Welding Techniques & Welding Defects

-

Upload

nana-delgado -

Category

Documents

-

view

347 -

download

24

Transcript of Welding Techniques & Welding Defects

-

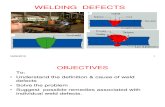

7/27/2019 Welding Techniques & Welding Defects

1/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 -

Module 3

Metal Joining

and

Cutting Processes

-

7/27/2019 Welding Techniques & Welding Defects

2/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 2

Welding Process Knowledge -A Benefit to Inspectors

Helps spot problems

Leads to better inspection

Gains respect of welders Gains cooperation

-

7/27/2019 Welding Techniques & Welding Defects

3/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 3

Common Features of Welding

Processes Source of energy

Source of shielding

Filler metal (optional)

-

7/27/2019 Welding Techniques & Welding Defects

4/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 4

Shielded MetalArc Welding

(SMAW)

-

7/27/2019 Welding Techniques & Welding Defects

5/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 5

SMAW

-

7/27/2019 Welding Techniques & Welding Defects

6/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 6

E X X X XSMAW Electrode Identification SystemElectrode

-

7/27/2019 Welding Techniques & Welding Defects

7/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 7

E X X X XSMAW Electrode Identification SystemStrength

-

7/27/2019 Welding Techniques & Welding Defects

8/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 8

E X X X XSMAW Electrode Identification System

Position

-

7/27/2019 Welding Techniques & Welding Defects

9/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 9

Position Description

1 - used in all positions

2 - used in flat or horizontal fillets only

3 - not used at present time 4 - used for downhill progression

-

7/27/2019 Welding Techniques & Welding Defects

10/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 10

E X X X XSMAW Electrode Identification System

Coating/Operating Characteristics

-

7/27/2019 Welding Techniques & Welding Defects

11/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 1

-

7/27/2019 Welding Techniques & Welding Defects

12/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 12

Low alloy steel electrodes

-

7/27/2019 Welding Techniques & Welding Defects

13/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 13

Low Hydrogen Electrodes

Types end in a 5, 6, or 8

Purchase in sealed, metal containers

Store after opening in heated, vented oven Limit atmospheric exposure

-

7/27/2019 Welding Techniques & Welding Defects

14/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 14

Stainless Steel Electrodes

E308, E308L - Weld 304 and 304L

E316, E316L - Weld 316 and 316L

E309 - Weld Stainless to Carbon Steel

-

7/27/2019 Welding Techniques & Welding Defects

15/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 15

SMAW Equipment

-

7/27/2019 Welding Techniques & Welding Defects

16/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 16

SMAW Limitations

Relatively slow

Slag removal

Electrode storage considerations Arc blow- solutions noted in text

-

7/27/2019 Welding Techniques & Welding Defects

17/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 17

GTAW Nomenclature

-

7/27/2019 Welding Techniques & Welding Defects

18/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 18

Gas Tungsten ArcWelding

Equipment

-

7/27/2019 Welding Techniques & Welding Defects

19/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 19

AWS Tungsten ElectrodeClassifications

Class Alloy Color

EWP Pure tungsten Green

EWCe-2 1.8-2.2% ceria Orange

EWLa-1 1% lanthanum oxide BlackEWTh-1 0.8%-1.2% thoria Yellow

EWTh-2 1.7-2.2% thoria Red

EWZr 0.15-0.40% zirconia Brown

-

7/27/2019 Welding Techniques & Welding Defects

20/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 20

GTAW application

AL welding

- EWP ( Green)

- AC ( Cleaning action )

Ferrous metals welding

- EWTh-2 ( Red )

- DCEN

-

7/27/2019 Welding Techniques & Welding Defects

21/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 2

GTAW Shielding gases

Argon ( 7-16 L / min )- High density

- weld all metals except reactive andrefractory

Helium ( 14 24 L / min )- Light gas ( suitable for overhead )

- Good penetration

Argon + helium or Argon + hydrogen15 % H2 increase welding speed by 50 %

-

7/27/2019 Welding Techniques & Welding Defects

22/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 22

GTAW Advantages

Good for thin materials ( .005 inch ) High quality welds

Good appearance

High quality for weld root by using current remote contro

No arc striking with high frequency start current No slag

No spatter

Autogeneous & heterogeneous

Mechanization potential

-

7/27/2019 Welding Techniques & Welding Defects

23/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 23

GTAW Limitations

Relatively slow

Low tolerance for contamination

Shielding gas expensive

Purging gas expensive

M d l 3 24

-

7/27/2019 Welding Techniques & Welding Defects

24/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 24

Causes of Tungsten Inclusions

Contact between:

Tungsten and base metal

Tungsten and filler metal

Excess current

Excess tungsten extension

Improper tungsten tip grinding

M d l 3 25

-

7/27/2019 Welding Techniques & Welding Defects

25/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 25

SubmergedArc Welding

(SAW)

Module 3 26

-

7/27/2019 Welding Techniques & Welding Defects

26/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 26

SAWEquipment

Module 3 27

-

7/27/2019 Welding Techniques & Welding Defects

27/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 27

SAW

Module 3 28

-

7/27/2019 Welding Techniques & Welding Defects

28/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 28

Defect

A flaw or flaws that by nature oraccumulated effect render a part or productunable to meet minimum applicable

acceptance standards or specifications. Theterm designates rejectability.

Module 3 - 29

-

7/27/2019 Welding Techniques & Welding Defects

29/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 - 29

Discontinuity

An interruption of the typical structure of amaterial, such as a lack of homogeneity inits mechanical, metallurgical, or physical

characteristics. A discontinuity is notnecessarily a defect.

Module 3 - 30

Weld Joint Discontinuities

-

7/27/2019 Welding Techniques & Welding Defects

30/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 30Weld Joint Discontinuities Misalignment (hi-lo)

Undercut

Underfill

Concavity or Convexity

Excessive reinforcement

Improper reinforcement

Overlap

Burn-through

Incomplete or Insufficient

Penetration

Incomplete Fusion

Surface irregularity

Overlap

Arc Strikes

Porosity

UniformlyScattered

Cluster Linear Piping

Cracks Longitudinal Transverse Crater Throat Toe Root Underbead and

Heat-affected zone Hot Cold or delayed

Inclusions

Slag

WagontracksTungsten

Spatter

Arc Craters

Heat-affected zone

microstructure alteration Base Plate laminations

Size or dimensions

Base Metal Discontinuities

Lamellar tearing

Laminations andDelaminations

Laps and Seams

Module 3 - 3

C k

-

7/27/2019 Welding Techniques & Welding Defects

31/53

Am e r i c a n We l d i n g S o c i e t y

Module 3 3

Cracks

Longitudinal

Transverse

Crater

Throat

Toe

Root

Underbead and Heat-affected zone

Hot Cold or delayed

Module 3 - 32

-

7/27/2019 Welding Techniques & Welding Defects

32/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A crack running in the direction of the weld axis. Ma

found in the weld or base metal.

Cause: Preheat or fast cooling problem. Also caused by shrinkag

stresses in high constraint areas.

Prevention: Weld toward areas of less constraint. Also preheat to

even out the cooling rates.

Repair: Remove and reweld

Longitudinal Crack

Module 3 - 33

-

7/27/2019 Welding Techniques & Welding Defects

33/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A crack, generally in the shape of an X which is fo

in a crater. Crater cracks are hot cracks.

Cause: The center of the weld pool becomes solid before the out

of the weld pool, pulling the center apart during cooling

Prevention: Use crater fill, fill the crater at weld termination and

preheat to even out the cooling of the puddle

Repair:

Crater Crack

Module 3 - 34

-

7/27/2019 Welding Techniques & Welding Defects

34/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A crack in the base metal beginning at the toe of the

weld

Cause: Transverse shrinkage stresses. Indicates a HAZ brittlenes

problem.

Prevention: Increase preheat if possible, or use a more ductile fil

material.

Repair:

Toe Crack

Module 3 - 35

-

7/27/2019 Welding Techniques & Welding Defects

35/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A crack in the weld at the weld root.

Cause: Transverse shrinkage stresses. Same as a throat crack.

Prevention: Same as a throat crack

Repair:

Root Crack

Module 3 - 36

-

7/27/2019 Welding Techniques & Welding Defects

36/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A crack in the unmelted parent metal of the HAZ.

Cause: Hydrogen embrittlement

Prevention: Use Lo/Hi electrodes and/or preheat

Repair: (only found using NDT). Remove and reweld.

Underbead Crack

Module 3 - 37

-

7/27/2019 Welding Techniques & Welding Defects

37/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A crack in the weld that occurs during solidification.

Cause: Micro stresses from weld metal shrinkage pulling apart w

metal as it cools from liquid to solid temp.

Prevention: Preheat or use a low tensile filler material.

Repair: Remove and reweld, correct problem first, preheat may benecessary, increase weld size.

Hot Crack

Module 3 - 38

-

7/27/2019 Welding Techniques & Welding Defects

38/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A crack that occurs after the metal has completely

solidified

Cause: Shrinkage, Highly restrained welds, Discontinuities

Prevention: Preheat, weld toward areas of less constraint, use a

more ductile weld metal

Repair: Remove and reweld, correct problem first, preheat may bnecessary.

Cold Crack

Module 3 - 39

-

7/27/2019 Welding Techniques & Welding Defects

39/53

Am e r i c a n We l d i n g S o c i e t y

Repairs to Cracks

Determine the cause

Correct the problem

Take precautions to prevent reoccurrence

Generally required to repair using a smallerelectrode

Module 3 - 40

-

7/27/2019 Welding Techniques & Welding Defects

40/53

Am e r i c a n We l d i n g S o c i e t y

Porosity

Single Pore

Uniformly Scattered

Cluster

Linear

Piping

Module 3 - 4

-

7/27/2019 Welding Techniques & Welding Defects

41/53

Am e r i c a n We l d i n g S o c i e t y

Definition: Slag entrapped within the weld

Cause: Low amperage, improper technique, Trying to weld in an

area that is too tight. Slow travel in Vertical Down Prevention: Increase amperage or preheat, grind out tight areas to

gain access to bottom of joint.

Repair: Remove by grinding. Reweld.

Slag Inclusion

Module 3 - 42

-

7/27/2019 Welding Techniques & Welding Defects

42/53

Am e r i c a n We l d i n g S o c i e t y

Definition: A tungsten particle embedded in a weld. (Typically

GTAW only)

Cause: Tungsten electrode too small, amperage too high, AC

balance on +, Upslope too high, electrode tip not snipped, electroddipped into the weld pool or touched with the fill rod, electrode

split.

Prevention: Eliminate the cause

Repair: Grind out and reweld

Tungsten Inclusion

Module 3 - 43

Incomplete or Insufficient

-

7/27/2019 Welding Techniques & Welding Defects

43/53

Am e r i c a n We l d i n g S o c i e t y

Incomplete or InsufficientPenetration

Definition: When the weld metal does not extend to the required

depth into the joint root

Cause: Low amperage, low preheat, tight root opening, fast travel

speed, short arc length. Prevention: Correct the contributing factor(s).

Repair: Back gouge and back weld or remove and reweld.

Module 3 - 44

-

7/27/2019 Welding Techniques & Welding Defects

44/53

Am e r i c a n We l d i n g S o c i e t y

Incomplete Fusion

Definition: Where weld metal does not form a cohesive bond with

the base metal.

Cause: Low amperage, steep electrode angles, fast travel speed,

short arc gap, lack of preheat, electrode too small, unclean basemetal, arc off seam.

Prevention: Eliminate the potential causes.

Repair: remove and reweld, being careful to completely remove th

defective area. This is sometimes extremely difficult to find.

Module 3 - 45

U d

-

7/27/2019 Welding Techniques & Welding Defects

45/53

Am e r i c a n We l d i n g S o c i e t y

Undercut Definition: A groove cut at the toe

of the weld and left unfilled.

Cause: High amperage, electrode angle,

long arc length, rust Prevention: Set machine on scrap metal. Clean metal before

welding.

Repair: Weld with smaller electrode, sometimes must be low

hydrogen with preheat. Sometimes must gouge first.

Module 3 - 46

-

7/27/2019 Welding Techniques & Welding Defects

46/53

Am e r i c a n We l d i n g S o c i e t y

Insufficient Fill

Definition: The weld surface is below the adjacent surfacof the base metal

Cause: Improper welding techniques

Prevention: Apply proper welding techniques for the weld type an

position. Use stripper beads before the cover pass.

Repair: Simply weld to fill. May require preparation by grinding.

Module 3 - 47

-

7/27/2019 Welding Techniques & Welding Defects

47/53

Am e r i c a n We l d i n g S o c i e t y

Reinforcement

Excessive

Insufficient

Improper contour

Face Reinforcement

Root Reinforcement

The amount of a groove weld which extends beyond the surface of the

plate

Module 3 - 48

-

7/27/2019 Welding Techniques & Welding Defects

48/53

Am e r i c a n We l d i n g S o c i e t y

Excessive Reinforcement Definition: Specifically defined by the standard. Typically,

Reinforcement should be flush to 1/16(pipe) or flush to 1/8 (platestructural shapes).

Cause: Travel speed too slow, amperage too low

Prevention: Set amperage and travel speed on scrap plate.

Repair: Remove excessive reinforcement and feather the weld toe

to a smooth transition to the base plate.

Module 3 - 49

-

7/27/2019 Welding Techniques & Welding Defects

49/53

Am e r i c a n We l d i n g S o c i e t y

Definition: When the weld exhibits less than a 1350 transition ang

at the weld toe.

Cause: Poor welding technique

Prevention: Use proper techniques. A weave or whip motion can

often eliminate the problem.

Repair: The weld face must be feathered into the base plate.

1350

Improper Weld Contour

Module 3 - 50

B h h

-

7/27/2019 Welding Techniques & Welding Defects

50/53

Am e r i c a n We l d i n g S o c i e t y

Burn-through (non-standard)

Definition: When an undesirable open hole has been completely

melted through the base metal. The hole may or may not be left

open.

Cause: Excessive heat input.

Prevention: Reduce heat input by increasing travel speed, use of a

heat sink, or by reducing welding parameters.

Repair: Will be defined by standards. Filling may suffice.

Otherwise, removal and rewelding may be required. Some standamay require special filler metal and/or PWHT.

Module 3 - 5

A S ik

-

7/27/2019 Welding Techniques & Welding Defects

51/53

Am e r i c a n We l d i n g S o c i e t y

Arc Strike

Definition: A localized coalescence outside the weld zone.

Cause: Carelessness

Prevention: In difficult areas, adjacent areas can be protected usinfire blankets.

Repair: Where applicable, arc strikes must be sanded smooth and

tested for cracks. If found, they must be remove and repaired usin

a qualified repair procedure and inspected as any other weld.

Module 3 - 52

S tt

-

7/27/2019 Welding Techniques & Welding Defects

52/53

Am e r i c a n We l d i n g S o c i e t y

Spatter

Definition: Small particles of weld metal expelled from the weld

operation which adhere to the base metal surface.

Cause: Long arc length, severe electrode angles, high amperages

Prevention: Correct the cause. Base metal can be protected with

coverings or hi-temp paints.

Repair: Remove by grinding or sanding. Sometimes must be test

as if it were a weld.

Module 3 - 53

L i ti

-

7/27/2019 Welding Techniques & Welding Defects

53/53

Am e r i c a n We l d i n g S o c i e t y

Laminations

Base Metal Discontinuity

May require repair prior to welding

Formed during the milling process

![[PPT]Welding Techniques and Defects - Tun Hussein Onn …author.uthm.edu.my/uthm/www/content/lessons/2475/Kimpalan... · Web viewSMAW Pipe Welding Techniques Positions 1G 2G 5G 6G](https://static.fdocuments.net/doc/165x107/5afd373f7f8b9a68498c8df9/pptwelding-techniques-and-defects-tun-hussein-onn-viewsmaw-pipe-welding.jpg)