Work in Progress --- Not for Publication 1 ERD WG 3/20/09 Brussels IRC FxF Meeting ERD/ERM – IRC...

-

Upload

elfrieda-gray -

Category

Documents

-

view

220 -

download

1

Transcript of Work in Progress --- Not for Publication 1 ERD WG 3/20/09 Brussels IRC FxF Meeting ERD/ERM – IRC...

Work in Progress --- Not for Publication1 ERD WG 3/20/09 Brussels IRC FxF Meeting

ERD/ERM – IRC FxF Meeting

Jim Hutchby & Mike GarnerBrussels, BelgiumMarch 20, 2009

International Roadmap Committee

TopicsTech Transfer to PIDS/FEP, Etc. Request to assess emerging research

memory technologies

Work in Progress --- Not for Publication2 ERD WG 3/20/09 Brussels IRC FxF Meeting

Tech Transfer to PIDS/FEP♦ Introduction of technologies involving new materials requires ~12+ years from publication to manufacturing♦ The last 4 – 6 years of this 12+ year total R&D period is development related to PIDS/FEP. The first 6 – 8 years is research related to ERM/ERD.

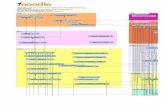

ITRS 2009 IRC Meeting – March 20, 2009Source: 2009 ITRS – ERD/ERM/PIDS/FEP

Production Ramp-up Model &Technology Cycle Timing for III-V MOSFET Channel Replacement Materials

Vol

ume

(Par

ts/M

onth

)

1K

10K

100K

Months-72

1M

10M

100M

Alpha

Tool

0 24-48

Development Production

Beta

ToolProduct

Tool

First

Conf.

Papers

1st 2Cos.

Reach

Product

Vol

ume

(Waf

ers/

Mon

th)

2

20

200

2K

20K

200K

-24

Research

-96

Transfer to PIDS/FEP(2009–2013)

20192017201520132011 2021

SRC/File name/ 4

TechnologyBackground /Infrastructure

Practicalrealization

1st Practical

useSponsor Entrant

1st

CustomerTelegraph 1801 –

(Voltaic Pile)1823(Schilling)

1844(Morse)

U.S. Gov. 1848 - MagneticTelegraph Co1856- Western Union

Radio 1865 (Maxwell) 1888 (Hertz)1896(Marconi)

1897(Marconi)

BritishPostOffice

1897 WirelessTelegraph&Signal Co

BritishNavy

Vacuumtube

1884(Edison effect)

Fleming (1904)De Forest(1906) - triode

1907 U.S. Navy 1913 - AT&T WW I

1906 AT&T 1907 Pickard Co WW ISolid statediode 1874 (F. Braun) 1900 ( Braun) 1940-

currentRadarProgram

1941 Thomson-Houston1942 AT&T, Sylvania

WWII

Transistor 1923 – 1939 1947-48 1951 AT&T 1951-52 - TI, AT&T,GE, HP. Motorola

DoD

IntegratedCircuit

1944 – 1957(micromoduleprogram)

1958–R.Noyce,J. Kilby

1961 U.S.AirForce

1961 TI, Fairchild NASA,DoD

DataProcessing

1889 Hollerith 1890 U.S.CensusBureau

1896 – TabulatingMachine Co (from1917 – IBM)

U.S.CensusBureau

1946 -Eckert-Mauchly Co(1951 – Remington)

U.S.CensusBureau

Computer 1841(Babbage)

1889Hollerith

1945 - ENIAC 1946-1951 DoD1951 IBM DoD

Disruptive Technologies in Electronics

5

Time Gaps

0

1

2

3

4

5

1870 1880 1890 1900 1910 1920 1930

Transfer of Knowledge

Prototype built (Disruptive Technology)

Entrant Co formed

Market production (Established Technology)

T1~ 20years~10years

T2 T3

Solid State DiodeT1 26 (1874-1900)T2 7 (1900-1907)T3 6 (1907-1913)Learning Period 13 years

Vacuum TubeT1 20 (1884-1904)T2 9 (1904-1913)T3 6 (1913-1919)Learning Period 15 years

TransistorT1 25 (1923-1948)T2 6 (1948-1954)T3 5 (1954-1959)Learning period 11years

Integrated CircuitT1 17 (1942-1959)T2 3 (1959-1961)T3 5(1961-1966)Learning Period 8 years

‘Research Curve’

Human Carrier

Sponsor 1st Customer

Example: Solid State Rectifier

Enabling B

ackground exists

6

Development Cycle Times for Sample IC Technologies

Year Initially Year Implemented LagTool or Technology Developed In Production Time

Silicon Epitaxy 1960-61 1964 4

APCVD Silicon Nitride 1965 1967-68 2

Ion Implant 1969 1973 4

TiW Metalization 1969-70 1975-77 6

Schottky TTL 1970 1974-75 4

Charge-Coupled Device 1970 1981 11

Reactive Ion Etch 1975-76 1980 5

Polysilicon Emitter 1976 1984-85 8

Refractory Gate 1976 1983 7

SOI (via Ion Implant) 1978 1989 11

Trench Capacitor 1979 1986 7

Silicide 1978 1985 7

Lightly-Doped Drain 1980 1986 6

Average 6 years

Source: Graydon Larrabee of Texas Instruments

7

Study of R&D Latency for a few Semiconductor Technologies¨ CMOS¨ Giant Magnetoresistance (GMR)¨ Copper Interconnect¨ 193 nm photoresist¨ Magnetic RAM¨ EUV lithography

Method. We used the following parameters:

1) The first publication on a given technology that appeared in the Science Citation Index database

2) The number of refereed articles in technical journals by year (Science Citation Index database)

3) The year of first production for a given technology

8

CMOS

1

10

100

1000

10000

1965 1970 1975 1980 1985 1990 1995 2000 2005

Year

# of

pub

licat

ions

1969 – 1st publication

1972 – Toshiba CMOS calculator IC

1982 – Intel 80286 CMOS microprocessor

1983 – 1st CMOS DRAM (Intel)

1984 – Motorola 68020 CMOS microprocessor

1987 –CMOS at AMD

1981 – National NSC800 CMOS microprocessor

12 years

9

Giant Magnetoresistance (GMR)

1

10

100

1000

1985 1990 1995 2000 2005

Year

# o

f p

ub

lica

tio

ns

1988 - discovery of GMR effect

1997- 1st hard disk product using GMR heads (IBM)

1992 – MRAM concept

9 years

10

Copper Interconnect

1

10

100

1000

1985 1990 1995 2000 2005

Year

# o

f p

ub

lica

tio

ns

2000 – AMD x86 Cu-based microprocessor

1998 - Power PC 750 microprocessor(IBM)

1986 – 1st publication

12 years

11

193 nm photoresist

1

10

100

1985 1990 1995 2000 2005

Year

# o

f p

ub

lica

tio

ns

2001- 3M debuts 193nm photoresist chemicals

1989 – 1st publication

12 years

12

Magnetic RAM

1

10

100

1990 1992 1994 1996 1998 2000 2002 2004

Year

# o

f p

ub

lica

tio

ns

1992 – 1st publication12 years

2004- 1st MRAM product projected (IBM/Infineon)

Work in Progress --- Not for Publication13 ERD WG 3/20/09 Brussels IRC FxF Meeting

New Technology Introduction Events

• Strained Silicon Example– First Technology Paper:

1991, 1994– Addition to ITRS

Roadmap: ~2001– Alpha Tool: TBD– ITRS Production: 2003

(12 years)– Technology Life: 3+

Generations

• High κ (HfO2) Example– First Technology Paper:

1972– Industry Interest ~1990– Addition to ITRS

Roadmap: 1997– Alpha Tool: TBD– ITRS Production: 2010

(38 years)– Technology Life: 3+

Generations

Beyond CMOS CTSG Feb. 3, 2009 Work in Progress: Not for Distribution14

Conclusions

The average time from first research paper on a technology typically using a new material to its’ first commercial production is about 12 years.♦ Research must have been in progress at least a few

years before the first publication♦ Development of technology leading to first product is

4 – 6 years, based on the time gaps study [(T2+T3)/(T1+T2+t3) = 1/3 to 1/2] applied to the current study.

Work in Progress --- Not for Publication15 ERD WG 3/20/09 Brussels IRC FxF Meeting

ERD ITWG Emerging Research Devices

Working Group

Proposal for Assessing Technology Options for Emerging

Research Memory Devices

Jim Hutchby & Mike Garner Friday March 20, 2009

Work in Progress --- Not for Publication16 ERD WG 3/20/09 Brussels IRC FxF Meeting

Objective of IRC/ERD/ERM discussion of this request from Samsung, Hynix, and Micron

ERD/ERM is seeking IRC guidance on whether we should conduct a review and assessment of emerging research memory technologies with the goal of recommending those most promising for detailed roadmapping and accelerated research.♦ Assess technology capability of being scaled beyond the

15nm node.♦ Identify precompetitive research required for top

candidates to scale beyond the 15nm node♦ Process will be completed in April 2010 with an oral report

to the IRC in the Spring ITRS Meeting followed by a written report/recommendation to the IRC.

Work in Progress --- Not for Publication17 ERD WG 3/20/09 Brussels IRC FxF Meeting

Assessment of Promising Emerging Memory Devices

• Samsung, Hynix , and Micron proposed that the ERD/ERM identify memory technologies needing more focused support

• Proposal: ERD & ERM hold a workshop in April 2010 to review and assess emerging research memory devices– Goal: Identify emerging research memory technologies that merit

more detailed roadmapping and more focused research.– Process: Same Process as the Logic Assessment in 2008

• Champions present Pros, Cons and research needed for technology• Friendly critic presents balanced assessment• White paper prepared on each memory and circulated prior to the

meeting• Face to Face Presentations & Discussion• Voting on Promising Technology• Identify Critical Research Needed

Work in Progress --- Not for Publication18 ERD WG 2/26/2009

Straw Candidate Emerging Research Memory Technologies

Capacitive Memory FeFET Memory

Resistive Memory Nanoelectromechanical STT MRAM Thermal PCM

FUSE/Anti-FUSE Nanowire PCM

Electrochemical Memory Cation migration Anion migration

Electronic Effects Memory Charge trapping Mott Transition FE barrier effects

Macromolecular Memory Molecular Memory

Work in Progress --- Not for Publication19 ERD WG 2/26/2009

DRAFT GOALWith the goal of providing input to resource allocation decisions, ERD/ERM WGs will conduct an in-depth review and assessment of specific emerging research memory devices to highlight the most promising device technologies for detailed roadmapping and acceleration of pre-competitive*research and development.

(*Pre-competitive refers to those technologies capable of being scaled beyond the 15nm node.)

Work in Progress --- Not for Publication20 ERD WG 2/26/2009

DRAFT SCOPE

The scope of the review of emerging research memory technologies will assess scalability beyond the 15nm node. – Identify precompetitive research needed to enable

scaling beyond the 15nm node.– Assessment will encompass both stand-alone and,

where different, embedded emerging research memory technologies.

Work in Progress --- Not for Publication21 ERD WG 2/26/2009

Draft Timetable1. Develop/decide process, milestones, timeline July 12, 2009

2. Develop invitation to advocates/proponents & friendly critics Introduction Potential of technology – fundamental limits Barriers – Fundamental vs. technological/engineering Evaluation Criteria Definition of specific emerging research memory devices for roadmapping Readiness in 10 - 15 years

July 31

3. Identify Major emerging research memory device candidates Strong technical proponent and friendly critic teams and their leaders Knowledgeable ERD/ERM mentor for each proponent team Key questions to be addressed by the teams Background materials for each technical candidate

July 31

4. Issue invitations to team leaders, friendly critics, and ERD/ERM mentors and obtain their commitments

Sept. 15

5. Obtain a white per & background materials from each candidate technology proponent team for ERD/ERM WG review

Jan. 15, 2010

6. ERD/ERM WG review candidate emerging research memory devices candidates based on white papers & identify key questions using a formal process prior to Spring Europe FxF meeting.

Mar. 15, 2010

7. Conduct a FxF review of categories with each proponent & friendly critic making a presentation

April yy, 2010Spring FXF Mtg.

8. On second day of ERD FxF meeting, discuss/decide ERD/ERM WG’s prioritized recommendation of narrowed emerging research memory devices options. This will include selection of specific devices for roadmapping within the recommended option

April yy+1,2010Spring FXF Mtg.

9. Write & submit report on ERD/ERM WG’s recommendations May 31, 2010

Work in Progress --- Not for Publication22 ERD WG 3/20/09 Brussels IRC FxF Meeting

Proposed ERD/ERM WG Process for Assessing Candidate Emerging Research Memory Device Technology Options

Develop/decide process, milestones, timeline Develop invitation to advocates & opponents

Introduction Potential of technology – fundamental limits Barriers – Fundamental vs. technological/engineering Evaluation Criteria / Benchmark memory technology Definition of maturing, high potential specific devices

for roadmapping Readiness in ~ 5 - 10 years

Work in Progress --- Not for Publication23 ERD WG 3/20/09 Brussels IRC FxF Meeting

Proposed ERD/ERM WG Process for Assessing Candidate Emerging Research Memory Device Technology Options

Identify Major emerging research memory technology candidates Strong technical proponent and opponent teams and their

leaders Knowledgeable ERD/ERM mentor for each proponent

team Key questions to be addressed by the teams Background materials for each technical candidate

Issue invitations to team leaders and obtain their commitments

Obtain a white paper & background materials from each candidate technology proponent team for ERD/ERM review

Work in Progress --- Not for Publication24 ERD WG 2/26/2009

Appendix 4a: Comparison of a NEM Relay with an ultimately scaled Si MOSFET Major Categories MOSFET NEM Relay

Basic description

Device Proposed Field Effect Transistor NEM RelayState variables and control Charge or Voltage Charge or Voltage

Number of logic states 2 (high and low) 2 (on or off)Principle of Operation Thermal injection over gate barrier Mechanical switching of currentMaterials Si Si, SiC, TiN, metals used in CMOS (top

down); CNT or NW (bottom up)Geometry Transistor, 3 or 4 terminal Mechanical relay: 3 or 4 terminal

Device density as a function of feature size F

~ 1/F^2 ~1/(F^2 x R) where F=gap=beam thickness. Lateral tech is assumed. R is aspect ratio.

Size in units of feature size F of a gate equivalent to a 2-input NAND gate, including contacts and isolation and necessary peripheral circuitry

>~65 F^2 >~10F^2xR (same assumptions as above , NAND =2x inverter area.)

Functonal Density in terms of "gate

equivalents" per cm2 using the primitive cell size defined above and an appropriate value of F.

Operating Parameters - Temp Usually 25C - 125C compatible with high-T electronicsOutput sensing device MOSFET RelaySelf gain gm/gd ~ Vdd/DIBL N/ASwitching Energy per gate or gate equivalent @ proposed clock rate

0.5*Cload*Vdd^2 0.5*(Cgap + Cload)*Vdd^2

Static Power Dissipation per gate or gate equivalent

Vdd*Ioff*(2/5) Essentially zero

Binary throughput (Gbits/nsec-cm2-joule)

Logic Family - Information processing basis

Universal set comprising NAND, NOR, NOT logic gates, also pass gates

Universal set comprising NAND, NOR, NOT logic gates, also pass gates

Interconnects Wire WireCompatible memory SRAM (fast) , DRAM (dense) SRAM (Fast) , DRAM (Dense), & NV M.

Clock or its equivalent CMOS based clock circuits Relay based clock circuitsCMOS compatible N/A Yes

Performance Potential

Switching speed & energy Lchan/v ~ 0.1ps Delay ~ ns range; Vdd ~ few 100mV, energy ~ aJ range

Interconnect delay per micron RC RCInterconnect energy as a function of distance at proposed clock rate

CV^2 CV^2

Limitations

Materials & Geometry - Sources of variability

LER, Doping fluctuations ~ 1/SQRT (LW) Gap, thickness, material properties, vdW forces

External parasitics Access resistance, fringe capacitance Fringe capacitanceNoise margin (Vdd-Vth)/ KT/q > 5 Better or comparable with CMOS

This section comprises a description of the proposed device family. The section may include textual and graphical descriptions but should be independent of (or

parameterized by) feature size F

This section comprises a list of known limiting factors for performance and manufacturing

This section comprises an extrapolation of the technology to about the year 2020, stipulating F=14 nm. Provide best estimate numerical values.

REDO THIS

SLID

E

Work in Progress --- Not for Publication25 ERD WG 2/26/2009

Appendix 4a: Comparison of a NEM Relay with an ultimately scaled Si MOSFET Major Categories MOSFET NEM Relay

Basic description

Device Proposed Field Effect Transistor NEM RelayState variables and control Charge or Voltage Charge or Voltage

Number of logic states 2 (high and low) 2 (on or off)Principle of Operation Thermal injection over gate barrier Mechanical switching of currentMaterials Si Si, SiC, TiN, metals used in CMOS (top

down); CNT or NW (bottom up)Geometry Transistor, 3 or 4 terminal Mechanical relay: 3 or 4 terminal

Device density as a function of feature size F

~ 1/F^2 ~1/(F^2 x R) where F=gap=beam thickness. Lateral tech is assumed. R is aspect ratio.

Size in units of feature size F of a gate equivalent to a 2-input NAND gate, including contacts and isolation and necessary peripheral circuitry

>~65 F^2 >~10F^2xR (same assumptions as above , NAND =2x inverter area.)

Functonal Density in terms of "gate

equivalents" per cm2 using the primitive cell size defined above and an appropriate value of F.

Operating Parameters - Temp Usually 25C - 125C compatible with high-T electronicsOutput sensing device MOSFET RelaySelf gain gm/gd ~ Vdd/DIBL N/ASwitching Energy per gate or gate equivalent @ proposed clock rate

0.5*Cload*Vdd^2 0.5*(Cgap + Cload)*Vdd^2

Static Power Dissipation per gate or gate equivalent

Vdd*Ioff*(2/5) Essentially zero

Binary throughput (Gbits/nsec-cm2-joule)

Logic Family - Information processing basis

Universal set comprising NAND, NOR, NOT logic gates, also pass gates

Universal set comprising NAND, NOR, NOT logic gates, also pass gates

Interconnects Wire WireCompatible memory SRAM (fast) , DRAM (dense) SRAM (Fast) , DRAM (Dense), & NV M.

Clock or its equivalent CMOS based clock circuits Relay based clock circuitsCMOS compatible N/A Yes

Performance Potential

Switching speed & energy Lchan/v ~ 0.1ps Delay ~ ns range; Vdd ~ few 100mV, energy ~ aJ range

Interconnect delay per micron RC RCInterconnect energy as a function of distance at proposed clock rate

CV^2 CV^2

Limitations

Materials & Geometry - Sources of variability

LER, Doping fluctuations ~ 1/SQRT (LW) Gap, thickness, material properties, vdW forces

External parasitics Access resistance, fringe capacitance Fringe capacitanceNoise margin (Vdd-Vth)/ KT/q > 5 Better or comparable with CMOS

This section comprises a description of the proposed device family. The section may include textual and graphical descriptions but should be independent of (or

parameterized by) feature size F

This section comprises a list of known limiting factors for performance and manufacturing

This section comprises an extrapolation of the technology to about the year 2020, stipulating F=14 nm. Provide best estimate numerical values.

Work in Progress --- Not for Publication26 ERD WG 3/20/09 Brussels IRC FxF Meeting

Proposed ERD/ERM WG Process for Assessing Candidate Emerging Research Memory Device Technology Options

ERD/ERM WG rate and prioritize candidate emerging research memory technologies using a formal process prior to FxF meeting.

Conduct a FxF review of categories with each proponent & opponent team making a presentation

On second day of ERD/ERM FxF meeting, discuss/decide ERD/ERM’s recommendation of most promising emerging research memory technology options.

Write & submit report to the IRC on ERD/ERM WG’s recommendations

Work in Progress --- Not for Publication28 ERD WG 2/26/2009

Proposed ERD/ERM WG Process for Assessing Candidate Emerging Research Memory Device Technology Options

Develop/decide process, milestones, timeline Identify

Major memory technology candidates Strong technical proponent and friendly critic teams and

their leaders Knowledgeable ERD/ERM mentor for each proponent team Key questions to be addressed by the teams Background materials for each technical candidate

Develop invitation to proponents & friendly criticsIntroductionPotential of technology – fundamental limitsBarriers – Fundamental vs. technological/engineeringEvaluation CriteriaDefinition of specific devices for roadmappingReadiness in 10-15 years

Work in Progress --- Not for Publication29 ERD WG 2/26/2009

Proposed ERD/ERM WG Process for Assessing Candidate Emerging Research Memory Device Technology Options

Issue invitations to proponent and friendly critic team leaders and obtain their commitments

Identify ERD/ERM Mentors – 1 per candidate memory technology

Obtain a white paper & background materials from each candidate technology proponent team for ERD/ERM review

ERD/ERM WG review candidate emerging research memory technologies using a formal process prior to FxF meeting to identify questions to be addressed in FxF meeting.

Work in Progress --- Not for Publication30 ERD WG 2/26/2009

Proposed ERD/ERM WG Process for Assessing Candidate Emerging Research Memory Device Technology Options

Conduct a FxF review of categories with each proponent & friendly critic team making a presentation

On second day of ERD/ERM FxF meeting, discuss/decide ERD/ERM’s recommendation of most promising emerging research memory technology options. Mentors will lead the discussion of their candidate technology

Write & submit report to the IRC on ERD/ERM WG’s recommendations

Work in Progress --- Not for Publication31 ERD WG 2/26/2009

Decision Making & Majority Voting Scheme Each member of ERD WG will be given a maximum of X votes to use

in voting for their top X choices among the candidate technologies (Majority Voting scheme) ERD/ERM WG members present in the FIRST DAY Workshop &

the SECOND DAY meeting will be eligible to vote at SECOND DAY meeting, based on their personal technical judgment, independent of their corporate affiliation or regional representation,

Only 0 or 1 vote can be cast for any candidate technology Member does not have to use all X votes, but cannot use more

than X votes. All members can participate in the straw vote.

The Candidate Technologies will be ordered according to which received the largest number of votes.

Consensus approval will be our goal, but a 75% affirmative vote will be required as a minimum. This is what is meant by the term approximate consensus.

REDO THIS

SLID

E

Work in Progress --- Not for Publication32 ERD WG 2/26/2009

ERD “Beyond CMOS” Technology Selection MtgAgenda – SECOND DAY

9:20 Review Process for selecting beyond CMOS emerging technologies

9:45 Discuss Technologies 9:45 NEMS Switch Technology

10:05 Spin Torque Transfer Technology 10:25 Carbon-based Nanoelectronics

10:45 Break11:00 Atomic Switch / Electrochemical Metal Switch

11:20 Collective Spin Devices (including M-QCA) 11:40 Single Electron Transistors 12:00 CMOL and FPNIREDO T

HIS S

LIDE

Work in Progress --- Not for Publication33 ERD WG 2/26/2009

ERD “Beyond CMOS” Technology Selection Mtg Agenda – SECOND DAY (Cont’d)

12:50 Preliminary vote on technologies – Majority voting process

1:00 Discuss preliminary results

1:45 Second vote on technologies

2:00 Discuss the leading technologies resulting from vote

2:30 Final vote on the leading technology(ies) to determine if we have approximate consensus (75% of those voting) to recommend one or more for roadmapping and enhanced engineering development

2:45 Decide next steps in roadmapping the chosen technologies REDO T

HIS S

LIDE