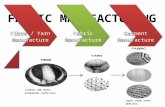

Woven fabric manufacture

description

Transcript of Woven fabric manufacture

Woven fabric manufactureWoven fabrics are made by interlacing two sets of yearns together at right angles to each other.http://www.tikp.co.uk/knowledge/technology/warping-and-weaving/weaving-process/The yarns that run up the length of the fabric are known as the warp threads.The yarns that run across the fabric are called the weft threads.The edge of the piece of fabric is called the selvedge

Plain weave

Most used woven construction

Properties of plain weave

• Strong• Firm• Hardwearing• Smooth• Relatively cost effective• Available in lots of different weights

CailcoPlain weave, low cost, made in different weights and widths, suitable for experimental textile work, especially in the production of toiles. Can also be used in the production of low cost furnishings.

Voile

• A lightweight plain weave sheer fabric made from cotton, silk or rayon, nylon or worsted.

• Used in blouses, dresses, children’s wear and curtains

Nylon voile

Rayon voile

Rip-stop nylon• High performance plain weave fabric

• Some of the warp and weft threads are doubled up at intervals.

• Extra strong tear strength• End use: kites, high

performance tents and performance sports wear.

• Light weight, abrasion-resistant, sometimes with flourocarbon finish

Poplin

• Is a plain weave, warp faced cotton fabric, which shows weft way ribs on its surface.

• The warp is finer and weft is coarser.

• Usually piece dyed or printed on.

• End use: shirting, summer jackets, coats and kids wear.

Seersucker• Plain weave construction• Crinkled warp way stripes, can be produced 3 ways:

• Fabric is woven in stripes, alternate stripes up under different tension on the loom. Uses: dresses or table cloths.• Linen or cotton treated with caustic

soda, usually in stripes resenting in crinkled stripes.• Fabric made with fibres with different

shrinkage properties which results in crinkles.

Palin weave sample and diagram

Twill weave sample and diagram

Satin weave sample and diagram

Twill weave

• Fabrics produce diagonal lines.• The direction of the weave will give different

properties to the fabric, for example:

• Herringbone Chevron:

Properties of twill woven fabric

• Drapes well.• Most used constructions, gabardine and

denim are twill weaves.• End uses: jackets, trousers, suits and curtains,

jeans.

Satin weave

• Warp faced fabric, which makes it strong in the warp direction, allowing it to drape well.

• Smooth shiney surface.• Weft thread only show through on the back.• End uses: curtain lining, evening wear,

upholstery, ribbons and trimmings depending on the fibre used, eg, cotton/ polyester, acetate, silk.

Damask fabricsAre made from more expensive mercerised cotton which is sometimes used for table cloths.Mercerisation is where caustic soda is used with cellulosic yarns to swell the fibres, the resulting yarn and fabric has better strength and an affinity to dye and the handle is improved.The designs in damask fabrics are due to the construction alternating between being warp and weft faced, this is also known as inter changing satin and sateen weaves

Damask fabrics

• Sateen, not to be confused with satin,[1][2] is a type of fabric often found in bed sheets.

• Grey cotton sateen used to line a cape• Sateen is a term usually applied to cotton, or sometimes rayon.

Better qualities are mercerized to give a higher sheen. Some are only calendered to produce the sheen but this disappears with washing and is not considered genuine sateen. Sateen may be bleached, dyed, or printed. It is difficult to make good bound buttonholes on it as it has a tendency to slip at the seams.

• Sateen produces the sheen and softer feel through the use of a different structure in the weaving process. The sateen structure is four over, one under, placing the most threads on the surface, making it extremely soft, though slightly less durable than other weaves. Standard non-sateen weaves use a one-over, one-under structure. Satin also uses this structure; however, materials such as silk, polyester, etc., are used instead of cotton. Sateen was also used for Vintage dress shirts and other Vintage type clothes

Sateen fabric

Crepe Fabric

• These fabrics have a crinkled or puckered surface.

• There is no definite pattern.• Wool crepes are used for high quality suits.• They are produced by using S and Z twist

yarns, a crepe weave construction and a chemical or thermal treatment that makes the fabric shrink differently.

Crepe fabric

Jacquard fabric

• Is a complicated pattern design in 3 or more colours.

• It’s made by knitting or weaving on specialist jacquard machinery.

• Woven jacquard fabrics are used interchanging all the different weaving patterns.

• Mainly used for expensive upholstery fabrics and formal evening wear.

Jacquard weave

Pile weave

• As with pile knits, this fabric has a raised surface effect.• This pile is formed by tufts or loops that stand up from the

fabric.• Velvet and corduroy are good examples of pile fabrics. They

are used for trousers/ jackets or in garment production.• Other end uses are upholstery or carpets. Different effects

can be applied, sculpted, curled or textured.• Pile upholstery fabrics that have a combination of cut and

uncut pile loops are the most hardwearing.

velveteen

Velveteen has a shorter pile after cutting than velvet.

Velvet

Needle cord or corduroy

• Corduroy is a ribbed cut weft- pile fabric that is brushed. The pile runs parallel to the selvedge and the cords may be medium or broad. Cotton corduroy is used for shirts, jackets and upholstery.

• Needle cord is made in the same way as corduroy, but the cords are very fine.

Corduroy

Needle cord

Terry towelling• Woven terry towelling is a plain weave cotton fabric

made from two warps.• The ground warp is tensioned and the pile warp is looser.• When the weft yarns are beaten into the fabric the looser

pile warp ends form loops on one or both sides of the fabric.

• Towelling is usually made from cotton and this combined with the loop construction makes it a very absorbent fabric, that’s easy to wash and doesn’t need ironing.

• Ideal for towels, mats and dressing gowns.

Terry towelling

Fabric mixture

• Is made with the warp of one fibre and the weft of another, e.g. cotton warp, wool weft.

• This is called a UNION FABRIC , which can be cheaper than using just one fibre.

• When mixture fabrics are dyed, the dye is taken up at different rates so that the fabric can looked speckled.

• This is a deliberate designed effect.

Colour woven fabrics

• Colour and weave effects are used by designers to create an unlimited variety of fabric effects.• Depending on the way warp and

weft yarns interact with the weave construction different aesthetics results can be achieved……

Stripes

Tartan

Houndstooth Chec

ked

fabr

ic

Chambray

• Has a warp in one colour and the weft in another, the result is a shimmering, changeant, shot silk effect.

Gingham• Is plain weave construction, its lightweight,

mainly checked fabric that uses white and colour yarns.

• A very popular fabric in the 1950’s.• Used for blouses, tablecloths and dresses/

uniform. When used for shirts it’s called MADRAS.

Tartan

• Construction is 2/2 twill.• Originally used for shawls, kilts made form

wool• Each Highland clan have there own distinct

tartan design.• Tartan is now made in other fibres and

constructions and is used in fashion and furnishing for interiors.