Woodsmith - 067

Transcript of Woodsmith - 067

-

7/24/2019 Woodsmith - 067

1/32

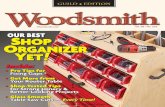

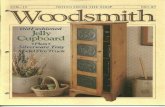

rmoire

K ID S l IIG H C H A IR

SHOP MADE

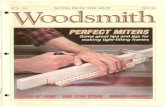

M O R TIS IN G T A B L E

A R C lE D M O L D IN G S

M O R T I S E S P L I N E

J O I N E R Y

3.95OTES FROM THE SHOP

O . 67

-

7/24/2019 Woodsmith - 067

2/32

No.6i

oodsmith

and be tter ups.the paym ent goes up 10 $100

il w e de vote an entire page to the tip. N atu

r a ll y , we ' re l oo kin g ( or g o d ideas th ai w ill

help o th er wo o dwo rk e rs . So

if yo u've

gOI

som e good idea s. s en d t hem in .

DETAns. 111C last pa ge of I'O Mll iit/

n ow c alle d ,in al D e ta ils , U p 1 0 n ow , w e 'v e

only had eno ugh room It>show one picture

o f e ac h p ro je ct. B UI t he re a rc u su ally s om e

details that de se rv e a c lo se r look.

T hu t's w h aJ this n ew I 'a f .{ ~is fo r. \Ve c an

show som e oflh . detail. Ihnt m ake the pro

je cts in this issue interesting .

1'01.\- '1C ' ) f l l l i l l l ,

s av e th e

issues. o

th e y wanuoreceive

th e m

in good shape. AJlythin CIllude o f paper

ca n

~ily

ge t

d am age d, tum, s oi le d. or bern,

So

we have. st andard policy to re place any

is sue t ha t 's d amaged in t he m a il .

But

I d e ci de d

thal th e

be ll w ay to protect

t h . . i ss ue ill t1 w

Iir st place w as

10 put

11

in

a

plas tic

b ag ...

a

bio ilcgrudab < pol)'.bag.

IV( lor i3mit l .

is

published

in IOW'J . w hic h is

fa mous for

01l~other

pr ba gi s all about.) l3 y adding

corn starch to the plastic, il supposedly

makes the bag b lo -deg radab le .

Thejury

is'$lill

out

on al l o(this.

But

it's

th e

besllechnology ava ila ble today,

TIlE

W O O D S MITl I

STORE

('ATALOG.

Along

w ilh Ihis issue of TV()(}(L~mith.wC 'v e e n

closed 3copy of the new

WOOl/smi th

Stor

calalOj(,

I've nlO 011 101 roOm 10 talk very m uoh

bollt

th is calaloj(.

excepl to say thaI Ihe

basic idea is 10 Ilrescnt m ore info rmation

aboul I I o o d sml h Back

I~ s u es . U ld

Project

S upp lies. inU tepast, wecoU ld o nl y show the

cove rs of bac k issues. T I,e new catalog for

m al allows us to s how ind iv id ua l p ro je ct . .

NE. 'ooTSS tIE.'nle next issu e 011,(,,011

milll

(No. 68) ,ill be mailed during Ih e week 01

Apr i l 9 , 1990 , _-_

A

s

s o o n

;15

t J l i s is s u e

arrived.

Y O l I

prob

ably noticed some changes.

Wood.~l i iJ lnowcomeswrappcd in a b io -d e

gradable po ly-bag , T IICo ld p ro te ctiv e c ov er

is go ne_ There 's a ~Vo0d8mi th S to re calalog

in clu de d a lo ng w ith the issue . And the b ig

gestchuDJ(e 01all-s-we'veadded e iRh l mo re

pages to chis is s ue .

I w ant 10 talk a liule a bout all of th es e

changes. Twelve years ago, the very fin;

i ssueof 1VOO(/l'Iltilirwasj)ublis hcd with only

ei ght pages. Dur iag fhe nex t th rccyears, we

gr adu ally increased t he s i? .e to 24 pages. It'S

been a t that sir , (~ r th e p as t e ig ht y ea rs , ..

until

now ,

Asyou can imagine, rve be en lo ok in g ( or

ward tv th es e e xtr a pa ge~ fora lo ng lim , II

mean st ha t we 'r ef inal lyable to present more

iuformation and get invo lve d w ith bigge r,

m ore com plex projects.

In

the past,

we

ha d

tough

decisions 10

m ake about large Pro .i tocLSike the Armoire

th at's in Ih is is sue, S holl id w e design it w ith

all the nice details like an arched lOp and

raised-panel d oo rs . e v en inl takcsup haiftht

is su e 1 0 s ho w how 10 do it? Or, shou ld we

simplify il s o il ca n be pu t on fe wer pages?

Even ifw e did show th e full -blown version.

w e c er ta inly would n't have room 10 a dd

II

c omp an io n art icle, li k e th e o ne s ho win g h ow

to m ake the a rched m old ing f or th e topotthe

Armoire, Now we ca n get im o all these de

sign

details ,

CONTENTS PAGE. W ilh th e added pages,

W e we re a ble to m ake som e other change s,

First, w e've added a C em ents page . This

~hould make it. easier 1 0 fin d art ic les il y ou

wam to re fe r b ac k to th em in the future.

TIPS

&

T1 CHNIQUES.

O ne of

the most

pop ula r pages in l Voodi< lIIith is Tops and

Tec hn iques, which for yean; w as Ih~ JiI1\I

article

in

ta ch

i~,c.

I t's s ti ll f lt S l. b ut we 'v e

shift ed illO the spread aftr U l Contents

page-and it'sbeencxpanded to two pages ,

Y ou g el m ore t ip s . .. and m ore UPllOrt unity

to

s e lld in

yo ur id~as,

As w e

were

m aking

t he o th crchnnge s. w e

dedd~dt o ch an g th e pa ym ent policy fo r

tips sent in b y rc ade n;. The am ounl paid fo r

eaeh tip is dClennioed by the amount of

space gi ve n to th e tip . T Ile b ett cr the tip. the

more the ~ount of space it g elS , a nd th e

m ore m Qnc y y ou gel.

Th e min imum am ounl pa id f ora till th at's

publi~hed is $15 . B ul 10 encourage b igger

avvdust

WOUDSMml

(ISS :>IOI l> I-j lI l) is pub

lished bimonthly (FcbnHll'Y, Apri l. J uno.

A u gl,ll' , O c to be r, J )(:c ( 'mlwr \

by Wood l , tb

I'IlblMllngc. . 22011Gmu l Ave.,

I) ,

.in,,,,

IA503J2.

\ V c > O d m i l ll

te

a rtgis\cr(t-d e rn e f t. - I n a rk o f

WoodSlOith'ubl i bingCo.

,( Coll) ' light I \)9 ) by

W oodsm llhI ' I lb lL 'ihinR

C O l n p a n ) . . 1 \ 1 1tll.thl~

esen ' l . f l.

Suh.oriptions: On. year (0

il; ''')

$1 5. 95 ,

r w o Y ( 1 2

b . u ,, '

Z 7

.9 5.

( ; : , , , . < lu

i tnd

For

ill1': adrJ$'.lOO)l.'Tycar,U s l~nrJ'( 'nJy.Singi.

cop) '

prj... 8:),9';,

Second CIus . .. I '(. ~

Pnidm Pe s Moin,. . .

I

a n d

~t

d d i t i o l l a l o f f i c < . . , . .

PO~HSI r:S end chullRe 01 addr('s '

Wood6mith.Box491,ML Monis. n .610Sf .

SubSCriptionQu_o ....? C.I 800-435-0715

In .

'idents : 1IIJCl. .892-0753)7 :3 0 A M

t o 8 : 3 0

PM. CST. WL kddY'

Sampl. CoP)': W ,

wil lsend n

fn :e sampl,:~ y

Q f V(Jod JS l~I t}1 t o o n Y Q n \- . J us t < :< n d u s h i rv 'h rr

na m e a n d a d d rc s i.

Store

MannSte ,~

SL

l.

-

7/24/2019 Woodsmith - 067

3/32

3

o 67

[ Sources} 31)

T he p la ce ,to look fo r th e harduare

-- ---------- - and s7 ' 'pp17eseeded /0)' a ll the p1 '0-

jec ts in th is is su e.

[ Talking Shop~ I J i I

A router and theright

type

0/ bit

a 're

~ what eally

,nake the M01'tising

Table uiork.

Arched Molding)

[ 6 Making

an,a l'ched mold ing doe~)1 '1

haue

to

bed'i/fic:u.lt,Here

aredeuiiled

imtruct i01 S

fo r eu en t s tep o ft lt e j ob,

Arm.oirej s

A

g ra ce fu l c Ul'lIe d

top asui ''aised

.... ... .. ...

pameidoors crea te astute ly hei rloom

project.

Sh pN tes

2 Tips

1011t inside

th e W O O dS 11 tith

-- 0-L__ O_ .... ~ Shop: 1.Burnishing a

ln ite l'.

2. Rats-

in gn orc hed.pam el;

8 Secul 'ingpanels in

frames. I . Working 'with

warp

[ Mortise

. Snlinel

[

A hUbri d_ jo in t ,ti l:,t doeen ' equ ire a

r: _ lot of tedious jittlng,

Mortising Table

[1;J This I; lb le lruJ,Ych~tnge the wal l y01l

1M I epproach . 11.100dwOl 'king,It holds

OILtel '

horizontally

80

c uttin gan acc urate

mortise is a suap.

_ . : m j i l ic i i a 4 1 f A 'I I{ jle d le g s dc'l l ' /

nec~ssal'iI i

' tea l'

~ a co ' tp le .l' p l'oJec t, S1?J 'tp leJOU le l'Y

and knoek doum fasteners make quick

wOl'ko/Ihi

Shl,? 'dy

maple Highchair,

Ti

s

Techn es

4

Si~

qrea;

Ups

/1 0 In

feUolU wood,

.....~~..;.,; __~-.;;.,;;.j .. II ioorkers: 1. A tenon cutting jig, 2,

Clantping to

dr il l pres s. ;I,Edge-giuing

trick I.,

D ovetail layottt,

5. Shnple

bUl-n ishel', 6.

Polishing Plexiqlo.

p g 26

p g 6

t ts

A LOOK INSIDE

-

7/24/2019 Woodsmith - 067

4/32

4

Woodsmith

No. 67

and the back edge against the

stop. Then you only need oue

hand on the jig 10 p ush it a long

the table saw renee,

Onelast tip , T o m ak e

it

asler

to tighten the clamp head, I

glued. V , -dia.do wel o ver the

end o( t he clamp hand Ie .

Em m ett fI O go (l

E y ) U L .

A 1 inl lc8

-

7/24/2019 Woodsmith - 067

5/32

5

ood nllth

o.6?

RlUHOLl

SAM[ S Zf OR \

SUGHTlY SMAWR

Ttt H v4 l. v r SlIM

DIA. WOOD

DOwn

W hen usin g th e burn isher .

grab the d owel with one IHUtd

an d

the

flauencd head or th e

vaive wiU, the other. T his lets

you

r eal ly apply p res su re

to

th e

sc ra pe r blad e makin l the job of

rolting th~ burr m uch easier.

CI,, 'e s A. ROl/d il/eU i

~ nyetl..

ui l , N0l 1h

Carol;

Ediloi Note 17,;A ualt

bl,ri,ishm u Ok 8 well. For more

rifo ,? a t(Q J l 011IW I( 10 tf JI (

rp e

ttlt~1

i(H t srrclper , ffR? to

\V oo dsmilh .V o. ,~9.

I ns te ad o f b uy in g . hardened

st eel b urn ish er to dra w a nd (Q rm

th e cuttin g burr on cabinet

serapers .I useanold a uto mo bile

enginevalve.

(1

get allthevalves

eed (rom a lo ca l mec banicjuSl

foraskins:.)

To m ake th is v alve burnisher

easier to usc. I added a small

h an d le t ha t's cut (rom p iece 01

J -diameter dow el. AlterCULling

li te sm all length o f d ow el. d rill a

h ol e in

t he -end o fi t. 'Then push it

ove r th e end

olth.

valve stern

se rve as a handle.

VALVE SCRAPER BURNISHER

HI G IiT OF S lO t s

THICKNISS

O.SIOCK

PINS

f y ou w o uld

lIk(

to share a

tip. or haye a better w ay 01

do in g something in your

.hO I). send In your idea

to

Wood.thill,.

Tips and Tech

n iq ue s. 2 20 0 C r oud A ve. . nes

Momo.;, Iow a 50312.

W ~ w ill

pa)'

upon pu bllea-

lion S15 to SI0 0 ( depen din s :

O il

th e published ICI1Jllhofthe

lipl. P lea . . ' i n cl ude all ex

planation and a sketch or

photo (w e11d ra w a n ew o ne ).

SEND IN YOUR

nps

dab on a clean w hile clo th a nd

ru b it alonll lhe ed gea few times .

Theajust wipeoffthe too tilpasll'

an d look dow n In to the ed ge of

O le Plexig~1s.

f the ~>dge sn 't clear af ter the

fi rst attempt . JU SL repeat the

process unti l it is. Then ri n se of f

the

pi ece and dry it w ith ;1 soi l

cloth.

Gil St r l,be l

Nag ,..tl}/lJll. Ma,y/and

.Aiter cuttin g the Plexiglas

windsc re en on my C lass ic Road

ster (shown

in ~Voot lRm itl ' No.

5] s u n had to get the edges

sm ooth an d clea r.

To do this. I used th ree steps,

First. to remov e th e b um ; a lo ng

th e edge, I tig h tened f ine fil e

f lat in

th e vise.

T he n I ru bbed the

edges

of

th e

Plexiglas over th e

fil e an d r emoved the burrs.

After fi lin g olf th e burrs. I

sanded th e ed ges with 240, an d

then 4()() gr it w eI/dry sand

paper.

(1 '0 keep

th e e dg es f la t.

lay

t he s an d pape r- down f la t, a n d

rub the edge of th e P lexig las

ov er t he s an d pape r.)

Sanding leaves

UH

ed ges

cloudy. To get a clear edge. I

use a b uf fing w heel. But if yo u

do n 't have a b uf fi ng w hee l. us e

the next best tbing -

toothpaste. Toothpaste is a very

lin e abrasiv e and w ork s th e

sa me w ay on Plex ig la s as it doe s

On your t ee th .

To use toothpaste, pu t a smal l

CLEAR EDGE PLEXIGLAS

w hat th ejoim

will

look lik e, hold

thecard against tile corner of'the

drawer . see Fig .2.

O nce y ou like th e layo ut , fo ld

th e ca rd o ve r on ilS~JIan d hol d i

the workpleces to mak e

starter marks for the tails an d

pi n s.

se e

Fi g. 3 .

R I t . tlay k O l Y W

. l h n l V I , l i e l ( / , j\I i.}l,llfJ..~otn

f R A N S .

L YOUT M JtKS_

ro WQlUCPUCE

FOtO

CAJtOIiOARD

AJ.ON G C N f A U N f

A ND STA ND U P T O

VIMPOUllU

JOiNt

T L S

Next draw base lines to th e

right and lell of the centerline

equal to th e

thickness

of the

draw er fro nt an d sid e.

Now I llY o ut the pins and tails.

o a ls o s ha de I n th e s ec tio ns

that

will

be

e nd g ra in o n

Ihe

boards.)

A ft erlhe pins

an d

ta ils

are

laid

out, erase the extra ba se lin es

an d fold th . . ca rd in half. T o see

w ill loo k on the corn er of a

drawer.I draw them out on a 3x

5 index card.

C ut the ca rd the same he igh t

as th e drawer , se e

F Ig 1. TItl JI

draw a lin e dow n the cen ter of

th e c ard . T his re pre se nts th e

co mer 01

the

draw er. Label one

side

o f the

lin e Fl tOl> T

an d

the

o th er s ide SID ~:.

.AIler

r eadi ng about dovetails

in II QI>d. ,itll No. 66,

here's

another method for design ing

and laying out through

dovecli l jo in ts,

O ne 01 the toughest jobs in

Iying outdovetai Is is visual izins:

how

they

will

l ook on th e a ct ua l

w orkpieces . 1 '01 ' example, to

h t tpv isl ll il ize how O le dovetails

3D DOVETAIL LAYOUT

-

7/24/2019 Woodsmith - 067

6/32

No. 67

OOrojl'C1Supplies.

s t

page 31 . Y ou su pply Ilw kid.)

H ow do

yo u m ake a highchair

c h c

s

easy

co

a ssemb le to d ay

and easy

to

disassemble

tom m orow?

Use mortise and sj l ine joints

to jo in

th e

legs and ho ld the ja rts to g ether w ith knockd own ConfitTnaL screws.

PROJECT

EATURE

-

7/24/2019 Woodsmith - 067

7/32

7

ooosm;rh

SUPPUES

II Board Feet ,,',Ihick hard

mople

~. thlC:kMosonl te IQrspl ines

(lo)Conflrmorsclem

(2)

6.

H'A'fhwoodscrem

~ P ln l at o otln POlYurethane

For mora Inlormollon on Ihe

swlve, trcv hardwore ond Ihe

sorerv strop. see Sources on

page 31

E

o~

I

A

I

8

~

E

i zZiZZ t z

ZZ~

II

Ii

I

G

: I

H

I

~;J ~

I

I

b : I r r =

s.

l Z l

CUnlNG DI GR M

t,

ROUND-OVlI

e lT

)

IUUNOSl_

EDGING DEt IL

M tERI LS ND SUPPLIES

mm

@

C O H F IR M A T

>:~.

_S R W

PILOT HOLE

L IO

.~

-_J

t

~

.,

. . .

t-CO U N T EItSINK

i

SHANK

I,_.

HOI.

1 .

-

CONNECtOR DEt ILPLINE DEt IL

1~DIU ON

aO nOM

CORNERS'---

;------- ,,-------

\

1

- '

ONIIRMAT

scuw

\,

LOWER

RAIL

-

LEG

c

SPUNE

. x I~x1~

'-

SEAT

RAIL

-

UPPER RAIL

@

BACK

H

No,67

j _ . ~ . ~

r

LOWER

STEP

OR iU . l

-

7/24/2019 Woodsmith - 067

8/32

N o. 67

WocxJsmirh

CU T OAOO ts ON lNSIDE-

0 fRONT lIGS ONLY

Non::

CUfFRONT

llO AS

MIIlRORlO Si T

cer OADOtS iN

ONt LlO, l HfN CUT

DADOES IN

O~lR

UCJAT7 iN II

OPPOsm DIRECTION ~

d; ~

attached an auxiliary fence to the m iter

g aug e so it w ould supp ort the upper end o r

th e le gwh ile c uttin g U te d a do es . s ee F ig . 5 .

C ut tw o d ad oes p ara Uelto

each

other ill

oneofthc(rontlegs (D).Then t um the rn it er

gauge

to

7

in

th e

O p p o s i / .

dircclion.and

CUt

matc hin g d ad oe s in th e o th er le g.

I

L

--

,2

- - . - -

I

-r

- 1 _ , -

I

)

'\

lOTTOM

- 'DOlS

lli,

. ......J IN ONT

GSONlY

(5(1 0. 61

MARK l )Cj\TION

__ MOIlTLSE

-L~~ ~

6

.

__ UNlS90

rolMlSOFltMS

I.

leg s hav e to be a

,i>'l'om

s et , 'Th is me an s

th ey h ave 1 0b e c lll o n th eills id ef ac eo r e ac h

leg so they're parallelto the bo ttom oHl1elcg

alul th e s ha llow part of th e dado is nearest

th e bottom

of

th e leg .

refer

10

Fig.

6 ,

DADO

nt

LEGS.To do this, I m arked the

POSitiono f b oth d ad oe s 011 each leg . Then I

4

Mno 10TH ENDS

OF-ifG AT7 . ........

- . . . .

After r f in is he d c ut

Lillg the rails and

ma rk in g t he mo r ti se

locations, I started

work in g o n t h e

high

chair 's lep

(D).

CUT Tn E t.EGS.

S ince all four leg s

( 1 ar e th e same

size, I slJIrted

by

cut ti ng :Y~ th ick tock imo

fo ur managebl e bl ank s. Ea ch b la nk isr ipped

to a f in is he d wid th of2~ and cu t. to a rough

length o f33 .

Then.the

legs

(0) arecuuo

th eir finished

length Of31 bym iterin g the top and

bottom

e nd o f e a ch leg at 7 ', se e F 1 g . 4.

DADOES. O nce .11 four legs are cut to

le ng th . th e b ac k le gs a re c omp le te

an d

ca n

b e t empo ra ri ly s et a si de . But th e front legs

still

need ' lt 4 w idedadoe scu l on the ir

i l U l idc

f aces to accept th e tw o tro nts te ps , S in ce th e

l egsang le f rcnuo backcncl

side-to-side.you

h av e to c ut th e d ado es at a c omp ou nd a ngle

to k ee l> th e s te ps paral le l 10the f loor.

SETTI1E BlADE. To cut the dado es fo r t he

steps.

start

by ti lting th e dado b la de to 7 ' an d

setting the miter ga uge at

r.

Theo , using a

rest pie ce , a dj uslthe depth of cut until the

s}wUo ' I '$1 p art o f t he d ad o b '4 dee p, s ee

Fig.

a

l..;\Y OUT Tltt:: OADOES. Here's where

th ings can get a lit~e

co nfusing. 11 1e

fr ont

t 1

~

~

. .

.::.>:;

~

: : ; . . . -

LEGS

justable mangle fro m an art sup ply store to

se t

t he m i te r g aug e 00 th e

t ab le saw .

M ORTISE LOCATION .TIle

ra lls arejoined

to

th e leg s w ith a m ortis e an d s plin e jo in t.

So

the next step is to la y o u tlh e p os itio n o fth e

m ortises o n th e

en~s

of th e r ails . ( Fo r a

complete article

o n m ortise and splin e j oi n'

c ry , see page 14 .)

T he m ortises are cen tered on the thick

ness o f each rail. But for now just m ark a

penc il l ine l '. ' in fro m O le to p and bo tto m

edges

o n b oth end s o f eacb rail,

see

F ig . 3 .

The

ac tua l

mor ti se s will

be

cu t

later.

,...-

2

NOn::

MAKf F1RST

CUlWlntOUT

S lO P & lO CK

STOP

:: :\

-~

~

~~

I

.5CRlW

AUXlUARY sr r MJ1tJl

[NCETO GAUOt

MITI~

GAUGf TO

(A), seat

(B),

an d tower mils (C ) to a

finished

width of2\. 'l '.

se e

fig. I.

Once tile stock h as b ee n cu t to width, tile

ne xt step is to cui each pair o f rails 10 their

finisbed le ngtl~H cre's w here you 're faced

wit h t he f ir st a ng le s t oe ut .

First. cut a 7 ' anglo o ff o ne en d o f

all

th e

r ai ls . Th e n t o k e ep e ach pairclrallsthesame

h , l I .h , I s crewe d a n auxDiary fence o n m y

mite r g auge

and u sed a step blo ck 1 0trim

th e

o ther ends 1 0len gth , s ee ig

S hop N ote: It 's impo rt ant th at th e an gles

be exac tly T S O I b ou gh t a d ra ftsm an's ad -

NOn::

ALl TOCK

~.-THICK

1

LEG R A ILS

i l

MmR

~ lACHfND

I

= = ~

AT7

1--71,. .11_ j_

IV hile the angled

legs on this high

chair mak e it very

sta b le, angles can

be co nfusing

to

werkwith. To l es sen

th e co nfusion, I

wo rked with only

one angled pa rt o f

th e hi ghchair at a lime. I fo und i t e a siest to

s ta rt w ith the leg rails fi rs t.

Cl1I1lNG TI IERAlJ.S . To make th e s ix ra il s,

startbyculling:Y4 -thickstockfo rth ~upper

LEG RAILS

-

7/24/2019 Woodsmith - 067

9/32

9

XIoodsmi ihI1 .67

outSID E JA CE

Of LEOR ME

COU RSNK I ---.~

AU. SHANK

HOlS

ltI ... DflP

~ ,

S H A N K

HOLl

13

COUNTtR INK

IT

I

11

N OtE LOC ATION

-~~. . . . . .

O .. a ACK

ONNlCfOR

\ I

\

,, ,

1/..

_1IAlL

~

\

.

, -

IHAHI(

HO II

uo

th e bac k. This hole is located near 0,, top

end ofU ,e rk legs onl y. see Fig 1 1

HOLES FO R STEPS .Th ere

are tw o

shank

h ole s to d rill i n t he front leg s to attach th e

steps. T o locate these hole s, e xtend a lin e

Irotn th e topcdgeofeachdado around tothe

out sid e fa ce ofth e leg (0), s ee F ig . 1 2 .Th en

measure down:va from th ls line and drill a

sha nk hole center ed on th e .. id th o f the leg .

se e Fi g. 1 2.

CO tINT ERSINK . Afle, all f iv e shank holes

life dr illed in boll leg frames, co un ter sink

each h ole V u l dee p. see Fig. IS .

C N11a All.

r

O l t T 1 . S E S

ON

THK:KN[SSQf

STOCK AN D

BlTWt N MARKS

betw een the leg s. t ran sfer th e loc ations of

the

mort ises (rom thee ndso fth e mils to th e

[ ac e o f th e

le.and in the

e nd s o f t he ra ils. s ee F ig . 8.0use d th e Mor

tis ing Ta ble

ShOW lOIl

pages 12 and 13.)

Thencutsplincs to fi llllC mort ise s (seepage

15) :UIIIglu e th e le gs and ra i ls together ,

9

. . . . . ., . . . . us,

I

SEEDn -A1L IN

I---

~

txPlODED

VIM

_ _

~

S H A N K

HOW

NOn:

f O R IACIC

COUNlIRSINK

sf r ,tG.

,t

AU .42

SHAHK MOllS

t-SHANK

rOR CONRItMAT

1

SCII(WS

JiOlS

F O J: S t A T

S R FJG 10

._ 5HAHKHOW

roR UPPtR

.

A N D l OW l R

mps

5( 10.12

\_

1-RADIUS

After tlw le g frames

WPI P

assembled.

roun de d th e c om ers

of the leg. to a 1

radius, refer to Ex-

ploded V iew . page 7.

The

leg

f rames a re

joined 1 0

the oth er

parts of th e hi gh

c ha ir w ith C on firm at screws. These arc

deep threaded screws w ith all unt apered

root t ha t a ll ows t he join to be easily put t o

gether and t ak en apart.

CONNECTORS

12

HOU-~\

.~,.

fROM

fOP01

SH A N K

0 0

HOU

;-

=

-

OAl>O

FO R

E N T ta HOlt ON

ST{P

WfD1HOfUOS

10

ORAW UN:ctNTtRtD

uo

ON WJOT~O F ltA lL

@

:

~I

~.

.

t

.

o a r u 9 , . ; t ,

SHAHlCHO U

f T

IIAII

to

AnACH

S E T

, -

~-

1I0UlS FORSEATAND RACK.

In

order fo r

I h f l fasteners to work, jv~ s l i g tt l y oversized

shank

holes

have

to

be

dri lled

into e ac h

le g

f rame . s ee Fig. 9.

To l ocate th e tw o h ole s in th e se at ra il (B),

start by laying out a lin e c entered on the

width

o f t he r ail . see P ig.

Ill.

Along th is cen

terline.

mark

point,

al

ea ch

end I

in from

where the centerline m eets Ihe joint be

tw een the seal rail and the leg . Then dri ll

~ dia. holes arth ese p oin ts, se e till . 10.

N ler the holes In Il,e seat rail ha ve b ee n

dr illed. lo ca te a nd dri ll a shank hole to a ttach

pos ition

the lower

rail (C). I plac ed

a

W

w ide spacer along the straightedge. and

p us he d th e

l ower r ail

agains t t hi s

spacer.

Atlhc t end . p os it io n th e upper ra il (A )

between th e leg s so it s flush wi th the ends of

th e legs,

N ow

clamp

these

two rai ls

in place .

The

seat

ra il (B ) is p ositioned by s li di ng i t

b etw ee n the

legs

un tll it s snug. see Ill. 7 .

MOR nSE LO CATIO N S .With all thre e mil

FL U SH T OP

WITH

top

Of l G

T I le n ex t s te p is t o d et crm in ct he l oc ations of

the m ortises on the edges of the leg s. The

problem

is If

ma ke s ur e thes e mortises

will

a lig n w ith th e r no rtis es o n th e ralls (A . B . C ) .

OR ASSEMRI.Y. To do

this,

I dry as

sembled

the legs and

run s

10 form two leg

frames.

Ttl

k ee p th e b ottom e nds o f th e le gs

flush. push them against a stralghtedge

damped

10

th e b en ch. se c Fig.

7.

Then.

10

LEG FRA ME A S S EM B LY

-

7/24/2019 Woodsmith - 067

10/32

N o. 67

-

ONIllMAf

sctIW

\

W OII ,bmlth

0

K

J

.1tQHT

~

3

i

TIlVIlOH

IIOTTOMOf &ACI t

M AT

CUT IOm

,

_ T

SlOt

Wl

uo

torn

l < l g e

o f th e back

10

till'

seal

w ith tw o

WOods cr ew s. s ee I'ig . 18n.

1(0111 'T IlE l IDGES .\Vhile the h igh ch ai r is

assembled,

m ark w here Ille to p ed ge o f t he

kg fram e m ee ts th e b ac k. l F ig . 1 8.Then

I ro u te d a b ulln o se pr of il o n a ll th eexposcd

, dg., o f the back . Icg f ra m. ,, -eai, an d

s tep s. see

Edging

De ta il o n p ag c 7 .

16

0It1lL );,.

SlOPCOUAa

MorHOLI

. ....

c ~

..._ 1 ..-

~~

i\

~;~

\,

~

~

c . . . . . . . - . . .

.-

\ nMPOUlY

,

CUAr nuSH

i

wnHlOTTOM

Of

KAT

tAIl

I----_,_..t.

SlAT

@

18

f

I

17

,,

L....._L--..... -.

IS

1-,01,

HOt

sneak up on th e

other

end until i t

fits,

Now la youl th e arc s (o r th r hl lnd ho le and

al O at th e to p and

bOUC)I I l

ends ( ) f th e

back .

se c Fig . 17 .

A

p atte rn f or I ny in go u l th e a rc s

i s avai lable. see pagt 31 .)

T he b ack can bem ou nted b etw een hcit'll

frames by d r ill in g p il ot ho ll'S fo r th e C o nfir

m a l s cr ew s . s ee rig

IS .

Then

fasten

th e

bo t-

e. 7 IlVlLON10TH

INDS Of StAT

TO . I.~

LOWER

STEP

to )

SEAT

10 ,.

NOTE:

~olsT

IUUHOSI

ONAUIOOU

.~

14

fter build ing th e

leg fram es. the n ex t

.t~ l) is to make the

upP tr and lower

,tell {E, F}, seat

(G), and back (H).

~ TEPS.First.

ri p

, the -ieps

to

a

width

o f 3 1 . : ,

sec

Fig. 14b.

'11 1< 'ncui th e up pe r step (E ) to a len gth o f

16 nnd th e lower step (1 ) to a leng th o f

1 7 1 / 1 1 .I

c ha m fe re d o ff

t h e s h ar p comers

at

both ends Q f th e SIC , >;( ( ~ig.>lb .

S EA r. N ex t. I glu ed u pa h la nk

fo r

th e s eat

(C)

In o rder to cut

Uti, blank

to

(E,~) i n p la ce b etw e en

th o le g fra me s. (S in ce th ~ top- re p i ss h or te r

thnn the boU om 011

-

7/24/2019 Woodsmith - 067

11/32

II

oodsmirn

SE t EOO ING DfTAIL ON PAG E 7

CUfTO UNf

THEN ROUT

SUUHOSE

AROUHD

I ;_ _J

iOOEOFTRAY

COMPASS

PO I.NT AT

fOOl Of

RECESS

a

WArn

22

U SE COM PAS S TO LAY OU T

1

ft

W ID E: IOR O R

, .

INS _ -

T

. ~~

. .

11>~ \IJ,l1IRFJ\IlU) SERlS. WillI t he s lo

< OI11I)k d,the n~XISI~Pis

t o i ns tall fo ur \/.

U ). II l rencl t-d I rb in Ih~ back p anel (E),

see F ill, 2 a. T w o o llh e l< l ' I n sert s are loca ted

o n II w f ro nlln c, ' lU i '1 1 11 'I l1ard ad juSmJeO l

knobs, and IWoan-on the buck face to all ow

th e rO U I r1 0be dju 'I , 'd up and down.

ote

It,importantthnt Ilwcenters of the

two bo l e- con

Ih , ' back

a r e exact ly }'\I~

apart,

IIlhcy , no t.th e ro uter p ia it' w o n't

fiL

\....l '1Bl\.

AJII rlh,lhrt adrd i ns er ts a n:

in:- . ta lI ,-d . l1 lu. up .Ulh,

pit

-ce (or the base

fram e Then drill and co unrersink eighl

shank hole, inte th, back panel (E) and

sete it t o t he ba,,, see FiR , ,

ROunR BASI PLAn

Afte r COlllpl ..-lil l l lthe base frame. I m ade a

new bas e p la u- fo r

I l l y router This base plate

p ro v id es a

InriI(

s ur fa ce 1 0

hold

th e route , 1 0

th e ta ll ver tical hack pane l (E),

(. '1rr l~ ) SII:r, To m ake Ih(' ba se plate

(F).

I staned w ith II V 4 th ick p iece ot M as onit e

and cu t it

TV

wltl~an d 11 :V 'long.see fig .

:1 .

(\V e 're

I,.) u fl rin l{ n p re -c ut

Phenolic

p tas uc b aw p late I hr ou gh IVrj ~/,. ,il Pro

ject

SuppU, ,,,.

J)Uj( , .

:11.)

Alkr th ., b ,< , plate is C ui 1 0 s ize , d riJi a

rh -dia. hall in t h .. . , 'm , 'r ( or t he routerbil

SUDnAlla_

SIIOI vA c .l (y uu 'r (' u sin g a s ho p -v at, cu t a

h oi .. . in o ne of Ih l' slde ~i('C('Se) 10accep t

th e e nd o rth e hose

lfyou' n-nat

g o in g 1 0 u se

a v a cuum .lcawouuhccenter divider

sc y ou

can c le an o U I th e sn w dust by hand,

D A O O I;' m idd le o f th e

p an el for th e ro ute r

bil

To do this. d ri ll t w e

I -diamclcr holes, 2 apart and complete the

slo t by c U llin lC th e w aste O u l b etw een Ih e

hoi. . . . ,

t'~;JI,~,

T

i ' fI Io nis in R I1 lb k i.something

1

b, , 'n

work ing

on

fo r

so me tim e. In

fact.

O l e

f ir . ;l p r l to typ c was

b uilt a y ear a go ,

W rl i. when 1 )( 01 Cl 'ady 1 ( ,m ake the mor

I . , , ,

fo r

till'

lI illhch,II ' lind the A rm oire. I

bh 'w Ih , tiusl

r r

IIw ,lroLol)'J)( UIIdR O Iseri

ou s a b o u t a

morti~i,,)(

t . . 1 b k ,

11'.' 'r , \u .J- :. The 111()rti~ingable is basi

ra lly a p ly w oo d b ox w ith 3 h ig h b ac k panel.

T hen a ro uu -r b m oun ted 10 the back so the

router

bi l

'Iic k. th ro ullh 1 0 cu i a mortise.

It 's a , im p l, ' i de th at s ol ve s t he

problems

cften

in vo lv ed w i lh

cUlting

mortises on

a

roun-r ta ble o r d rill pn'~ First. th e work

p iec e l ays Rat . mull than on ed Ile , Second .

t he mo r ti se cr an b t,c ullo fu lld ep lh in a se ries

of

p.1 -e

es w i thou t

113\il1,J{

t o c h ang e

the

pos i -

tio n o f tl b it. (F or m o re

(In how

1 0 use the

table, se IX I l., ..I an d 1 5,)

BASEFIlAMI

To f ll ll k ,' th , bast frnm e. sta rt by cutting the

lO p (A) li nd bottom (8) 1 11 .1 . wide and

I ~ I I 101111ut ( . , = \ 1 1 p lywo o d, s ee rlg,.L

Al le r c li llin ll ll ll ' lO P and b ot to m , c ut tw o

,ides (C) H. w id~ by 11

I I .

lang. Then I

added a cent er di vider

D)

1 0 f orm an en

closed box -o I cou ld use a shop -vac 10 re

move rhi . ,,,'I';g, I.

~ r t i s i t l g 1 l a l b l e

SHOP PROJECT

~ ~

-

7/24/2019 Woodsmith - 067

13/32

13

@.

1l0ClC

lACK

. . . . . . . . .

Nn,67

. -

cur OUT

, .,WlDI

L b 1

saa r

,

S

otttU. t ,oo .

BLOCK

-..

r _

'; 1 ',

,

~

I

II,.

. . .

-;,)

. .

:

.

-..111

CHAMlllt

fOllCH04l

alAIANtI

6

...-i

UPRIGHT@

a

I . 1 . .. .

tHf(J(

II ~-

..c~

0_.J

1 . -

COUNTU .~

S IN K it .... , .71~

SHANK ClIU PlIXtOLAS

HOII

I. PIVOT

OOWtL

/

l K

'@

AnAC:H ~

...u,PI,At1

TO lACK WITH KNOtS OR 60lTS

5

ClAMP PLYWOOD

lASt TO OlltLL

ST I U

IASl PlAT

I

c

M.ASOHITQ

-...

...-

I,._,. .t .... ~_

1 T T

cu r ou r

3

, , lJ.

t

t + It: ~ .

\-;....r . . . ,

~ r

It,. ,.j

H IL L H OlI S T O t. M O UN T IN G

n YOUIlIlOUTtI MOL(

3

wid.- b) 7W ~ ,nll. (:> ;o t ' If yo u can't fi nd

~ ,' thick 1'k'il:LN . yo u can R lue lo ge ther

tw o pi eces o ( ~ Il t ick P k .xigla , )Then I

sanded a W rudius on

th e

two outside

c om , ''' '' a nd l ig ht ly . .am ll 'i l t he

fronl

ed ges ,

To mount

lite

Plexiglas

10

the

uprighl d rillc o un lc rs u nk b olc so o th e bot

tom

sid. , u llh . pia l an d s cr ew

the

plat e

tel

t he b lo c k s I'Fig. 6. 1 .

ItE-F ~H.Ntt I.INI:S.Vhcn

tile

~ :lrd is

s c rewed l o g l lw r, posiuon II o ver the to p o f

t he b ie . T lu -n

U,;j

311X a l lo knife 10 scribe

IWo line. o n the bo tt om u llh . . p la te 1 0a lig n

with ea ch , id ,' o f 11ll'b it . s ee Fill . 7 . Byusing

the Ii ,,,

asa

.' lJid.-. 1knowexac t lywhere I 'm

starting and ...

oJ,pil1K

a

CUl

create (Ill arched

S IO I, >~~ig . I

(C I~ aJl

ou t

t ill '

s te t

w ilh a fi lc .)

Wllh the 101

fini sllt '

-

7/24/2019 Woodsmith - 067

14/32

N o. 6 7

oudsmlch

MO TISI N SPUNE

T lw ( ()>IIIcrti/ 1

HII /

i

/ ('

oJti

ill

joi

II /

/ ) I O u i d e a

a l ar g e g /u i,, {/ .ur/orf. P l us l he t r iz c C (l lt be

( t ried to f t,

malll/opll/icatiolts.

ro un d ilc asie rlo cu l th em o n th e

Mort lsin llT ab le sh ow n o n

p a g e s

12and 13.

W ilh th is tab le

I ca n

cu I

cleun,

a cc u ra te mort ises and

ad d

II

s p line -1 1 1 1

in

a

fr act ion 01

th e lim e I I used [0 la ke 1 .0cui

mor ti se and t en on jo ints,

11IE n r r s . T he whole idea 01

Ih . M ortising Table is to cut

mortises with a ro ute r that's

m o u n t e d

horizontally.

To

do

this

) 00ca n U a r eguJa rS l r. ti gl u b it

(tikI: a

lwo-Oule earbide-ti (J l lCd

sltaillhl

bn),

However .

I

would

highly recommend using a

s p O -

ral end m ill biL These bils a re Speci fi ca ll y

d esig ne d 1 0 m ake p lu ng e c uts a nd ro ut sid e

to-side mu ch e as ie r than sLraighl

bits.

(F or

mo re ln fo nn atio n o n th es e b its , s ee T alk in g

ShO I),

p a g e

30,)

STEP BY T P

One ' you h n ve th e M orl is ingTablc and

the

bi t s, I t's a s im pl e mau vr

to cut

U C mortises.

Firs],

udjus, Ih, '

r ou te r s o the

b it is

se t

to

th e c or re ct I ol;lI hl lo r I he mort lses y ou wan t

1 0Cu i . se e S 1 1 1 l2 . O n e re as on th is joim c a n

be madesoquickly, isthatthemortisesalign

automatically. Ju_'

mark the face side 01

bo th p ieces and m ake su re the m arked side

laces I wh( ' I1 c ullin g b olh p iec es. T h e n

d urm g . ~ m bly . k e e p th e m a r k e d sides

facing

the

same di rec tion.

OEVnI O F' nrr, U ltr setting

the

height.

a dj us t th e

d('J)\h

orCUI,see

Stl'P

2 . ' IOIe :The

depth o tCUIi s a ff ec ted by b it l eng th

and

lype

01router , Sl 0/(/ ' /

b e u se d

l or t lw I rl lmt ' 01 1 both the H igh

c hn ir a nd I h~ A n n o

ire

s h o w n in

this i~su(' didn't.

lnstead, I used a

hybrid

join I, m nrti-e and ,p/i'lf,

It

co nsist' 0 1

WI) m or t i se s

joinl?d

by

a

connl'Cl in l : p i t' ( :( '

ealled a

spline, ~ v d rawIl l { a t ri g ht.

\0\ \T\(;r~.

There art>

a

couple 01

advantage

10 u~ing

t hi s j oi nl i ns te a d 01 a mo rtis e a nd te no n -

c'PC'CialJy

on

the two 11r0j('ct.~

n t hi s i ss ue .

First.

since

the

(c:g$ on

the

Highchair

are

an gled , an angled tenon wou ld b e re qu ir ed .

This

is

1101

only d if fi c l Ilo

cut, bU I

irs a lso

di lficul t to flt ,

S e c on d

e ;

material to u se

ror'illinl. .

SlLEO~IotmsE.Asa r ule o lth umb . mo l

Ii arc u sually on e th ird the th ickness of

th e < to ck 1 0

b e

jo in ed . F or e xam p le , w he n

working

,th

~, Ihkk

I O C f J I l O ' / i 1 < e .

Ro , , - , / o l 'e / edges. CUls/)ib,e. to /elloth I/S

I .

thu If cvmbi l fed

depth I)Jm/)di .se.~.

I

~

I

IUJlD UP LAY fRS

OF OAM

T O H OL D P AN EL

ClHTIRID IN FlAMS:

sn L l .......

a

c e nt er ed , a n d

when

th e

panel

e x

pands, Ow rnam

compresses

I 've o u n d fo a m w e a t h e rs tr ip

Il ll

tape with an a d he siv e b ac k

works

gre. t .

II s

available

a

h a rd w ar e s to re s in

1 , 1 .

w i d t h s

(perfect (or th e

1 , 1 .

slots). Buil

up layers

in

the slots

unt il th e

pane l is

O U R :

with in t he f rame

see fiR

2a

2

an d bottom o f each panel. The

brud shou ld 110through the

to n gu e a nd in LOth e r ail, s ee rill .

ta ,

B y

using o n e brad Ih e panel

ca n

expand/contract

in

both

directions

rom

th e center.

FOAllI TA PE. A s ec on d m e th od

is10use foam

r ub be r in th e

slots.

s ee F ilt. 2. Pullin s: fo am o n all

four

sides keeps the panel

D OOR

smzs When

il'

tim

LOselect

th e

wood

(o r

th e

d o o r

tile

(especially the in sid e

st i les.

part.

AA), .iaht down th e

le ng th o ( e ach p ie ce an d lo ok fo r

an y bo w

warp).

Ther e s u re t o

be a

liule bit

ove r

51

feet .

Now

position

tbe

sl il,'

SO

th e

hig h peint

O(

the bow will (act

u ( away tr om

the

cabin et), Sl e

F ig .

1. Then,

w h e n th e

door i~

clo sed , Ihe

lOp

nnd bo tt om

will

to uch th e cabinet (acinl l fil ll. O

pu ll t he

b owed

c en u-r o lthe do o r

in tighl, l located th e d oo r catch

o n th e ca bin et n car th e cen ter o f

th e

d o or 's h eig h],

CIAU ING WARI.

A n o th er ex

am ple w here I usc warped

b o a r d to m )' a dv an ta ge is

whcn

damping

d own ( oc t' (r .lm e ~ In a

cabinet. S o m e t i m e - ,

it',

diff icult

t o p o s it io n clamp

-

7/24/2019 Woodsmith - 067

18/32

No,67

LUMBER

21 - : .Shee t . ' I tt lc :k cherr y plYwood

I Sheet hick cheuy plywood

5 9 5 B oO td J oe l ~ .' 1 'C k I O IId c he 011 )

(2Qvorn)

lunllol

SUPPL S

T

h is < h~nyarmoire i, o ne o f t he la r e st ro jl '

w e 'v e e v er f c tItlrf:< in oodsn it u t

t~

nell th v

size, it's Ihl details tl uu rea lly make l t in te rcs l ln j ( ,

,\K CUEI) TOI' ,Tlu- m s l s tr ik in g r ea lu rt is

th e a rc h ed

cro w n ,o kliull o n Ih., la p o f t he ca bine t-a dcta iltha l

lo o ks v er y difJkllh 1 0 bu ild, 1 1 0yo u ha ve 1 01 0(1 0yo u I ,,, 1 0U a ,ha Pt'r w hh hllK '

cutter 1 0 ,h ap e t he mu ld in . ?

Actually

it < panel -,

ute

r ua k e th .: d o er s l oo k g n- al .

Okay.

bu l h ow d oy .. u C U Ith e h ew l

on

tbt'CI'I'\',

-

7/24/2019 Woodsmith - 067

19/32

19

AlSO aQUIRfDl

2Jtt SH10S{4 x J f~PlYWOOD

1 SHErr . x J Of 14 .. PLYWOOD

I

. ~ I 1 . m J

O

C SE

A SIdes(2)

'II.

ply x 19w~ 73

B

OMder(l) 'II.plyx

19y.67,>.

C TOp(l) .,.plyx b'~19

o

Bollom(l)

,.plyx~~-19',.

E Bock(l)

V.plyxd7-73

F 51119.(2) 4x3- 14rgh.

G BotiomRoII(I) .,.x4'n~dll,.:,

H A,ch( dTopRo 1(1)

~

3'''''gn 4111

I DividerCop I ,x 11I.-69rg

J

Ogee Fn.MO ld .

I .y .

x

2% .

49

K Ogee SideMold (2) .y . x~. -

2GIt .

l Cove F r t Mold, (I)

%

x% -SOIt.

M

CoveSideMold.(2l lC

21 '1

SE

N Bul lnose

Fronl (1)

'1 '.

X 2,. - 51 '12

o

BuI InoseSdes (2) 1 1 1 x 2. 22

P KlCkbOOrdfr./8lc.(2 )

1

4V. 50 0:

Q

1

-

7/24/2019 Woodsmith - 067

20/32

N o. 67

oodsonith

0

NOTE:

TONOU

MUS T . IT

GROOV

DADO

4

TONGUE DETAIL

I > lVWOOO

uac

3

.- 1

DADO

IOl1OM

@

BOTTOM

3

. . . .

il 67l . '& \

y

D rv fD ER SIDE

; ; .

~

SIDE

culon the ends of the bottom piece). [n my

cssc.Lcut.the

divider

(B ) 67:jf.

long.

TO P

AND IJOTTOM.The

last pieces

Of ll4

plywood to c ut (o r the case ar e th e to p (C)

and

bottom (D). see

Fig.

I.

To

determine

th e w i( ll h

of the

to p piec e

(C),

measure

the

sid e p ie ce s a nd

subtract

V ' . .1 n

my

c as e t hi s

made

th e to p p ie ce

19

wide.

The

b ottom piec e

(D) has a 4 tongue

on

th e (ront edge

10

later a cc ep t a

hardwood

(a dng

ra il.

so

I

cut it V.I

wider (19\(.1 )than

the top piece. A fter the top and bottom

p ie ce s a re C U I to w idth . cut bo th piece s to a

uniform length 0 46W .

TONGUES .

The f in al s te p b ef o re a ss embly

is

10

CU lV . .th ic k to ng ue s o n th e f ro nt e dg es

of the sid e p ie ce s lA) . d iv ider 8 . an d

bot

lorn pi ec e 0 . se e ~ig.4.These t ongue s a re

used

to

attach

ha rdwood (ac ing .

referto ~lg.

6. AI the same time. I also cut id en tic al

tongues o n th e

end

o( t he bo tt om p ie ce

(D )

10 f it i n to i he d adoes in th e side pieces (AJ.

T o m ake the to ng ue s, r out

V.1 wide

rab

bets on the top and bottom edges with a

router b it and edge guide. Increase the

dep th of cut until the tongue betw een the

rabbe ts f i ts thedado es in th esid e p iece s (JI).

I t

fIOUR

-j

SAVI_

@

SHIlVlS

T

l\

~

~

@

DMOIII

~

~

1\

5. lWfoa

_va

[

~

~

5

-

~

~

~

\:

PLYWOOD

CUmNG DIAGRAM

. . .. D A D O

s t

FIGUR

IGURt3

1

straightedge fence a cr os s th e b la nk SO a

I I .

straight bit in th e r ou te r

will

be pos tioned

4

u p (r om th e bottom

end . s ee

Fig.

1 .

AABUJrr O R TO P.

After routing th e dado.

the

next step is to

rout

a

114 -

-

7/24/2019 Woodsmith - 067

21/32

21

I

GWESnU

fWS HWJTH

aOnOMfN

Of SIDEPIEef

IOnOM

@

DIVID ER

C P

. 1 ) (

@

Ola

PRIADGWl

IN

Mor:tnSl .

T HEN POS fTIO N R AILS .rrw N

STtLlS AND IN .s ER T SPU NES

No,67

6

r ~SPUN~ff i . '

S - , T rt;; M otm sn

~ DE W

t . ~

~

4

fOP I tA IL

I

0 : ,.. ..

WIDE.

V m i l

6~.

RSTRIP.

One f ln a lstepcn the base is

to CUl filler strip (R) lO fit on top of the

ki ckbnard back .

se e

Fig . 9b. B efore glu in g

th efiller str ip in place. cu t

arabberalong

th e

lOPe dg e o f the strip to accept th e ca bi net

back.refer toHg. 12.

8 i\ S E T O C A S E .

After th e base is

co m p le te,

itcan be att ach ed lO th e c ase. see F ig , I L To

do th is. I l aid the ca se dow n on us b ac k.

Nowce nte rthe base on th ecasean d align

bo th s ec t ions flu s h acros s th e bac k, se e F ig .

12.When they re in positicn. drill pilolholes

th ro ugh the shank holes in the bullnose

fr a m e a n d in to

th e bottom of the case, see

F ig. Ua. 11 1 [\ screw the sections togeth er

an d th e back 10 th e Iil le r s tr ip . see F ig. 12 .

la.,. , i

fit

WOOD

scalWS

Non:

BUL lNOSE fR AM J

OYl RlAPS ki(K IOARD

In

ON FRONT A NO S ID ES ONLY

tEN TtR B A S t

UND fRCASE

ANIl O N

I JACI (S nUSH

11

. . . .

t

-

7/24/2019 Woodsmith - 067

23/32

o . 67

~

t

CLOT~ESROD

. 1 OOWtt.,

2.l ..

-LONO

lit DOWELp iNS MU t

AU QN WfTH UPPOR ~

HOUS INCAIlN

15

wid .. an d 1 9 l ong . Ne .x t. d r il l I holes.

Qllly

p

c en te re d o n

each piece. Theil ro ut

an

escape

ar ea fo r the ro d 10 b e removed

above one o f t he ho les, see F ig . lS a.

N ow d rill h oles a nd m o un t

V

do wel p ins

on the

backside

of ea ch

supponto

align

with

the ho les in the cab ine t. F i na ll y.

fit tile

sup

p o rt s into lh ec abinetand cu t a Io()ia.do wel

1 0l eng ti l s o il wedges

betw een

th es upports .

SHELF

EDGING--

I

14

d ri ll in g templat e to 6 l betwee n the bo tto m

and top o f the c ab in et a s shown in F ig . 1 3.

curmes

ROO , Ifyo u

want

to use

th e

ar

moire to hang c lo th es , you w ill h ave to add a

cl o th e s rod Y), se e

fig. 15.1 s up po rte d the

ro d wilh two ro d su ppor ts 00. The

SUI)

ports in t um

arc held in p lace w ith tw o pins

thal

iii

lnt o th e ~helf suppor l ho les .

CU i t he su pp orts (ro m ~ -thick stock 2

Non:

CUTSlOE MOlDINGS

RUSH wtT H l ACK

Of CASt

OOIRONT

MOt ING

2 ; . ..

2S, 49

O I U E C O W

MOLDING

IN PlACE

HOLlS S 'ACtO

APART

.1 ,,1.,,

fh

W O O D -

SCIttW

d. OGll

fRONT

MOlDING

.. 11/4-

Fh WOOl .

SCRrw

Woo were attached .

J

made

th e ~ 1 I

plywoodshelv c$

C V ) .se e F ig . 1 4.

CUTlO

SIZE.

To determ ine th e size o f t he

shel ves , m easure th e inside o f th e c as e. To

a ll ow f o r edging ,

J

CUIthe sh elv es to w id th

1 2

les s than the depth o f my c as e. Then CU I

th e shelv es

W

les s than the dista nce be

twee n th e divider and the cabi net side.

TONGUES.Mtc rcutt ioglhes ltelves iosize.

the next step is 10 rou t to n gues on th e from

fo r th e

edj,~ngstrips. see F~. L,1.(For

more

on

~ W ,

N o , 62. )

EDGING. N ow cui the Jwide shel f o o g

ing (X)

from V 1 -t hic ksto ck. N ext cut < f f -

cent er gro oves

In

each Sl r il ) to

Iit

over th e

tongues on th e shelv es . And then glue th e

ed gin g;n p lace.

SlIt 'I 'O AT RO L S . To ho ld th e shelves , 1

use d brass

l in

suppor ts. Ori l lll, ho les (o r

pin support s

in

th e cabinet sid es

(A )

and the

divider (8). To po sitio n the ho les . I

CUl

a

SHELVES

W hile th e c as e was

still laying on its

back.

I

added

mold

in g a ro u nd th e

base.

O G . .

~101.0ING.

Firs i,

I

u t en ou gh

2-'i1l w idem old ing

to

f i taround

tile

front

a nd sid es o f t he cabi

ne t.Then

ro uta R o m an

ogee

o n th e

lO P

edge

of eac h piece,

M iter. fro nt pi ec e

(J)

to

at

across

t ile f ro n t o f t he cabinet and

screw

it in

plac e f rom beh ind . se e F ig . l3d .

N ow . m iter th e fro nt ends o f th e side

pi eces

K .

and then

CUI

a ll the back ends

Bush w i th

tile

b ac k o f the c as e. S c rew th es e

pi eces in place as well. see F ig . 13.

COl' MOWtl 'OG.Next.I added cove mo ld

in g L.M) in fro nt o

th e

o g ee

mo lding. To

m ak e th ese strip s. ra ul a I 'z cove on the

edg es o f a

ll'. wide

s trip O fW ,U lic k s to ck.

Then trim the W w id c molding o f f t he out

si de edges . N ow

miter th e

mo lding

to fil

a ro un d th e c ase a nd g lue lh e str ip s in p lace.

CROWN M O l.O ING . After gluing the mold

in g aro un d tlle

base. I started

work on th e

crOWD

m o ld in g a t the to p. The c row n m old

ing is

m a d e

fro m tw o

p ie ce s o f

:v., th ick

stock laminated together,

'1110fr on t arc h strips (base piece San d

tr im piec e U ) are both

cui

from ~ 1 2 -w ide

blank.

(F o r mo re on

this, see pages 28

an d

29 .)

Aftermilo rin g the ar ched f ro n t mo lding

to f il t he cabin et. Ic rewed ilto

th e

fro nt o f

th e lo p

r a 1 I

(Ii). se e F lg . 13a .

The s tra ig ht sid e mo lding strips

T. V)

ha ve th e

sa m e

profi les as the arched front

strips. A fter th e pieces ar e glu ed to geth er,

m iter th e ron t e nds an d cut U ,e back cod o ff

square w it h the

back

o f the cabinet. see Fig .

;

-

7/24/2019 Woodsmith - 067

24/32

No.67

.OUT GROOVlS ON tJOTH./

D OS 01 MIDOLERAIL

RAil

TtMPLAfE AN D TOP IND

Of IN SIDE STlLl MUST

Ie

RU SH

T R A N s n a

SH APE OF

OOR OP NING

ONTO lOP DOOR

RAIL AND

snus

9

TRAN rot Me, ,S( MEASUJ[M1NTS

FROM RAILS

TOsnW

,N SIOE

STill NO

snu

DONTROllT

< BEYON D

NO

2

o.

CAIID'

1 \

m o . P l A T I I

20

TO P (A RCH

RAIL

1 . . . . . . . . . . . . . .~ ~ . . . ;

[

0

~~

~~~

14\

All RAIlS AND

mlfS ~ THlCK

@

O UTS IDE INS IDE

STILE STILE

..

6

1

~

'I 3 . 1

24

The last step in

bui ldingthe armoire

is tom a k ea nd inslall

th e d oo rs .

I

tarted

wi th Ihe frames.

srnzs, S in ce th e

doors have an

arched top, the in

side stiles (M ) w ill

beloo.gcr than Ihe outs ide stiles (BB), se e

F ig. Begin

by

cU lt ing a ll t he st iles

10

a

w id thof3 and the twoout side s ti le s (BB) to

a r ou gh le ng th o f 6 4 , ( Th e to p en ds will

be

t rimmed down a ft er t he a rc hed r ai l i s CII .)

To d ete rm ine the length of the inside

s til es (AA) ,m easure the he ig ht o f th e d oo r

op enings alth eir highe st p oin t (6 7W ' in m y

ca se). The n, since th edoorsoverlapihecase

by V4 , add l'l lO t h is measurement.

MUS . N ext, I cut t he r ai ls . F i rs . g lu e-up

IW O

:V .' lthick bl an ks (o r th e lop ra il s (C C)

an d rip

th em

9 wide,

we

FiJ. . l7.

rille

arch

shapewhl be cu tl ate r.) The n rip t he m iddle

m ils (~O ) '1 \1 w id e an d the bottom mils

(EE) 3 wide,

se e

Fig.lS,

Th e lo rmula lo r th e length of the ra ils is to

m eas ure a cro ss th e d oo r o pe nin g (2 0 11 1')

a nd s ub tr ac t th e c ombined w id th o f th e two

st iles (6 ),Then add

i

fo r t he overlap .

MQRTtSIlS.

The fram es are assem bled

withmortise and splinejoints, Start by la ying

o ut th e locations o r th e mo rtis es OD a ll t he

rails,see Figll. 17 an d 1 8.

To t ransfer the loca tionsofthe mor ti se s

10

t he s ti le s ( se e F i g. 19 l, I laid all of th e pieces

down exacOy as tl ley will appear in th e as

s emb le d d oo r, s ee F ig. 16 .Then . ma rk and

cu t the m ort is es in b oth th e s tile s a nd rails.

(Nole: T he V 4 widemortises a rc o ff se t 01 1

th e th ickness

to

align

with

grooves cut later

(or the ra ised panels. se e

Figs

1 7 an d 1 8,)

Now.cursplln e s to fit th e mert isesand dry

as semble t he door f rame s.

(;Lm1NG TIlEARclI.111e

nex t s t ep i s

10

cut

O le

lO Pdoorrails

CC)

10th e ir a rched shape.

To lay

O UI

th is s ha pe , I m ad e a te mpla te b y

tracing th e ar ched doo ropen lng ont oa p ie ce

o fc a rdboa rd , s ee F i g. 2 0 , T hen cut the tem

plate to s h ap e and t ransfer il 10 the lO P door

ra il (CC)and outside stile (BB ). s ee F ig . 2 1 .

Af t tr cu tt ing tile lO Pe dg e o f th e rails and

to p en d o fth e out si de sti le s to sh ape, cutthe

bot tom edge of the arched rails u sin g th e

bandsawanddrumsandcrtechniqucshown

o n p a ge 2 8.

1',\.'1EI.CROOV1 S.111e la s t ste p o n t he d oo r

f rames i s

10

ro ut g roove s Around th e i ns ide

o r th e s tiles and rails lor th e ra is ed p an els,

s ee F ig. 22 . I

CUI

the g roov es w ith a ~ slot

c ut te r on t he r ou te r t ab le.

T o d o th is, raise th e b il u mil lt' s aligned

w ith the m ort ises, Then . rout t he g roove s

along lIe in sid e e dg es o r th e ra ils . O n the

in side

edges

of the s tile s. don't r ou t b e yond

th e mo rti se s. s ec F i g. 22

DOOR FRAMES

-

7/24/2019 Woodsmith - 067

25/32

oodsmith

o. 67

DOOR PANELS

After th e grooves w ere ro ute d in th e

fram e

pan els (FF).

take a liule

more work.

in the ~ slot in the door frame.

pieces. J

dry

assem bled th efra me s s o I could

First.cuuhe panel towidth

(%

m ore than

Note;

11,. panel is

cu t to fi t only

iY ,s

in to

r ou t s topped

chamfers

around the in sid e of

the opening). N ow ce nter th e panel on

the

th e

siOI .

but a ra bbet is cu t O n the back.

th e fram es and ta ke th e m ea suremen ts for w idth ofthe opening andtrace th e arch onto

This leaves a

i f i l l

gap so th e pan el ca n ex-

th e p anels. se e F ig . 2 6.

the p anel.Then cut along the curv ed line. pan d w ith changes in

humidity,

CIIAMFF.RS.

o

rouubechamfers,

m ount

a

T o d ete rm in e where to cut th e

bouom

FlNISR

PANElS.

Bef ore ass embling

the

chamfer ing bit in th e rout er and lower

i;

Ia edge. m easure th e hei ght

of

th e opening at

door. it 'S a good Id ea to finish th e panels.

{

below th e ba se. see F ig. 24

a,

Then. il yO Il the highest point. Then transfer th is

you

don't,

and the panels shrink.

the uo-

pla ce a W . w ide b l ock in eac h comer. th e

measurement

to

the

panel and add

% . f inished

to ngue co uld be

exp osed,

bearing w ill h it th e block

and

Slop th e

IWSINCnlF. PM'J lS.

Aft er the panel s

arc

ASSElI IJ JLY. Now the doors can be as -

cbamfcr fill (rom

the

in sid e c omer. cut 10 s iz e.the next step is to rou t U lC ra ise d

se m bled. G lue up the m ort ise an d

spline

PANElS.

After ro uting

the

chamfers . work

p an el profile on the fr ont face

01

each panel. join ts. but d on 't put an y glue on th e

pan elso r

ca n beg in on th e ra ise d panels . S ta rt byedge-

Since I use d ar aised pane l b it

whhoura

bea r- in the sl ots.

(The

panel has

10

be ab le

10

glu ing enough . -t hic k

stock 10

m ake tw o

in g on th e route r

table,

I had

ro use

the router expand and

co ruract, se e pag e 17.)

to p panel

(FF)

blanks roughly 16

x

36 .

ta ble fence to

gulde

th e edge

of

th e panel. ROUND-OVER

NDRARRET.

There are tw o

Then rlu e up the bottom panel CC) (N ote: To

routthe

arc hc d s ection. I c lamped

more st ep on th e d oors. Round over th e

blanks to a rough size of 16x 26 .

a

nib

ann

on th e

fen c e, s ee

paRe 16.) front edges

w i t h

a

1 1 1

round-o ver

b i t , se e

cur TO SIZE. To

dete rm ine

the

fi nished

Start

by r ai si ng th e b it

above th e t ab le ,

S tep 1 in F ig . 2 6 a,Then ro ut a :VS -d eeprab-

size of th e pan els. m ea sure the

openings

in

se e

Fig.

25.

Then,

ro ur (h e

profi le in

a ser ies

bel in the back edges, see Step 2.

th e fram es and add

% 10he height and 01 p as se s s o ies l w ide. sceS tcps 1 and 2 .

t1NISH AND HARIlWARE.The

on ly IhiOR

wid th . This a ll ow s f or a 'Is'-Iong longue on RABRIIT. Next. tum th e panels over an d that's lc ft lstofin ish thec abin et, Then mount

thepanels

to

filinto

thcgrooves . s ee F ig .

27.

ro ut

a

ra bbet in the bac k.

see

Step

3

in F ig. th e do ors w ith o ffs ethin~ see Figs. Z I and

A fter yo u k no w th e

size

of th e p an els. cut

25. Make

th e c utin

a series of passes

sneak-

27. Finally . s cr ew th e cat ches a nd k no bs in

the

bottom panels to siz e. B ut t he a rch ed top

in g upon th e hei gh t unti l th e L O n g u e ju st fi ts place . see the Exploded View on page 19.

23

~~ ;;;~.

INGE

L

liON

-

,7

-.

. . . .

f--

;,

i. I

I T

~ r.9~

. .

3

, ,Your

~

I

I

ClNTUUNi (_

~

I

i

IILWIDTH

.

\

P~Tto\VOTOINl

,...~ er srne

WlDlH OF CAlINtJ

~ __

OtIlfAM COMPASS

~

51\. .

_ PrvOT POINT

TO TOUCH8 TH 14

r

Sf fOp M AO e

ARCS ANI TtfN

alA M COM PA SS

STR IKE U RA DIUS ARC

STR IKtlWO ,. RAD IU S

/;

i

A RCS W ITH PW OT PO INT S

AIOVI TlMPLAT[ BLANK

J.6

. TWEEN

P EN CIL P O IN T A ND

STEP 2

.

64 .)

'Vhn e th is m c tho d w o rks fi n e .

an even Cas le r me tho d is

to

r o u t

O UI the mortise

with

a router,

But. to r o u t mortises you need

th re e th ings:

a router.

th e

cor

rec t bit, an d so me means o f

at

CU'

rately

a li g ni n g the

cuts,

TI le Mc>rti s in g

T ab le sho w n

o n pa ges 12

an d

13isaneasy way

10 al ign mort ise s an d cu t them

w iih a ro ute r. Bu t .. . w h at k in d

o f ro ute r

is b es t 10

u se o n

th is

table ,

a nd w ha t k in d o f b i t?

ROUTER

I've

b e en

using a Porter-Cable

N 6 90 router, It b as a co u p le o f

fe atu re s I lla t w o rk w e ll w i th the

d e s i gn o fthc Mo rU sin gTab lc .

N o te .The Po r te r Cab le rou te r

ha s c e rta in a dv an ta ge s fo r the

M o rt is in g T ab le . b ut yo u

1 1t

I e e d

thisspecific r o u te r. It's n ic e

10

ha ve

a

ro u te r

with th ese

fe a

tu re s ,

b u t. a lm o st

a ny ro u te r \\i ll

w o rk .

R O llT ER F EA 11J RE S.

O n e

fea

ture l

li k e n b o u t

the

Por te r

Cable

ro u te r is that U te co ll e t c an b e

low e re d flu sh w ith the b as e . U

the collet SlOpS

h ighe r.

il

c an

l imi t t he d ep th o f cu t s in c e some

o f U le b it 's c utt ing ed g e w i l l $U II

b e above th e

router

ba s e .

Ano the r fe atu re that m ake s

l it is r o u te r e asy to w ork w ith is

thatthemotcrcan becompletety

removed (rom tb e

base.

This

m ean s yo u

can

moun t the

rou ter 's b ase

10

Ule Mo n i$iD g

Table

b u t s ti ll re move th e mo to r

to chan g e b il s e asily .

SPIRAL END MIU BITS

A1U lo ugb the re are scve ra l

types

o f b its that c an cu t m ortis e s .

I

p r e fe r s pi ra l e n d m ill b ils ,

MORTISING ROUTERS ND BITS

Talking Shop

QUESTIONS

NDOMMENTS

-

7/24/2019 Woodsmith - 067

31/32

3 J

ooJsmirh

o. 67

l luk s to

tl

t

kftJo rd ,rlitl l*r /.

,\nll

Ilfl ~8

tl 4h; rc114

e/ tI fgr

n{t,.. Stpl, w6t:r, l i9(l,

Woodworker 's Supply

5 6 0 4 Alameda, N E

Albuq uerq ue. NM 871J3

Router Bits. Mhltisillg Bits

The Woodworkers' Store

21801 In dustr ial Blvd.

Ro ge rs , MN 553 14

High

ellai1',/Wilier

Bits

Garrett Wade

161Avenue o r the Amer ica s

New Yo rk . NY 100 13

[{()I,(e Bit . JI101ti8illg Bits

Woodcraft Supply

P.O . Bo x 1 68 6

Parker sburg.

\VV26102

Rout , Bits, .1/

-

7/24/2019 Woodsmith - 067

32/32

l llml s l I; ( et y .tmp ilable Jor t/le

Y o u

g e t ,

I I I I O O S t 1'l ICted

vWwojtile

c 1 .

yo,,'r e

ATM. ~ItOpblliU llfo,t i$ing Table ~kc8

1T ick I/)ork ou t aeccllmlc mor -

A

~VitJI t[(

door.oplm

11011all

really

8ee

alL

tile

8IQ1'G{f6p_i.

lI ilitie. ill

O li$

8ew>' fool t .a l lA r moi, .. , Addauoth erc lose t

11 /

to

create moc lt anging 8 p 1 IC f 1 ,

Or,

i/ lo1 t p~./trr, O Il can place ad.-

jU8 t a bic

shelves both

r id e. o f t l lC

cllbillel.

i

S u l id c a .t I Il 'u

ot'< l

pul l . a lOl l1/

will

t il e s tender. ekc

o1 ' l l t ive b l Y l l b a c k

l ate '

C '