West Texas Gas Distribution Pipeline IMP 2012 6-22-12

-

Upload

shriram-avasarkar -

Category

Documents

-

view

214 -

download

0

Transcript of West Texas Gas Distribution Pipeline IMP 2012 6-22-12

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

1/45

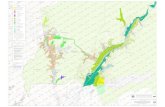

West Texas GasGas Distribution Pipeline Integrity Management

P

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

2/45

P

WEST TEXAS GAS

GAS DISTRIBUTION PIPELINE INTEGRITY MANAGEMENT PROGRAM

TABLE OF CONTENTS

1-SECTION 1-REVISION LOG ................................................................................................................... 4

2-SECTION 2-INTRODUCTION .................................................................................................................. 5

2.1. The Federal Integrity Management Rule ..................................................................................... 5

2.2. Pipelines Operated by West Texas Gas ...................................................................................... 5

2.3. Terms as Used In the IMP ........................................................................................................... 5

3-SECTION 3-WEST TEXAS GASDISTRIBUTION PIPELINE INTEGRITY MANAGEMENT PROGRAM................... 6

3.1. Overview of West Texas Gas Program ....................................................................................... 6

4-SECTION 4-KNOWLEDGE ..................................................................................................................... 7

4.1. Regulation ................................................................................................................................... 7

4.2. System Knowledge ...................................................................................................................... 7

4.3. Updates ....................................................................................................................................... 7

4.4. DOT Annual Report ..................................................................................................................... 8

4.5. Annual Review............................................................................................................................. 8

5-SECTION 5-THREAT IDENTIFICATION PLAN ............................................................................................ 9

5.1. Regulation ................................................................................................................................... 9

5.2. Threat Factors ............................................................................................................................. 9

5.3. Threat Factor Information ............................................................................................................ 9

5.4. Threat Identification by System ................................................................................................... 9

6-SECTION 6-RISKANALYSIS PROCESS AND RISK FACTORS................................................................... 10

6.1. Regulation ................................................................................................................................. 10

6.2. Process ..................................................................................................................................... 10

6.3. Risk Determination .................................................................................................................... 12

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

3/45

9.3. Improvements ............................................................................................................................ 23

9.4. Metrics Review .......................................................................................................................... 24

9.5. Communication of Results ......................................................................................................... 24

10-SECTION 10-RESULTS REPORTING .................................................................................................. 25

10.1. Regulation ............................................................................................................................... 25

10.2. Review Process for Plan Effectiveness ................................................................................... 25

10.3. Performance Measures Submittal to PHMSA and appropriate State Regulatory Agency ....... 25

11-SECTION 11-COMMUNICATIONS PLAN .............................................................................................. 26

11.1. External Communications ........................................................................................................ 26

11.2. Safety Concerns ...................................................................................................................... 2611.3. Internal Communications ......................................................................................................... 26

11.4. External Communications ........................................................................................................ 26

12-APPENDIXA-PIPELINE INFORMATION................................................................................................ 27

13-APPENDIX B-SUMMARY AND RISKANALYSES.................................................................................... 28

14-APPENDIX C-INFORMATION GATHERING FORM................................................................................. 29

15-APPENDIX D-PERFORMANCE METRIC INFORMATION GATHERING FORM.............................................. 30

16-APPENDIX E-EVALUATION OFA/AACTIONS ...................................................................................... 35

17-APPENDIX F-STEEL SERVICE LINE REPLACEMENT............................................................................ 41

18-APPENDIX G-MAINLINE STEEL REPLACEMENT.................................................................................. 43

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

4/45

WEST TEXASGAS

GAS DISTRIBUTION PIPELINE INTEGRITY MANAGEMENT PROGRAM

1 - Section 1 - Revision Log

REVISIONNUMBER

REVISIONDATE

REVISION SUMMARY

0 July 14, 2011 New Gas Distribution Pipeline Integrity Management Program

1 June 22, 2012 Minor revisions to 4.3 Updates, 6.2.1.1 Records Retention, 9.4 Metrics Reviewand Appendix EEvaluation of A/A Actions

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

5/45

2 - Section 2 - Introduction

2.1. The Federal Integrity Management Rule

The Department of Transportation/Pipeline and Hazardous Materials Safety Administration(DOT/PHMSA) issued a new Subpart P to 192 titled Gas Distribution Pipeline Integrity Management(DIMP) on December 4, 2009. The latest amended version of Subpart P was issued on February 1, 2011.

The Rule specifies regulations for identifying threats, evaluating risk, implementing measures to addressrisk, measure performance, monitor results, and evaluate effectiveness.

Operators are required to develop and implement a gas distribution integrity management plan no later

than August 2, 2011.

2.2. Pipelines Operated by West Texas Gas

West Texas Gas (WTG) operates approximately 485 gas distribution systems in Texas and Oklahomatotaling over 5000 miles. The systems consist of steel and plastic (ABS, PVC, and PE) and range in sizefrom less than 2 to 22.

2.3. Terms as Used In the IMP

Terms as used in West Texas GasIntegrity Management Program, e.g. Hazardous Leak, are as definedor described in 192, the Texas Administrative Code, and the West Texas Gas Operations andMaintenance Manual.

The Integrity Management Department consists of the Director of Integrity Management and the PipelineIntegrity Specialist.

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

6/45

3 - Section 3 - West Texas GasDistribution Pipeline Integrity Management Program

3.1. Overview of West Texas GasProgram

WTG is preparing its Program based on the requirements described in Subpart P. As such, it contains thefollowing sections:

Distribution

Integrity

Management

Program Elements

Periodic Evaluationand Improvement

Section 9

Results Reporting

Section 10

Communications

Knowledge

Section 4

Threat Identification

Plan

Section 5

Additional andAccelerated Actions

Section 7

Performance Plan

Section 8

Risk Analysis

Process and Risk

Factors

Section 6

Task

Knowledge

Task

Additional or

Accelerated Actions

Task

Administration

Appendix A

Pipeline

Information

Appendix B

Summary and Risk

Analyses

Appendix DPerformance Metric

Information

Gathering FormAppendix E

Evaluation of A/A

Actions

Appendix C

InformationGathering Form

Revision Log

Section 1

Appendix F

Steel Service Line

Replacement

Appendix G

Mainline Steel

Replacement

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

7/45

4 - Section 4 - Knowledge

4.1. Regulation

49 CFR 192.1007(a)

(a) Knowledge. An operator must demonstrate an understanding of its gas distribution system

developed from reasonably available information.

1) Identify the characteristics of the pipeline's design and operations and the environmental

factors that are necessary to assess the applicable threats and risks to its gas distribution

pipeline.

2) Consider the information gained from past design, operations, and maintenance.

3) Identify additional information needed and provide a plan for gaining that information overtime through normal activities conducted on the pipeline (for example, design, construction,

operations or maintenance activities).

4) Develop and implement a process by which the IM program will be reviewed periodically and

refined and improved as needed.

5) Provide for the capture and retention of data on any new pipeline installed. The data must

include, at a minimum, the location where the new pipeline is installed and the material of

which it is constructed.

4.2. System Knowledge

Knowledge of a distribution system can be defined as information, such as the materials and type ofconstruction, the operating conditions of the pipe or facility, and other relevant factors within thesurroundings in which the system operates. This knowledge of the system will help identify the threats tothe system and establish which systems or segments should be subject to a risk evaluation.

4.2.1. Data Gathering

In order to develop an accurate risk assessment of each system, WTG collects data from the followingtypes of sources:

1. Paper records.

2 Electronic records

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

8/45

1. Location.

2. Pipe type.

3. Pipe size.

Data discovered in the field may become part of a leak report or other maintenance work order. In thiscase, notification shall be made to the Integrity Management Department of the additional systemknowledge. Field personnel should carefully complete the necessary forms and documentation for thework being performed. Updates to system knowledge may be made from the collected data.

Each time a pipeline is exposed, WTG Form 1100 should be filled out to document the condition of thepipe. A check box is included in this form to verify if the DIMP data currently being used is correct. If theDIMP data is incorrect, the form will be sent to the Integrity Management Department with the corrected

data in order to update the DIMP risk model and associated databases.

Each time a new pipe line is installed, the Project Report Form WTG-1400 will be filled out to documentpipe material, size, manufacturer, year manufactured, grade, material designation code, pipe category,wall thickness and test pressure. WTG-1400 along with shape files showing the exact location will besubmitted to the Integrity Management Department for processing and installation into GIS mapping.

4.4. DOT Annual Report

PHMSA Form 7100.1-1, Gas Distribution System Annual Report, contains the basis of WTGs systemknowledge. Form 7100.1-1 is also a source of historical system information. Before data from the annualreport is used as system knowledge, it must be verified as current and accurate by the IntegrityManagement Department.

PHMSA Form 7100.1-1 may also be used as a source of information for past design, operations andmaintenance decisions. The Integrity Management Department shall review historical filings for trendsrelating to segment risk and incorporate this information into the body of system knowledge.

4.5. Annual Review

At least once per calendar year, at intervals not to exceed 15 months, the Integrity ManagementDepartment shall review this program for consistency with 49 CFR 192 Subpart P and for necessaryupdates to system and threat information. The program review shall be documented and retainedaccording to 49 CFR 192 1011 The annual program review shall include interviews with field personnel

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

9/45

5 - Section 5 - Threat Identification Plan

5.1. Regulation

49 CFR 192.1007(b)

(b) Identify threats. The operator must consider the following categories of threats to each gasdistribution pipeline: corrosion, natural forces, excavation damage, other outside force damage,material or welds, equipment failure, incorrect operations, and other concerns that could threatenthe integrity of its pipeline. An operator must consider reasonably available information to identifyexisting and potential threats. Sources of data may include, but are not limited to, incident andleak history, corrosion control records, continuing surveillance records, patrolling records,maintenance history, and excavation damage experience.

5.2. Threat Factors

Threat factors used in the Risk Analysis are listed inSection 6.6.

5.3. Threat Factor Information

The specific threat factor information used in the Threat Identification process is located inAppendix A.

The Integrity Management Department reviews and updates this information annually perSection 6.2.5.

If sufficient information is unavailable or is considered unreliable by the Integrity Management Departmentfor a particular threat factor, the Integrity Management Department with assistance from the SME of thatspecific discipline will either identify that particular threat factor as unknown which scores at the highestpossible value or make a conservative, but realistic, estimate for that information element. The IntegrityManagement Department will document the use of all estimated information elements in the Risk Analysisfor that particular segment.

For potential for frost action and corrosive properties of soil data, WTG utilizes information published onthe USDAs National Resources Conservation Services website.

Earthquake faults and acceleration data is obtained from the USGS.

5.4. Threat Identification by System

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

10/45

6 - Section 6 - Risk Analysis Process and Risk Factors

6.1. Regulation

49 CFR 192.1007(c)

(c) Evaluate and rank risk.An operator must evaluate the risks associated with its distributionpipeline. In this evaluation, the operator must determine the relative importance of each threatand estimate and rank the risks posed to its pipeline. This evaluation must consider eachapplicable current and potential threat, the likelihood of failure associated with each threat, andthe potential consequences of such a failure. An operator may subdivide its pipeline into regionswith similar characteristics (e.g., contiguous areas within a distribution pipeline consisting of

mains, services and other appurtenances; areas with common materials or environmentalfactors), and for which similar actions likely would be effective in reducing risk.

6.2. Process

This Section describes the use of the relative risk model to evaluate the relative risk posed by eachSystem, in order to determine the highest priority pipeline segments for use in the Additional and

Accelerated Actions evaluation. Risk is defined as the: Likelihood of Failure times the Consequences ofFailure.

6.2.1. Information Sources

The Integrity Management Department utilized sources such as leak history, corrosion records,continuing surveillance records, patrolling records, maintenance history, excavation damage experience,and SME knowledge for initial gathering of threat and consequence related information. The currentinformation is found inAppendix Aand is updated annually perSection 6.2.5.

6.2.1.1. Records Retention

All WTG records that pertain to DIMP will be maintained as required by 192 and the West Texas Gas

O&M Manual. In addition, all DIMP related records must be maintained for at least ten years even if 192or the West Texas Gas O&M Manual requires less. This will include any superseded revision to this plan.The Integrity Management Department will be contacted prior to the purging process of all DIMP relatedrecords.

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

11/45

6.2.3. Threat Severity Index

Each Threat category has numerous factors with which to evaluate the particular pipeline/seg ments

threat level. The factors are evaluated using a scoring system1and the ratings are then summed for eachcategory to arrive at a raw Threat number. This raw number is normalized by dividing the sum of thethreat scores by the maximum possible threat scores. This number is called the Threat Severity Index.The Threat Severity Index is established based on guidance found in Criteria and Risk Assessmentsections of ASME B31.8S-2010 Appendix A.

6.2.4. Significant Threats

If the Threat Severity Index is > 67%, that particular threat is deemed to be a Significant Threat and A/A

actions will be considered for that segment.

The Threat Severity Index (TSI) is calculated with the following formula.

TSI = [total risk score points from risk model minus number of risk factors]/[4*number of risk factors]

This methodology is explained as follows.

1. Each threat factor can be scored with a range from a minimum value of 1 to a maximum value of5. Consequently, there is a scoring range of 4 for each threat factor.

2. Each threat factor is scored appropriately and the individual threat factor scores are summed todetermine the total threat score.

3. Similarly for each threat, e.g. corrosion, the maximum number of points that can possibly bescored is 4 (range from 1 to 5) times the number of threat factors.

4. For example, if there are fourteen threats in a threat category and total points scored for thatthreat is 52, the TSI is 68% by the following calculation; [52-14]/[4*14].

6.2.5. Threat Weighting

The threat sum score is then divided by the number of criteria in each Threat category. This normalizednumber is then multiplied by a rating factor for that particular Threat. This yields a series of weightedThreat category numbers that are summed to determine the Likelihood of Failure for a particular System.Systems with multiple pipe material types, sizes, or other factors are ranked by their individual Segmentsand then averaged to get a System total

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

12/45

2011 THREAT WEIGHTING

THREATTHREAT WEIGHTING FOR STEEL

SYSTEMSTHREAT WEIGHTING FOR NON-

METALLIC SYSTEMS

Natural Forces 10% 15%

Excavation Damage 25% 30%

Other Outside Forces 20% 25%

Material or Weld 10% 15%

Equipment 6% 6%

Incorrect Operations 6% 6%

Other 3% 3%

6.2.6. Consequence of Failure

Consequence of Failure is a function of the severity of a release. In this case, ten factors found in theConsequences section of the Risk Analysis are evaluated to determine the consequence of a releasefrom any West Texas Gas distribution segment.

6.3. Risk Determination

The Risk for each Covered Segment is determined by multiplying the Likelihood of Failure by theConsequences of Failure. These numbers for each segment are found inAppendix B.

6.4. Regions

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

13/45

4. Detailed knowledge of the WTG DIMP Program.

5. Thorough knowledge of the principles of risk management.

6. Detailed knowledge of the WTG risk model and ability to interpret results produced by the model.7. Ability to communicate results shown by the risk model to other WTG personnel including

management.

6.6. Pipeline Threats with Associated Threat Factors

CORROSION

Coating

Liquids on the system

Number of Mainline CP readings not within spec

Percentage of Grade 1 Corrosion Leaks

Percentage of Grade 2 Corrosion Leaks

Percentage of Grade 3 Corrosion Leaks

Corrosion A/A Actions

NATURAL FORCES

River or Stream Crossing

Frost Heave Susceptibility

E th k F lt Z

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

14/45

Number of 3rd

Party Damage that did not result in a leak

Number of 1stParty Damage that resulted in a leak

Number of 2nd

Party Damage that resulted in a leak

Number of 3rd

Party Damage that resulted in a leak

Mapping Quality

Percentage of non-metallic system with tracer wire

Percentage of Grade 1 Excavation Damage Leaks

Percentage of Grade 2 Excavation Damage Leaks

Percentage of Grade 3 Excavation Damage Leaks

Excavation Damage A/A Actions

OTHER OUTSIDE FORCES

Number of shallow sections excluding identified patrol points

Percentage of Grade 1 Other Outside Force Leaks

Percentage of Grade 2 Other Outside Force Leaks

Percentage of Grade 3 Other Outside Force Leaks

Other Outside Force A/A Actions

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

15/45

Material or Weld A/A Actions

EQUIPMENT MALFUNCTION

PCV Failures

PRV Failures

Odorant Failures

Percentage of Grade 1 Equipment Malfunction Leaks

Percentage of Grade 2 Equipment Malfunction Leaks

Percentage of Grade 3 Equipment Malfunction Leaks

Equipment Malfunction A/A Actions

INCORRECT OPERATION

Incorrect operations or inadequate procedure failures

Percentage of Grade 1 Incorrect Operation Leaks

Percentage of Grade 2 Incorrect Operation Leaks

Percentage of Grade 3 Incorrect Operation Leaks

Incorrect Operation A/A Actions

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

16/45

6.7. Consequence Factors

CONSEQUENCES

Business District

Residential Area

Number of Irrigation Services

Number of City Commercial and Public Authority Services

Number of Rural Commercial and Public Authority Services

Number of Rural Domestic Services

Number of City (Municipal) Services

Significant Services Affected (facilities that would be difficult to evacuate, e.g. hospital, day care, etc.)

Home or Business Dwellings Intended for Human Occupancy

Operating Pressure

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

17/45

7 - Section 7 - Additional and Accelerated Actions

7.1. Regulation

49 CFR 192.1007(d)

(d) Identify and implement measures to address risks.Determine and implement measures designedto reduce the risks from failure of its gas distribution pipeline. These measures must include aneffective leak management program (unless all leaks are repaired when found).

7.2. Process for the Identification and Evaluation of New Measures for Line Pipe

The Integrity Management Department will evaluate each System within twelve months of completing arisk evaluation for the possible implementation of Additional and Accelerated (A/A) actions.

The Integrity Management Department will use the form inAppendix Eto facilitate the evaluation of newA/A actions.

The Integrity Management Department will review the individual Threat and Consequence scores foreach System. Within each System, the Integrity Management Department will identify each threat factorhaving the maximum score of five and each System having an individual Threat Severity Index

2score

67%.

The Integrity Management Department will then review those Systems for possible application of A/Aactions in order to reduce the individual threat factor scores and the Threat Severity Index score.

The Integrity Management Department will develop a specific A/A action plan for the system/segment thatrequires A/A actions. This plan will include A/A actions, implementation dates, responsibilities, expectedoutcome, measurement and management approval. Management approval will consist of VP, OperationsManager, District Manager and Integrity Management Department.

The following table provides examples of A/A action to be considered. WTG may implement one or moreof these examples in order to address the threats to each System. The examples given are not intended

to rule out any other reasonable action that WTG may select to reduce the risk of a System.

THREATS

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

18/45

THREATS

EXAMPLES OF POSSIBLE A/A ACTIONSPRIMARY SUBCATEGORY

Atmospheric corrosion

Coat (paint) the exposed piping.

Increase survey frequency.

Replace or rehab.

Relocate.

NATURALFORCES

Outside force/weather:(e.g., earth movement,lightning, heavyrains/floods, temperatureextremes, high winds)

Steel pipe

Plastic pipe

Cast iron pipe

Relocate pipe from high risk locations.

Replace pipe in high risk locations. Install slip or expansion joints for earth

movement.

Install strain gages on pipe.

Install automatic shut-offs.

Expand the use of excess flow valves.

Conduct leak survey after significantearthquake or other event.

EXCAVATIONDAMAGE

Third-party damage

Operator damage

Conduct enhanced awarenesseducation.

Request regulatory intervention.

Inspect targeted excavation andbackfill activities.

Inspect for facility support.

Improve accuracy of line locating.

Participate in pre-constructionmeetings with project engineers andcontractors in high-risk areas.

Use warning tape.

Expand the use of excess flow valves.

Improve system map accuracy andavailability

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

19/45

THREATS

EXAMPLES OF POSSIBLE A/A ACTIONSPRIMARY SUBCATEGORY

Vandalism

Install or improve fences/enclosures.

Increased surveillance.

Relocate hard-to-protect or criticalfacilities.

Blasting

Perform leak survey after blasting.

Relocate away from frequent blastareas (e.g., mines).

Replace with more ductile pipematerial.

MATERIAL ORWELD FAILURE

Manufacturing defects

Construction/workmanshipdefects

Mechanical damage:

o Steel pipeo Plastic pipeo Pipe components

Replace or repair.

Increase frequency of inspection andmonitoring.

Investigate if a type of joint orequipment is being used ininappropriate situations or locations.

Improve installation procedure.

Trend equipment failure.

EQUIPMENTMALFUNCTION

Malfunction of system equipment

Replace or repair.

Increase frequency of inspection andmonitoring.

Investigate if a type of joint orequipment is being used in

inappropriate situations or locations. Improve installation procedure.

Trend equipment failure.

I d

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

20/45

7.3. Leak Management Program

WTG has implemented an electronic Leak Tracking System (LTS) which stores all leak data. The LTS is

used as a scheduler for upcoming leak surveys, repairs to non-hazard leaks, and re-probes for any openleaks. The LTS also houses the data used to trend all leaks within WTG.

7.4. West Texas Gas Distribution Pipelines Located in Texas

7.4.1. Service Line Removal or Replacement (TAC 8.209)

WTG owns and operates 424 distribution systems within the state of Texas. These 424 systems have atotal of 269 TRRC system identification numbers. The following is WTGs risk -based program to meetTAC rule 8.209 for Distribution Facilities Replacement.

TAC rule 8.209 requires each operator to determine what the greatest risk to public safety is for eachsystem. The process that WTG uses to determine this risk is determined by calculating the number ofleaks for steel service lines and comparing this to the number of leaks on main lines for an equal period oftime. This information will determine if the systems greatest risk is either steel service lines or main lines.The data used for this comparison is made using the number of leaks reported by WTG on the PS95filings. The initial determination was made using data from 2009 and 2010. Going forward three years ofdata will be used. The following procedure will be followed after the above mentioned determination ismade. The initial scheduling for replacement of any facilities will begin on January 1 , 2012.

7.4.1.1. Systems that fall into the Steel Service Lines category:

Each system will have an annualized steel service line leak rate calculated using the following formula:

1. Number of below grade leaks repaired on steel service lines (excluding third party damage leaksand leaks on steel service lines that have been removed or replaced by this regulation) divided bythe number of steel service lines reported to PHMSA on form F 7100.1-1. Beginning in 2012 threeyears (3) of data will be used for this calculation, however for initial implementation only two (2)years of data is being considered.

Based on the results of the leak rate calculation, the following schedule will be used for replacement:

1. Any system with an annualized steel service line leak rate of 7.5% or greater will be consideredPriority 1 and removed or replaced by June 30 2013

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

21/45

2. Coated steel segments with document history of effective corrosion protection (exposed pipereports & pipe to soil readings).

3. Pipeline segments greater than 500 foot from a building intended for human occupancy or a well-defined outside public gathering area.

For each system/segment that meets this DIMP risk score greater than 4.99, the Integrity ManagementDepartment will develop a system specific written plan for replacement and/or removal. Specific writtenplans will not be developed for systems that require less than 100 foot of replacement and/or removal.Required replacement and/or removal footage will be completed under normal routine maintenanceactivities. The system specific written plans will be included on the annual report submitted to the TRRCon or prior to March 15th of each year.

If greater than 5% of a systems mainline footage is replaced and/or removed in a calendar year, thisexcess footage will be credited to the following years replacement schedule.

Any system with a total risk score in the DIMP risk model of less than 5.0 will not be included in themandatory replacement program.

The results of the initial data have determined that 412 WTG systems have main lines as the greatest riskto public safety. Of the 412 systems, 30 systems have a DIMP risk score greater than 4.99. Thesesystems can be found inAppendix G.

7.4.1.3. Reporting Requirements:

On or prior to March 15th of each year, WTG will develop and submit to the TRRC an annual report whichwill include the following:

1. A list of steel service lines or other distribution facilities (by system ID number) replaced duringthe prior calendar year.

2. Revisions to WTGs risk-based replacement program.

3. Proposed specific work plan (by system ID) for the current year.7.5. Mechanical Fitting Failure Regulation

49 CFR 192.1009 What must an operator report when a mechanical fitting fails?

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

22/45

8 - Section 8 - Performance Plan

8.1. Regulation

49 CFR 192.1007(e)

(e) Measure performance, monitor results, and evaluate effectiveness.

(1) Develop and monitor performance measures from an established baseline to evaluate theeffectiveness of its IM program. An operator must consider the results of its performancemonitoring in periodically re-evaluating the threats and risks. These performance measures mustinclude the following:

(i) Number of hazardous leaks either eliminated or repaired as required by 192.703(c) of this

subchapter (or total number of leaks if all leaks are repaired when found), categorized by cause;(ii) Number of excavation damages;

(iii) Number of excavation tickets (receipt of information by the underground facility operator fromthe notification center);

(iv) Total number of leaks either eliminated or repaired, categorized by cause;

(v) Number of hazardous leaks either eliminated or repaired as required by 192.703(c) (or totalnumber of leaks if all leaks are repaired when found), categorized by material; and

(vi) Any additional measures the operator determines are needed to evaluate the effectiveness of

the operator's IM program in controlling each identified threat.

8.2. Introduction

The Integrity Management Department utilizes this Performance Plan to determine if the West Texas GasDistribution program is effective in assessing and evaluating the integrity of distribution systems. ThePerformance Plan includes internal evaluation of the Programs performance, internal and external audits,and reporting of performance results.

8.3. System Specific

The Integrity Management Department will annually, by January 31 for the previous years data, collectthe following performance metrics data for each System as listed below. The form used to document thisinformation can be found inAppendix D or may utilize an alternative form to document this information.

http://www.cyberregs.com/cgi-exe/cpage.dll?pg=x&rp=/pseudo.htm&sid=2011042008215245694&aph=1&Hi=2&qy=B31%2E8S&hlc=00FF00&srchm=0&cid=rcp&uid=wbyrd&clrA=0663B2&clrV=0663B2&clrX=0663B2&ref=/indx/CFR/49CFR/CFR_49_192_-_5_P.htm&pseudo=UN1%2C%2CCFR%2CCFR_49_192_-_5_M%2Cg=5~c=703~h=~i=%2C(c)#g=5~c=703~h=~i=~(c)http://www.cyberregs.com/cgi-exe/cpage.dll?pg=x&rp=/pseudo.htm&sid=2011042008215245694&aph=1&Hi=2&qy=B31%2E8S&hlc=00FF00&srchm=0&cid=rcp&uid=wbyrd&clrA=0663B2&clrV=0663B2&clrX=0663B2&ref=/indx/CFR/49CFR/CFR_49_192_-_5_P.htm&pseudo=UN1%2C%2CCFR%2CCFR_49_192_-_5_M%2Cg=5~c=703~h=~i=%2C(c)#g=5~c=703~h=~i=~(c)http://www.cyberregs.com/cgi-exe/cpage.dll?pg=x&rp=/pseudo.htm&sid=2011042008215245694&aph=1&Hi=2&qy=B31%2E8S&hlc=00FF00&srchm=0&cid=rcp&uid=wbyrd&clrA=0663B2&clrV=0663B2&clrX=0663B2&ref=/indx/CFR/49CFR/CFR_49_192_-_5_P.htm&pseudo=UN1%2C%2CCFR%2CCFR_49_192_-_5_M%2Cg=5~c=703~h=~i=%2C(c)#g=5~c=703~h=~i=~(c)http://www.cyberregs.com/cgi-exe/cpage.dll?pg=x&rp=/pseudo.htm&sid=2011042008215245694&aph=1&Hi=2&qy=B31%2E8S&hlc=00FF00&srchm=0&cid=rcp&uid=wbyrd&clrA=0663B2&clrV=0663B2&clrX=0663B2&ref=/indx/CFR/49CFR/CFR_49_192_-_5_P.htm&pseudo=UN1%2C%2CCFR%2CCFR_49_192_-_5_M%2Cg=5~c=703~h=~i=%2C(c)#g=5~c=703~h=~i=~(c) -

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

23/45

9 - Section 9 - Periodic Evaluation and Improvement

9.1. Regulation

49 CFR 192.1007(f)

(f) Periodic Evaluation and Improvement.An operator must re-evaluate threats and risks on itsentire pipeline and consider the relevance of threats in one location to other areas. Each operatormust determine the appropriate period for conducting complete program evaluations based onthe complexity of its system and changes in factors affecting the risk of failure. An operator mustconduct a complete program re-evaluation at least every five years. The operator must considerthe results of the performance monitoring in these evaluations.

9.2. Audits

The Integrity Management Department should determine if an audit is warranted after the annual reviewof the Annual Integrity Management Report found inSection 10.2.Events that would indicate the needfor an audit include the following.

1. Failure to meet expected performance for System Specific performance measures as identified inSection 8.3.

2. Notice from PHMSA or a state regulatory agency of a pending formal inspection.

The audit may include consideration of the entire Program or only specified sections as determined by theIntegrity Management Department.

The Integrity Management Department may choose to schedule an audit at other times if circumstanceswarrant.

After determining that an audit is necessary, the Integrity Management Department should determine if aninternal or an external audit shall be performed.

9.2.1. Internal Audits

The Internal Audit team shall be composed of personnel both with and without direct responsibility for anydistribution integrity management work. This team is constituted by the Integrity Management Departmentand reports directly to that position. The audit team will forward its audit results to the IntegrityM t D t t ithi thi t d f l ti th dit

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

24/45

Improvements may also be proposed by any West Texas employee. These improvements may be theresult of exceptional performance achieved at a particular time for one or more metrics or unsatisfactoryperformance on a similar scale. The improvements will be documented in the Annual Integrity

Management Report that is described inSection 10.2.

9.4. Metrics Review

The Integrity Management Department will annually review and update, if necessary, the currentlyeffective system specific metrics based on regulatory changes to current metrics or for other reasonsdeemed appropriate.

Within 90 days of a significant revision to this plan, the Integrity Management Department will forward arevised copy to PHMSA and appropriate state agencies.

9.5. Communication of Results

The Director of Integrity Management will distribute performance results and audit results in accordancewithSection 11.3.

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

25/45

10 - Section 10 - Results Reporting

10.1. Regulation

49 CFR 192.1007(e)

(g) Report results.Report, on an annual basis, the four measures listed in paragraphs (e)(1)(i)through (e)(1)(iv) of this section, as part of the annual report required by 191.11.An operatoralso must report the four measures to the state pipeline safety authority if a state exercises

jurisdiction over the operator's pipeline.

10.2. Review Process for Plan Effectiveness

The Integrity Management Department will prepare an Annual Integrity Management Report by April 30th

each year beginning with year 2012 that includes the following:

1. Overall assessment of the Programs effectiveness.

2. List of A/A actions completed and results obtained.

3. Process improvements identified and implemented.

4. Performance against the previous years Program Performance Parameters and any identifiedtrends.

5. Any other Distribution Integrity Management Activities carried out in the previous year.

6. Determination if an audit is required in the forthcoming twelve months.7. Identification of any Distribution Integrity Management work scheduled in the previous year but

not completed.

8. A Recovery Plan for work scheduled but not completed.

9. A review of the overall contents within the DIMP to ensure compliance with 192 Subpart P.

10. An Integrity Management Department and SME review of the current pipeline data used in therisk assessment to ensure that the most up-to-date information is being used.

The Annual Integrity Management Report will be reviewed and approved by the Vice President ofOperations.

10.3. Performance Measures Submittal to PHMSA and appropriate State Regulatory Agency

http://www.cyberregs.com/cgi-exe/cpage.dll?pg=x&rp=/pseudo.htm&sid=2011042012454447066&aph=1&Hi=2&qy=B31%2E8S&hlc=00FF00&srchm=0&cid=rcp&uid=wbyrd&clrA=0663B2&clrV=0663B2&clrX=0663B2&ref=/indx/CFR/49CFR/CFR_49_192_-_5_P.htm&pseudo=UN1%2C%2CCFR%2CCFR_49_191%2Cg=5~c=11~h=~i=%2C#g=5~c=11~h=~i=http://www.cyberregs.com/cgi-exe/cpage.dll?pg=x&rp=/pseudo.htm&sid=2011042012454447066&aph=1&Hi=2&qy=B31%2E8S&hlc=00FF00&srchm=0&cid=rcp&uid=wbyrd&clrA=0663B2&clrV=0663B2&clrX=0663B2&ref=/indx/CFR/49CFR/CFR_49_192_-_5_P.htm&pseudo=UN1%2C%2CCFR%2CCFR_49_191%2Cg=5~c=11~h=~i=%2C#g=5~c=11~h=~i= -

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

26/45

11 - Section 11 - Communications Plan

11.1. External Communications

11.1.1. Public Awareness Program

WTG will cover external communications for the general public, local officials and emergency respondersthrough the West Texas Public Awareness Program.

11.2. Safety Concerns

11.2.1. DOT/PHMSA

The Integrity Management Department will continually monitor the DOT/PHMSA website for rule changes,advisory bulletins, new information and recommended practices. An electronic log sheet will be kept todetail and describe all visits to the PHMSA website. Any changes or notices that would affect the DIMPwill be documented on the log sheet.

11.3. Internal Communications

Internal communications are made per the following table.

DOCUMENT ORIGINATORDOCUMENTRECIPIENT ACTION REQUIRED

Annual DIMP UpdateIntegrity Management

Department

Vice President of GasPipeline Operations,

Pipeline Operations andMaintenance

Review and approval byVice President of GasPipeline Operations

Annual Distribution IntegrityManagement Report

Integrity ManagementDepartment

Integrity ManagementDepartment

Review, approval anddistribution within WTG

Annual Risk Analysis UpdateIntegrity Management

DepartmentVice President of GasPipeline Operations

Include in DIMP updateincluding consideration of

A/A actions

E t l d I t l A dit I t it M t Vi P id t f G U d t DIMP

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

27/45

12 - Appendix A - Pipeline Information

The Pipeline Information spreadsheet is too large to fit into a Word

table. The most current version of thePipeline Information spreadsheet can be found on the WTG internal employee website under the IntegrityManagement Department section.

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

28/45

13 - Appendix B - Summary and Risk Analyses

The Risk Analysis spreadsheet is too large to fit into a Word

table. The most current version of the RiskAnalysis spreadsheet can be found on the WTG internal employee website under the IntegrityManagement Department section.

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

29/45

14 - Appendix C - Information Gathering Form

The Pipeline Information Gathering spreadsheet is too large to fit into a Wordtable. The most current

version of the Pipeline Information Gathering spreadsheet can be found on the WTG internal employeewebsite under the Integrity Management Department section.

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

30/45

15 - Appendix D - Performance Metric Information Gathering Form

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

31/45

West Texas Gas

Information from January 1, _____ to December 31, _____

Date:___________________________________________________________

Distribution Gas Pipeline Performance Information

Gas Pipeline/Segment Name: ______________________________________

PERFORMANCE METRIC SPECIFIC METRICMETRIC RESULT

ACHIEVEDCOMMENTS

Corrosion

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorizedby cause

Corrosion

Total number of leakseither eliminated or

repaired, categorized bycause

Corrosion

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorizedby material

Corrosion WTG specific measures

Natural Forces

Number of hazardousleaks either eliminated orrepaired as required by

192 703( ) t i d

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

32/45

PERFORMANCE METRIC SPECIFIC METRICMETRIC RESULT

ACHIEVEDCOMMENTS

Excavation DamageNumber of excavation

damages

Excavation DamageNumber of excavation

tickets

Excavation Damage

Total number of leakseither eliminated or

repaired, categorized bycause

Excavation Damage

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorizedby material

Excavation Damage WTG specific measures

Other Outside ForceDamage

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorizedby cause

Other Outside ForceDamage

Total number of leakseither eliminated or

repaired, categorized bycause

Number of hazardousleaks either eliminated or

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

33/45

PERFORMANCE METRIC SPECIFIC METRICMETRIC RESULT

ACHIEVEDCOMMENTS

Material, Weld or JointFailure

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorizedby material

Material, Weld or JointFailure

WTG specific measures

Equipment Failure

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorizedby cause

Equipment Failure

Total number of leakseither eliminated or

repaired, categorized by

cause

Equipment Failure

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorizedby material

Equipment Failure WTG specific measures

Incorrect Operation

Number of hazardousleaks either eliminated orrepaired as required by

192.703(c), categorized

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

34/45

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

35/45

16 - Appendix E - Evaluation of A/A Actions

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

36/45

West Texas Gas

A/A Actions

Date: ____________________

INSTRUCTIONS:

1. The Integrity Management Department completes Part 1 Segment Identification on the form.

2. The Integrity Management Department reviews the individual Threat scores and the individual

Consequence of Failure scores for each segment from the latest risk analysis and completes Part2: Threat and Consequence Hazard Identification.

3. The Integrity Management Department completes the Part3: Possible A/A Actions section of theform.

4. The Integrity Management Department completes the Part 4: Evaluation of Possible A/A Actionssection of the form by performing an evaluation of each possible measure which includes, at aminimum, pros/cons, cost/benefit, technical analysis, and all assumptions.

5. The Integrity Management Department determines if the identified action is to be implement andchecks the appropriate box in Part 4.

6. The Integrity Management Department retains this form for the service life of the pipeline.

Part 1: System Identification:

System Name: _________________________________________________________

Pipeline System Identification: _____________________________________________

Calendar Year: _________________________________________________________

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

37/45

Part 2: Threat and Consequence Hazard Identification:

Pipel ine Segm ent Threat Scores :

Threat Factors with Risk Analysis Score of 5 or Threat categories with TSI > 67%:

T 1. _____________________________________________________________________

T 2. _____________________________________________________________________

T 3. _____________________________________________________________________

T 4. _____________________________________________________________________

T 5. _____________________________________________________________________

Threat Factors with Possible A/A Actions:

T 1. _____________________________________________________________________

T 2. _____________________________________________________________________

T 3. _____________________________________________________________________

T 4. _____________________________________________________________________

T 5. _____________________________________________________________________

Pipel ine Segment Consequ ence Scores:

Consequence Factors with Risk analysis Score of 5:

C 1. ____________________________________________________________________

C 2. ____________________________________________________________________

C 3. ____________________________________________________________________C 4. ____________________________________________________________________

C 5. ____________________________________________________________________

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

38/45

Part 3: Possible A/A Actions:(reference 192.1007(d)):

List all of the possible A/A Actions that could lower the individual threat or consequence factor risk.

T 1. _____________________________________________________________________

T 2. _____________________________________________________________________

T 3. _____________________________________________________________________

T 4. _____________________________________________________________________

T 5. _____________________________________________________________________

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

39/45

Part 4: Evaluation of A/A Actions:

Add additional sections if necessary.

1. A/A Action from Part 3:

Threat to be addressed: ____________________________________________________

Specific Action to be implemented: ___________________________________________

Analysis of Action (pros/cons, cost/benefit, technical analysis, all assumptions, and give details of outsidetechnical review if appropriate):

1. _________________________________________________________________

2. _________________________________________________________________

3. _________________________________________________________________

Implement Identified Measure: Yes No

Location Affected: _______________________________________________________

Time Frame for Completion: _______________________________________________

Specific Responsibilities for Implementation: ____________________________________

________________________________________________________________________

2. A/A Action from Part 3:

Threat to be addressed: ____________________________________________________

S ifi A ti t b i l t d

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

40/45

3. A/A Action from Part 3:

Threat to be addressed: ____________________________________________________

Specific Action to be implemented: ____________________________________________

Analysis of Action (pros/cons, cost/benefit, technical analysis, all assumptions, and give details of outsidetechnical review if appropriate):

1. _________________________________________________________________

2. _________________________________________________________________

3. _________________________________________________________________

Implement Identified Action: Yes No

Location Affected: _______________________________________________________

Time Frame for Completion: _______________________________________________

Specific Responsibilities for Implementation: ____________________________________

________________________________________________________________________

Prepared by: ___________________________________________________________

Date: _________________________________________________________________

Approved by: District Manager: _____________________________________________

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

41/45

17 - Appendix F - Steel Service Line Replacement

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

42/45

42

WTG DIMP Risk Scores TAC 8.209 Service Line

SYSTEM NAME SYSTEM TRC ID #RISK

SCORE

# OF STEELSERVICE LINE

LEAKS IN 2009 AND2010

# OF SYSTEMSTEEL SERVICE

LINES

ANNUALIZED STEELSERVICE LINE LEAK

RATE

PRIORITY

Miami 110356 6.578 2 216 0.005 3

JUNCTION 211162 6.528 2 511 0.002 3

Devine 710231 6.220 2 2 0.500 1

Christoval 211087 5.654 2 95 0.011 3

Higgins 110240 5.271 3 240 0.006 3

BALMORHEA 210022 4.654 1 0 0.000

Leak was on a

steel riser,

service line ispoly

Waka 110597 4.290 4 31 0.065 2

Morton System

95110675 3.876 1 4 0.125 1

Groom Mainline 110455 3.657 1 24 0.021 3

Lelia Lake Rural 110819 2.989 1 0 0.000

Leak was on a

steel riser,

service line is

poly

Poor Boy 110002 2.685 1 8 0.063 2

Regan Lateral 960478 2.496 1 5 0.100 1

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

43/45

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

44/45

-

8/12/2019 West Texas Gas Distribution Pipeline IMP 2012 6-22-12

45/45

45

WTG DIMP Risk Scores TAC 8.209 (Scores > 4.99)

DISTRICT SYSTEM NAME TRC ID #RISK

SCORETHREATSCORE

CONSEQUENCESCORE

TOTAL SYSTEMLENGTH (FEET)

SYSTEMLENGTH

LESS POLY& COATED

STEEL

SYSTEMLENGTH LESS

POLY & COATEDSTEEL X 5%

Shamrock Wheeler Mainline 110617 5.998 1.304 4.600 188139 59604 2980

Pearsall LaPryor 710495 5.778 1.481 3.900 55956 13599 680

Shamrock Old Mobeetie 110363 5.670 1.319 4.300 32400 22307 1115

Shamrock Allison 110016 5.652 1.285 4.400 8704 1564 78

Pearsall East Central 411375 5.612 1.369 4.100 34320 31152 1558

Ft.

StocktonIMPERIAL 210327 5.467 1.367 4.000 83424 57024 2851

Stratford Etter 110176 5.344 1.406 3.800 20095 8710 436

Dalhart NORTEX 110392 5.203 1.334 3.900 658705 0 0

Amarillo Goodnight 110209 5.015 1.433 3.500 88980 79426 3971