)

Y (mm)

Z (mm)

L (mm)450mm 300mm 150mm 100mm 200mm 300mm 600mm 900mm

SA-G2FT39

& AC531

0.7 1.68 1.3 1.2 1.1 1.0 1.0 0.8 0.6 0.5 0.7 200 260 380 2.11.5 2.58 1.2 1.1 1.0 0.9 0.9 0.8 0.7 0.5 1.5 210 290 380 2.12.0 3.0 0.8 0.8 0.7 0.6 0.5 - - - 2.0 230 300 380 1.8

SA-G3DFT46

& AC543

1.5 3.36 3.7 3.5 3.3 2.9 2.8 2.5 2.3 2.1 1.5 230 320 380 2.72.0 3.9 3.4 3.3 3.1 2.8 2.7 2.6 2.4 2.2 2.0 240 340 420 2.73.0 5.22 2.8 2.7 2.5 2.4 2.2 2.1 1.9 1.7 3.0 270 370 460 3.04.0 6.6 1.9 1.8 1.6 1.5 1.3 1.2 - - 4.0 280 390 480 2.7

SA-G4CFT51

& AC546

1.5 4.08 5.1 4.8 4.5 3.8 3.7 3.5 3.0 2.4 1.5 190 230 270 3.42.0 4.68 4.9 4.7 4.4 3.6 3.4 3.2 2.9 2.3 2.0 200 250 280 3.43.0 6.18 3.4 3.2 3.0 2.2 2.0 1.7 3.0 - - 220 270 300 3.03.5 7.02 2.2 2.0 1.7 - - - - - - - - - -

SA-G5CFT51

& AC551

1.5 3.78 7.6 7.2 6.6 5.7 5.4 5.1 4.6 3.7 1.5 170 220 270 3.42 4.38 7.6 7.3 6.8 5.9 5.7 5.5 5.0 4.2 2.0 180 230 290 3.43 5.76 6.4 6.1 5.7 5.0 4.5 4.1 3.3 - 3.0 200 270 330 3.4

3.5 6.6 4.2 3.7 3.2 2.6 - - - - - - - - -

Performance Data

Performance Data

XD-FG FLAT FAN SPRAY - GRAVITY & SIPHON METHOD

XD-RG FULL CONE SPRAY - GRAVITY & SIPHON METHOD

Nozzle Features

XD series flat fan and full cone siphon / gravity fed internally mixed air atomising nozzles produce very fine spray particles in spray angles of approximately 10° to 85°. The siphon / gravity fed method system draws / feeds the supply of liquid once compressed air is initiated, mixed internally in chamber to produce a spray pattern.

Flat Fan Spray Pattern

150mm250mm

400mm

Z Y

L

X

Full Cone Spray Pattern

LY

X

Ordering Example Available Materials1/4-XD-RG-316SS-SA3B ENPB, 303ss, 316ss

* Other materials available on request