WÄRTSILÄ -...

Transcript of WÄRTSILÄ -...

issue no.

012012Tw

enty

four

7.

WÄRTSILÄ TECHNICAL JOURNAL

[ WWW.WARTSILA.COM ]

Flexibility in dispatching Modelling power systems

15

21

ENERGY

MARINE

34

Smaller scale LNG deliveriesLogistics model can open new markets

Composite technologyWärtsilä solutions for seals and bearings

LNG conversions A viable option for environmental compliance

55

page04

COVER STORY

SMART POWER

GENERATION FOR

the oil and gas industry

DEAR READER

issue no. 01.2012 in detail

E-mail and feedback: [email protected]

2 in detail

Flexibility in power generation . . . . . . . . . . . . . . . . . . . . .4

GD power plant conversions . . . . . . . . . . . . . . . . . . . . . . .9

Forecasting power demand . . . . . . . . . . . . . . . . . . . . . . 15

Facilitating smaller-scale LNG availability . . . . . . . . 21

System support enhances use of renewables . . . . . 26

Ancillary services secure power supply quality . . . 31

New composite seal and bearing technology . . . . . 34

LLC offers additional levels of redundancy . . . . . . . 40

Blending on Board improves lubrication . . . . . . . . . . 47

LNG conversion for marine installations . . . . . . . . . . 55

Wärtsilä 32 has greater power output . . . . . . . . . . . . 61

Publisher: Wärtsilä Corporation, John Stenbergin ranta 2,

P.O. Box 196, FIN-00531 Helsinki, Finland | Editor-in-Chief: Marit Holmlund-Sund | Managing Editor and Editorial Office:

Tarja Vuorela | English editing: Tom Crockford, Crockford

Communications | Editorial team: Kärt Aavik, Stephane Debiastre,

Niklas Haga, Marit Holmlund-Sund, Tom Kreutzman, Dan Pettersson,

Marialuisa Viani, Virva Äimälä | Layout and production:

Otavamedia Ltd., Kynämies, Helsinki, Finland | Printed: May 2012

by PunaMusta, Joensuu, Finland ISSN 1797-0032 | Copyright ©

2012 Wärtsilä Corporation | Paper: cover Lumiart Silk 250 g/m²,

inside pages Berga Classic 115 g/m²

ENERGY

MARINE

Contents

The Wärtsilä-powered Antelope Station facility is providing grid stabilisation services in West Texas, one of the USA's premier wind farm locations (more on page 26).

THIS ISSUE OF IN DETAIL is also available on iPad as a Wärtsilä iPublication app from Apple's Appstore, as well as in a browsable web version at http://indetailmagazine.com/.

WÄRTSILÄ CONTINUES to strive to provide, both for land and

sea based applications, power and propulsion solutions that

are reliable, sustainable and affordable. For these are the

shared demands of power plant and ship owners throughout

the world, and a few of Wärtsilä's innovations to meet the

current and future needs of its customers can be seen in this

issue of In Detail.

SMART POWER GENERATION is an outstanding example of

this far-sighted vision in not only responding to the present

situation, but in anticipating the likely requirements of the

energy sector in the years ahead. As utilities everywhere

continue to add renewable power sources, such as wind and

solar, to their systems, they seek also ways of adjusting their

generating capacity to the inherent variability in supply

that these new sources create. Traditional, conventional

systems are not designed for responding to such rapid

variations, and Wärtsilä is a pioneer in providing an

economically sound and technically feasible alternative.

SIMILARLY, WÄRTSILÄ'S LEADING ROLE in developing

multi-fuel engine technology is paying dividends in reducing

operating costs and helping the environment. One clear

example is illustrated in the use of oilfield associated gas to

generate power instead of being flared into the atmosphere.

IN THE SHIPPING AND OFFSHORE MARKETS too, Wärtsilä's

advances in engine technology are enabling the emergence of

liquefied natural gas (LNG) as a viable marine fuel. Despite its

obvious advantages in cost and environmental sustainability,

LNG has for years been looked upon as being impractical

for use in fuelling marine engines. Wärtsilä has shown

the world that this is not the case at all. On the contrary,

thanks to the company’s innovative thinking and dedicated

development work, LNG may well become the marine fuel

of the future. Conversions to gas powered propulsion are,

therefore, likely to increase rapidly as we look ahead.

THESE LARGE-SCALE DEVELOPMENTS, and the many

smaller-scale innovations that are presented in this issue of

InDetail magazine, not only provide Wärtsilä with business

opportunities, they are also reason for every employee

across the globe to be justifiably proud. Above all, they offer

our customers solutions that are

absolutely in line with the need

to meet tightening cost budgets,

and to comply with increasingly

stringent environmental

legislation.

I wish you enjoyable reading,

Frank Donnelly President, Wärtsilä North America Contributing editor to this issue of In Detail

iPad

Web

WÄRTSILÄ TECHNICAL JOURNAL | WWW.WARTSILA.COM

in detail 3

WÄRTSILÄ LOW LOSS CONCEPTNew Wärtsilä platform supply vessel design with LLC achieves the highest possible

Environmental Regularity Number without increasing installed engine power. PAGE 40

Blending on Board concept aids lubrication

After extensive testing, Blending on Board to be installed on a Maersk Line container vessel.

Upgraded Wärtsilä 32 engine

The Wärtsilä VS 465 design vessel being built for Atlantic Offshore will feature the higher-output Wärtsilä 32.

Reduced gas flaring after GD conversion

Successful co-operation with PETROAMAZONAS enables electricity to be produced from associated gas at Eden Yuturi.

MORE ON PAGE 47RE

FE

RE

NC

ES

MORE ON PAGE 65MORE ON PAGE 11

4 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

Fig. 1 – A pumping station on the Baku-Tbilisi-Ceyhan pipeline in Turkey. The pipeline, for which Wärtsilä has supplied engines, crosses several mountain ranges.

The oil and gas business is a multi-billion

dollar industry with a huge need for

prime movers – whether in the form of

combustion (reciprocating) engines or

combustion turbines (rotating machines) to

deliver electrical power or mechanical drive.

As oil and gas become more difficult

to recover and operators attempt to

extract more from existing wells, the

demand for investment in power

generation will continue to increase.

Smart Power Generation for the oil and gas industryAUTHOR: Junior Isles, Man in Black Media

The oil and gas industry has a tremendous need for prime movers that can provide electrical power or mechanical drive. With their high efficiency and fuel flexibility, combustion engines offer the most competitive solution.

The total investment in the upstream

segment is currently in the region of EUR

300 - 350 billion a year, a figure that is

expected to grow in the coming years.

The choice of whether to use rotating

or reciprocating machines is one that

operators need to consider carefully,

especially in the face of growing

environmental awareness and the need

for greater energy conservation.

Increasing energy demand continues to

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

5in detail

drive oil and gas exploration in regions such

as the Middle East, Russia, the Caspian and

Latin America. Underground gas storage

projects, and the development of gas

transport and distribution in Europe and

the U.S., are also increasing demand for

investment. For example, the U.K. is

planning to build many new underground

storage facilities to increase its severely

limited storage capability.

Applications

The market for combustion engines in

the oil and gas business can be split into

three segments: power plants, pumping,

and compression.

Power generation: Power plants are often

needed to provide power; the location can

be at an oil or gas field, a refinery, or even

at a compression or pumping plant in cases

when the compressor or pump is driven

by an electrical motor.

Such power plants are much the same as

in the electric utility industry. One of the

key differences, however, is the available fuel

to drive the power plant. Fuels can range

from associated gas to crude oil, have

varying quality and quantity, and often

cannot be burned in turbines.

This is where Wärtsilä’s technology comes

into its own. Wärtsilä has engines that can

run on gas or virtually any liquid fuel. It has

gas engines capable of running on normal

pipeline gas; liquid fuel engines that can run

on crude oil, heavy fuel oil (HFO) or light fuel

oil (LFO); and dual-fuel (gas-diesel) engines

capable of burning gas of varying quality

and liquid fuel at the same time. Gas-diesel

(GD) technology, which is unique to Wärtsilä,

is particularly well suited for oil field power

plants where there can be changes over

time in the quality of the associated gas, as

well as in that of the crude oil produced.

With engines ranging in size from 1 MW

to 23 MW, Wärtsilä can build oil or gas fired

power plants ranging from 1 MW up to 500 MW.

The modular design of Wärtsilä’s solutions

means that plant size can be increased by

adding additional units as the operators’

needs change.

Pumping: The same engines used for

generating electricity can be used for driving

pumps. Wärtsilä has large engines suited for

big pipeline projects. It has supplied engines

to projects such as the BTC Pipeline (see side

story) in Turkey, and the OCP Pipeline

in Ecuador.

An advantage of the Wärtsilä technology

is that its engines can run on the crude oil in

the pipeline without any refining or treatment.

Compression: Gas compression is a big

market for combustion engines. Gas

compression is a business worth several

billion dollars a year globally.

Smaller 0.5 - 2 MW engines are used for

small gas distribution lines, as well as in

the shale gas market, which are typically

very small fields.

Larger engines are used for underground

gas storage projects. Indeed, reciprocating

technology is better suited than centrifugal

technology for the high pressures needed

for underground storage.

Currently, the pipeline compression

sector has a prevalence of turbines driving

centrifugal compressors. The turbines used

for this application are typically 5-10 MW

but can also be bigger.

However, using combustion engines to

drive centrifugal compressors offers huge

savings in fuel. The arrangement would see

a gas engine driving the compressor directly,

or a power plant supplying electricity to

electrically driven compressors. Although

the latter would be a more expensive solution,

it would increase flexibility. Using a gas

engine in place of a gas turbine also provides

much better fuel efficiency. Lifecycle studies

of real cases show that such a solution could

deliver fuel savings of more than

EUR 100 million over a 20-year period.

Better efficiency

The efficiency argument presents a strong

case when comparing combustion engines

with other technologies. When a lifecycle

cost evaluation is made, the fuel cost over

the lifetime of a plant is many times that

of the capital expenditure cost.

Historically, operators of power plants,

and compression or pumping stations,

have paid little attention to fuel efficiency

as the fuel is often provided free of charge

from the owners of the field. With free fuel

meaning low operating costs, the main

impact on profitability is capital investment

i.e. the cost of equipment. Operators have

therefore opted for the cheapest equipment,

which is usually not the most fuel-efficient.

But this is changing. As energy prices

continue to increase, efficiency is becoming

an important part of the evaluation process.

In order to save energy, reduce the

environmental impact and cost, energy

efficiency programmes are now common

in the production of oil and gas.

As a traditional industry, oil and gas

operators have a tendency to use technology

they are familiar with. This often means that

when issuing tenders, only turbine

technology is specified, despite their much

lower efficiency compared to combustion

engines.

Although some larger gas turbines can

demonstrate efficiencies of around 40

percent, the smaller turbines (around 10 MW)

typically used in many applications have

an efficiency of about 30 percent or less,

depending on operating conditions.

Efficiency decreases during part-load

operation, and there is a significant drop-

off in power as the ambient temperature

increases. Gas turbines also lose output

and several percentage points in efficiency

due to wear between overhauls.

By comparison, Wärtsilä’s gas and diesel

combustion engines have shaft efficiencies

of around 45-48 percent. Efficiency above

40 percent is maintained even at loads as

6 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

low as 50 percent. Gas engines lose virtually

no efficiency over time, and liquid fuel

engines lose only about one percent between

overhauls of the fuel injection system.

Unlike combustion turbines, combustion

engines do not derate over time but

maintain full output during their lifetime.

Fuel flexibility

The ability to burn almost any liquid or

gas fuel in a Wärtsilä engine can help to

drastically reduce the cost of fuel, even from

a purely logistical standpoint.

The ability to run on a wide range of fuels

is why combustion engines are playing a

major role in the drive to reduce flaring.

Gas flaring is a practice that is coming

increasingly under the spotlight due to

environmental concerns and the need for

energy conservation.

In 2010, Wärtsilä became the first solution

provider to become a member of the Global

Gas Flaring Reduction Partnership (GGFR).

The GGFR was formed by the World Bank

in 2002 to support the efforts of oil producing

countries and companies to increase the use

of associated natural gas, and thus reduce

flaring and venting. It estimates that over

138 billion cubic meters (or 4.9 trillion cubic

feet) of natural gas is being flared and vented

annually.

This is equivalent to 25 percent of the

United States’ gas consumption, 30 percent

of the European Union’s gas consumption,

or 75 percent of Russia’s gas exports. The gas

flared yearly also represents more than

the combined gas consumption of Central

and South America.

At a gas price of about USD 4 per million

Gas engines: Wärtsilä gas engines are

suited to normal pipeline quality gas.

They are spark-ignited (SG) engines

that use the lean-burn Otto cycle.

In this process, the gas is mixed with air

before the inlet valves. During the intake

period, gas is also fed into a small pre-

chamber, where the gas mixture is rich

compared to the gas in the cylinder. At

the end of the compression phase the gas/

air mixture in the pre-chamber is ignited

by a spark plug. The flames from the

nozzle of the pre-chamber ignite the gas/

air mixture in the whole cylinder. After

the working phase, the cylinder is emptied

of exhaust and the process starts again.

Oil-fired engines: Wärtsilä liquid fuel

engines can run on crude, heavy fuel

oil (HFO) or light fuel oil (LFO). In the

diesel process, liquid fuel is injected into

the cylinder at high pressure by camshaft-

operated pumps. The fuel is ignited

instantly due to the high temperature

resulting from the compression.

Combustion takes place under constant

pressure with fuel injected into the cylinder

during combustion. After the working

phase, the exhaust gas valves open and

the cylinder is emptied of exhaust gases.

With the piston in its upper position, the

inlet valves open just before the exhaust

gas valves close, and the cylinder is filled

with air. In Wärtsilä engines the inlet

valves close just before the piston reaches

the bottom dead centre. This method,

Wärtsilä engine technology

Fig. 2 – Wärtsilä's gas-diesel technology offers the opportunity to reduce flaring of associated gases, thereby enabling fuel savings and a reduction in greenhouse gas emissions.

Btu, the value of the gas flared in oil fields

and refineries today is around USD 20

billion a year. This wasted associated gas

could produce 65 GW of electricity a year.

With Wärtsilä’s gas-diesel technology,

associated gas can be used for power

generation or gas re-injection at the oil field.

Its fuel sharing technology allows

the engines to cope with variations in gas

quantity and quality.

Reliability

Another key benefit of using combustion

engines is the high reliability they provide.

Oil and gas are highly valuable

commodities and any failure in, for example,

pump or compression equipment can have

serious financial consequences.

Operators, therefore, always install spare

or backup engines or turbines to ensure

there is no interruption in oil or gas

production.

There is a general perception that a

turbine is more reliable than an engine due

to its fewer moving parts. However, modern

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

7in detail

medium speed engines have been proven to

provide reliability equal to that of turbines.

With the clear benefits of better

reliability, greater fuel flexibility and lower

operating costs, it is time for the oil and

gas industry to change its conservative

mindset and focus on using the more

efficient and environmentally friendly

solutions that combustion engines provide.

called “Miller timing”, reduces the work

of compression and the combustion

temperature, which results in higher

engine efficiency and lower emissions.

Dual-fuel engines: Fuel flexibility and

high efficiency are the main advantages

of the dual-fuel technology. They can

be characterised as “anything in, and

anything out”. They can run on crude

and other liquid fuels as well as gas of

varying quality, and can be used for

power generation, combined heat and

power, pumping or compression.

Wärtsilä dual-fuel engines are unique

because they have two different injection

systems. A micro pilot injection system

injects a very small amount of liquid

fuel when the engine is operating in

gas mode. The micro pilot system is of

the common rail type, which allows

for very small injection amounts.

This makes it possible to meet very

stringent emission regulations, which

would be impossible if a normal injection

system were used. A conventional injection

system is used when the engine is run on

liquid fuel. The engine transfers from gas

to fuel oil operation (LFO, HFO) at any

load instantaneously and automatically.

Because the gas is injected to the

engine at high pressure, the engine

is not sensitive to the methane

number or other gas components.

Fig. 3 – One of four Wärtsilä pumping stations in the Turkey section of the BTC Pipeline.

Pumping for BTCAs one of the longest of its kind in the world,

extending across three countries from the

Caspian Sea to the Mediterranean coast,

the Baku-Tbilisi-Ceyhan (BTC) Pipeline is

described as one of the great engineering

endeavours of the new millennium.

Designed for the transport of 1 million

barrels (50 MTPA) of crude oil per day, the

pipeline is of regional and international

significance and is the main export route

for Azeri crude to world markets.

Commissioned in 2006, the state-of-the-

art pipeline was built by a consortium led

by B.P. It extends from Baku on the Caspian

Sea, through Azerbaijan, Georgia and Turkey,

to the port of Ceyhan on the Mediterranean

coast of Turkey. From here the crude is

further shipped via tankers to European

markets.

Much of the route through which

8 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

Fig. 4 – BTC pump station with five pump sets driven by Wärtsilä 34SG engines.

the pipeline passes is mountainous. From

the lesser Caucasus Mountains on the border

with Georgia, the pipeline heads west across

the Anatolian Plateau before crossing south

through the Taurus Mountains. At this point

it follows a steep descent to the Cukurova

plain on the north shore of the Gulf of

Iskenderun.

The Anatolian Plateau forms the

principal landform on the route. The terrain

comprises a number of broad plains at

elevations between 1500 m and 2000 m

above sea level, and upland mountains

rising to 3000 m. With a total length of

1769 km, the major portion (1076 km) of

the pipeline’s route is located in Turkey.

Pumping oil across such a vast distance

and high elevations called for the installation

of eight pumping stations – two in

Azerbaijan, two in Georgia and four

in Turkey.

The BP consortium awarded the entire

design and construction of the Turkish

section of the pipeline, including the

pumping stations, to BOTAS, the Turkish

Petroleum Pipeline Corporation.

In 2002, BOTAS awarded a contract to

Wärtsilä for the equipment for the four

stations in Turkey. The scope of the contract

covered the supply of nineteen 18-cylinder

Wärtsilä 34SG engines in V-configuration

with selective catalytic reduction (SCR)

systems, a starting air system, lube

oil systems for the engine, and for the

pump and gear box, cooling radiators,

auxiliary modules for heat exchangers

and filters, air intake ducts, exhaust gas

systems, and pump seal oil systems.

The BTC pump stations in Turkey,

installed along the pipeline from the Georgia

border down to the Ceyhan Marine Terminal,

are designated PT1, PT2, PT3 and PT4 and

are at elevations of 2140 m, 1720 m, 2028 m

and 1595 m, respectively above sea level.

The gas fired reciprocating engines offer

several significant benefits. Compared to

gas turbines, reciprocating engines have

the main advantage of retaining high

efficiency at high altitude. A reciprocating

engine has an efficiency of about 40 percent

compared to less than 30 percent for a gas

turbine driver. Gas turbines experience a

significant loss of power at higher altitudes

and are further handicapped by a steep drop

in efficiency at deviations from the design

point.

Following more than five years of

operation, BTC and Wärtsilä are considering

modernising the engine automation

system with the introduction of a torque

measurement system. This would allow the

engines to automatically adjust according

to the flow of oil in the pipeline.

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

9in detail

Fig. 2 – Gas re-injection combined with power generation.

Fig. 1 – The Wärtsilä solution for re-injecting associated gas into the oil well. This maintains the pressure, enhances oil production, and can even be used as a means of storing gas for later use.

Wärtsilä s gas-diesel (GD) technology was introduced in 1987 with the Wärtsilä 32GD, the first gas engine in the Wärtsilä portfolio. This technology has been used mainly in offshore applications, but has later found applications in the power plant sector.

GD technology makes it possible to run

a power plant on either associated gas or

crude oil, where the gases could contain

heavy hydro-carbons, or heavy fuel oil to

provide the operator with fuel versatility

and security against gas supply disturbances.

The system accommodates daily/frequent

variations in gas quality and quantity.

GD- power plants

In power installations, the economic viability

of gas is becoming ever more apparent.

At the same time, emission issues related to

the use of liquid fuels are becoming more

complex. Not surprisingly, therefore, the

use of gas to generate power is rapidly

increasing, although in order to convert

older LFO /HFO operated installations to

natural gas, there needs to be a reliable

Gas-diesel conversions for power plant applicationsAUTHORS: Jyrki Anturaniemi, Project Proposal Manager, Project Proposals , S olut ion Management

Sergey Cheprasov, Project Manager, S ervices Projects Nor th America

Heikki Huhtala, Project Manager, S ervices Project Centre Finland

10 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

supply of gas available. Nevertheless,

the conversion of a HFO plant to natural

gas offers several benefits that make this

upgrading feasible for many customers.

Currently, a conversion project can be

offered using most of the Wärtsilä 32,

Vasa 32 and Vasa 46 engines. Typically,

the two main drivers for fuel change are:

Reduced emissions and fees

Reduction of fuel costs.

The GD conversion concept

Wärtsilä's gas engine portfolio (GD, SG and

DF types) is well known, and if the current

total running hours are, for example, less

than 10,000 hours, a GD conversion is

feasible. In any case, the number of engine

parts that need to be changed is limited.

Diesel engines provide one of the best heat

rates, while GD engines in addition to this

also enable the use of most gas types

available on the market.

There are a number of factors to take into

account when considering a gas conversion.

The most logical place to start is to establish

whether or not the existing engines on site

can be converted, or if they should be

exchanged for new ones. Converting an

existing engine is usually economically more

feasible than installing a new one, especially

since a conversion basically brings the same

benefits as a new engine. For example, the

same warranty is granted as for a brand

new engine. Furthermore, there are also

savings to be made on maintenance costs

since the running hours are reset to zero

(0). However, with smaller installations,

e.g. below 10 MW, it would most likely be

more cost effective to install new engines.

The plant equipment required for

operating on gas can be divided into six

main areas:

Gas delivery

Gas compressor

Fig. 3 – W2W: The Waste To Wire schematic process.

Well

Water

Separator

Crude oil

Gas Pre

-co

od

er

Co

od

er

Tre

atm

en

t

Se

pa

rato

r

Co

mp

ress

ion

Ve

sse

l

Power Generation

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

11in detail

High pressure gas

High gas pressure oil

Control

Electrical feed.

Each gas conversion is installation specific,

and requires a basic engineering evaluation

before a detailed offer and scope can be

given. The scope can encompass a turnkey

delivery that includes the installation and

commissioning of the plant. The plant’s gas

supply and gas line connection to the gas

delivery system is normally the

responsibility of the customer. The most

important benefits of such a conversion are

lower emissions, improved plant efficiency,

and the fact that all the work can be done

on site.

Currently there is an upsurge in demand

for gas conversion installations, based on an

increase in gas supply. In countries without

pipeline gas, liquefied natural gas (LNG)

offers a potential alternative solution.

Gas conversions are yet another example

of Wärtsilä´s ability to help owners and

operators throughout the lifecycle of their

investment, and the company can offer

a broad variety of possibilities to meet

each customer´s specific requirements.

Wärtsilä is also supporting its customers

in gas conversions by providing relevant

training courses on gas operation

Eden Yuturi Conversion Project

In 2008, PETROAMAZONAS EP (PAM), an

Ecuadorian state owned oil company,

initiated a mission named “Optimisation

Generation Electric- OGE” that they also

nominated as a Waste to Wire, or Well to

Wire (W2W) project.

During the crude oil extraction process,

crude oil, water, and associated gas

come to the surface, where they are then

separated at the production facilities (see

Fig. 4 – Associated gas supply characteristics.

Figure 3). Given the unstable condition

of the associated gas (both in terms of

composition and supply) it is usually

vented or flared. The World Bank-led

‘Global Gas Flaring Reduction Partnership’

estimates that globally this amounts to

approximately 150 billion cubic meters of

gas each year, causing some 400 million

tons of carbon dioxide emissions. That is

equivalent to 30 per cent of the European

Union’s total gas consumption. It is

important to point out that associated gas

is quite different to natural gas, in that

its composition and volumes change

significantly over time. If you add to this

the fact that the supply of associated gas

is extremely unstable (see Figure 3), it

becomes clear why in most cases the oil

companies prefer to simply vent or flare it.

In order to reduce gas flaring at the

Eden Yuturi site, PETROAMAZONAS EP and

Wärtsilä entered into a joint development

12 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

agreement aimed at developing an integrated

"gas/crude" product, able to cope with the

dynamic condition of associated gas. In

line with the technological developments,

PAM and Wärtsilä jointly developed the

Clean Development Mechanism (CDM)

programme as a means to co-finance the

project. The objectives of the project are to

mitigate the environmental impact through

reducing the exhaust and noise emissions;

to develop and implement a flexible solution

that will adjust to the challenging conditions

of associated gas; and to replace the use of

diesel/crude oil for power generation by

utilizing the associated gas.

Technology

Thanks to Wärtsilä's multi-fuel technology,

associated gas can be converted to electricity

instead of being continuously flared into the

atmosphere. This technology offers a unique

degree of fuel flexibility, permitting the

engines to run on any combination of liquid

fuel and associated gas. This is essential for

oil and gas companies operating in

environments where the associated gas

volumes and composition are constantly

changing. This flexibility in the utilization of

associated gas serves to maximize power

production while, at the same time, reducing

greenhouse gas emissions.

Although the first phase of the project has

been completed, PAM and Wärtsilä are

already looking at taking the "energy

efficiency" concept to a next phase by

developing new state-of-the-art technological

features. The overall goal is to eliminate any

waste, thereby allowing PAM to reduce

the "carbon footprint" per barrel of crude

oil extracted.

The Project Outcome

The conversion of the Eden Yuturi power

plant from crude oil-fuelled to associated

gas-fuelled operation enabled PAM to

utilize associated gas that was being flared.

Four 18-cylinder Wärtsilä Vasa 32 low nox

gas (LNGD) engines in V-configuration

generating 20 - 24 MW power were

converted, and the hand-over to PAM took

place in November 2011. Every 1 million

cubic foot per day of flare gas optimised for

power generating represents approximately

160 barrels of crude oil per day. Thus,

PAM expects to save up to 640 barrels

thanks to the project. As PAM likes to say:

it increased the net crude oil production

by an average of one well without having

gone through the drilling process.

The PETROAMAZONAS EP and Wärtsilä

co-operation succeeded in developing an

"in-house" Ecuadorian Project Team and

Project Implementation Structure capable of

taking a project from an idea to commercial

operations. This has been duly recognized

by the government of Ecuador, which has

now decided that this vehicle should be used

to implement energy efficiency projects

throughout the country's petroleum sector.

Furthermore, technological solutions

were developed and implemented that

focused on mitigating the challenges of

quantity and quality fluctuations in the

delivery of associated gas. At the same

time, PAM’s power supply matrix was

re-engineered so that today more than

60 MW of capacity has been installed to

operate with associated gas. This will be

increased to 70 MW in phase three. The

other critical technical achievement of the

project has been the transformation of

isolated power generation systems towards a

distributed power system, by installing low

environmental impact underground cables.

Wärtsilä's multinational team can reflect

on a successfully implemented solution for

PAM. It has also created an international

benchmark for oil sector energy efficiency

and consequently, a business model that

focuses on long term sustainable prosperity.

Carbon Finance

The gas conversion is expected to save

over 1Mt of CO2 emissions over 10 years

by using previously flared gas for power

generation. In parallel with Wärtsilä's

delivery of the gas conversion project, the

Development and Financial Services group

at Wärtsilä assisted PAM in the successful

registration of the project under the UN’s

Clean Development Mechanism. During the

2 ½-year process Wärtsilä's carbon finance

experts guided the PAM CDM team in the

CDM registration process, and arranged

the sale of Certified Emission Reductions

from the project. The income from the

Certfied Emission Reductions provides

an ancillary income stream for PAM over

at least 10-years and was one of the key

elements in the investment decision.

Aksa Samsun conversion project

Aksa Enerji Uretim A.S, a part of Kazanci

Holding, is one of Wärtsilä’s biggest

customers in Turkey. This energy sector

company operates diesel and gas power

plants, wind farms, hydro-electric plants,

solar energy, biogas and landfills, as well

as distributing and selling electricity.

The company made an agreement with

Wärtsilä in early 2000 for the supply of a

120MW power plant, equipped with seven

18-cylinder Wärtsilä 46 engines, to the

Turkish city of Samsun on the Black Sea.

The Samsun region has industry, but is also

an agricultural area and the local authorities

pay considerable attention to environmental

impacts. The emission levels from the big

factories and power plants were, therefore,

of high concern already at that time and

the Wärtsilä power plant was equipped

with SCR and SOx scrubber systems.

With the tightening of Turkey’s

environmental legislation, the company

was anxious to convert the engines to

use more environmentally friendly fuel.

At the same time, however, it had to be

kept in mind that the rated output from

the engines could not suffer any losses.

Additionally, operating costs needed to be

Fig. 5–6 – Gas Flaring at Eden Yuturi before and after the GD conversion.

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

13in detail

Fig. 7–8 – Aksa Samsun before and after the GD conversion.

reduced to make the plant’s operations more

economical. Since the engines were running

for only 5000 hours each, only minor

modifications to the engines were preferred.

Wärtsilä’s suggestion for the challenge was

a GD concept, which could cope with all

the requirements with improved engine

efficiency, yet still be able to provide not

only back up fuel flexibility with HFO and

LFO, but also natural gas/HFO fuel sharing.

As the undersea natural gas pipeline from

Russia already exists in the city of Samsun,

the set up was clear, and the GD concept

was proposed as a means of continuing the

plant’s operation under the tight emission

laws. The EEQ contract to convert six of the

power plant’s engines to GD operation was

signed in November 2009, and the project

team’s involvement began accordingly. The

seventh engine was relocated to Cyprus

by Aksa Enerji during the execution of the

GD conversion project in order to make

room for the first Wärtsilä 50SG engine.

Safety is the driving force

Safety is imperative when using high pressure

gas as a main fuel. The fuel oil system, gas

detection and automation system, and the

fire fighting system were designed according

to stringent safety regulations. Different

ratings and areas of Ex-zones were

determined, and even the access road to the

power house building had to be changed

due to the compressor house design and

location. Ex-proof components were

considered for all electrical and automation

parts, when located inside the Ex-zone.

A new gas feed arrangement with double

wall piping, a new HFO injection system, a

control oil system for 370 bar pressure, and

a new improved engine control were added

to the engine. Basically, therefore, very minor

modifications to the engine itself were

required.

For external systems, the conceptual

design was made through close co-operation

between Wärtsilä and Aksa Enerji A.S

Uretim. A ‘Safety Concept with a Cause &

Effect’ study was made by Wärtsilä and Aksa

Enerji based on the Wärtsilä GD concept and

local regulations, and this was used as a

design and execution guideline. The safety

concept emphasizes all the necessary aspects

and measures included in the GD power

plant concept to achieve an acceptable

safety level.

An optimal gas feed system based on

the local conditions was calculated and

designed by Wärtsilä experts together with

Aksa Enerji A.S Uretim’s gas department.

14 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

The gas itself is good quality Russian

natural gas with high low heat value

(LHV), a low consistence of inert gases,

and high methane number (MN). Two high

pressure gas compressors supply the six

Wärtsilä 46GD engines via an engine wise

gas valve skid, which is also able to share

the load upon request from the Wärtsilä

plant control system. The gas feed piping

inside the power house is double walled

to enable proper ventilation for the safe

evacuation of any possible gas leaks. A

reliable, sufficient, and safe gas feed into

the engine is an important factor, but the

gas blow down and venting cannot be

overlooked. Because of maintenance or

other planning reasons, the gas flow must

be able to be led out (blow down) from the

system back to the gas grid. This must be a

safe and controllable operation. There is a

further need for emergency venting of the

gas flow into the atmosphere, which has

to be well planned so that it is activated in

accordance with the plant controls, etc.

A project specific gas valve skid was

tailored by the project team to achieve the

optimal reliability and performance for

operation with a very low, <2 bar, pressure

drop over the skid. The gas valve skids

were further located inside the gas tight

individual cabinet, which is continuously

ventilated and furnished with gas detection

equipment that issues a gas alarm in case

of any leak or malfunction of the skid.

Testing and commissioning took place

in autumn 2011, engine by engine, by the

Wärtsilä commissioning team assisted by

the Aksa Enerji team. Start up of the GD

engine is carried out using LFO or HFO,

and then ramped up to 25% to 30% on

fuel sharing mode prior to change over

to full gas operation with an HFO fuelled

pilot. After a few days tuning, the 17 MW

was reached with very good heat rate

figures. Furthermore, the key issue, the

exhaust gas emissions, were accepted by

the local authorities, who are continuously

monitoring the plant’s exhaust gas emissions

via engine wise emission sensors installed

on each exhaust gas stack. So, in other

words, the production of electricity can

continue with far lower levels of exhaust

gas emissions, while providing financial

benefits through lower operation costs. An

additional advantage is that HFO no. 4, or

even no. 6, can be used as a pilot fuel to

reduce the operational costs even more.

New automation

No conversion project is without a

challenge or a surprise of some kind. This

is especially true when something new

has to fit into an existing environment.

The engine and plant automation and

monitoring systems were renewed totally, so

old panels, sensors, etc were disconnected

and removed prior to assembly of

the new ones, which were also partly

interconnected to the existing systems. In

addition, considerable quantities of safety

equipment, including detectors, sensors,

limit switches, and so on, were installed

based on the required safety concept. Once

the dismantling and installation work

was finalised, the software needed to be

updated to the final revision, and once

again this was based on the safety concept

and the final setting of the equipment.

Overall, however, through close and

open co-operation with the customer, the

Wärtsilä organizations in Finland and

Turkey, and other stakeholders meant that

no major surprises occurred - even though

the project specific and tailored design

was developed during the project itself.

Fuel flexibility

Wärtsilä products are flexible and easily

adaptable for utilizing gas as a main fuel.

This makes the converting of power

plants to gas operation very interesting,

for example in terms of lower operation

costs, less exhaust gas emissions, fuel

flexibility, and short payback time. This

is especially important now when the

gas grids are expanding and emission

levels are being tightened globally. The

GD concept requires very few engine

modifications, and provides considerable

benefits with real fuel flexibility.

Fig. 9 – Pressure testing of the gas pipeline.

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

15in detail

Fig. 1 – In a wind integration study for the Mid Western United States, the PLEXOS® simulations quantify the ability of Wärtsilä Power Plants to load follow against rapidly changing wind output.

The modelling of power systems AUTHOR: Kimi Arima, Advisor, Advisory S ervices, Marketing and Business Development

How does one quantify the value of flexibility? For this one would have to model an entire power system, insert flexible power generation, and observe the results. Wärtsilä has a tool that can do just this.

Dispatching

Dispatching could be concisely described

as the act of continuously optimising the

operation of the power system from one

minute to the next. In the context of a

developed and complex power system,

the responsibility for dispatching usually

resides with the system operator. To be

able to optimise the power system, the

system operator is continuously engaged

in three activities that define dispatching:

forecasting, planning, and controlling.

Forecasting is the task of finding out the

expected load demand and what generating

assets are available to meet that demand.

For traditional longer-term forecasting,

considerations include seasonal variations

in load demand, macro-level weather

patterns and their effect on demand, as

well as planned outages of large generating

units. Shorter term forecasting involves

daily load variations and, which is of

increasing importance in many systems,

the output of intermittent renewable power

generation. The result of forecasting is a

net load curve, that is, the forecasted load

demand less the forecasted output from

intermittent renewable power generation.

This is the part of demand that needs to be

met with dispatchable power generation,

i.e., generating units that can be started

and stopped as and when needed.

16 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

Based on the forecast, the system operator

can plan which generating units will be

used to meet expected net load demand

at each point of the coming day. One

approach is to rank the units in the system

in ascending order of their marginal cost

of generation, known as a merit order.

Renewable sources come first, as they

have no fuel costs. These are followed by

nuclear and coal plants, which typically

have very low marginal operating costs,

notwithstanding the emission costs imposed

on coal plants in some countries. Next come

CCGTs, combustion engines, and OCGT

plants running on gas, while possible oil-

fired units come last, as their fuel costs

are the highest. Having planned which

generating units need to be running and at

which times, the system operator accounts

for start up times and ramp up rates to

see when each generating unit needs to be

started up. In case a generating unit has

to be started up twice during the day, the

minimum uptime and minimum downtime

also have to be taken into consideration.

Finally, contingencies, such as a

malfunction in a big generating unit, or a

forecasting error, also have to be accounted

for. Some generating units are needed to be

at the ready in case of an unexpected shift,

positive or negative, in net load demand.

Reserve requirements are system-specific,

and can be met with a combination of

spinning and non-spinning generating units.

In many countries, the planning phase

takes place on the market. Plant owners bid

their production onto the market, whereby

a merit order is established according to

bid prices. Reserves can also be organised

via separate market mechanisms.

In parallel with forecasting and planning,

continuous controlling is needed to keep

frequency stable throughout the grid, and

maintain stable voltage locally. Routine

control chiefly revolves around the dispatch

plan based on forecasts and the merit

order. If actual demand deviates from

the forecast too much or too quickly, for

whatever reason, reserves will be called

upon to regulate generation as needed.

The goal of dispatching is two-fold. The

first objective is to ensure security of supply.

In the short term, this is achieved mainly

by successful controlling of the system.

In the longer term, forecasting accuracy

needs to be maintained, and reserves

capable of meeting both the scale and speed

of unexpected variations are required.

45

40

35

30

25

20

15

10

5

0

GW

00 01 02 03 04 05 60 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23Hour

Dispatchable

Wind

Solar

Fig. 2 – Net load curve, actual data in a Spanish power system. Notice the difference between the smooth curves of aggregate demand and the output of dispatchable power generation.

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

17in detail

Fig. 3–4 – The generation curves in the graph to the left are the result of one hour resolution, whereas the actual generation data in the graph to the right shows generation on a 10 minute interval basis. The surge in wind output and subsequent rampdown of CCGT output between 6 and 7 am is almost invisible in the one hour resolution forecast.

50

40

30

20

10

0

Hour

GW

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23

HYDRO-RoR

NUCLEAR

CCGT

WIND

OCGT

COAL

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23

50

40

30

20

10

0

Hour

GW

HYDRO-RoR

NUCLEAR

CCGT

WIND

OCGT

COAL

The second objective of dispatching is to

minimise total system costs. The merit

order approach is an important tool here.

Quite a lot also depends on the accuracy

of forecasting – both long term and short

– as unneeded start-ups will inevitably

manifest themselves in the form of higher

operation and maintenance costs.

Emerging challenges in dispatching

Today, many system operators face

challenges due to the growing share of

intermittent power generation in their

systems. While well established and robust,

the traditional methods of dispatching

are ill equipped to cope with the demands

imposed by increasing levels of variability

in both generation and demand. As most

power systems have traditionally consisted

only of dispatchable power generation, the

conventional dispatching methods have not

been developed to account for variability

in generation, at least not on today’s scale.

There are numerous challenges regarding

power system dynamics that must be

overcome in the coming years if targets for

renewable power generation, and reductions

in emissions, are to be met. Firstly, the

variability of intermittent renewable power

generation has a magnifying effect on load

changes for dispatchable generation. The

smooth curves of aggregate load demand

hide behind them violent shifts in the net

load demand. These rapid shifts entail

more cyclic – i.e., start-ups, ramps – as well

as part-load operation for dispatchable

units, with obvious cost implications.

Secondly, traditional tools for system

and feasibility analysis do not take these

kinds of phenomena into account. Typically,

forecasts and models used for analysing and

optimising power systems are based on an

hourly resolution, i.e., load demand, and

the corresponding generation is considered

24 times in a day. This approach does

not reflect the stresses imposed on the

system by intermittent generation. Indeed,

when comparing the result of a dispatch

model with an hourly resolution to actual

grid data on a ten minute resolution, the

discrepancies can be striking (see Fig. 3-4).

The forecasting challenge is compounded

by the fact that, due to basic mathematics,

increasing forecast error is an inevitable

by-product of the increasing variability

in generation. Thus, either decisions

have to be made based on forecasts less

reliable than previously, or decisions are

made on the same level of reliability but

with less time for implementation.

Thirdly, the interplay of shortened

forecasting horizons and rapid shifts in net

load demand, combined with the relative

inflexibility of traditional dispatchable

power generation, leads to unit commitment

issues. Starting up a plant is costly, especially

if the wind picks up again and the start

up turns out to have been unnecessary.

Similarly, shutting down a plant is risky

since, due to minimum downtime, the

plant will not be able to help for some time

should the net load demand suddenly

increase. Due to inadequate flexibility, in

many systems the response to this issue

has been an increase in partial loading.

The fourth point is that the combined

effect of all the above challenges undermines

the cost objective of dispatching. Costs are

impacted by increased wear and tear due to

violent shifts in net load demand; even more

wear and tear due to unnecessary start-ups

as a result of decreased forecasting accuracy,

decreased total system efficiency and, thus,

increased fuel costs due to partial loading.

Finally, these challenges also have a

negative impact on emissions. Partial

loading, besides increasing fuel costs,

also increases the emissions per unit of

electricity generated. Moreover, modern

emissions reduction technologies don’t

operate at optimum levels in unstable

conditions. In other words, during

start-up, shutdown, and steep ramp,

emissions are invariably higher than

during stable operation at full load.

A tool for the job: PLEXOS®

PLEXOS® is electricity market and power

system modelling and simulation software

developed by Energy Exemplar, an

Australian software company (for more

information on PLEXOS®, visit their website

at www.energyexemplar.com). The main

reason for selecting PLEXOS® as the tool to

demonstrate the value of flexibility is its

accuracy or, as it is known in the context

of modelling, its resolution. As noted

above, the difference between one hour

and ten minute resolutions can be striking,

and PLEXOS® is capable of even higher

resolutions, if necessary. Consequently,

18 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

Fig. 6 – PLEXOS® gives a wide range of output.

Fig. 5 – A PLEXOS® model requires vast amounts of quality data.

PLEXOS® is able to offer a very realistic and

accurate picture of, for instance, how a

proposed plant would actually operate as

part of the power system in the future.

In order to build even a rudimentary

model of a power system, immense amounts

of data are required (see Figure 5). It bears

mentioning that typical models with

one hour resolution do not incorporate

the dynamic features of the various

technologies present in the power system.

Nevertheless, on ten minute resolution

– as well as in real life – these properties

make all the difference. That is why our

models include start-up and shutdown

times, ramp rates, and minimum up

and down times for all technologies.

The amount of output available from

PLEXOS® is even more impressive than the

data required as input (see Figure 6). For the

purposes of this article, the most important

outputs are, firstly, the total generating costs

for the system, and then the running profile,

operational efficiency, and CO2 emissions

of each generating unit in the system.

Case study: Spain 2020

As of late 2011, Spain was already one of

the leading countries of the world with

respect to installed capacity of wind and

solar power. Nevertheless, the government

has set an ambitious agenda to more

than double renewable output by 2020.

Thus, we decided to see how the Spanish

system would cope with the challenges.

As it is important to analyse how the

system would cope with challenging

conditions, output from hydro reservoirs

was modelled according to the year 2005,

which was somewhat drier than average.

Furthermore, modelling was focused on

a week of the year that was identified as

having higher than average variability in

wind power output. This week was then

simulated using ten minute resolution

for two separate cases. The first case

constituted the Base Case, whereas for the

second case nine gigawatts of Flexicycle

capacity was added to the system.

In the Base Case, the effects of the

compound intermittency of wind and

solar are clearly visible (see Figure 7). After

satisfying the previous evening’s peak,

CCGT plants quickly shut down for the

night. As wind output increases in the early

morning, and especially after solar output

starts to grow around 6 am, the pumped

storage load climbs to over five gigawatts.

Due to the prohibitive start costs, it is

Plexos

Cost information

Consumable prices • Lube oil • Water • Etc.

Fuel prices Emission prices

Grid information

Transmission network • Lines (transfer capacity) • Nodes (generator / load points) • Interconnections

Market information

Market information • Market mechanisms • Real bid information for model verification

Reserves • Regulation up / down • Spinning • Non-spinning

Load and production profile library• Uncertainly (forecast error)

Load profiles • Load demand

Intermittent profiles• Wind• Solar

Power Plant profile library

Power Plants types • Coal • Nuclear • OCGT, CCGT • Etc.

Power Plants features• Efficiencies• Dynamic features• O&M costs• Etc.

Plexos

Power plants

Production by plant • Generation • Fuel offtake • Efficiencies • CO2 emissions • Loading factor • Etc.

Costs by plants • Generation • Emission • Operation & Maintenance • Start-up and shutdown • Etc.

Reserves • Provision of reserves • Etc.

Power system

Balance of system • Total generation • Load demand • Unserved energy • Dumped energy

Grid

Transmission system • Power flows • Losses total / per line • Bottlenecks (overloads), if any • Voltages

Energy market information

Energy • Prices • Marginal prices • Income by plant / company

Reserve marketinformation

Reserves • Reserve margin requirements • Prices • Provision by plant • Income by plant

Optimising total generating costs of the system with the

generation fleet

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

19in detail

Fig. 8 – Base Case operating profile for a single day. Notice the sharp fluctuations in CCGT output and the heavy reliance on pumped storage hydro capacity.

Fig. 7 – Base Case distribution of capacities in the Spanish power system model for 2020 (RoR = run-of-river, R = reservoir, PS = pumped storage).

cheaper to run 5 GW of CCGTs on partial

load and use the excess electricity to run

pumped storage hydro plants in reverse,

than it would be to shut them down.

This has a considerable impact on

total system efficiency. The roundtrip

efficiency for a typical pumped storage

hydro plant is around 70%. Thus, running

a CCGT on partial load, i.e., with poor

efficiency, and then ‘recycling’ that

electricity through a pumped storage

facility yields very poor overall efficiency.

Consumption catches up with the

renewable output around 10 am, after which

fluctuations in renewable output are met

with a combination of CCGT and hydro

power. Between 5 and 6 pm, an increasing

number of CCGT plants are started up to

compensate for the decreasing solar output,

and then subsequently ramped up to meet

the evening peak. Reservoir hydro and

pumped storage hydro are also needed to

meet demand between 7 pm and midnight.

It is worth pointing out that, because

of their low efficiency as compared

to CCGTs, the nine gigawatts of OCGT

plants in the system remain completely

unused throughout the day.

Projected generation fleet in 2020: 119 GW

CCGT 25 GW

FLEXI-CYCLE™

OCGT3-9 GW

COAL8 GW

NUCLEAR7 GW

WIND35 GW

HYDRO-RoR4 GW

SOLAR12 GW

HYDRO-R13 GW

HYDRO-PS6 GW

45

40

35

30

25

20

15

10

5

0

GW

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Hour

PUMP LOAD

HYDRO-RoR

NUCLEAR

COAL

CCGT

WIND

SOLAR HYDRO-R

HYDRO-PS

20 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

Fig. 9 – Operating profile with 9 GW of Flexicycle™ added to the system. Notice the difference from the Base Case in CCGT and pumped storage profiles.

A dramatic change occurred when nine

gigawatts of Flexicycle capacity was added

to the system (see Figure 9). Immediately

noticeable is the generation profile from 6

am to 10 am. In the Base Case, CCGT plants

were kept running, despite the impact on

total system efficiency, as they were needed

for the evening peak, and it would have

been too expensive to shut them down

only to start them up again in the evening.

At 9 GW, however, the Flexicycle capacity

is capable of covering such a large share

of the evening peak that no additional

CCGTs plants are needed. Consequently,

CCGTs don’t need to be kept on minimum

stable load through the afternoon, and are

shut down instead. The remaining CCGTs

get to do what they do best, namely run

on full load throughout the evening.

During the afternoon, the benefits of

combustion engines are clearly visible.

Between 11 am and 5 pm, Flexicycle plants

cover four major peaks in net load demand,

ramping from below 1 GW to 5 GW and back

again in less than one hour. Moreover, due

to the negligible start cost and excellent part

load efficiency of the Flexicycle, the ramps

and starts had no impact on system level

costs. In fact, adding 9 GW of Flexicycle

reduced the system level costs by 4.3% as

compared to the Base Case, delivering

annual savings of USD 633 million.

As for the CCGTs, the addition of 9 GW

of Flexicycle decreased their generation

by 34%. For the CCGTs that remained in

use, however, the operating profiles were

considerably smoother, and the average

load increased from 87.5% to 90.6%. It

should be noted that the most impressive

increase was achieved with 6 GW of

Flexicycle, whereby the CCGT average load

rose to 93.9%. In other words, the addition

of Flexicycle enabled a more optimal

running profile for the other generating

units in the system, in this case CCGTs.

SUMMARY

The future impact of intermittency needs

to be analysed on a much finer resolution

than traditional methods are capable

of delivering. In addition to optimising

dispatch, tools such as PLEXOS® can be

used to analyse how our current power

systems should be improved to be better

able to respond to future challenges. In

doing so, valuable insight for strategic

decision-making can be accumulated.

By balancing rapid shifts in net load

demand and optimising the operating

profiles of other generating units in the

system, the addition of flexible capacity,

such as Flexicycle, to a power system can

help to mitigate many of the problems and

costs related to intermittency. In the future,

with further increases in variability likely,

such flexibility can have tremendous value.

And, with PLEXOS®, we can show it.

Flexicycle™The new Flexicycle solution combines the advantages of a flexible simple

cycle plant with the superb efficiency of a combined cycle plant.

The Flexicycle solution is based on combustion engines with heat recovery

and steam turbine for combined cycle operation. The plant is capable of instant

switching between the dynamic and fast simple cycle mode and the highly

efficient combined cycle mode, enabling competitive operation on the energy,

capacity & ancillary services markets.

45

40

35

30

25

20

15

10

5

0

GW

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Hour

PUMP LOAD

HYDRO-RoR

NUCLEAR

COAL

CCGT

WIND

SOLARHYDRO-R

OCGT

FLEXICYCLE

HYDRO-PS

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

21in detail

Gas is increasingly becoming the fuel of choice for thermal power plants. Many regions do not have access to natural gas via pipelines, but liquefied natural gas (LNG) can be transported cost efficiently from one part of the world to another.

The world’s economically recoverable

natural gas reserves have increased

substantially during recent years. This is

largely thanks to shale gas, and the advances

made in developing efficient methods

for extracting it. As a result, according to

industry experts, there are now reserves of

natural gas for more than 200 years. With

this abundance of gas, it seems likely that

gas prices will remain competitive over

the long term. Add to this the fact that

natural gas is the cleanest of all fossil fuels,

and its popularity is easy to understand.

Transporting LNG

Liquefied natural gas (LNG) is an obvious

way to transport gas where pipelines

are not available. The traditional way to

distribute LNG is to use dedicated ships that

are as large as possible. These large ships

transport LNG from major liquefaction

facilities located in a handful of places

around the world to the LNG import

facilities, which are not that numerous

either. Since many ships are not designed

to transport partial loads, these import

facilities need to have tanks large enough

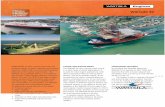

Fig. 1 – The Bahrain Vision is a small scale LNG carrier with a capacity of 12,000 m3. It has been in service since November 2011.

Delivering LNG in smaller volumesAUTHOR: Sampo Suvisaari, General Manager, Power Plants, Central America and the Caribbean

Phot

o: C

ourt

esy

of I.

M. S

kaug

en. L

ocat

ion:

Bah

rain

.

22 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

to receive the full cargo from an LNG ship.

While this large-scale approach

keeps transportation costs down, the

problem is that it creates limitations.

Firstly, the receiving terminals need to

be relatively large. A receiving terminal

of say, 160 000 cubic meters, requires a

very significant investment. For a power

plant having a 100 MW of capacity, this

160 000 m3 would represent about half

a year’s consumption, which is far too

much for an efficient use of capital.

The most common solution to this

problem has been to build LNG import

terminals only at locations where the

gas consumption is large enough, thus

completely ruling out smaller disconnected

locations, such as islands or small

countries. However, this is now changing.

Smaller-scale transportation

The transportation of LNG on a smaller

scale is already happening in several

places around the world, most typically

using trucks. LNG trucks are essentially

vehicles having a pressurised LNG tank.

These are offered by many manufacturers,

and come in different sizes. In some

countries even multi-unit trailers are used.

Unfortunately, this solves only regional

and not overseas transport requirements.

Another method is to use dedicated LNG

containers. This makes it possible to use

the same container for both marine and

road transport. The disadvantage is the

relatively small capacity possible, which

only makes sense for smaller power plants.

Using smaller vessels to transport LNG is

not yet common, but it is already happening.

Norway has been one of the early users

of small vessels for the distribution of

LNG, since the geography of the country

is attractive for marine transportation,

even in quantities as small as 1000 m3.

The Caribbean, on the other hand,

needs slightly larger scale transportation

capacity. Vessels of around 10,000 m3

are ideal for many locations, but such

vessels are not yet shuttling back and forth

from island to island. There needs to be

LNG sources that make LNG available for

smaller vessels, and in order for this to

happen, their business model needs to

take smaller scale vessels into account.

By trying to load smaller vessels from

the same loading bays as the larger ones,

valuable dock time would be utilized for a

smaller volume sale. LNG export terminals

Fig. 3 – Unloading an LNG truck can be a one man operation. The LNG tank in the truck is at a higher pressure than the recipient allowing LNG to flow from it without the need of any pumps. A clever, simple system.

Fig. 2 – LNG truck unloading at a small two-tank LNG storage facility.

Phot

o: C

ourt

esy

of T

ropi

gas,

Dom

inic

an R

epub

lic.

Phot

o: C

ourt

esy

of T

ropi

gas,

Dom

inic

an R

epub

lic.

WÄRTSILÄ TECHNICAL JOURNAL 01.2012

23in detail

need, therefore, to have additional loading

bays dedicated for these smaller vessels.

An analogy could be trains and trucks.

Trains are more cost efficient for cargo

transportation, but that does not mean

that trucks are not needed, or that they

are cost prohibitive. Both are essential

for a functioning transportation system.

In the same way, LNG needs to be

transported using both cost efficient large

vessels, as well as flexible 10,000 m3 small-

scale vessels that reach more places.

Hub and spoke concept

A natural solution for improving the

efficiency of transporting LNG on a smaller

scale is to use a hub. The hub can be a

new, or even an existing LNG terminal.

It can be land-based or floating. Smaller

vessels could make ‘milk runs’ to several

locations, or back and forth trips to a single

location, which would keep the distances

relatively short. The trips of the smaller

vessels are the spokes, hence the name ‘hub

and spoke’ for this distribution model.

At present this distribution model is not

yet applied in the Caribbean. Nevertheless,

due to the imminent widespread demand

for gas, it would be surprising if this

concept does not materialize within the

next few years. On the other hand, as

several new LNG export terminals have

been announced in the region, including

several terminals in the Gulf of Mexico

and one in Colombia, some of the export

terminals themselves may become regional

small-scale LNG distribution hubs.

Boil-off gas

Liquefied natural gas needs to be at a

very low temperature, approximately

-160 degrees Celsius. No matter how well

insulated the LNG tank is, the liquid will be

constantly producing boiling off gas, which

needs to be taken into account. Different

tanks handle boil-off gas in different ways.

Let us have a look at the different tank types:

Pressurised small-scale tanks

LNG can be stored in cylindrical metal tanks,

which are essentially spherical tanks that

are made longer. This is a geometrically

strong shape, and the tanks are made to

resist pressures of typically up to 8-10 bar

(116-145 psi). The benefit of having such

pressure resistance is that the boil-off gas,

which is inevitable no matter how good

the thermal insulation, can remain in the

tank. An increased amount of boil-off

gas will simply increase the pressure and

temperature inside the tank. The length

of time that this can be sustained depends

on the tank specifications, and on how

full the tank is. The less fuel there is, the

more space there is for boil-off gas. Some

manufacturers claim their tanks can stay

idle for three weeks and more without the

need for venting the boil-off gas. When the

excess pressure is controlled by releasing

gas through a control valve, the evaporation

inside the container lowers the temperature

and keeps the container in equilibrium.

The benefit of having a tank that can

withstand pressure is that the tank does

not need a reliquefication system at all.

The boil-off gas will be used in parallel

with the consumption of the LNG. As a

result, the tank arrangement is extremely

simple, having no compressors or rotating

equipment of any kind. It simply consists

of the tank, an emergency pressure relief

valve, regasification heat exchangers, and an

outgoing gas pressure stabilisation valve.

Pressurised small-scale LNG tanks come

in different sizes, ranging from very small

tanks for vehicular use, up to larger tanks of

several hundred cubic metres, and even up

to about 1000 m3 in capacity. Their size is

limited by transport constraints and weight.

For example, a tank of 1000 m3 is over

45 metres long and 6 metres in diameter.

Typically, many tanks are placed side by

side to get to the desired overall volume.

Even larger pressurised LNG tanks of

10,000 m3 and more do, however, exist.

The pressure resistance of the larger tanks

Phot

o: C

ourt

esy

of C

hart

Fer

ox a

nd G

asen

er. L

ocat

ion:

Øra

term

inal

in N

orw

ay.

Fig. 4 – A small scale LNG storage system can consist of a large number of prefabricated tanks. Ambient air evaporators seen in the back on the right side of the image.

24 in detail

[ ENERGY / IN DETAIL ]

[ EN

ER

GY

/ I

N D

ET

AIL

]

tends to be smaller, about 4.5 bar (65 psi),

as the weight and cost of the tank steel

would otherwise become cost prohibitive.

These larger pressurised tanks have so far

been used only on ships and barges, due to

transport limitations.

Atmospheric pressure tanks

Traditional large land-based LNG tanks are

designed for atmospheric pressure only.

These tanks are built on site over flat base

concrete foundations, and their tops have

such a large area (the diameter can be

over 60 metres) that even a small internal

pressure inside the tank would create a

strong upward force against them. These

tanks are not designed to withstand such

upward forces, and the pressure inside the

tank has to be maintained equal to the

outside atmospheric pressure. The only

way to ensure this is to have a system to

compensate for the boil-off gas, by