World Bank Document...1995/05/22 · be rehandled by the draglines was under-estimated at...

Transcript of World Bank Document...1995/05/22 · be rehandled by the draglines was under-estimated at...

Document of

The World Bank

FOR OFFICIAL USE ONLY

Report No. 14512-JO

IMPLEMENTATION COMPLETION REPORT

THE HASHEMITE KINGDOM OF JORDAN

SHIDIYA PHOSPHATE MINE PROJECT(LOAN 2902-JO)

MAY 22, 1995

Private Sector Development and Infrastructure Division

Country Department IIMiddle East and North Africa Region

This docurment has a restricted distribution and may be used bv recipients only in the performance oftheir official duties. Its contents may not otherwise be disclosed without World Bank authorization.

Pub

lic D

iscl

osur

e A

utho

rized

Pub

lic D

iscl

osur

e A

utho

rized

Pub

lic D

iscl

osur

e A

utho

rized

Pub

lic D

iscl

osur

e A

utho

rized

Pub

lic D

iscl

osur

e A

utho

rized

Pub

lic D

iscl

osur

e A

utho

rized

Pub

lic D

iscl

osur

e A

utho

rized

Pub

lic D

iscl

osur

e A

utho

rized

IMPLEMENTATION COMPLETION REPORTJORDAN

SHIDIYA PHOSPHATE MINE PROJECT (LOAN 2902-JOI

CURRENCY EOUIVALENTS(Dec. 1995)

Currency Unit = Jordan Dinar (JD)JD 1.00 = US$1.418JD 0.705 = US$1.00

FISCAL YEAR

January 1 - December 31

WEIGHTS AND MEASURES

1 cubic meter (m3) 1.308 cubic yards1 metric tonne (t) = 1,000 kilograms (kg)1 metric tonne (t) = 2204.6 pounds1 kilometer (km) = 0.62 mile

ABBREVIATIONS AND ACRONYMS

DAP - Di-ammonium PhosphateJFI - Jordan Fertilizer IndustriesJPMC - Jordan Phosphate Mines Company Ltd.MMTC - Minerals and Metals Trading Corporation (India)mt - Million Metric Tonnesmtpy - Million Tonnes per Yeart - Metric TonneTPC - The Aqaba Port Corporation

FOR OFFICIAL USE ONLY

IMPLEMENTATION COMPLETION REPORTJORDAN

SHIDIYA PHOSPHATE MINE PROJECT (LOAN 2902-JO)

TABLE OF CONTENTS

Paae No.

PREFACE

EVALUATION SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .Project Objectives . . . . . . . . . . . . . . . . . . . . . . . . .iImplementation Experience and Results ............. . iiSummary of Findings, Future Operations, and Key Lessons Learned . . iii

PART I - PROJECT IMPLEMENTATION ASSESSMENT

A. Project Objectives .... . . . . . .. 1B. Achievement of Project Objectives . . . . . . . . . . . . . . . . 2

Sector Policy Improvements . . . . . . . . . . . . . . . . . . 2Physical Objectives ............... ... 3Institutional Development ....... ... 3Environmental Improvements ... . . . . . . . . . . . . .. 4Financial Objectives ... . . . . . . . . . . . . . . . .. 4Public Sector Management ... . . . . . . . . . . . . . .. 5

C. Implementation Record and Major Factors Affecting the Project . . 5Factors not Subject to the Borrower's Control . . . . . . . . . 5Factors Subject to the Borrower's Control . . . . . . . . . . . 6

D. Project Sustainability . . . . . . . . . . . . . . . . . . . . . 6E. Bank Performance .. 6F. Borrower Performance ... . . . . . . . . . . . . . . . . .. 7G. Assessment of Outcome ............... ... 8H. Future Operation . .. . . . . . . . . . . . . . . . . . . . . . 8I. Key Lessons Learned ................. ... 9

PART II - STATISTICAL ANNEXES

Table 1: Summary of Assessments . . . . . . . . . . . . . . . . . . 11Table 2: Related Bank Loans . . . . . . . . . . . . . . . . . . . . 12Table 3: Project Timetable .12Table 4: Loan Disbursements . . . . . . . . . . . . . . . . . . . . 12Table 5: Key Indicators for Project Implementation . . . . . . . . 13Table 6: Studies Included in Project ... . . . . . . . . . . . . 13Table 7A: Project Costs ..................... . 14Table 7B: Project Financing ................... . 14Table 8: Economic Costs and Benefits ... . . . . . . . . . . . . 15Table 9: Status of Legal Covenants . . . . . . . . . . . . . . . . 16Table 10: Bank Resources: Staff Inputs . . . . . . . . . . . . . . . 17Table 11: Bank Resources: Missions . . . . . . . . . . . . . . . . . 17

Appendix: Borrower Contribution to the ICR

This docutment has a restricted distribution and may be used by recipients only in the performance of their|official duties. Its contents may not otherwise be disclosed without World Bank authorization.l

IMPLEMENTATION COMPLETION REPORT

JORDAN

SHIDIYA PHOSPHATE MINE PROJECT (LOAN 2902-JO)

Preface

This is the Implementation Completion Report (ICR) for the ShidiyaPhosphate Mine Project in Jordan, for which Loan 2902-JO in the amount of US$31million was approved on January 19, 1988, and made effective on April 25, 1988.

The loan was closed on October 31, 1994, following an extension of4 months to the original loan closing date of June 30, 1994. Final disbursement

took place on December 22, 1994.

The ICR was prepared by Mr. Christopher Wardell, Industry and MiningDivision, Industry and Energy Department, Vice Presidency for Finance and PrivateSector Development and reviewed by Mr. Alastair McKechnie, Chief, Private Sector

Development and Infrastructure Division, Country Department II, Middle East andNorth Africa Region and by Mr. Gianni Brizzi, Project Advisor, Country Department

1I. The Borrower provided comments that are included an an Appendix to the ICR.

Preparation of this ICR was begun during the Bank's final supervision

mission in June 1994. It is based on material in the project file. The Borrowercontributed to the preparation of the ICR by frankly exchanging views on the

project preparation, procurement, implementation and initial operations'experiences and related issues, by commenting on the draft ICR and by preparing

its own evaluation of the project's preparation and execution.

IMPLEMENTATION COMPLETION REPORT

JORDAN

SHIDIYA PHOSPHATE MINE PROJECT (LOAN 2902-JO)

Executive Sumnary

Introduction

During the 19700 and early-1980s, Bank assistance to Jordan wasdesigned to support national development plans aimed at restructuring the economyto achieve a wider manufacturing base, to reduce dependency on external grants,and to spread development among different regions. Particularly, Bank assistancewas developed to diversify the country's economic base, to promote exports, andto alleviate manpower and infrastructure constraints in the productive sector,and encourage a more balanced growth among regions. In the industrial sector,Bank assistance was directed at a better utilization of domestic resources andmanpower skills, toward the establishment of a broader export-oriented industrialbase. Bank involvement in the industrial sector had consisted of an EmergencyCredit (1975) in the potash sector, potash projects (1978, 1986), an EnergyDevelopment Project (1983) and several power projects. IFC investment had beenin the production of ceramic tiles, aluminum fluoride, phosphate fertilizers,bricks, and the development of the Amman Capital Market.

Proiect Obiectives

(a) The primary project objective was to increase Jordan's phosphate rockproduction by 1.5 million tonnes per year, thus increasing the country's totalrock exports to a level in excess of 7 million tonnes per year. other objectivesincluded (i) ensuring that the production from the new project site would beinter-phased effectively with existing and declining phosphate rock productionat traditional mines; (ii) reorganizing and restructuring the phosphate sectorby the methodical integration of traditional mining operations with downstreamfertilizer facilities; (iii) investigating and remedying environmentaldegradation at phosphate loading operations at Aqaba; and (iv) optimizing thedesign of downstream phosphate beneficiation plant facilities planned as a secondstage Shidiya development (Section A).

(b) Although loan covenants were not designed specifically to promote theachievement of all the project objectives, a supplementary (side) letter to theloan agreement outlining dated agreements regarding environmental measures to beadopted, provided a framework to ensure that phosphate dust emissions at the portof Aqaba were brought quickly to international standards. In addition, covenantsin the Guarantee Agreement ensured effectively that project infrastructure wascompleted in a timely manner.

(c) Sector and institutional development, physical, and environmentalproject objectives were broad, clear and precise, and provided an excellentframework for successful project development and implementation (Section B). Theproject design and its implementation were neither complex, nor particularlydemanding for the Borrower. Risks attendant with projects involved in commodityexports facing cyclical trends were encountered. Borrower circumstances changed

- ii -

in the latter stages of project implementation due to a serious decline in worldphosphate rock markets. As a result, the Borrower had to scale back projectproduction build-up and mine development priorities in the context of plannedinter-phasing of Shidiya development with the output of traditional mines.

IuwvlementatLon Exrerience and Results

(a) Notwithstanding significant project delays, the project can bedefined as a success since it achieved the major part of its objectives. Sectorpolicy improvements have been effected (para. 8); physical objectives, within theconstraint of tight market conditions that have developed during projectimplementation, will be met within the next 12-15 months (para. 9); substantialinstitutional development of the Borrower's enterprise have been effected (para.11); phosphate mining and phosphate loading for export are now undertaken tointernational environmental standards (para. 12); and the financial and economicbenefits, even under an onerous fiscal regime imposed by government duringproject implementation, are substantial (para. 13). Project sustainability islikely, bearing in mind the Borrower's long experience in operating similaroperations with comparable technology (para. 18).

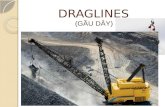

(b) The project has been completed at a cost of US$76.9 millionequivalent, compared with the forecast cost of USS87.1 million equivalent (PartIII, Table 7A). The cost savings result from the highly competitive bids formining equipment under international competitive bidding and the resultant lackof need to utilize estimated price and physical contingencies. Financingarrangements were essentially as planned (Part III, Table 7B), with the Borrowercovering most of the project costs not funded by the Bank loan. However, theBorrower took advantage of certain concessional loans: (i) a US$11.0 millionequivalent loan was mobilized from the Islamic Development Bank (US$2.0 wereutilized directly for the project) and (ii) supplier/export credits totallingUS$8.5 million equivalent were obtained and used to support Borrower's internalcash generation. The project construction was completed with the commissioningof the second dragline in October 1991. This compares with the plannedconstruction completion date of end-1989.

(C) Three key factors affected the achievement of the project's mainobjective of increasing the production and export of phosphate rock from Jordan(para. 16). Firstly, initial procurement had to be repeated after the non-responsiveness of initial bids received for draglines and for dump trucks.Secondly, the crisis in the Gulf in 1991 delayed erection of draglines and alsothe import of spare parts for mining equipment and the export of phosphate rock.Thirdly, serious market constraints occurred, starting in 1992, causing theBorrower to scale back the project production build-up and reduce Jordan's levelof exports. Phosphate ore stocks nonetheless accumulated in 1992-93 tounacceptable levels and the Borrower was obliged to focus on reduction of thesestocks to manageable levels, largely at the expense of production. In addition,the quantity of overburden created from the rnitial mining cut and which had tobe rehandled by the draglines was under-estimated at appraisal. This reduced thecapacity of main mining equipment to expose sufficient phosphate rock to meet theplanned production schedule. The performance of main mining equipment also didnot reach levels warranted by suppliers. Due to the delays associated with thesefactors, the quantity of lower quality Shidiya ore beds released from the initial

- iii -

mine development exceeded forecasts and with the delay of construction ofbeneficiation plant facilities (under Loan 3172-JO) to process this lower qualityore, led to the Borrower slowing the initial mine development production build-up(para. 17).

(d) In general, the performance of the Bank, the Borrower and thegovernment as Guarantor, was highly satisfactory throughout projectimplementation (Sections E and F). The Borrower prepared a bankable feasibilitystudy; handled procurement efficiently; and constructed the project in acommercial and well organized manner. The Guarantor arranged the timelyprovision of project infrastructure and ensured that a necessary share issue toincrease the Borrower's capital base was fully subscribed. Bank staff assistedin defining a project scope that was within the financing capability of thecountry and that secured early project output and revenues. Bank and Borrowerstaff participated in a major development impact assessment. Although thisoccurred towards the end of project implementation, it proved critical to focuson key project issue. and the adjustment of corporate strategie. for the Borrowerduring serious market difficulties. The main weakness of the Bank was in itsoptimistic forecast of world market growth for phosphate rock exports and indeveloping spare parts (working capital) management arrangements that wereunworkable as defined originally in the loan agreement. The main weakness of theBorrower was its failure to (i) transfer the most experienced operating personnelfrom existing mines to the new project site; and (ii) adjust quickly itscorporate strategies during the latter stages of project implementation, in thelight of declining market conditions.

(e) On the basis that the major project objectives have been met and thatthe physical objective of developing an early mine production scheme at Shidiyais reachable in the near-term, the project outcome is rated as satisfactory. Inaddition, it provides a sound basis for ensuring the success of the subsequentIntegrated Phosphate Project (Loan 3172-JO).

Summary of Findings. Future Operations, and Key Lessons Learned

(a) The Borrower's overall production plan is now focused on thedevelopment of the low unit production cost Shidiya mine area and its orderlyinter-phasing with traditional mine areas. Production build-up is continuing tostrengthen and the target output is planned to be achieved in 1996, in phase withthe start-up of beneficiation plant facilities under Loan 3172-JO. On the basisof the Borrower's long experience in the operation of phosphate mines utilizingsimilar technology, the recent change of senior management, and the commitmentof operations and maintenance staff to the mine site at Shidiya, the projectoutput is reachable and should pose no problem in terms of sustainability(Section H).

(b) There are two key findings/lessons to be learned from the projectimplementation experience (Section I). Firstly, with a simple project design anda strong commercially oriented enterprise, substantial project benefits can beattained in terms of sector and institutional development, physical output, andenvironmental and financial/economic impact. Secondly, for any enterpriseinvolved in commodity exports subject to cyclical trends, market growth prospectsmust be addressed with caution and sensitivity analyses undertaken to ensure

- iv -

project viability and *ustainability. In addition, the enterprise managementmust remain flexible and be able to adjust quickly its corporate strategies tosurvive serious market fluctuations and down turns. In this case, however, themajor economic dislocations that occurred in eastern Europe in the early-1990'sthat affected seriously phosphate world demand could not be anticipated in anymeaningful way in sensitivity analyses.

(C) Following the Borrower's successful upgrading of its corporate andproduction planning, financial analysis skills and overall corporate financialmanagement, Jordan's phosphate sector operations management should continue tomake a major contribution to the country's economy. Together with the corporateupgrading the project should place the Borrower in a strong and predictablefinancial position, such that, with adequate guidance, private sector interestscould now be encouraged to assist and actively participate in future industryexpansion.

IMPLEMENTATION COMPLETION REPORT

JORDAN

SHIDIYA PHOSPHATE MINE PROJECT (LOAN 2902-JOb

Part I - Project Implementation Asses me nt

A. Proiect Ob ectives

1. Recognizing that phosphate is the most important of Jordan's mineralresources and provides substantial foreign exchange earnings (through the exportof phosphate rock and phosphate fertilizers) and thus a substantial contributionto gross domestic product, the primary project objectives were (a) to increasephosphate rock production and the level of phosphate rock exports and (b) toopen-up the first stage of the newly discovered Shidiya phosphate area.

2. Phosphate rock had traditionally been mined at the Zl Hansa and Z1Abiad mines. However, these mines were faced with limited economicallyrecoverable phosphate rock reserves and were becoming increasingly high cost,thus reducing potentially the international competitiveness of Jordan's exports.Exploration campaigns at Shidiya had identified extensive reserves of phosphaterock of relatively high quality and over a continuous area, as opposed toexisting mines with rock only occurring in isolated lenticular and thus separateore bodies. Pre-feasibility assessment had indicated that mine development atShidiya could be undertaken at lower unit production cost, thus reducing Jordan'soverall production costs and increasing its international competitiveness. Theproject recognized the need for an orderly inter-phasing of declining output fromthe existing mines with the start-up of Shidiya operatlons. Thus the primaryproject objectives were both clear and realistic.

3. Initlal pre-feasibility study assessments had focused on thedevelopment of a 10 million tonnes per year Shidiya mine operation as anintegrated mine-beneficiation plant-rail-fertilizer plant development. Thesubsequent project redesign as an early mine production scheme (1.5 milliontonnes phosphate rock per year), to be followed by the development of phosphatebeneflclation plant facilities at Shidiya to produce an additional 1.5 milliontonnes phosphate rock concentrates per year from the benefiLiation of lowerquality rock from the initial mining area, brought the project scope within thefinancing capabilities of the country, thus facilltating the generation of earlyphosphate rock production and revenues from the Shidiya deposit.

4. Serious environmental issues existed at the port of Aqaba wherephosphate rock was loaded onto ships for export. The project objective ofprovidlng technlcal assistance to evaluate options to do-dust phosphate rockproducts at the various mlne sites in Jordan and to investigate the nature of andremedy the environmental degradation at the ship loading facilities at Aqaba waswell conceived. In addltion, the Lnvestigation of the utilizatlon of phosphatefines in the fertilizer plant facilities at Aqaba was designed to enhance theeconomics of the overall phosphate industry in Jordan.

- 2 -

5 The implementing agency (the Borrower) for the project was the JordanPhosphate Mines Company (JPMC) Limited. With long experience in the development,construction and operation of phosphate mines in Jordan, utilizing similartechnology, the project was well within the Borrower's capabilities. Theproject's institutional objective was to assist the Borrower to reorganize andrestructure the phosphate sector by the methodical integration of JPMC'straditional phosphate mine operations with downstream fertilizer plantoperations, formerly managed by the Jordan Fertilizer Industries (JFI). Arelated objective was to restore the private sector's confidence in JPMC inanticipation of its participation in future expansion phases. This was necessarymince the financial impact of the integration of JFI's fertilizer complex hadplaced the company in a tight cash position and with reduced profitability. Theproject also included provision for technical assistance to help optimize thedesign of beneficiation plant facilities at Shidiya to process lower gradephosphate rock to be mined in addition to the direct export rock.

6. The project faced no technical risks beyond those associated with anyopen-pit mine development. On the basis of JPMC's long experience in minedevelopment in Jordan, these risks were recognized as minimal. Main risks wereforeseen in phosphate market development forecasts and prices. Sensitivityanalyses demonstrated that under worst foreseen assumptions, the project was notexposed to serious risks in these areas.

7. Borrower circumstances changed dramatically in 1992 with a markeddeterioration in market conditions for the export of phosphate rock. EasternEurope markets virtually collapsed, particularly in Romania and Poland (due toserious internal economic difficulties and limited foreign exchange to procureimports), and in Yugoslavia (due to internal conflicts). In India, one ofJordan's key markets for phosphate rock exports, market penetration wasaggravated by (i) the removal of India government subsidies to farmers, and (ii)liberalization by the Indian government of procurement of phosphate fertilizerraw materials imports for both public and private enterprises, responsibility forwhich had previously rested on a monopoly basis with the Indian Minerals andMetals Trading Corporation (MMTC). Lack of adjustment of corporate strategiesto these deteriorating market conditions led to serious Borrower financialresults in 1993 and a need to cut back quickly rock production to draw downexcessive levels of stocks. As a result, Jordan's overall phosphate rockproduction (including the project development) had to be pared back and the levelof phosphate rock exports declined.

B. Achievement of Proiect Obiectives

8. Sector Policy Improvements The Shidiya Mine Project was notdesigned specifically to address policy issues. However, important sector policymatters were addressed. The mining and fertilizer operations of the phosphateindustry in Jordan were fully integrated and the management, planning, budgetingand accounting of the new company's (mine and fertilizer) operations wererationalized. By the time of loan closing, the Borrower had committed itself toimplement a program to upgrade production planning and financial management andto focus production on a cost-driven (as opposed to an export/production-driven)basis and to focus production on the lower unit cost Shidiya mine area.Phosphate fines are now collected at mines during de-dusting and are utilized at

the fertilizer complex with sub-commercial phosphate rock grades as an integralpart of the fertilizer plant feed, thus enhancing the overall economics of thesector. During the project implementation, JPMC developed private sector jointventure contracts for the construction of downstream intermediate and finalphosphate fertilizer products in Jordan, providing not only a captive supply fora portion of phosphate rock production but further diversifying its product linesand thus its ability to adjust to phosphate market demand variations.

9. Physical Obiectives. The project was designed to produce 1.5 milliontonnes of direct export ore from the high quality A2 phosphate bed at Shidiya,by 1989. Production in 1994 reached almost 1.0 million tonnes and is scheduledto reach 1.4 million tonnes in 1995, with target production being attained in1996, to phase with the completion of beneficiation plant facilities under Loan3172-JO. The delayed production build-up is due, inter alia, to (i) initialprocurement delays; (ii) the crisis in the Gulf in 1991; (iii) excessive levelsof overburden from the initial mine opening cut that have had to be rehandled;(iv) tighter than anticipated world phosphate rock market conditions; and (v)levels of stocks of the lower quality Al and A3 ores that has accumulated due todelays in starting construction of the Shidiya beneficiation plant. Constructionof the beneficiation plant under Loan 3172-JO is now advancing as per the revisedproject schedule and will be commissioned at end-1995, at which time, Shidiyamine output should reach its target production. Although this will represent adelay of the attainment of the key project objective, the reduced project costshave translated into strong project benefits (para. 13).

10. Although the objective of increasing production at Shidiya to 1.5million tons will be achieved, the objective of expanding the export of Jordan'sphosphate rock has not been achieved. Due to the collapse of the economies ofkey east European importing countries and more onerous conditions for the importof rock in India, world phosphate trade deteriorated substantially in the early1990s. Jordan's phosphate rock exports, forecast at appraisal to increaseprogressively to 8.0 million tonnes by 1994, declined actually from the 1986level of 5.3 million tonnes to only 3.8 million tonnes in 1994 and are notexpected to exceed 4.0 million tonnes in 1995. Nevertheless, through aggressivemarketing strategies, JPMC has maintained its world market share of approximately14 per cent.

11. Institutional Development. Substantial development of JPMC hasoccurred during the project preparation, appraisal and implementation phases.At the time of project preparation, the government had reached agreement withJPMC management that the company would assume responsibility for the state-ownedJordan Fertilizer Industries (JFI), operator of a di-ammonium phosphate(DAP)/phosphoric acid plant at Aqaba. JFI had failed to reach its target project(output) objective and faced financial distress. In taking over responsibilityfor this fertilizer operation, JPMC management saw the benefit of (i)consolidating the mining and processing phosphate industry operations in Jordan,(ii) increasing the vertical integration of Jordan's phosphate mine andfertilizer industries, and (iii) developing a more diverse market product spread.However, JPMC also recognized that institutional restructuring would beimportant. It recognized that although there would be benefit in production(mines and fertilizer) units maintaining operational and managerial autonomy,functional units would require enhanced integration. Although the integration

of technical, marketing and finance functions was advanced at the time ofappraisal, agreement was reached that administration, internal audit, cost andfinancial accounting systems, financial studies and budgeting, and corporateplanning would be upgraded to improve corporate cost effectiveness. The lastphase of technical assistance (production planning and financial management) hascompleted effectively the overall corporate restructuring plans, JPMC is nowcommitted to further upgrade its corporate planning/financial management and isthus well placed to conduct its affairs in a controlled commercial manner and tomaintain its international competitiveness.

12. Znvironmental Imnrovement . No serious environmental issues wereforeseen at the mine site and none have developed. The key issue addressedduring appraisal and loan negotiations related to the phosphate dust emissionsduring ship loading of phosphate rock at Aqaba. Phosphate dust emissions hadbeen associated traditionally with (i) rail and truck movements and unloading atthe port site, (ii) conveyor transfer to ship berth areas, and (iii) shiploading. JPMC committed themselves to the procurement of local consultants whodeveloped monitoring stations and measured deposition in the town of Aqaba, atthe port site and in the general environs of the port. As a result of this studyprogram, it was established that the major environmental issue at and aroundAqaba was generated by dust blown from the adjacent desert areas. Backgrounddust levels were such that monitoring stations were unable to measure anyquantity of phosphate particles. Nevertheless, JPMC accepted that dust emissionsduring ship loading were measurable and committed itself to (i) a program of de-dusting phosphate rock at the inland mine sites to mitigate phosphate finesarriving at the port; (ii) successful testing of the utilization of phosphatefines at the fertilizer complex and their transportation to that plant; (iii) theinstallation of dust collection devices at unloading points within the portcomplex; and (iv) the procurement and installation of choke feeders to controlduct emissions during ship loading. In addition, general housekeeping at theport site (road cleaning etc.) was substantially upgraded. The quantities offugitive dust now generated by JPMC operations at Aqaba having been essentiallyeliminated. Nevertheless, through ongoing discussions with the Aqaba PortCorporation (TPC), further improvements in housekeeping, focusing on additionalfine tuning of phosphate unloading areas and conveyor transfer towers is planned.This will bring the environmental position of the phosphate loading at Aqaba portinto a world class statas.

13. Financial Objectives. Significant financial and economic benefitsfrom the project were estimated at project appraisal, confirmed during adevelopment impact assessment (mid-term review) and reconfirmed at loan closing.Although the economic benefits are lower than originally forecast, they arenevertheless, highly positive (Part II, Table 8). The economic rate of return,now recalculated at 20 per cent (as compared to the originally forecast 37 percent) underscores the beneficial impact of the project on the Jordanian economy.The rate of return has been reduced due to delayed revenue (production build-up)development brought about primarily by (i) initial procurement difficulties; (ii)the impact of the crisis in the Gulf; and (iii) depressed world phosphate rockmarkets. The financial rate of return, now forecast at 10 per cent, confirmsthat the project will contribute to the future financial health and stability ofJPMC and to the future competitiveness of the Jordan phosphate industry (througha reduction in overall JPMC production costs) and can be considered, therefore,

as satisfactory. The financial rate of return has been impacted significantlyby the government imposition, during project implementation, of a JD5.0 (US$7.1)per tonne production tax (the financial rate of return without the production taxiu octimated at 16 percent which can be compared to the originally forecast 36per cent). This tax is essentially a windfall profits tax, representing anopportunity taken by the government to draw down a portion of JPMC profits tofund development in other sectors of the economy. In the short-term, such a taxmay be considered to be in the overall interest of the country; however, in themedium term, this fiscal taxation environment (which by international miningstandards is onerous) would deter potential private interest in JPMC. Inaddition, such a fiscal environment detracts from JPMC's ability to maintainfinancial stability (as evidene d by the new share issue that had to besubscribed by the government in 1993) and weakens the company's ability to retaincash generation to fund future investments/expansion. Financial benefits are alsoaffected by government imposition of (i) axle-load charges on phosphate trucktraffic to Aqaba port (a road maintenance cost recovery mechanism); and (ii)incroaxcd port fees.

14. public 8etor Managment. JPMC is an excellent example of a publicsector enterprise operating on a commercial basis and able to implement a projectin a highly successful manner. JPMC Projects Department staff produced abankable feasibility study; handled international procurement in an expeditiousmanner; and organized project construction with a high level of coordination andffriciency. The project has placed JPMC in a potential financial position whereprivate interests would find the company more attractive, subject only togovernment recreating a favorable fiscal and regulatory environment that matchesthat of the mining industries of other countries.

C. IDli_ ntation Record and Kaior Factors Affeftinw the Proiset

15. Based on the near achievement of sector policy, institutional,physical and financial objectives, the project can be considered as a substantialsuccess. The implementation record of the project is satisfactory, albeit that(i) initial procurement difficulties were faced; (ii) the crisis in the Gulfinterfered with expeditious equipment erection and commissioning, and spare partsprocurement; (iii) production build-up was slower than planned; and (iv) targetmine production has yet to be attained.

16. Factors not Subiect to the Borrower' Control. Procurement (ICB) wasmarred by the initial non-responsiveness of bidders for main mining euipment.Following re-bidding, contracts were finalized successfully but the 6-monthproject implementation delay incurred could not be recovered. The crisis in theGulf immediately prior to the completion of erection of the main mining equipmentcaused an additional 9-month delay. The performance of main mining equipment didnot reach levels warranted by suppliers. Difficulty in spare parts procurementfor trucks was experienced following the Gulf crisis. Production build-up to thetarget output of 1.5 million tonnes A2 ore year has been slower than planned.Initially this was due to procurement difficulties and the crisis in the Gulf.However, the key factor affecting production build-up has been deterioration inworld phosphate demand, which still constrains the Borrower's export levels(including the export of A2 ore from Shidiya).

- 6 -

17. Factors Subiect to the Borrower's Control. Dragline performance hasyet to reach level, forecast at appraisal, primarily due to incompletecalculations by both Bank and Borrower staff at appraisal regarding the quantityof overburden to be rehandled from the initial box-cut. Procurement processingof turnkey contracts under Loan 3172-Jo, non-responsiveness of turnkey contractbids received and the advent of the crisis in the Gulf, have caused delay in theconstruction of bensficiation plant facilities to process the lower quality (Aland A3) ore, with the consequence that excessive stockpiles are developing. Thisfact, together with the overall market constraints (outside of the Borrower'scontrol), led to the Borrower's focus on reduction of excessive levels ofphosphate stocks to a manageable level and a resultant slow down in Jordan'soverall phosphate rock production and Shidiya mine development.

D. Proiect Sustainabilitv

18. Bearing in mind the long and successful track record of the Borrowerin developing and operating phosphate mines based on similar dragline and mobilemining equipment technology, the probability that the project will reach andmaintain its major objective of producing 1.5 million tonnes direct export oreper year from the new and low cost Shidiya mine area, is high. It is now plannedthat the project's physical objective will be reached at end-1995, when thebeneficiation plant (being constructed under Loan 3172-JO) is scheduled to becompleted. From that date, the project is considered likely to be fullysustainable. Although project delays have occurred and project benefits arelower than forecast at project appraisal, realized project costs are lower thanplanned and benefits are highly positive (para. 12).

R. Bank Performance

19. The performance of the Bank can be considered highly satisfactory.During project preparation, Bank staff assisted the government to re-define theproject scope, reducing it from a complex, high cost integrated mine-fertilizerplant-rail configuration to a simple early production mine scheme that permittedthe early development of the potentially lower unit production cost Shidiya minearea, within the financing capabilities of the country. This reconfiguration ofproject design led to an extensive (4 years) project preparation (identificationto appraisal) cycle and to the subsequent formulation of a follow-up operation(Integrated Phosphate Project - Loan 3172-JO) to complete the first phase Shidiyamine development. During successive supervision missions, Bank staff assistedthe Borrower to maintain focus not only on project implementation issues but alsoon overall corporate development objectives and strategies.

20. A key contribution of the Bank was an interim assessment of thedevelopment impact of the project. Although undertaken toward completion of theproject, this assessment was invaluable in reassessing the likely benefits thatwould result from project implementation and actions necessary to ensure thatbenefits were maximized. The assessment was undertaken (June 1993)coincidentally at a time when the Borrower, and other world phosphate producers,were facing serious marketing constraints and facilitated the Borrower's focuson the urgent need to adjust quickly its corporate strategies, productionplanning and overall financial management to optimize the integration of Shidiya

with traditional mines output consistent with maximizing cash flow, liquidity andprofitability.

21. The main weakness of the Bank's performance was its forecast of worldphosphate market demand. At appraisal, Jordan's rock export levels were forecastto rise progressively to a level of 8.0 million tonnes by 1994. Actually, Jordanexports in 1994 are likely to reach only 4.0 million tonnes, reflecting primarilythe collapse of Eastern European economies and the ability of those countries tofinance phosphate (and other) imports and the withdrawal of subsidies to farmereand the dissolution of the central fertilizer procurement agency in India.Although these economic changes could not have been foreseen easily at the timeof appraisal, more realistic sensitivity analyses could have helped the Borrowerfocus better on the importance of production planning, and to anticipate andprepare better for the financial stress that resulted in 1993 from a delayedcorporate adjustment to deteriorating market conditions.

22. Although the need for the Borrower to focus on materials (spareparts) management was recognized during project appraisal, the loan agreementcovenant developed was impractical and ill-conceived. Subsequently, thiscovenant was redefined and effective assistance provided to JPMC to recruitinternational specialists to upgrade spare parts (working capital) management.

P. Borrower Performance

23. The performance of the Borrower (JPMC - the project implementingagency) in preparing, implementing and operating the project has been highlysatisfactory. The Shidiya project feasibility study prepared by the Borrower wasof an international and bankable standard and greatly facilitated the Bank'sappraisal of the project. Project procurement was handled efficiently. Mineinfrastructure was developed progressively and ahead of schedule. The Borrowerutilized effectively equipment from existing mines to open up the initial minecut in a timely and well organized manner. The government (as Guarantor) ensuredthat a mine access road and power lines were completed on schedule and that theissue of share capital was fully subscribed, supporting international (Kuwait)participation. In particular, the government, although the principal shareholderin JPMC, continued a hands-off approach, leaving the company management toconduct its affairs in its traditional and commercially successful manner.

24. The Borrower and Guarantor participated in the Bank's developmentimpact assessment with enthusiasm and commitment, agreeing with the estimate oflower, through satisfactory, economic and financial rates of return and in theneed to adjust corporate strategies to weakened world market demand and to focusbetter overall production planning and financial management. In the depressedworld phosphate market that developed during project implementation, the Borrowermade excellent and successful attempts to develop a market for Shidiya phosphateore. Although the Borrower continues to be faced with tight world phosphatemarket conditions, technical assistance was retained successfully to assist inupgrading production planning and overall corporate financial management tooptimize the inter-phasing of Shidiya with existing mines with declining reservesand to develop a fully cost-driven planning model.

25. The main weakness of the Borrower was in not transferring fully-experienced key management, operations and maintenance personnel from itsexisting mines to the start-up (initial operations) of the Shidiya development.This led to somewhat of a lack of focus on the importance of quick productionbuild-up and equipment availability and utilization that was corrected only inthe later stages of implementation. In addition, important upgrading of thecompany's corporate and production planning, and the development of financialanalysis skills and improved corporate financial management, was achieved onlyin the later stages of the project cycle.

26. In relation to loan covenants, the Borrower and Guarantor were ingeneral compliance throughout project implementation. In the later stages of theproject implementation, the Guarantor introduced an onerous fiscal regime for thephosphate industry encompassing a phosphate production tax, truck axle-loadcharges and increased phosphate port fees to be paid by the Borrower. Themefactors, together with the Borrower's failure to adjust corporate strategies todeteriorating world market conditions, led to the Borrower's failure in 1993 and1994 to maintain a financial working ratio as covenanted. New JPMC managementhas adjusted now its corporate strategies and is upgrading its overall corporateand production planning, and financial management functions. The Borrower shouldnot face difficulty in complying with all financial covenants in future years.This position will be monitored during ongoing supervision of the IntegratedPhosphate Project under Loan 3172-JO.

3. Assessment of Outcome

27. On the basis that major project objectives have been met and thephysical objective of 1.5 million tonnes phosphate rock is considered reachableand sustainable, the project outcome is rated as satisfactory. Since thecompletion of project construction and the start of initial mine operations,Shidiya mine production has progressively increased. Although the production(1.0 million tonnes) of A2 direct export ore in 1994 is below the targetproduction of 1.5 million tonnes per year, over 90 per cent of target productionis planned and realizable in 1995. The outcome of the project is thus consideredsatisfactory, bearing in mind (i) the likely attainment of target production in1996; (ii) the presently depressed world phosphate markets; and (iii) the delaysin construction of the Shidiya beneficiation plant (under Loan 3172-JO). TheBorrower's production planning and overall corporate financial management arebeing upgraded and the Borrower is poised now to return to its earlier years ofsound financial health and security and to make a continued strong contributionto the country's economy and foreign exchange earnings.

H. Future Overation

28. The Borrower's overall corporate plan is focused now on the lowerunit production cost Shidiya mine operation and its orderly inter-phasing withexisting mines. The Borrower's Shidiya operations plan foresees A2 oreproduction reaching the target level in 1996, in phase with the completion andstart-up of the Shidiya beneficiation plant (under Loan 3172-JO) to process lowerquality Shidiya ore. The Borrower's Production Department and Shidiya minemanagement personnel are focused in a way that will likely assure the success ofthe future operation of the Shidiya area.

-9-

29. The key indicators for monitoring and evaluating the future operationof the Shidiya Mine project, although not identified during the project appraisalor during loan negotiations, include the rate of recovery of world phosphate rockmarkets, and the performance (availability/utilization, and output per unit time)of the dragline and truck/shovel mining systems. Bank follow-up will be anintegral part of the supervision of the ongoing Integrated Phosphate project(under Loan 3172-JO), scheduled for loan closure on December 31, 1995. A projectimpact evaluation by the Operations Evaluation Department is not recommended asa priority.

I. Kev Lessons Learned

30. The most significant positive lesson learned from the implementation'of the project is that with a simple project design, substantial project benefits(physical, institutional, environmental, and financial) can be realized by anenterprise such as JPMC, run on commercial lines, and with a committed managementteam, well organized project staff to handle procurement and construction,experienced operations staff to manage initial operations, and support fromgovernment and other shareholders.

31. The key negative lesson to be learned is that enterprises involvedin the export of commodities (such as phosphate rock) that are subject tocyclical trends, are subject to variable demand patterns as well as to economicand political changes in importing countries. In developing market growthforecasts against such uncertainties, great care needs to be exercised in basecase analysis, and sensitivity analyses are of critical importance. In addition,overall corporate management of such an enterprise must be flexible enough so'that corporate strategies and financial management can be adjusted quickly toride out serious market fluctuations.

- 10 -

IMPLEMENTATION COMPLETION REPORT

JORDAN

SHIDIYA PHOSPHATE MINE PROJECT (LOAN 2902-jon

Part II - Statistical Annexes

- 11 -

Table 1: Summary of Assessments

A, Achievement of oblectives Substantial Partial Neallolble Not anURl&able

Macro policies O3 3 E3 Sector policies E3 E3 [3Financial objectives 0 3 l O

Institutional development Ez 03 03

Physical objectives E 0 E O

Poverty reduction O3 0 0 0Gender issues Ol 0 0 0

Other social objectives O3 E3 0 0Environmental objectives 0i3 OEl 0Public sector management E3 0 0Private sector management O El 0

HiahlyB. Prolect sustalnablllty atisfactor Sa tifactory Deflcient

0 O O3 ElHiahlv

C. Bank performance Satisfactory Satisfactory Deficlent

Identification 0 0l ElPreparation assistance 0 El ElAppraisal E3 0 E3Supervision 0 El El

HichlvD. Borrower performance satisfactory Satisfactory Deficient

Preparation 0 E iO

Implementation 0E 0 0Covenant compliance E3 0 0Operation (if applicable) El; 0 E3

E. Assessement of outcome satisafactor Satisfactory llns disf oryunstisfatory

O 0 E3 El

- 12 -

Table 2: Related Bank Loans

Loan/Title Purpose Year of StatusApproval

Preceding Operations1. Jordan Fertilizer Phosphate Fertilizer Plant Development 1975 Completed

Design/construction engineering Loan closed2. Potash Engineering Potash extraction refining 1975 Completed3. First Arab Potash Potash extraction expansion 1978 Loans closed4. Second Arab Potash 1987

Following Operations1. Integrated Phosphate 1) Shidiya beneficiation plant 1990 1) Advanced

development construction2) Ferdlizer plan rehabilitation 2) Completed

2. Indo-Jordan Chemical Phosphoric acid plan development 1994 Loan signed & effective

Table 3: Project Timetable

Steps in Project cycle Date planned Date actual/latestestimate

Identification Feb-83 Feb-83Appraisal May-97 May-87Negotiations Dec-87 Dec-87Board presentation Dec-87 Jan 88Signing Jan-88 Feb-88Effectiveness Jan-88 Apr-88Midterm review Jun-93Project completion Dec-93 Dec-93Loan closing Jun-94 Oct-94

Table 4: Loan Disbursements: Cumulative Estimated and Actual(USS Thousands)

FY88 FY89 FY90 FY91 FY92 FY93 FY94 FY95

Appraisal estimate 2000.0 9900.0 17400.0 23000.0 26800.0 30200.0 31000.0Actual 2000.0 6610.0 22860.0 27150.0 29480.0 29480.0 30690.0 31000Actual as % of estimate 100.0 66.8 131.4 118.0 110.0 97.6 99.0 100.0Date of final disbursement 12/22/94 I I I I I I I 100.0

- 13 -

Table 5: Key Indicators for Project Implementation

Key Implementation Indicators (1) Estimated Actual1. Organizational/management Complete by 12/88 Completed on schedule

improvements

2. Phosphate production 125,000 tonnes 85,000 tonnes per month (2)

3. Infrastructure development Completed on schedule

4. Environmental Complete program 08/88-12190 Completed with some delaysinvestigations/remedialactions

Table 6: Studies Included in Project

Stud Purpose Status Impact of Study1. Phosphate beneficiation Refine plant engineering Completed Assisted plant engineering

under Loan 3172-JO

2. Materials management Improve working capital Completed Improved materialsmanagement management practices and

working capItal managementongoing

3. Protection planning/financial Upgrade corporate planning and Completed Improved corporatemanagement financial stability I _Iplanning/financial management

- 14 -

Table 7A: Project Cost

SAR ESTIMATE ACTUAL COST

Local IForeign I Total Local I Foreign Total

US $ Million US $ Million

Mine Equipment 2.9 30.3 33.2 36.6 36.6'/Milisite Equipment 1.3 6.2 7.5 4.8 9.5 14.3Civil Works & Infrastructure 8.1 8.2 16.3 7.1 5.6 12.7Dust Control 0.6 1.5 2.1 0.02/Engineering & Technical Assistance 4.6 0.7 5.3 0.9 0.6 1.5

Base Cost 17.5 46.9 64.4 12.8 52.3 65.1

Physical Contingencies 0.9 4.7 5.6Price Contingencies 0.7 2.1 2.8 _

Installed Cost 19.1 53.7 72.8 12.8 52.3 65.1

Working Capital 4.3 10.0 14.2 5.2 6.6 11.83/

Total Project Cost 23.4 63.7 87.1 18.0 58.9 76.9

Interest during Construction 1.9 1.9 10.1 10.13/

Total Financing Required 23.4 65.6 89.0 18.0 69.0 87.0

(1) Includes support vehicles.(2) Costs assumed by The Ports Corporation.(3) Includes all costs and provisions to end 1993 (effective date of commercial production).

Table 7B: Project Financing

|Apraisal Estimate (US$M) Actual/Latest Estimate (US$M)SOURCE Local Cost Foreign Cost Total Cost Local Cost Foreign Cost Total CostIBRD 31.0 31.0 31.0 31.0Islamic DeveloPment Bank - - 2.0 2.0Export Credits -l- - - 8.5 8.5Domestic Contribution 23.4 34.6 58.0 18.0 27.5 45.5TOTAL 23.4 65.6 89.0 18.0 69.0 87.0

LArranged through equipment suppliers (KfW, Creditanstalt and US Community Import Program).

Table 8: Economic Costs and BaneXft(JD 000 in real 1994 terms)

1988 1989 1990 1991 1992 1993 1994 1995 19961 19971 1998 1999 2000 2001 2002 2003

< -- Actuals > - Projected - >

SALES REVENUEA2 5,434 13,164 11,545 15,247 28,168 28.394 31,004 41,019 42,001 42,001 42,001 42,001 42,001 42,001 42,001

Al _IA2

TOTAL BENEFITS 5,434 13.164 11,545 15.247 28.168 28,394 31,004 41,019 42,001 42.001 42,001 42,001 42,001 42,001 42,001

CAPITAL INVESTMENT-INITIAL CAPITAL 3.277 10,766 18,355 8,623 3,170 1,035-REPLACEMENT 3.520 2.620 1,240 1.860 2,280 3,110 1.240 1,240 2,280 2,981 2,981

CHANGE IN WORKING CAPITAL 1,851 2,373 474 899 2,616 154 (95) 2.706 396 224I,'tn

PRODUCTION COSTS 3,099 6.404 9,426 10,228 10,502 11,044 8,766 11,820 12,572 13.432 13,432 13,432 13.432 13,432 13,432TRANSPORT 550 1,075 925 1,500 2,217 2.523 2,755 3,665 3,665 3.665 3,665 3,665 3,665 3,665 3, 665MARKETING 286 559 481 780 1,153 1,329 1,544 2.383 2.369 2,365 2.365 2.365 2,365 2,365 2,365

TOTAL OPERATING COSTS 3,935 8,038 10,831 12,507 13,872 14,897 13,065 17,867 18,606 19,461 19,461 19,461 19,461 19,461 19,461

PRODUCTION TAX

TOTAL COSTS 3,277 16,552 28,766 19,928 16,577 21,043 17,671 14,210 22,433 21,262 22,795 20,701 20,701 21,741 22,442 22,442

INFLATION INDEX 1.64 1.55 1.27 1 18 1 11 1.05 1 00 100 100 1 00 1.00 1 00 100 100 1.00 1.00

NET BENEFITS IN 1994 TERMS (5.363) (17,215) (19,883) (9,686) (1,470 7,481 10,723 16,794 18.586 20.719 19,206 21,300 21,300 20,260 19,559 19,559

ECONOMIC RATE OF RETURN 19.6 %

- 16 -

Table 9: Status of Legal Covenants

AGREEMENT Section Covrnt Present Original Revised Descnption of Commerts

type atus futhilment fufitlmrnet convenant

date date

Loan 2.02 (b) 1 C Borrower to maintain Special Account

4.02 5 C Borrower to operate/maintain facilities make necessary

repairadrenewals to sound practices in accordance

with acceptable environmentaUs;ltety stndards.

4.02 (b) a CO 08/a8-12190 06f8-1 2/91 Borrower to: (a) monior dust levels at port (b) provide CompleWtd

reports on monitoring (c) provide specifications for dust

removal equipment (d) take action to ensure healthirenriron-

ment standards and reduce emissions, and (e) allocate

funds for equipment procurement in (c) above, and ensure

dust =colection equipment installed and phosphate fines

cclected, separated. tansported and disposed of.

4 03 5 C Bomrwer to take out and maintain insurance.

4X08 2 CD = - Borrower to (i) provioes tatement on statusvalue of Working capital (pre parts)

spares; (ii) confirm disposal of obsolete spares, and (iii management program under

provide statement on procedures to minimize inventory. implementatbon.

5S01 1 C Borrower to maintain separate unit accounts and have

accounts audited, including audit of special account

and SOE.

5 02/34 2 CD Borower to maintain a debt service ratio above 1.5 in FYd8 Due to onerous fiscal rgime

and thereafter, a long-term debtVequity rabo belowv W40 (production ta) introduced by

in FY88 and thereafter, obtain Bank agreement to any new govemment during implementabon,

long-term loans in excess of JD 1.5 million, maintain working rbo at loan closing was O.U.

working ratio below U.t from Fy88 onward, and prepare a With ongoing upgrading of pro-

5 year financing and investrnent plan duction plans and financial management.

all financial coivenants will be met in

1t95 and therafter.

5 05 2 C 128 Borarwer to raise its capital end special reserves by a Completed

minimum of JD 25 ml to ensure that the valu of its equity

is equal to or greater than JD80 ml.

Sction Section 5 5 C 06/8806/8 Borrower to implement action plan for managenal Completed

integration; Ci) establish intemal audit unit (ii) stablish

planning unit (iii) unify administntion of personnel-

(rv) integrate accountng systems; (v) establish

unn for financial and cost accountng purposes; (vi)

establish unit for financial analysis; and (vii) provide

for plan for TA and appoint consultants.

Guarantee Z02 2 C Govemrnment to Subscnrbe to new share issue. Complted

2.03 3 C Government shall cause the Min. Public Works to complete Completed

ac&ess roads and JEA to complete construction of pr re

line/subsation and finance corresponding shares.

- 17 -

Table 10: Bank Resources: Staff Inputs (Weeks)

Stage of Project Cycle Planned Revised ActualThrough Appraisal _ 102.0Appraisal - Board 38.7Board - Effectivenes 86.1Supervision 80.0 110.1 104Completion 8.0 10.0 6.2

Table 11: Bank Resources: Missions

__ _ _ ___ Performance Rains IStage of Month/ Number Days In Specialized Implemntsion Development Types ofProject Year of Fied Staff Sklill status Objetives ProblemsCycle Perons Represented 11 3/

Through Feb '83 3 11 M (2), FAppraisal Jan '84 4 a M,F,E.FE

Sep '84 4 4 M,F,FE,RJul'85 2 7 M,ENov '85 6 11 M,F,E,FE,PO.EN -

May'86 1 4 M -

Feb'87 3 12 M (2). F -

May'87 3 10 M,F.POAppraisal - -throughBoardapproval _Board Apr'88 2 13 M,F I I PRapprovalthrougheffectivenessSupervision Dec '88 3 10 M.F,E 1 1 P,E,R

Oct '89 3 10 M (2),EN 1 1May'90 3 10 M,F,FE I IMar'91 1 3 M 1 1 R,PJun'91 2 8 M (2) 1 1 P,S,FApr'92 3 14 M (2), E 2 2 P,MDec'92 2 13 M (2) 2 2 P,MJun'93 2 14 M,F 2 2 P,MDec'93 3 16 M (2),F 2 2 P,MJun '94 3 12 M 12),F 8 21 8 21 P M

Completion Jan '95 2 13 M,F - - I __ I

J/ M=Mining Enginew, F=Financial Analyst, E=Economrist FEwFertilizer Engineer, RaRailwmy 8pecelist,PO=Port Specialist, EN=Environmental Specialist

J/ SatisfactoryJ PR=Procurement, P=Production Build-up, E=Environmental, R=Reporting: 88pare Parts Availability,

F=Corporate Financial Position, M=Phosphate Marketing.

- is -

IMPLEMENTATION COMPLETION REPORT

JORDAN

SHIDIYA PHOSPHATE MINE PROJECT (LOAN 2902-JO)

Borrower Contribution to ICR

JORDAN PIOSPIATE MINES CO., LTD.Amman - The Hashemitr Kingdom of Jordan

Our Ref. : 5/j Sj/1ASO Tel. . 00962 6 607141TelsiL 21228,2247 , 2281a21849, 2a975 FE9FAT JO

Fax.: 00962 6 691290 & 6696500962 6682290

Date ...... P. 0. Bo: . 30 AMMANCAble. PHOSPHATE - AMMAIN

To: Mr. Chris Wardell, Task ManacerThe World Bank GroupWashington, D.C.20433, U.S.AIndustry and Mining DivisionDept No.613/10, Room No. G2-039Tel: (202) 458-2884

Subject: Eshidiya Phosphate MineProject - Loan 2092-JO.

Dear Mr. Wardell,

Attached is Part II of the Implementation Completion Report(ICR).

sincerely yours,

Sameh MaeManag irector

JORDAN PHOSPHATE MINES CO.AMMAN - JORDAN

IMPLEMENTATION COMPLETION REPORTESHIDIYA PHOSPHATE MINES PROJECT (LOAN 2902-JO)

EARLY PRODUCTION SCHEMEFEBRUARY 15, 1995

INTRODUCTION

The project is an important first step in the development ofthe large unexploited Eshidiya Phosphate deposit estimated at 1.2Billion BCM. The project was planned to increase Jordan's Phos-phate Rock production by 1.5 MTPY from the rich A2 Layer, and toprovide a foundation for future phases of development to reach 10MTPY at the turn of the century, when all other existing phos-phate mine in Jordan are expected to reach the end of theirphysical/economic life. The full loan amount of USS 31 millionhas been utilized for foreign procurement of: (i) 2 Electricwalking draglines of 21 mr bucket capacity; (ii) 22 rear dumpstrucks of 50t capacity (iii) different mine and millsite mobilevehicles and support equipment. (iv) Technical assistance includ-ing (a) beneficiation flotation technology (b) spare parts andworking capital management (c) accounting, finance and corporateplanning (d) dust monitoring at Aqaba Port.

A. Project Objectives:___________________

The basic objectives of the project can be summarized asfollows:

1. To increase the production of the company from themarketable high grade rock phosphate (A2 Layer) by 1.5MTPY.

2. To maximize cost reduction by exploiting Eshidiya ore,which offers greater advantages in mining, quality,processing and transport to Aqaba as compared with theexisting mines.

3. To provide a foundation for future expansions atEshidiya area.

4. To compensate for the progressive depletion of the mosteconomically recoverable orebodies at El-Abiyad & El-Hassa.

5. To utilize the superior characteristics of EshidiyaOre, in respect to its very low content of heavy met-

1

als, and phosphate fines, to penetrate into new marketsin Europe, Australia, and Newzeland.

6. To minimize environmental impact of the various com-ponents of the project by improving on the alreadyadopted provisions to reduce dust emission at minesites as well as at Phosphate export port at Aqaba.

B. Achievement of Project Objectives:________________________________

1. Sector policy improvements:__________________________

The sector policy at the time the Early ProductionScheme Feasibility Study was prepared (end of 1987),was limited to : (i) Establishing a foundation for theexploitation of Eshidiya large resources; (ii) expand-ing the production thereafter from Eshidiya not only,to compensate for the loss of production from El-Hassaand El-Abiyad but also to reach a total productionlevel of 9 MTPY in 1994, out of which 8 MTPY will betargeted for export and 1 MTPY for domestic consumptionat the Fertilizer plant at Aqaba; and (iii) To maintaina production level of 9-10 MTPY starting 1994 throughthe year 2002.

The above sectorial policy which has relied on the as-sumption that the international market demand is ex-panding at a rate of (3.5% p.a) was to be modifiedduring the implementation of the project, to readjustfor the drastic changes which took place in the worldmarket demand and local policies such as:

(i) The purchase of Fertilizer Unit in 1986; (ii) thecollapse of the Eastern Block markets during 1989/1990;(iii) the restructuring of the economy and industry incountries which are the major markets of Jordan Phos-phate (iv) Lifting of government subsidies, on fer-tilizers, in a number of countries in South East Asia,as a result of decanalization and privitizationpolicies. (v) The growing environmental and healthmeasures and restrictions in importing countries espe-cially in EEC countries, Australia and Newzeland.

Accordingly phosphate rock world demand shrank fromabout 48 million tonnes in 1989 to about 24m tonnes in1993.

To face the above challenges JPMC was, therefore, com-pelled to modify its sector policy by adopting newstrategies which can be summarized as follows:

2

i. The company has adopted a cost driven policy basedon mining the most economical orebodies at exist-ing mines and to expedite Eshidiya Mine develop-ment for its lower unit cost, as compared to the,higher cost of El-Hassa and El-Abiyad mine areas.

ii. The full integration of mining and fertilizeroperations in terms of management, planning,budgeting and accounting. Accordingly, Phosphatefines and other subcommercial grades are beingutilized at the Fertilizer Complex at Aqaba andalso in the Joint-Venture Projects.

iii. To increase the local consumption of phosphate oreby the end of 1999 to about 4 MTPY, by estab-lishing a number of Joint-Venture Companies forthe production of down-stream intermediates andfinal fertilizers products such as : Phosphoricacid, NPK, DAP .. etc. This policy will help insecuring a captive supply for about 40-50% ofJPMC's annual production of commercial & subcom-mercial grades on the one hand, and in diversify-ing JPMC products on the other hand.

iv. Jordan Phosphate rock exports throughout 1995 to2002 is envisaged to be in the range of 4-5.5 mil-lion TPY.

V. To utilize the medium and sub-commercial grades ofPhosphate rock locally, while exporting highgrades only.

It is anticipated that the above factors together withthe maximization of the domestic value in thedownstream products will increase the economics of thesector and definitely will enhance the ability of JPMCto adjust to the variations in the World market demand.

2. Physical Objectives:__________________

The main objective of the Early Production Scheme wasto produce 1.5 MTPY of high grade phosphate rock at theend of 1989. The production in 1993 and 1994 were 0.65million tonnes and 1 million tonnes respectively. Theproduction in 1995 is scheduled to reach 1.35 MT equalto 90% of plant planned capacity. Full production willbe reached in 1996 after the completion of constructionand commissioning of the Beneficiation Plant by the endof 1995 ( under Loand 3172-JO).

3

The delay of production build up could be attributed tothe following reasons:

i. Re-bidding associated with lengthy evaluation andcontracting of major mining equipment (draglinesand dump trucks) due to non-responsivness and overbudget bid prices initially received. This hascaused an inevitable procurement and productiondelay of about 9 months.

ii. The Gulf crisis and its consequent repercussions,whereby the construction and commissioning of thetwo draglines, the handling and load-outfacilities (which lies on the critical path of theproject implementation schedule), were delayed byanother 12 months. Foreign contractors and ex-patriate supervisors were instructed by theirgovernments to leave the site.

iii. Low draglines' performance: The rehandling bydraglines of the spoils excavated from the box cuthad not worked as planned. According to the miningplan the spoils were to be heaped along the sidesof the box cut with a height of 2m to ease itsrehandling by dragline again into the box cutafter the removal of the phosphate ores. Due topoor haul truck availability and utilization at-tributed mainly to the tack of spare parts causedby the Gulf Ware, the spoil were heaped closer tothe box cut at heights exceeding the plannedheight by 4m, in order to the shorten the haulingcycle time. This arrangement impacted negativelythe draglines effective digging capacity and theproduction from A2 by 201.

iv. The build-up of excessive large stocks of subcom-mercial, from Al and A3 layers due to the delaysin the construction of the beneficiation plants.

V. The big decline in phosphate rock export levelsdue to the drastic changes in the world market.JPMC exports in 1993 were 3.56 million tonnes and3.83 million tonnes in 1994: as compared to 6.5million tonne exported in 1989 and B milliontonnes envisaged to be in 1994.

Nonetheless, the following major objectives weresuccessfully achieved:

4

i. The completion of construction ahead of time ofthe infrastructure required for the project andfor future developments.

ii. Inspite of all delays, the project was completedat a lower than anticipated investment cost.

iii. High quality phosphate rock from A2 layer is cur-rently produced at a reduced cost in comparisonwith similar grades at existing mines. Eshidiyaproduction in 1994 has represented about 25 ofJPMC total exports.

iv. The total production in 1994 (1 million tonnes)was completely sold to new markets in EECcountries and Australia.

V. Phosphate fines dust emission at the Mine and atAqaba port was successfully suppressed by usingefficient dust collectors at the mines andshiploaders. The collected phosphate fines andsub-commercial grades were utilized at the Fer-tilizer Unit in Aqaba for the production of Phos-phoric Acid.

3. Institutional developments:__________________________

The following institutional developments were success-fully achieved during the implementation of theproject.

i. The consolidation of phosphate mining anddownstream Production of phosphoric Acid and fer-tilizers, associated with successful integrationof activities for the two units.

ii. Through the technical assistance programme for(production, planning and financial management)the company has succeeded in improving on the ex-isting level of integration between technical,marketing, financing functions in the company.Also, it has completed effectively the overallcorporate restructuring plans of upgrading and in-tegrating the administration, internal audit, costand financial accounting systems, financialstudies and budgeting, spare parts management andtechnical functions (exploration and geology, min-ing, processing). Consequent corporate restruc-turing requirements have been identified, and anexecutive implementation project unit was formed

5

to enable the achievement of the plan by 1996.

4. Ecology Improvements:…___________________

From the outset serious environmental hazards threaten-ing the ecology at the mine site were not foreseen andnone have developed. Dust emission from the miningroads is contained by spraying with water, regularly,while from mine installation and equipment, phosphatedust is collected by cyclones and electrostaticprecipitators and the fines are recovered andtransported to Aqaba for processing at the Fertilizerplant.

The key environmental issues addressed in the "loanAgreement" covered mainly dust emissions at Aqaba port,emitted from the phosphate loading and unloading han-dling facilities. In this regard JPMC procured a localconsultant to monitor the dust levels at various loca-tions surrounding the port area as well as Aqaba town.The study has established that the dust generated inthe environ of Aqaba town was due to dust blown fromthe surrounding desert areas expect in the port proper,the phosphate dust was measurable.

To this end, JPMC committed itself to the followingprogram:

1. De-dusting of phosphate fines at the mine sites tominimize dust arriving at port.

2. Utilization of phosphate fines recovered and it'ssuccessful processing at the Fertilizer Complex.

3. Procurement & installation of choke-feeders atship-loaders which reduced dust emission by 90Z.Ship-loaders were the main culprit of phosphatedust plume which can be seen then miles away.

4. Installation of dust collection devices at theloading & unloading points in the port.

As a result of these measures, fugitive dust atthe port area was minimized. However,methodological housekeeping at the port site willfurther decrease fugitive dust emission, wherebyAqaba port phosphate loading facilities will be-come one of the world outstanding clean harbors.

5. Financial Objectives:____________________

The feasibility study analysis had shown very high

6

financial and economical benefits of the project. Thefinancial rate of return (FRR) of the Base case was 36%and 15.6% under worst sensitivity analysis scenario.The Base case Economic Rate of Return (ERR) was 37% and16.9% also under worst sensitivity analysis scenario.The actual Financial and Economical indicators stillshow very strong financial and economic benefits. Theactual (FRR) and (ERR) based on real 1994 terms aresomewhat lower than the originally forecasted figures,due to the following reasons: (i) The low build-up ofproduction and exports; (ii) The consequent higher thanforecasted working capital management; (iii) the highertransport cost; due to new axle-load charges imposed ontrucks hauling to Aqaba. (iv) 230% increase in Aqabaport charges. (v) Imposition by the government of JD 5per tonne production tax. Actual indicators were asfollows:

* FRR : 10%**ERR : 21%

* Inclusive of (production tax).*"Exclusive of (production tax).

C- Implementation Record and Major FactorsAffecting the Project:---------------------------------------

Considering the overall achievement of project objec-tives as summarized under paras 1 and 2. The projectcan be considered as a substantial success. The delayin project implementation, production build up can beattributed to:

1. Factors not Generally subject toJPMC'S control:---------------------------------

i. Delay in mining equipment procurement due to non-responsivness of Bidders and over budget bidprices. Contracts were eventually finalizedwithin budget limitation at the expense of 9months delay in project implementation schedule.

ii. The Gulf war and it consequent aftermath asassociated with difficulties in spare partsprocurement which impacted the availability andutilization of mining equipment and lowered thenumber of ships arriving to Aqaba port, causingserious export problems.

iii. Delay in construction of Beneficiation plant (underLoan 3172-JO) caused by: (i) delay in floating theBid (ICB) by 9 months due to Gulf War (ii) Lengthy

7 4

discussions with the Bidders during Bids evalua-tions stage due to 60% overbudget Bid price in theinitial bids received. The contract was finalizedsuccessfully and within budget limits. However,this process of avoiding capital over-run hascaused an additional delay in project implementa-tion of about 6 months. (iii) The K.D 8 millionfund short-fall created by the cancellation fromone side by Kuwait Government, of the Kuwaityloan extended by Kuwaity Fund for financing theIntegrated Phosphate Project ( Loan 3172-JO). Thecompany was compelled to cover the fund short-fall by a local loan from a consortium of localBanks. The time required for concluding thisloan Agreement caused a further delay of 5 months.

The resulting 20 months delay in the constructionof the Beneficiation plant and the consequentdelay in processing the lower quality (Al and A3)ore, has caused the build-up of an excessivestockpiles from these grades. Thus any attempt toincrease the production from A2 will consequentlylead to substantial increase in the level of thestock piles and the company's working capital.

iv. The above three factors together with thedeterioration of world phosphate demand wereresponsible for the slow production build up.

2. Factors subject to JPMC Control:

The failure of the company to allocate a fully ex-perienced key management, operation and maintenancestaff at the project start-up of production has led tosome deficiencies in the implementation of mining planduring the opening of the Box-Cut needed for draglinesoperations. The spoils from the Box cut were heaped toheights which hindered dragline productive diggingcapacity. The draglines have to spend more time onrehandling the spoils contrary to plan. In addition, aninadequate maintenance management associated with scar-city of spare parts has resulted in lower than normalavailability and utilization of equipment, lowerproduction and higher mining unit cost. This issue wascorrected at the later stage of implementation.

E. Project Sustainability:______________________

The production from A2 Layer is expected to reach itstargeted capacity during 1996 after the completion ofconstruction and commissioning of the Beneficiation

8

plant scheduled at the end of 1995. Considering thelong experience of JPMC in developing, operating, andmaintaining similar mining equipment and beneficiationplants, in allocating when needed the required tradesand expertise, the experience and capability of absorb-ing new up-to-date technologies & by implementingsuccessful technology transfer programmes. This com-piled with the strong financial benefits of theproject, makes us very assured that the project will befully sustainable.

E. JPMC Performance:________________

The performance of JPMC (The Borrower) can be ranked ashighly satisfactory. This company has efficientlyhandled the following tasks:

i. The preparation cf the feasibility study and bank-able report of ar. International standard, whichwas very instrumental to the bank in carrying theproject appraisa.

ii. The preparation cf all project basic engineering,designs, and drawings.

iii. Preparation of --he Bidding Documents and handlingof all internat:dnal and local procurement in avery expeditiou: and professional manner whichresulted in a sa-ing of US Dollars 7.7 million ofproject installa:ion cost.

iv. Organized project construction efficiently. Themain infrastructure: roads, electric power, watersupply, telephore service, housing facilities,mine support workshops and stores...etc., weredeveloped ahead cf time. Except for draglines anddump trucks, al' other mining and handling equip-ment were purchaEed, constructed and commissionedon schedule.

V. JPMC has managed under tight market competitioncaused by depressed international phosphatemarket, to develop new markets for Eshidiya Ore inEurope and Australia. The company had faced nodifficulties in selling all quantities producedfrom Eshidiya.

vi. With the valuable assistance of the world Bank un-der (Technical assistance programme), the companyhad succeeded in up-grading its capability inrespect to spare parts and working capital manage-ment. Also, in implementing production and finan-

9 et\

cial corporate planning management which assistedthe company to adopt more efficient cost-drivenpolicies.

vii. The weakness of JPMC as previously discussed waslimited to not transferring on the appropriatetime the best experienced personnel to assist inthe proper of start-up of mining operations.

viii.JPMC was in full compliance with all loancovenants, until the imposition by the Governmentat a later stage of the production tax (JD5/tonne). This have affected in increasing JPMCconsolidated working ratio slightly above theratio covenanted in the Loan Agreement (0.8), byexcluding this tax the projected financial workingratio is (0.72) in 1994. According to the projec-tions in the newly developed five years plan thecompany will face no problem in complying withall loan Agreements' covenants staring from 1995.

F. Bank Performance:

The performance of the bank can be rated as highlysatisfactory. From the outset starting with projectappraisal through implementation, impact assessmentand until project completion, the Bank had providedthe Company with valuable assistance in the technicalfields, production planning skills, management andfinancial matters all of which were very instrumentalin upgrading the company's performance to an interna-tional standard level.

The Bank further had successfully pinpointed the areasand subjects were the company needs improvements.Through its technical assistance programme, the Bankhad successfully managed to upgrade the companycapabilities in new fields: Flotation techniques,processing, working capital and spare parts management,development of the company's corporate and productionplanning, and the development of financial management.The assistance of the Bank was highly appreciatedduring the prevailed depressed phosphate world market,in correctly advising the company in maximizing cashflow and profitability by the liquidity of the existinghuge stocks, of final and semi-final products, and inadvising more cost driven policy. The focus on cleanerenvironment at Port of Aqaba phosphate handlingfacilities was successfully achieved in 1993.

10 tNY

G. Assessment of outcome:_____________________

Considering the achievement of project major objec-tives, while the production build-up is expected toreach the target level at the end of 1995, and the sus-tained strong project financial and economicalbenefits, the project outcome is considered satisfac-tory, and will definitely make a substantial contribu-tion to the company's financial position as well ascountry's economy and its foreign exchange earnings.

H. Future Operations:_________________