Window & Facade Magazine - 2nd Anniversary Issue

-

Upload

f-f-media-and-publications -

Category

Documents

-

view

363 -

download

46

description

Transcript of Window & Facade Magazine - 2nd Anniversary Issue

Volume 2 | Issue 6 | ` 100

Face to FaceAr. Reza Kabul

ARK Reza Kabul Architects Pvt. Ltd.

Industry SpeaksMario Schmidt

Lingel Windows and Doors Technologies Pvt. Ltd.

Tech Talk Adarsh Raina, Ramboll

Optimising Façade Designs forWind Loads

SMART FAÇADES

Responsive Designs for Optimal Day Lighting &

Energy Conservation

SMART FAÇADES

Responsive Designs for Optimal Day Lighting &

Energy Conservation

Anniversary Edition

www.wfm.co.in WE ARE LIVE!

profine India Window Technology Pvt. Ltd.501, 5th Floor, Kailash Building, 26, K.G Marg, New Delhi, 110001. | Phone: +91 11 42368600 ⁄ 610

Email: [email protected] | www.koemmerling.co.in

KOEMMERLING systems with new age German technology reflect innovative features and elegant design. If you are planning for an amicable home that makes your life peaceful and secure, KOEMMERLING is the best choice!

Range of products:•Casement doors & windows system (Outward/Inward open) •Tilt & Turn window system •Sliding windows & doors •Lift & Slide doors •Sliding folding doors •Tilt & Slide doors •Insect Screen available with all systems •Wood finish windows & doors

KOEMMERLING windows keep your home dust-free. They also protect you from rain, heat and wind. Keep your home clean and peaceful with KOEMMERLING.

Here's the solution.Koemmerling doors & windowskeep dust and pollution away.

Worried aboutdust and pollutionoutside?

l 4 WFM Anniversary Edition l

Published by: F & F Media and Publications C-55, Okhla Industrial Area, Phase - 1, New Delhi 110 020 T: +91-11-42576205

Co-Founders: Syed Ahad Ahmed Amit Malhotra Sarvesh Bagla

CEO: Arun. R [email protected]

Technical Panel: Mahesh Arumugam - Director, Meinhardt Façade Consultants KR Suresh - Regional Director, Axis Façade Consulting Ar. Ravindra Kumar - Principal, Pragrup YP Singh - Treasurer, UWDMA Sharanjit Singh - Chairman, GSC Glass

Editorial: Renu Rajaram [email protected] +91 9312864830

Esha Sharma [email protected] +91 98119 86040

Marketing & Operations: Kapil Girotra [email protected] +91 9560925255

Studio Design: O Positive Communication Pvt. Ltd.

“Printed and Published by Amit Malhotra on behalf of M/s F & F Media and Publications. Printed and published at Aegean Offset Printers, 220 B, Udyog Kendra – 1, Greater Noida, UP, India 201306. Telephone: (+91 120) 4725400 Name of the Editor-Ms. Renu Rajaram”

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email [email protected]. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfm.co.in and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

Contents

Cover Credits: Abin Design Studio

WINDOW&FACADEMAGAZINEVolume 2 I Issue 6Anniversary Edition

RN

I: D

ELE

NG

/201

4/57

870

High Pressure Laminate Cladding for High-Rises

Advantages of HPL as a cladding material for high-rises

06

Fully Glazed High-Rise

On a highly designed and developed façade

09

Role of Sealants, Foams & Adhesives on Energy Conservation in Buildings

Effective use of the said components in building design

18

Tips for Optimizing Daylighting

Discussing factors that can optimize daylighting

24

Optimising Façade Designs for Wind Loads

Advanced engineering methods to be considered while optimising the façade design for wind loads

36

“Our Customer’s Faith is Our Strength”

Interview: Mario Schmidt, Director, Lingel Windows and Doors Technologies Pvt. Ltd.

44

Creating Façades with Robust Characters

Interview: Ar. Abin Chaudhuri, Principal Architect, Abin Design Studio

79

Façades in India are Getting Better

Interview: Ar. Reza Kabul, Director, ARK Reza Kabul Architects Pvt. Ltd.

88

A case study by Amit Khanna, Founder & Design Principal, AKDA (Amit Khanna Design Associates)

The Perforated Brick Façade

116

Intelligent Glazed Façades

Project feature - The office for the architectural firm ‘Abhikalpan Architects Pvt. Ltd’

120

Standing Seam Roof

The aluminium roofing can achieve various shapes and still be leak proof

15

Integrated Façades for Energy Conservation and Daylighting

Designing facades as energy mediators

30

l Anniversary Edition WFM 5 l

EDITOR’S NOTE

Renu Rajaram [email protected]

With serious issues of global warming being discussed, we are racing in search of

smarter and responsible ways to combat environmental crisis. Buildings use about

40 per cent of global energy, 25 per cent of global water, 40 per cent of global

resources, and they are responsible for approximately 1/3 of Greenhouse Gas

(GHG) emissions, as per UNEP (United Nations Environment Programme) web site.

Façade & fenestration is often considered the biggest hurdle in achieving higher

levels of energy efficiency in buildings. Heat flow and energy lost through openings

in buildings is very high. About 37 per cent of interior energy loss is through

fenestration. Existing buildings present significant energy saving opportunities

because their performance level is frequently far below current potentials.

This edition gives an insight into integrated façade systems which provide ample

daylighting and at the same time help in achieving maximum energy conservation.

The cover story of this special edition is on Smart Façades, which explicates

responsive designs for optimal daylighting and energy conservation, and we have

included views from many experts in the industry on the subject. Article by

Ar. Prashant Sutaria gives many interesting tips for optimizing daylighting in

buildings. Gurleen Kaur & Sakshi Jindal from HKS – India, explain designs for

integrated façades which would help in energy conservation and in optimising

daylighting. Article by Niten Patial from McCoy Soudal Sealants has delved into

details of role of sealants, foams & adhesives on energy conservation in buildings.

This edition also presents a few very informative articles on cladding and roofing

too. Anuj Sangal from Greenlam Industries explains the advantages of using high

pressure laminate as a cladding for high-rises, which is a novel concept. Another

interesting article by Vijaynath Shetty is on Standing Seam Roof, which is an

aluminium leak proof roofing that can take various shapes. Adarsh Raina of Ramboll

talks about ‘Optimising Façade Designs for Wind Loads’.

India has one of the fastest growing construction sectors in the world. Swift

developments put pressure on living conditions of millions of people. It also adds

to the environmental pressures of increased demand for resources. Members of

the construction and real-estate industry must address these situations and build

sustainably so as to enable healthier and more productive environments. They

must understand that investment in building energy efficiency is accompanied

by significant direct and indirect savings, which help offset incremental costs,

providing a short return on investment period. With these thoughts we present to

you our Second Anniversary Edition and I hope you will enjoy the read!

l 6 WFM Anniversary Edition l

High Pressure Laminate Cladding for High-Rises

Anuj Sangal, Country Head Sales – Laminate &

Allied Vertical, Greenlam Industries Limited

Cladding

About the Author:Anuj Sangal has over two decades of experience in building material industry across sales & marketing, warehouse management and production. He has successfully handled Pan-India assignments like building material products including plywood, laminate, veneer, glass, doors and construction chemicals. Greenlam Industries is India’s leading manufacturer in the decorative laminates, decorative veneers, engineered wood flooring and engineered doors segment. It is also the Asian market leader in the decorative laminates space. With over two decades of experience in the surface décor space, Greenlam Industries has been a pioneer in introducing international décor trends in India.

The journey of use of high pressure compact laminate (HPL) for façade started in early 1980’s in Central Europe. They were used as decorative exterior panels for facade cladding. High pressure laminates were well known nearly worldwide at this time as an interior decorative product, but slowly the trend for high pressure compact laminate for exterior use as façade started growing.

In India, the use of high pressure compact laminate for façade started some years ago and now the product has really caught the imagination of the architects, designers, builders and end user.

HPL Cladding - Greenlam Clads project done in Jaipur, designed by

Ar. Raman Raina

Today the use of high pressure compact laminate is not only limited to bungalows, low-rise buildings but is gradually moving to high-rise building. The HPL

clads are applied as ventilated façade systems.

The HPLs are gaining popularity in high rise building because they provide energy efficient, long-lasting properties. They allow circulation of air and aids in increased ventilation. A ventilated façade system may result in a variety of advantages. First, a chimney effect draws air through the cavity, aiding in the removal of heat and moisture from rain or condensation. Second, the rain-screen also blocks some solar gain and accommodates continuous insulation, considerably reducing the need for air conditioning. Third, these results are shown

l 8 WFM Anniversary Edition l

to improve comfort within living areas. Residents and users not only find themselves in a low-maintenance-environment, but the dry and comfortable conditions of the building may also make a positive contribution to indoor environmental quality.

It is important to have a good quality panel when used on a high rise building facade. A good panel comes at a price. The panel should be symmetrical on both sides, with high quality UV resistant protection on both the sides. It should be of same decorative paper, with a phenol treated core. Although the full

size panels are quiet heavy, with advanced logistics technologies used for construction of buildings, there is not much logistical problem for carrying the panels to high rise building.

There are precautions which have to be taken during the installation of the panels especially in high rise buildings. In fact the fabrication has to be done with perfection. It is important to maintain a uniform minimum and maximum distance from edge of the panel to the hole.

Chart in Figure. 1 shows the minimum and maximum distance between panel edge and hole.

Fix Point and Sliding Point

Changing weather conditions and humidity levels could

make the compact laminate expand or contract. In order to accommodate such variations, there should be only one fixed point in one panel and remaining points should be sliding points. Fixing point should be the nearest (upper) fastening point to the middle of the sheet (Figure.2).HPL Cladding - A project

in Moscow, Russia

Fig.1: Minimum and maximum distance between panel edge and hole

Compact

[mm]g [mm]

min. max.6 20 - 608 20 - 6010 20 - 60

Figure.2: Position of fixing point – It should be the nearest (upper) fastening

point to the middle of the sheet.

Greenlam Industries Limited launched exterior compact panels two years ago under the brand name “Greenlam Clads”. It comes with revolutionary unmatched GLE technology that makes them fade resistant, weather-proof and fire-resistant. Over and above this, Greenlam Clads are highly durable and longstanding which makes them cost efficient. They are also low on maintenance and contribute to increased indoor environment quality, making it the best suited cladding option for exterior applications. These compact panels are highly energy efficient as they allows the circulation of air and aids in increased ventilation. They create a chimney effect that draws air through the cavity, aiding in the removal of heat and moisture from rain or condensation. Also, the rain-screen blocks some solar gain and accommodates continuous insulation, thereby considerably reducing the need for air conditioning. The ease of application and installation of Greenlam Clads also add significant value to the user. The panels can be combined easily with other building materials to create unique effects and highlights that can help make your home one-of-a-kind.

Greenlam Clads

Local Government Restrictions

The height up to which the panel can be installed is mainly restricted by the local rules of construction as well as building physics.

Conclusion

Combining powerful features of appearance and performance, wall claddings and HPL compact panels can completely transform the way your home looks. While aesthetically enhancing the appearance of the structure, it can also improve air-flow and lighting and is in line with sustainable and green building practices.

As innovations across the world of construction and decoration continue to emerge, wall laminates and HPL compact panels are certainly here to stay.

l Anniversary Edition WFM 9 l

Fully Glazed High-Rise An Architectural Dream Stays a Reality!

During the times of modern architecture and the international style the dream of fully glazed high-rise buildings became a sparkling reality – creating astonishing façades, allowing an interaction between inside and outside and paying homage to great views. But in present days due to building regulations and higher sustainability demands this architectural intent becomes more and more impossible to realize.

Therefore the recently opened Festo Automation Center with its all-glass façade points out the enormous technological accomplishments and the intelligence that lies within the design of the building. A normal or rather passive building envelope is transformed into an active building component reacting dynamically to changing environmental conditions. As a result cooling energy needed can be reduced by up to 20 per cent and the user comfort can be increased.

About the Author:

Lars Anders is the Managing Director of the Priedemann Group

and Façade-Lab Research & Development Centre, which deals

with assignments relating to the façade or building envelope.

Lars manages and leads, a team providing all services in façade

designing, consulting and engineering as well in other project-

related assignments. Lars holds a degree in Civil Engineering from

the University of Applied Sciences in Berlin. Lars has given several

lectures on building envelope related topics, with broader as well as

speci�c issues such as technology transfer, process and management.

Lars’ vision and mission is to create the leading global Façade

Research & Development Company, with consultancy and engineering

practice beyond limits – from product development via concept design

through to the execution.

Lars Anders, Managing Director, Priedemann Group and Façade-Lab Research &

Development Centre

Smart Façade

Fig.1: The Festo Automation Center Tower standing proudly in Stuttgart

© F

esto

Aut

omat

ion

l 10 WFM Anniversary Edition l

Thanks to new technical details and an optimization process within the designing face, the textile blind creates an exhaust air corridor between the blind and the glazing. Through this space, the exhaust air from the office space is sucked off taking with it the heat from solar radiation captured by the blind within this corridor. Thanks to this combination of façade engineering and building services, this façade element also features a dynamic g-value lowering the cooling demand inside and creating a higher user comfort - thanks to similar surface temperatures throughout the office. The above mentioned façade systems ensure that already in the first summer since putting the Automation Center into operation in July 2015 the inside temperature never exceeded 26°C even at outside temperatures of up to 40°C. Besides the high energy efficiency, the increase in user comfort, ensuring high job performances, the developed single-skin unitized façade was realized with a depth of only 75mm of glass construction, increasing the usable floor space in the building. To keep this newly generated absolute view clear at all times a new cleaning robot was used for the Automation Center. Thanks to vacuum technology this robot can move along the whole façade like a gecko by itself cleaning it in only one day.

Finally the façade was designed to incorporate the building into the Festo campus and the companies technological innovation, pneumatic air systems, intelligent control systems and last but not least the companies colours blue and grey – using these colours for the façade profiles. This commitment to the company is highlighted throughout the whole

This high performance façade is based on a unitized system of two different elements adding up to 8.500 sq m in total. By this the façade is a main part of the new eye-catching 67 m high landmark within the Festo campus, visible from everywhere in the metropolitan region of Stuttgart.

The two façade elements consist of one parallel-opening window and a fixed glazing element. The smaller element measuring 0.70 x 4.00 m sets a new standard in manually openable windows and glazing technology. Its parallel opening window can be operated by the user, increasing its comfort also from a psychological point of view. The floor to ceiling glazing consists of a two-piece panel of electro-chromatic glazing. This new glass technology allows changing dynamically the g-value by various steps and therefore lowering the solar radiation and heat income into the building. This technology also prevents from glare and at the same time ensures a high visibility trough the glazing. Festo also sets a new milestone in this field realizing the largest façade area of electrochromatic glazing in Europe. The bigger façade element is 2.70 x 4.00 m big and is carried out as one fixed glazing panel. With a high quality sun control glass still a good view from the inside is ensured. To counteract glare, an internal blind is needed nevertheless. At the Festo Automation Center, this mandatory blind is used to create a new type of air-exhaust façade.

Fig. 2: A close up overview of the Festo Automation Center Tower with its all-glass façade

Festo - vertical section

© F

esto

Aut

omat

ion

l 12 WFM Anniversary Edition l

The Capital with its complex structure

Rendering of the egg-shaped structure

day: a LED-system was integrated into the façade profiles letting the façade sparkle in Festo blue by night as well.

After all the new Festo Automation Center façade is mainly built like a conventional single-layer unitized façade but thanks to a lot of highly designed and developed details and a smart controlling of the building services, a highly innovative, efficient and sustainable façade could be realized. All these design and technological masterstrokes were only feasible thanks to the openness of the architect, client, industry and research institutes towards new approaches by the façade designer and its leading position in the designing and construction of the façade. This close collaboration made it possible to fulfil all the project targets, queuing in previous ground-breaking construction projects by Festo and realizing innovations as a reference for buildings to come.

Anees Backer Micha Pawelka Praveen Chaubey

Client: Vijay Associates (WADHWA) DevelopersOwner - Developer: Vijay Associates (WADHWA) DevelopersArchitect: James Law CybertectureProject data: approx. 103 m building heightBuilding function: Commercial BuildingTechnical features: Stick system façade, Unitised system, Frameless glazingOur scope: Typical detailing, Design development, Design review, Site installation reviewStatus: Completed 04 / 2013

THE CAPITAL, MUMBAI – FACT FILE

The Capital, Mumbai

The Priedemann Middle East and India is headed by Managing Directors: Anees A. Backer leading the Project Operations across GCC / India, and Micha Pawelka leading the Business Development in the region. With Project Manager - Praveen Chaubey as the point of contact for Priedemann Mumbai office.

Priedemann Office: 423 Avior Nirmal Galaxy, LBS road, Mulund West 80, Mumbai, India; Phone: +91 222 591 306

© J

ames

Law

Cyb

erte

ctur

e

l 14 WFM Anniversary Edition l

One BKC, Mumbai

Client: Vijay Associates (WADHWA) DevelopersOwner - Developer: Vijay Associates (WADHWA) DevelopersArchitect: James Law CybertectureProject Data: approx. 83 m building heightBuilding function: Office BuildingTechnical Features: Structural glazing façade, Point-fi xed façade, Stick system façade with sliding elements, Sun control louvres, Aluminium sheet claddingOur scope: Concept design, Detailed design, Thermal building physics, Acoustic analysis, Typical detailing, Tender documentation, Site control, Shop drawing reviewStatus: Completed in 2015

The Priedemann company was founded in 1993 by Wolfgang Priedemann in Berlin, Germany. With his partners; Lars Anders and Wolfgang Feurlein they expanded the German company into an international brand. Since 1993, the company has provided façade consultancy and design services to investors and developers, architects and general planners, main contractors and fabricators. Priedemann has grown international since, opening branches in the following locations: Dubai, Mumbai, Istanbul, St. Petersburg, Beijing, Nairobi and London. In 2012, Priedemann established their consultancy branch in Mumbai and developed an engineering hub in South India (Cochin) where they train local staff to support all their design activities.

ONE BKC, MUMBAI– FACT FILE

Fig. 5: One BKC Mumbai, completed in 2015

Concept design for the structural glazing facade - with a different opening option - Vertical detail

© J

ames

Law

Cyb

erte

ctur

e

l Anniversary Edition WFM 15 l

Standing Seam Roof

About the Author:

Vijaynath Vittal Shetty started the firm Vijaynath Interiors & Exteriors Pvt. Ltd. in 1992, and later diversified into dealing in interior and exterior architectural products. Now it has become India’s premier architectural solutions provider having a turnover of over Rs. 82 crores and employee strength of over 200. Headquartered in Mumbai, the company, renamed as Vijaynath Roof & Wall Cladding Systems Pvt. Ltd, has branch offices in Pune, Nasik, Kolhapur and Mangalore. It has full-fledged in-house facilities like design studio, engineering and fabrication expertise and networking with global materials manufacturers to independently undertake turnkey installation of highly specialized industrial and heavy duty roofing and exterior work. The company’s clientele include prestigious names like Mercedes Benz, Ichiban Honda, Delhi Airport, Lucknow Airport, Kempe Gowda International Airport (BIAL), Bangalore and Cochin International Airport.

Vijaynath Shetty, Founder & Managing Director,

Vijaynath Roof & Wall Cladding Systems Pvt. Ltd.

Roofing

Ichiban Honda, Mumbai

Standing seam roof is a roofing profile which is quite old in the international roofing industry, but new in the Indian market. Standing seam is a non-piercing roof. The roofing profile is roll formed at site and it is seamed on the side laps; that’s why it is called standing seam roof.

Applications

Standing seam is normally used in the roof. The aluminium roofing can achieve various shapes and still the roof can be leak proof. It is also widely used for wall cladding because it give a neat look. Standing seam roof can be used for very low slope as low as 1.5�.

Standing seam are available in various sizes/profiles like SS 2000, MR- 24,65/400 by Kingspan, 32/320 by Vijaynath etc. This standing seam is available mostly in Steel Galavalume by most of the vendors/manufactures and in aluminium by Kingspan. Standing seam was first introduced in the country by M/s Interarch building Products. In steel the thickness ranges from 0.60mm

l 16 WFM Anniversary Edition l

Patna International Convention Centre

CIDCO Exhibition Centre, Navi Mumbai

to 0.75mm and in Aluminium 0.9mm. In steel normally you use bare galvalume or SMP (Silicon Modified Polyster) PVDF 2 and in aluminium Stucco, PVDF 2 and 60µm durabond finish.

The Advantages of Standing Seam Roof

∙ Design: In aluminium, you can achieve various shapes and is suitable for any kind of difficult roof design. Because of the seam height being more for e.g., 50mm or 65mm high you can achieve minimum low slopes till 1.5 degree.

∙ Waterproofing: because of the high seam and seaming of the sheets at the side laps by special seaming machine, you can achieve water tightness on the roof.

∙ Sheet length: The specialty of standing seam is that the roll forming machine is always brought to site and the sheets are roll formed at the site and we can achieve maximum single length sheet. We have installed a single sheet length of 136mtr without any joints.

∙ Strength: on a standing seam roof, the minimum thickness of steel should be 0.6mm thick and that of aluminium should be 0.9mm, which adds to the strength of the sheet.

l 18 WFM Anniversary Edition l

Kempe Gowda International Airport (BIAL), Bangalore

Challenges of Installation

Installation of standing seam roof is very simple, if you are technically trained. But for difficult shapes and design, to install, you need to have a good trained engineer with lot of experience.

Test to be Done to Have Sustainable Roof

The roof should be tested for:∙ Wind load test calculation report, ∙ Thermal conductivity repot i.e. ‘U’ value

calculation.∙ Acoustic insulation i.e. STC report ∙ Water leakage test: on site water leakage test

using water jet spray

In India, lot of standing seam profiles are available, but none of them are tested & approved for wind uplift. Hence architects /consultants should specify sheets manufactures who have special wind uplift test done like Underwriters Laboratories Inc., British Board of Agreement, International Standard Organization and FM which clearly assures the client of a tested product from a reputed agency.

Tirupati Meditation Center

Cummins, Pune

l Anniversary Edition WFM 19 l

WEA

THER

RESISTANCE

INSUL ATION

AIRTIGHT

Untitled-5 1 11/05/16 17:19

Role of Sealants, Foams & Adhesives on Energy Conservation in Buildings

About the Author:Niten Patial holds a Bachelor’s degree in Civil Engineering with Masters in Marketing Management. As the Vice President in McCoy Soudal Sealants Foams & Adhesives Pvt Ltd., he is responsible for managing the business activities for Mccoy Soudal in India & neighboring Asian countries. He is based out of Gurgaon. McCoy Soudal offers innovative products, providing solutions to most bonding, sealing, waterproo�ng & jointing applications & the products are used in three principal market segments: construction, industry and DIY/hardware. Niten has vast experience from the core �elds of civil & mechanical engineering which includes water proo�ng, thermoplastic paints, survey & mapping, geo-synthetics, HVAC, MEP & FP. He had been instrumental in providing solutions to power, mining, oil & gas, construction & infrastructure companies. During this journey of more than 18 years, he has served on various positions & successfully developed innovative solution for strategic OEM & customers.

Niten Patial, Vice President, McCoy Soudal Sealants

Adhesives & Foams Pvt. Ltd.

Green Talk

Air Tightness and Insulation

Energy Conservation has gained momentum in recent years. The increasing demand for energy efficiency has influenced the technical development of right construction methodology and usage of right products for façades and windows. Now a days advanced and technically superior innovative solutions are available which are cost effective and facilitate greener buildings with a low carbon footprints.

On an average depending upon the location in the world, it is observed that buildings consume more than 30 – 40 per cent of energy. In extreme cold and hot regions this consumption may go more than 40 per cent as well.

Windows and façades are few of the most important factors while considering the overall energy efficiency of a building. Therefore the requirement and selection of right construction methodology and right products is very important

and it helps in achieving the overall performance. Special type of products in the form of sealants, foams and adhesives with better weather ability, durability and waterproofing properties are required to achieve this.

Thermalinsulation

Air-tightness

l 20 WFM Anniversary Edition l

The use of sealants, adhesives and foams in building design, has given extra dimension with the increased durability of structures, better performance and preservation of the building’s environment and a reduction in material consumption for the construction of the façade and windows.

Concepts of EPB, NZEB and Passive House

The European concept of EPB (Energy Performance of buildings) to reduce CO2 gas emissions by 20 per cent, to reduce energy consumption by 20 per cent and to increase the share of renewable energy to 20 per cent (reference year: 1990), and NZEB (Net Zero Emission Building) has gained significant attention these years. The concept of nearly zero or very low amount of energy required should be adopted to a very significant extent by energy from renewable sources, including energy from renewable sources produced on-site or nearby. These stricter norms not only advocate the use of one form of energy, but pays significant attention on reduction in energy consumption.

For translating these principle into building practice, it is of prime importance to take great care ensuring that the building envelope is very well insulated and airtight. Attention should also be paid to good compactness, orientation and of course, controlled ventilation. In the original concept, the ventilation ducts were also used for heating purposes; due to the absence of a classic ‘active’ heating system, this type of house was called a passive house. Meanwhile, even though other “heating aids” are being used, the basic criteria for a passive house have remained the same:∙ 1-Net energy need for heating ≤15 kWh/m2 per

year∙ Airtightness n50-value ≤ 0.6 vol/h∙ Temperature exceedance factor above 25°C ≤

5per cent

This translates into a building which has, in winter as well as summer, a very comfortable interior climate and requires only a minimum amount of heating. It is obvious that a passive house is the

ideal way to achieve an NZEB as the limited energy need can easily be met by renewable energy.

Major Issues in Building/ Window Systems

Thermal BridgesIn many European countries, while calculating the energy performance, any thermal bridges (cold bridges) calculation in a building is taken into consideration. This is quite logical as poorly executed building knots may lead to large transmission losses resulting in an average heat loss of 5per cent (for an average house). Designers must therefore pay attention to joints, especially joints between various construction elements. Window-to-wall joints, for example, are important potential thermal bridges, which easily amount to 100 meters for an average house.

Many available Window System (SWS) can contribute to lowering heat loss, as thanks to the use of Flexifoam in the SWS details the, possibly pre-calculated, Ψ-value can be kept low and, as the case may be, below the limit imposed by prevailing EU legislation (e.g. 0.1 W/mK).

Joints In comparison to other aspects of construction, joints are often not given the attention they require. Building joints need to be thoroughly planned and are necessary to compensate for the expansion and contraction of building materials or to create fitting tolerances. In practice, however, the result can be irregular joint dimensions or even unplanned joints. The sealing of joints can result in one of the following functions or a combination thereof∙ Acoustics ∙ Airtightness

Thermal Bridge: calculating transmission losses & energy performance

l 22 WFM Anniversary Edition l

Flexi foam application can contribute to lowering heat loss

Testing for air leaks in window systemsWindow Installation and application of sealants

∙ Aesthetics ∙ Thermal insulation∙ Fire protection ∙ Protection against burglary∙ Protection against driving rain and humidity

AcousticsFor quite some time now, tightened requirements with regard to acoustics (NBN S 01-400-1) apply in many countries. But the saying “a chain is as strong as its weakest link” certainly applies to soundproofing. An elastic filling material or a combination of these materials is particularly suitable to reduce the transmission of sound. A reduction of air sound is expressed in a reduction index ‘R’.

AirtightnessIn the context of airtightness not only refer to joints (planned), but also to seams and crevices,

which are mostly undesired or irregular joints or interfaces. For products able to seal seams, crevices and joints, the current product standards contain none or very few specifications or requirements regarding airtightness. However, in European standard, EN12114, which describes a general testing method to measure the air permeability of building products (in laboratory conditions). The result is a value indicating the leak flow per m or m2. For sealants and adhesives, it generally applies that there should be sufficient cohesion (the material does not tear) and adhesion (bonding) to guarantee the airtightness over a longer period. For sealants, the cohesion is linked to the movement capability of the product; the adhesion is strongly determined by the preparation and condition of the surface. In brief: selection of the correct product for the application, due care when applying the product and choosing a good quality product will always lead to the best results.

l Anniversary Edition WFM 23 l

AestheticsJoints, and especially the correct finish of joints, can contribute to a smooth appearance, of the inside as well as the outside of a building or construction. Not only the texture, but also the colour of the sealant play an important role.

Thermal InsulationA number of products, especially construction foams, score very well in terms of heat insulation. The lambda-value (λ) is used as indicator. In particular in wider joints, thermal bridges need to be avoided. The 3D correction factor in a joint between 2 insulating surfaces is called the psi-value (ψ). The minimum requirement in Belgium for window to wall interfaces is set at 0.10 W/mK.

Protection Against FireJoints and penetration seals are an important link in the finish of compartments. Compartmentalization forms an essential part of passive fire protection in buildings. The relevant standards are EN1366-3 for penetration seals and EN1366-4 for joints. Fire resistance is expressed in minutes; for joints and penetration seals mostly related to flame integrity and insulation.

Protection Against BurglaryFor exterior joinery this characteristic is classified in accordance with EN1627 to EN1630. Elastic glazing sealants can certainly have advantages here and will also ensure better airtightness and water tightness of the window.

Resistance Against Driving RainThese are, in fact, products which are not simply watertight, but can also keep water from entering when it is combined with an increased (wind) pressure. This pressure increases in proportion to the height of the building. For instance, at a building height of 50 m or more, this pressure may increase to 600Pa or more. As a primary barrier, these are mainly joint sealants suitable for use in facades and glazing, which also have good movement capability. They have been classified in accordance with the new CE marking (harmonised standard EN15651) or the EN ISO11600 standard: ‘F’ for façade, ‘G’ for glazing – 20per cent or 25per cent movement capability. As we are talking about outside applications, these products must also be UV resistant.

Vapour ControlDamp protection and vapour control is also an important issue for a healthy building. It can therefore be important to include the µ-value of a substance when sealing joints or even the Sd-value of a specific building material.

Conclusion

Windows, Doors & Facades are very important part of building, it is very important for architects & consultants to consider the use of energy efficient & sustainable products available in the market to achieve the best results in conserving the energy. In nut shell the Energy conserved is the Energy saved.

For further information on this subject applications, You can reach us at [email protected] Installation: construction foams,

score very well in terms of heat insulation

l 24 WFM Anniversary Edition l

Tips for Optimizing Daylighting

About the Architect:

Prashant Sutaria, Principal Architect, PSA, is a creative

and thinking architect, who believes in design

solutions for long term and likes to explore various

architectural vocabularies. After graduating in the year

1989 from Mumbai, over the years, he has worked

on a variety of projects. He passionately works on

projects of various types across India, and contributes

significantly towards better built environment and

sustainable development. He, along with his wife,

Architect Hemanti Sutaria, has created CELPT - Centre

of Living and Planning for Tomorrow. At present, he is

working towards creating knowledge based solutions

for affordable and low-cost housing.

Prashant Sutaria, Principal Architect, PSA

Green Talk

A hotel in Mumbai - achieved energy efficiency and optimum daylighting by controlling floor to window ratio, using recessed

windows for solar shading and high performance clear glass

Since inception, the primary function of buildings was to provide shelter and protection from the environment. As time passed, lifestyle changed

l 26 WFM Anniversary Edition l

Mixed Use, Durgapur – strategy of using deadwalls and windows to achieve energy efficiency in this gold pre-

certified building in extreme climate

and so did architecture where the original concept of providing shelter transformed into providing comfortable indoor ambiance. During this transition, building façades have gone through a lot of changes and modifications. The building façades remain one of the most important exterior components for building functionality. Apart from just aesthetic point, it also has a critical role related to energy performance and interior functioning of a building.

In case of a window, the basic objective is to admit daylight in a building and also provide view to the user. As quoted “a window that admits sunlight for winter heating also has to reject sunlight during summer peak cooling season”. In such conditions, high-performance glass, mechanical shading devices and façades that are ventilated (active or passive) with air volume in between two glasses

Factors That Can Help Optimize Daylighting

As per ‘Whole Building Design Guide’, a program of the National Institute Of Building Sciences, the design factors that can help optimize daylighting in building are:

∙ Daylight-optimized building footprint: Can be achieved by orienting in north-south (siting) and designing building such that maximum surface is exposed to daylight.

∙ Climate-responsive window-to-wall area ratio: The window area has to balance between admission of daylight and thermal issues (wintertime heat loss and summertime heat gain).

∙ High-performance glazing

∙ Daylighting optimized fenestration design

∙ Skylights (passive or active)

∙ Tubular daylight devices

∙ Daylight redirection devices

∙ Solar shading devices

∙ Daylight-responsive electric lighting controls

∙ Daylight-optimized interior design (such as furniture design, space planning, and room surface finishes).

Residential Project, Ranchi – the façade design allows sun in winter but controls in harsh summer besides

forming a strong architectural element

l Anniversary Edition WFM 27 l

could be used. High performance glazing (e.g.: solar control façades) admits more light and less heat than a typical window that allows daylighting without affecting the building cooling load in the summer.

Daylighting

Daylighting is to bring controlled natural light inside a building to create a visually stimulating and productive environment for the occupants, thus reducing the total building energy costs. Executing daylighting on a building goes beyond fenestration and windows, it calls for integrated design approach as it involves important aspects like building orientation, building form, climate, lighting controls , design criteria and interior planning.

Daylight Redirection Technologies

Daylight redirection technologies reflect incoming direct sunlight onto the ceiling of a space. Interior design which includes furniture design, placement, and room surface finishes also plays an important role with respect to daylight

performance. These devices serve two purposes, one being glare control and the other being daylight penetration, where sunlight could spread deeper into a space that would not be allowed otherwise.

Skylights

Skylights are used for admitting daylight from above, so it can either be passive that simply allows daylight into the room through openings in the roof or active which has a reflective system within the skylight that tracks the sun movement and redirects the light down through a light well. Selection of the above devices can be decided depending on the desired indoor conditions and occupants’ expectation.

U-values

U-values are used to measure effectiveness of building’s fabric as insulators. The better (i.e. lower) the U-value of a building fabric, the less energy is required to maintain comfortable conditions inside the building. As the awareness towards the shortcomings of energy has increased, energy saving in the built environment has become a progressive concern since then. Therefore the following design aspects could be taken into consideration to achieve a desired U-value:∙ Use of insulation materials∙ Using building elements such as cavity walls

and double glazing ∙ Overall make up of a building’s fabric (for

example, reducing the proportion of glazing)

Integrated Façades

An integrated façade serves as a mediator between the exterior environment and designed interior spaces.

The constraints involved in designing integrated facades are:∙ Energy efficient glass are generally more

expensive than the regular glass material used.

Office building off BKC , Mumbai – use of high performance coloured reflective glass façade with ‘ aluminium screen ‘

sun cutter in south and south west creates the design with performance

l 28 WFM Anniversary Edition l

∙ With the tangible benefits of high performance glasses, clients tend to overlook the extra costs as life cycle costs.

∙ Usage of traditional methods like building blocks and mud walls has its own pros and cons. Being a suited material for its insulating properties, due to poor applicators there could be chances of leakages.

∙ Selection of less efficient HVAC technologies due to lack of comparative analysis, higher initial cost and space constraints.

∙ Solar energy is trending but comes with the following constraints:o Space consumption is higher than the

power generation.o Life span being 7-10 years, owners may

have to replace the panels often, which may not seem practical.

o This makes it difficult or less feasible to incorporate solar panels in large scale commercial or residential projects.

o With time the efficiency of the solar panels reduces, thus adding energy load on the building.

Mixed Use, Udaipur – fusion of local architectural vocabulary inspired elements with modern façade technology

Residential Project, Ranchi: design strategy of using terraces as sun breaker and add aesthetics and utility

Conclusion

Façades, being interface between interior and exterior of a building, can do multiple things for creating an energy efficient building. The Building façade has played a very vital role right from historical times to the modern times for daylighting and energy conservation. We are fortunate to have a rich architectural history as our platform and exposure to modern technology and material for construction of façade and fenestration systems. I think we have to acknowledge and get inspired from the master pieces like Jaisalmer fort which were created 300 years ago with very little modern technology at their disposal.

The use of simulation technology and western worlds advanced façade and fenestration systems along with specialized hardware and sections can help the designers in India to create energy efficient buildings which have desired daylighting. The need of the hour is use of modern technology and customizing it to our local conditions.

Over million VEKA Windows and Doors fitted around the world is a strong testament to VEKA’s unrivaled leadership in design and manufacture of uPVC Profile Systems.

100

l 30 WFM Anniversary Edition l

Integrated Façades for Energy Conservation and Daylighting

About the Authors:Gurleen Kaur, Designer, HKS - India, attained her masters in Sustainable Building Technology from University of Nottingham, UK. Her goal is to broaden her expertise in the � eld of sustainable technology in future.

Sakshi Jindal, Designer, HKS - India, is a sustainable champion, a LEED Green Associate and an IGBC Accredited Professional. She has worked with dbHMS Consultants pvt ltd. in the past as an intern.

HKS is a worldwide network of professionals, strategically located and working seamlessly as one � rm with individual expertise in design, research and management. A design � rm leader, HKS operates from 25 worldwide of� ces, with India of� ce operating out of Gurgaon. Since its founding in 1939, the � rm has completed construction projects totalling more than $77 billion in over 1,648 cities in 84 foreign countries.

Gurleen Kaur & Sakshi Jindal, Designers, HKS - India.

Tech Talk

‘Integrative’ is the most popular word of this era on a sustainable platform. Be it in any process, function, application, etc., everything is said to be integrative. Owed on a large scale to the construction industry, this is currently a necessity. The participation of people from various sectors is mounting and the approach has to be integrative – a proper collaboration and coordination of all. Even when talking about the façade, it has to be an integrative approach to design, as the façade envelops the building and all of its functions (Figure 1). The façade is a major contributor toward the

l 32 WFM Anniversary Edition l

overall energy consumption, daylight and well-being of the occupant.

The building is not just an envelope to protect us from the natural occurrences but a filter that will enhance what is desired and reduce what is unwanted. The initial conceptual design phase should be where the designer infuses the climatic characteristics of the region and then proceeds toward invention. Hence, climate is indisputably the most significant aspect in designing a structure. The building envelope, which was conceived to be a barrier first, has its definition reassessed to now be called an energy mediator. This calls for designers to make an energy-conscious design, which will sustain the functioning of the building inside, in accordance with the natural factors outside. To be economically feasible, it is imperative to integrate cooling and heating systems in the building envelope.

The potential for daylighting has been recognized as an energy-efficient design strategy for buildings, which can effectively diminish the supplementary cooling loads and electricity demand. Although this can be achieved by provision of flexible façade designs, dynamic façade mechanisms with one or more shading devices are growing in today’s age. Moreover, this ideology is not restricted solely to the

Fig.1: Integrative approach

Double-skin façade

MANAGER/ENHANCE

HUMAN COMFORT

MinimizeMaximize

soil washing

bioremediation

phytoremediation

native flora

CO2 scrubbing concrete

building orientation

wind tower

sheerwind turbine

cross ventilation

stack ventilation

trombe wall

ventilated concrete slab

thermal energy storage

water wall

roof pond

earthen berm

night puge

solar panels

flexible pv film

photovolatic glazing

expansive roof

dynamic shading

vegetative shading

water bodies/features

constructed wetlands

air well

fog fence

MinimizeMaximize

Conditioned Space

Landscape Design

Habitat reconstruction

MICROCLIMATE

WIND

THERMAL

SOLAR

WATER

Thermal mass

Rain water collection

Condensation collection

Pollution Reduction

Solar Energy

Daylighting Control

Water Retension

Wind

Event Potential

Comfort Hours

Impervious Surface

Wind Capture

Solar Capture

Water Capture

Revenue

HOMEOSTASIS

l Anniversary Edition WFM 33 l

materials (PCM). They rely on the method of absorbing and releasing the heat when the material changes its state. This technique paves the way for futuristic architectural opportunities, as they can be integrated in façades and wall panels for new, as well as existing, construction. These are usually coupled with ventilated façades. The efficacy

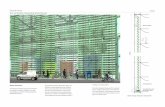

Fig.2: Capital One Bank Headquarters: Tysons Corner, VA, Annual Daylight Useful Illuminance Diagram

design of façades. With current development, it also depends upon the shading effect due to neighbouring buildings (Figure 2)

Brise soleil is a simple, yet effective, concept integrated on façades and fenestrations. Its major role is to deflect sunlight, thus reducing heat gain. This concept involves use of numerous sun-shading devices, placed at an angle, to deflect the direct sun rays.

Unglazed transpired solar façade is another type of façade design that acts as a heating system without storing excessive heat in the wall. This type of design eradicates the use of glazing on façades, and along with being cost-effective, it is also very suitable for retrofitting.

Breathing membranes, or more technically called a double-skin façade, is a solution pertaining to passive ventilation in buildings. The well-known stack effect can also be linked to this

type of façade. This double skin façade is an answer to the building that fails to harness the natural wind through simple fenestration layouts on vertical surfaces of the building.

In improving the thermal performance of the building, there is another very interesting and important phenomenon known as phase change

Regulation on the transfer of heat and daylight from outdoors to indoors

Annual Useful Daylight Illuminance (UDI) Diagram Main Lobby

3’ Extruded Louvers at 3’ Intervals Average UDI: 47%

VRE1-46

VUE1-30Solarban 72

N

l 34 WFM Anniversary Edition l

Fig.4: Transfer of heat and daylight from outdoors to indoors

of these façades is directly proportional to the energy storage and energy release, which, in turn, is linked to the climate.

In terms of materials, lightweight concrete walls are lighter and comparatively faster to construct. Autoclaved aerated concrete block is one such example. These are thermally insulating materials and due to their quick installation, are widely used in high-rise structures.

With the help of the tools we have, we can make this process less tedious and more integrative and accurate. Architects and engineers can monitor the overall performance of the building from the design phase and can monitor any required change with parametric modelling. Modelling and coordinating a project at an early stage for its efficient working and comfortable indoor environment holds true, as per

popular saying of “better safe than sorry.”

“Dynamism” is another word that’s being recited on the larger platform as being responsive to nature. This is a façades that changes its colour, orientation of fins and behaviours of opening as per the requirement of the indoors in reaction to outdoor sun, wind, air quality, etc. – like the skin of a living

being that protects all of the internal organs from the foreign contamination and transfers only what a body needs. Dynamism and intelligent integration of computation, design and engineering can bring us closer to having such an efficient façade (Figure 3). Every organism’s outer shell behaves in a required way to keep that organism comfortable in that environment. Following the similar principle on the outer shell of buildings is popularly known as biomimicry.

Regulation on the transfer of heat and daylight from outdoors to indoors for achieving energy efficiency is important (Figure 4). Together with this, the way the envelope effects the outdoors is also very important. Knowingly or unknowingly, buildings contribute toward the heat-island effect with changes to the microclimate of that region, which, in turn, can increase the demand of energy inside a building.

Baseline Insolation Analysis Impact of Fritted Vertical Fins on SHG

Fig.3: Capital One Bank Headquarters: Tysons Corner, VA

Gradient Frit Pattern Generated from solar studies

Slidefix®

Fixscreen®

Discover how to match esthetics with functionality. With its zip blinds,

RENSON has developed the firast external motorized sun screen in

the world that was truly wind-tight.

• Solar heat rejection up to 90 %

• Considerable reduction in air-conditioning cost & requirements

• 100 % retractable, motorized, BMS controlled

• Wind-tight up to 130 km/h thanks to ingenious zip system

• For glass surfaces up to 22 m² (width up to 6 m and height up to 6 m)

• No glare inside, no disturbing reflection in television or computer screens

• Insect-proof in closed position

Kendre Makarand | Area Sales Manager IndiaMob: +91 98 22 912 403 • [email protected]

www.renson.eu

Project : Private Residence (Germany)Products : External motorized sun screens Fixscreen® 150EVO & Topfix® Max

‘Beat the heat’ with RENSON sunprotection screens!

Fixscreen®

india_ENG_architect_and_interiors_225x300_0216.indd 1 24/02/16 15:17

l 36 WFM Anniversary Edition l

Optimising Façade Designs for Wind Loads

shows that Asia alone accounts for more 70 per cent of high buildings, which are above +200 m, globally.

With early involvement of façade engineering expertise, savings can be made through coordination of the structural design. Added value can be achieved with a façade design that is sympathetic to the local environment, that meets the performance parameters and maximises a developments overall value.

Advanced engineering methods should be considered when optimising the façade design for wind loads. These include

About the Author:

Adarsh Raina is one of Ramboll’s specialist façade engineers, with

over 11 years of experience in feasibility, design, analysis and

construction of building envelopes. He has worked extensively on high

value projects in the Middle East, India, Africa and Europe. Adarsh’s

commitment to realising the architectural intent with optimised

façade solutions has been instrumental to delivering successful

solutions across a broad range of projects from airports, to high rise

residential and commercial towers and hotels. He enjoys working on

projects with challenging geometry and delivers optimized solutions

using his experience and the latest modelling techniques. Adarsh is

part of Ramboll’s specialist façades team, who are located in the UK,

Italy, the Middle East and Denmark.

Adarsh Raina, Principal Engineer, Façades, Ramboll

Tech Talk

A façade typically represents 30 per cent of the total development cost. The taller and more complex the building becomes, the figures escalate. A key component of the cost is the thickness of glass, framing members and size of brackets – all which are largely dictated by the wind loads that the building is subjected to.

In today’s world, tall buildings dominate the skyline thus defining the prosperity of any modern city. Over the last two decades, the number of tall buildings over 200m in height has increased by 352 per cent (Reference CTBHU Research) and is growing. An estimate

wind tunnel testing and Computational Fluid Dynamics (CFD). The application and benefits of these methods are discussed in the context of two case studies: Port Baku Towers 2 in Azerbaijan and Mitre Square in London.

The Challenge

Wind pressure assessment is a key parameter when designing the façade. The accurate prediction of wind pressure becomes more critical while dealing with complex and high rise structures. It not only helps to mitigate wind induced damages, such as broken glass and failure of the façade

l Anniversary Edition WFM 37 l

Creechurch Place - optimising the façade design for wind loads

a façade design in terms of safety and economics. While dealing with complex and tall buildings, it is always recommended to use a scaled wind tunnel test as results have shown that the wind loads calculated based on codes can be too conservative

structure or components, but also directly correlates to the initial high capital cost of the façade.

Accurate prediction of wind pressures are essential at an early stage of a development to ensure the feasibility of

compared to wind tunnel tests and potentially lead to higher façade costs.

In case of tall and complex buildings, CFD wind simulations should be considered in the earlier stages to assess the risk associated with the desired architectural intent. It provides façade engineers sufficient information to calculate the façade system structure based on localised pressures rather than the overall pressure.

The movements and deformations that need to be considered while designing the façade include differential column shortening, lateral story drift, building racking, slab and beam edge deflections and building vibrations.

Strong collaboration between the façade engineer and the structural engineer becomes a priority to ensure the façade performs as intended. A lack of coordination can have significant impact; failure modes may include panel fallout, connection failure, excessive rotation of glass within the framing, and irregular joints.

To accommodate high inter-story drift due to high wind and seismic loads, customisation of the façade system may be required in some cases with wider vertical joints and stiffer profiles. These considerations are explored further in the case studies that follow.

l 38 WFM Anniversary Edition l

Case Study 1

Port Baku Tower 2

model of the development. Pressures were determined for each façade elevation. The results were quite challenging

The original development comprised of 2 towers (240m and 100m), a 4 storey podium with shopping facilities and multi storey underground car park. The complex façade geometry mainly comprises of a curved unitised curtain wall along the south face resulting in a spectacular skylight over the main entrance area. In all there were 12 different façade typologies that where defined and designed accordingly.

Considering the complex geometry, there were initial challenges involved in determining the wind loads for the façade elements. This was resolved by conducting wind tunnel testing on a scaled

Fig.1: Port Baku Tower 2

as wind pressures were shown to be in excess of 4.0 kPa at podium levels and up to -7.5 kPa for the main tower areas. These high magnitude wind pressures resulted in bespoke design of façade system elements. A unitised façade system was developed to overcome problems associated with the installation of a stick system and reduce on-site installation time. Coordination at an early stage with the structural consultant resulted in an agreement on the allowable building movements, deflection and structural tolerances. Slab edge deflections for the structure where limited to 1.5mm/1m length for dead load to reduce

l 40 WFM Anniversary Edition l

any potential racking façade panel units. The vertical and horizontal joint widths of the units as well as restraints were designed to accommodate all the building movements and prevent any potential rotation of panels. The designed joints between the units were also assessed taking into consideration the worst case scenario to accommodate the movement resulting from the inter-storey drift, considering the limit of H/300 to the peak high magnitude wind load/Seismic loads.

Challenges also involved designing unique façade brackets due to the complex geometry and high wind loads. The special bracket was designed to safely transfer the loads back to the main structure without compromising the structural integrity of the façade system.

Fig.4: Rotation of units due to slab edge deflection with and without horizontal restraints and horizontal racking.

Project: Port Baku Tower 2Location: Baku, AzerbaijanArchitect: Chapman Taylor ArchitectsFaçade Types: Curved Unitised FaçadeSolid Rainscreen CladdingLouvered Façade Storefront Façade Podium Terrace Standing Seam Roofing SystemSkylight Status: Re-design

QUICK FACTS

Fig.2: Wind Tunnel test model (above) Test Results (below)

Fig.3: Generic Façade Details

Notes:1. All values presented are in kPa2. All pressures stated are working pressures and need to be

applied in conjuction with the appropriate code-compliant wind loading combination factors.

3. For architectural features of the proposed development, where both sides of surfaces are exposed to the wind such as parapets, canopies and roofs, cladding pressure are assessed as peak differential pressures (resulting net wind force. All other areas are assessed as peak net pressures, which incorporated internal pressures

4. Geometries presented in red indicates the louvers on the proposed development

5. Geometries presented are in Full scale measurements in units of mm

Peak Net & Differential Facades/Cladding Negative Pressures

l 42 WFM Anniversary Edition l

which comprised of air intake through the transom joint and of air outlet staggered through perforated parts in the mullions creating hidden vents. This design allowed for a reduction in external pressures by ventilation (pressure equalised system) and significantly reducing potential water ingress.

Even though every unit has been fitted with an operable full height window, the air leakage could be reduced to a very low ratio, way below the usual requirements. This could be achieved using standard window components comprising triple gaskets with multi-lock ironmongery in combination with the external laminated glass which

reduced the stress on the inner construction.

Early involvement of specialised high rise façade engineering can not only significantly reduce the overall façade investment, through identifying the need for and carrying out methods such as wind tunnel testing and / or Computational Fluid Dynamics (CFD), but can also deliver considerable benefits in terms of performance and appearance. Ultimately leading to a conducive environment for its occupants and adding value to the overall scheme.

Creechurch Place

CFD model for Wind Pressure Assessment

Results of CFD analysis for Wind Pressure Assessment

Project: Creechurch Place Location: London, UKArchitect: Sheppard Robson ArchitectsFaçade Types: Unitised Façade, double Skin with Vertical Fins Long Span Double Height Glazing Louvered Façade Link Bridge Structurally Bonded Double Glazing Status: under Construction

QUICK FACTS

Creechurch Place is a 96 m tall office building. The façade mainly comprises of double skin curtain wall, which incorporates automated blind system within the cavity and inner operable leaf for cleaning and maintenance access. There were 15 different façade typologies which have been defined and designed accordingly. CFD analysis has been used by the façade engineering team to determine initial cladding loads and enable more detailed pressure maps to the established elevations compared to code calculations. The units have been designed by means of temperature analysis in the ventilated cavity,

Case Study 2

Creechurch Place

l 44 WFM Anniversary Edition l

“Our Customer’s Faith is Our Strength”

Mario Schmidt, Director, Lingel Windows and Doors

Technologies Pvt. Ltd.

Industry Speaks

India has taken a leap in fenestration product technology. Use of alternate materials such as UPVC and aluminium instead of traditional wood not only furthers green initiatives but reduces costs in the long run. Lingel, a German based veteran and one of the leading manufacturers of high quality doors and windows in Europe, entered Indian market in the year 2006 with Mario Schmidt at its helm. With a meagre workforce and little experience of the nascent Indian market, it wasn’t a cakewalk for the company and Mario to reach where they are now. Mario Schmidt, Director, Lingel Windows and Doors, shares the details of his

journey of 10 years in the Indian sub-continent, growth of his company and the industry, their newly launched product and his company’s future plans with WFM.

WFM: Please give us a brief background of your group and your products?

Mario Schmidt (MS): Lingel is a family owned company. We started our operation in Germany in 1959. We came to India exactly 10 years ago, in April 2006, with our UPVC window products. Recently we have introduced a new set of products: our high-end Aluminium windows and doors.

In Germany, we launched the best and a very wide range of products including various types of windows and doors, window and door accessories like insect nets, hardware, and roller shutters. Our product list includes types of glass including laminated glass, tempered glass, insulated glass, bent glass, sound control glass, burglar resistant glass, and more. We had also introduced all kinds of façades and other possible items related to façades and fenestration in the German Market. We found that these products were very well adopted and had great demand in German market. Hence

Great Lakes Institute, Chennai by Pradeep & Varsha Verma Architect

l Anniversary Edition WFM 45 l

decided to bring them to India. That’s how we launched the high-end Aluminium doors and windows in Indian market. Moreover, when we launched our product here, there were already three or four brands who had come up with similar products in the market.

WFM: How did you foray in to this industry?

MS: After completing my education, I was in search of fortune. A new factory manufacturing windows came up in my n eighbourhood, in my home town Saxony, Germany. This was in 1994 and I just had completed my education in mechanical sciences. I had great interest in learning more about manufacturing of windows and various aspects associated with it. I started working in this factory. That is how my association with window industry started.

In 2005, Lingel was searching for experts to start their uPVC Window business in India and I joined the company. I came to India in 2006 and established the business for our company here. Now I have reached at the conclusion that the company and me are ‘made for each other’.

WFM: Now you are grown in to one of the largest players in window systems in India. How did you achieve this?

MS: I presume that we entered the Indian market at

the right time. People had no knowledge about uPVC windows and we introduced this new concept and system. For us, as a fabricator, we had the advantages of being here at the right time. Our management too provided full support to introduce our systems in India. This helped us to reinvest and work extensively. All the system providers like Veka, Kommerling, Fenesta and Rehau were just entering the market then. We expanded our market starting from Delhi and Chennai, entering Bangalore and then to most of the other cities in India. Our network is spread nationwide now. Rather than selling through dealers, our employees sell the products directly since it requires a lot of technical knowledge to explain the products and its proper installation. Hence we train our employees on the technical aspects and they deal directly with the buyer. But in smaller

cities, we are working with dealer network too.

We believe in direct selling even though we have a well-connected network of dealers all over India. We always want to be as close as possible associated with our dealers. We train our employees to be resourceful, and provide them with all the necessary training in technical aspects. For selling the product, one need to have thorough knowledge of its technical aspects. We focus on maximum satisfaction and happiness of our customer.

WFM: Please tell me about the growth of your company and the Industry.

MS: The Company and the window industry has seen the same growth curves in the past years. In 2006 it was a 600 crore industry and from there, in 2015, the industry has grown to a 1500 crore industry. That is, the growth was three and a

Residence for Kiran Reddy, Chennai; Architect: Vivendis - Sunil.

l 46 WFM Anniversary Edition l

Amara Avana, AR Foundation, Chennai

half times. Our company is also growing at the same pace.

WFM: We understand that the builders and home owners have not accepted uPVC as much as wood or Aluminium. What is the reason for this?

MS: It is not true if you consider the entire sub-continent. It may be true for Delhi or northern India. But in Bangalore and other south Indian states, uPVC is being used widely. People in states like Goa and Kerala has realized that wood is not the right product which can be used for the kind of climate in those places. In places like Chennai, people have adopted uPVC in a big way. In high-end houses, instead of wood, people have started using wood finish uPVC windows. From a distance 10 feet no one can make out whether it is a wooden window or wood-finish uPVC window.

WFM: Tell us about uPVC and Aluminium in India and about your sales too?

MS: uPVC windows were introduced in India just 12 years back. In February 2016, uPVC Window and Door Manufacturers Association (UWDMA) introduced guideline for uPVC windows. uPVC window fabrication and installation need to be done carefully. Many inferior quality products are being sold in the market and lack of knowledge in fabrication and installation of uPVC window has given a

disrepute to the industry many a times. Though it is a greener and stronger material than aluminium, it is not accepted as much. Steel Reinforced uPVC profiles are strong because of the steel, but will not rust like steel.

In India, the sector is much unorganized. Aluminium systems can be manufactured locally, and they may not be following any specific standard or guideline for quality. These small scale window manufacturers sell their products at a cheaper rate and the quality of their products are very low. Many architects and contractors purchased windows from local vendors. But in the case of uPVC windows, the brands manufacture them in factories, following certain quality checks. Because of the above said reasons, branded uPVC windows available in the market are reliable.

Aluminium products can be of high quality with good system

engineering. Such products cost much more than locally available products. Now the concerned organizations and companies should come forward and spread knowledge on System Aluminium and its benefits rather than looking at just cost of the product which is a simple aluminium system.

In unorganized sector, no one gives guarantee or warranty to the products, neither assures quality. But when you are buying system aluminium from USA, Germany, UK or from India, all the features like window measurements, quality of components and standards are very well specified. The drawings of profile sections also explains the measurements. When you buy such products, it gives a guarantee that the system is tested and it is compiled to some standards with proper guidelines. System Aluminium Windows are new entry in the market and we want to take this opportunity to present the

l 48 WFM Anniversary Edition l

Aashish Foundation, Chennai; Architect- Natraj & Venkat

product to the clients and end users in the right way. We do not want to repeat the mistake happened in uPVC sector, by allowing low quality product from local fabricators infesting the market and finally losing faith on the product itself. The challenge is to train the fabricators to understand the technicality of the system Aluminium products and installing systems properly.

10 years ago uPVC was a new concept. Still it is in nascent stage. We still advise that uPVC is the best system for India because of its insulation properties, which helps preventing heat and noise inside.

WFM: Please tell us about your company’s strengths? How do you compete with the local vendors who supply cheaper products?

MS: Local vendors are definitely a challenge, but we get a mileage in giving proper information and support to our

customers. We promise service up to 10 years after installing our products. These kind of long term services are not provided by local vendors. This helps to build faith and that is our strength. Because of this, all our customers come back to us and we are getting repeated customers all over the country.

WFM: Please tell us about your diverse product portfolio? Are your systems designed in-house?

MS: In the past 10 years we have progressed a lot in in-house designing and manufacturing Systems, especially the hardware. Initially the products were designed and manufactured in Germany, which was not suitable for the harsh Indian climate. And this had an impact on the product’s cost also. Moreover, the products had the tendency to rust when used in coastal areas. So we started designing and manufacturing systems

in India which are suitable for the conditions here. Started manufacturing our own series in which all the hardware are made of steel SS 304 and SS 316 for coastal areas since it is rust free. At times, as and when there is a necessity, we put together or combine our various systems so that it provides the best benefit for the customer. They can make advantage out of all our products and experience the best of our engineering. The customer gets the best of windows made of best profiles and hardware. The components are fabricated in the right way.

WFM: What are the major special features of your products? And how is your product unique compared to other products available in the market?

MS: Whatever the customer is looking for in windows, we have a solution for the same. We are the only one uPVC fabrication company manufacturing 90 degree corner opening sliding doors.

Further, we provide1. Wonderful security rid

solutions 2. A great range in double

shutter windows and doors3. Unique dust and noise

reduction solutions to our customer.

4. In-built air purifiers affixed to our windows

We always try to be one step ahead of others in product

l Anniversary Edition WFM 49 l

Amara Akasha - AR Foundation, Chennai

designs, innovation and technologies. Our research and development of products are exceptionally good.

WFM: How do you assure quality check and quality control?

MS: We follow ISO 2008 9001 quality assurance in our products. For us, the quality is customer satisfaction at any point of time.

WFM: Who are your major customers?

MS: We had, in the last financial year, 1500 individual customers. Most of our projects are villas and bungalows and houses for independent customers. We are not focusing on developer market but on retail.

We do work for few developers, like Puri Construction in Delhi, AR foundation in Chennai and GINA Engineering in Bangalore, etc. – all of them are our long-time associates. We work with developers who accepts quality products and that is our policy.

WFM: Please tell us about your manufacturing capacity of your facility?

MS: Our fabrication facility in Bhiwadi in Rajasthan. It is centrally located and helps us to ensure the quality of our products and this is one of the biggest facility and have huge capacity. In the last financial year