Welding and cutting in the new millennium - esab.de · submerged arc welding, gas-tung-sten arc...

Transcript of Welding and cutting in the new millennium - esab.de · submerged arc welding, gas-tung-sten arc...

A welding review published by The Esab Group Vol. 54 No. 1–2 1999

Welding and cutting in the new millennium

Svetsaren No.1–2 1999

Contents Vol. 54 No. 1–2 1999Challenges for welding consumables for the newmillenniumImportant trends for materials development challenges the development of consumables andprocesses.

From prototype to integrated production system10 years of research and development results in theTHOR ArcWeld production system — a system forthe automatic programming of welding robots.

Welding duplex chemical tankers the ESAB wayA review ot the production of chemical tankers atFactorías Vulcano S.A in Spain.

Consumables for welding modified 9 Cr-1 Mo steelA comparison between modified and conventionalcreep-resistant ferritic steels and the consumablesto be used.

Laser welding catalytic converters — a complete success for AP Torsmaskiner AB, SwedenLarge-scale production of laser-welded componentfor vehicles.

Consumables for welding high strength steelsThe use of high strength steels increases the needfor new welding consumables

Cutting systems in an environmental contextThe environmental issues have become an increas-ingly important point on the agenda when it comesto the design of cutting systems

New ESAB OK Tubrod 15.13 for robot welding atFincantieriThe future success of the European Union projectfor Fully Automatic Ship Production ultimately de-pends on the performance of cored wires when itcomes to optimising productivity.

Stubends & Spatter

Laser welding — A mature process technology withvarious application fieldsThe possible applications for laser welding in themanufacturing industries will be more or less unlimited.

Energy efficiency in weldingLower energy costs give better economy and environmental effects with the choice of the rightequipment.

Effect of interpass temperature on properties ofhigh-strength weld metalsThe microstructure of high-strength weld metals becomes sensitive to variations in the interpass temperature in multirun welds.

“The technology of tomorrow” has already been implemented at BORSIG in GermanyInstalling the new technologies for adaptive weldingand automatic robotic oxy-fuel cutting at BORSIG’sheavy-duty plant has clearly increased productivity.

Increasing availabilityWith modern cutting systems it is possible to unifymachine investment and to cut workpiece idle timesdramatically.

Fabricators pleased with increased submerged arcproductivity from cored wiresSAW with cored wires gives great benefits directlyfrom improved welding economy due to an increaseddeposition rate converted to higher travel speed

Welding and cutting beyond the year 2000Major trends and conclusions from a gas-relatedpoint of view

Modern MIG welding power sourcesFeatures of modern power source technology.

2

Articles in Svetsaren may be reproduced without permission but with an acknowledgement to Esab.

PublisherBertil Pekkari

EditorLennart Lundberg

Editorial committeeKlas Weman, Lars-Göran Eriksson, Johnny Sundin, Johan Elvander, Dag Jacobsen,

Jerry Uttrachi, Stan Ferree, Ben Altemühl, Nils-Erik Andersen, Susan Fiore

AddressEsab AB, Box 8004, S-402 77 Göteborg, Sweden

Internet addresshttp://www.esab.se

E-mail: [email protected]

Printed in Sweden by Skandia-Tryckeriet, Göteborg

A welding review published by The Esab Group No. 1–2 • 1999

3

12

15

22

26

29

34

38

39

43

51

53

59

65

70

74

77

The Friction Stir Welding process isbeing used for the welding of fuel tanksin the Boeing Delta space rockets.

Nya Svetsaren 1, 1999. 1999-07-01 10.15 Sidan 2

Svetsaren No.1–2 1999 3

Arc welding was invent-ed around 100 years agoand, at least during thepast 50 years, it hasbeen the main fabrica-tion method for struc-tures made of steel andother metallic materials.There are several arcwelding processes,which means that thereare many possible waysto optimise the weldingoperation. With many ofthe methods, the me-

chanisation of the pro-cess is possible and thiscan decrease the cost ofwelding. With the largenumber of consumablesavailable, the flexibilityrequired to achieve ap-propriate properties inthe welded joint is veryhigh.The potential for adjusting thechemical composition of the weldmetal is almost unlimited. By us-ing different flux systems, weldingcharacteristics such as drop trans-fer, arc stability and the fluidity

of the molten metal can be con-trolled.

However, to maintain profit-ability, industry must always lookfor ways of improving and ration-alising working processes. Aswelding is such a central processfor many fabricators, the weldingoperation has been the focalpoint for many of the improve-ments which have been madeover the years. These improve-ments can be categorised intothree main groups:

developments in designdevelopment of welding pro-cessesdevelopments in materials.

Of course, these developmentscannot be seen in isolation but

Challenges for welding consumables for the new millennium

by Lars-Erik Svensson and Johan Elvander, Esab AB, Göteborg, Sweden

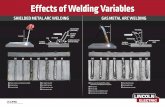

Figure 1. The relative use of different welding processes, measured in the form of weld metal consumption.

Nya Svetsaren 1, 1999. 1999-07-01 10.20 Sidan 3

4 Svetsaren No.1 1999

are interrelated. In order to dis-cuss possible future develop-ments, it may, however, be helpfulto make this division.

Design developments fall out-side the scope of this paper, but itcan be briefly stated that, withthe introduction of high-speedcomputers, finite element calcula-tions of critical details in a struc-ture have become a standardtool, helping to optimise the con-struction significantly. Althoughdesign is traditionally conserva-tive, due to the major conse-quences of a failure, there is defi-nitely a trend towards utilisingmaterials such as higher strengthsteels or aluminium to producelighter structures with a highload-carrying capacity. In thiscontext, it must be realised thatone of the controlling factors indesign is fatigue, which is a limit-ing factor for the use of high-strength steels.

With the development ofmechanised welding, it is moreadvantageous to use fillet weldingrather than butt welding. To im-plement this, the development ofthe welding processes took placeprimarily from 1930 and onwards.The most common processes likesubmerged arc welding, gas-tung-sten arc welding and gas-metalarc welding were all developedmore than 50 years ago. Theyhave been further refined withthe aid of sophisticated electroniccomponents in power sources,elaborate handling devices likecolumns and booms and seamsensors. Many of the methods arenow fully automated. The produc-tivity of the processes has alsobeen increased by a number ofmodifications. The best exampleis probably submerged arc weld-ing, where productivity can be in-creased by using multi-wire sys-tems or by feeding metal powderinto the weld pool. In gas-metalarc welding, the use of coredwires has led to an increase inproductivity. Here, too, modifica-tions to the process, as in RapidArc and Rapid Melt, have ac-quired some degree of popularity.

In parallel with the develop-ments in productivity, consum-ables have also been developedto meet new and higher require-

ments. Three different situationshave been encountered;

higher strength and impacttoughness as well as enhancedcorrosions resistance is de-sired to match the develop-ment of steel,higher impact toughness atlower temperatures is neededfor structures operating inharsh environments to main-tain strength and toughnessfor welds deposited with high-er productivity (which gener-ally means higher heat inputand coarser microstructures).

Arc welding has been estab-lished for many years as the lead-ing joining process. In certain ap-plications, other processes haveacquired increasing popularity. Inthe automotive industry in partic-ular, many other joining process-es, such as adhesives and laserwelding, have taken over fromtraditional arc welding. In mostother circumstances, arc weldingis still the leading process, despitethe fact that many other process-es have been developed. In recentyears, two other processes, laserwelding and friction stir welding,have been introduced and devel-oped to such an extent that theycan be regarded as realistic chal-lengers to arc welding. The bene-fits to the user of these processesare that they are often performedin just one or two passes, even forrelatively thick material, and thatthe distortion of the plates is verysmall, resutling in far less workfor rectification. The drawbacksare the large investment costs andthe need for much closer fit-up ofthe plates. In the case of laserwelding, special grades of plateare needed and, in the case offriction stir welding, the supple-mentary equipment for handlingthe plates is quite extensive. Inthe large research projects thathave been run or are still in pro-gress and in which these process-es are being evaluated, otherdrawbacks have also been noted.The ductility of laser welds is usu-ally lower than that found in arcwelds and, due to the very highcooling rates, martensite is oftenformed both in the heat affectedzone and in the weld metal. Fric-tion stir welding is still very much

more at the development stageand has only been used commer-cially for welding aluminium, withvery promising results. It is stillnot known whether it will be pos-sible to use this process for steelson a larger scale.

Process developmentThe relative use of differentwelding consumable types, meas-ured in terms of weld metal con-sumption, for welding structuralsteel between 1975 and 1996 isshown in Figure 1. The figureshows the development for threeregions: Western Europe, theUSA and Japan.

The use of covered electrodeshas been replaced by methodsproducing higher productivity.MIG/MAG welding, using solidwires, has captured the largestmarket shares. The consumptionof tubular wire was less than 5%for many years, but, during thelast few years, it has increasedmarkedly and is now almost 10%.This consumption is expected tocontinue to increase rapidly.

The decrease in the use of cov-ered electrodes is expected to beless dramatic in the years tocome, although some further de-crease can still be foreseen. Thegrowth of tubular wires will thenbe due in part to a change in pro-cess from covered electrodes, butit will mainly result from the re-placement of solid wires with tu-bular wires.

The major change which is cur-rently taking place is the increas-ing use of welding robots andother forms of mechanisation.This trend is particularly strong incountries with high labour costs,but another, equally importantfactor is the difficulty involved infinding qualified welders who arewilling to perform manual weld-ing. It has, in fact, been found thatthe wear and tear experienced bywelders, especially when weldingwith semi-automatic processes,can be quite high. To address thissituation, two possible methodscan be considered: either fullymechanise the operation or intro-duce another method which im-poses less weight on the welder’sarms and shoulders. The secondmethod has sometimes been

Nya Svetsaren 1, 1999. 1999-06-24 10.27 Sidan 4

Svetsaren No.1 1999 5

used. One example of this comesfrom Norway where, in a particu-lar application, MMA weldingwith high-recovery covered elec-trodes replaced semi-automaticwelding. It was actually foundthat productivity was not reducedbut was instead enhanced. Thelesson to be learned here is thatthere are several ways of achiev-ing high productivity. High flex-ibility and a careful analysis ofthe different options is most like-ly to promote the optimum choi-ce, which will in turn lead to max-imised productivity.

Environmental questions haveattracted increasing interest inmodern society. The demand formore environmentally-friendlyoperations has been stepped up— in the welding industry andother areas. Esab has played anactive part in improving the situ-ation with regard to the impacton the environment from manyparts of its operations. Detailsabout Esab’s environmental ac-tivities can be found in (1). Anew report describing further im-provements will be issued in1999.

The main welding process inFigure 1 is MIG/MAG weldingwith solid wire. This is not sur-prising, due to the combination offlexibility, productivity and qual-ity the method offers. The latestdevelopments here are related tothe packaging system. For appli-cations with high duty cycles, theintroduction of Marathon Pacwas a major improvement. Mara-thon Pac has been further refinedand is now made of recyclablematerial. Using a special system,the wire always comes outstraight, producing extremely lowfriction in the wire conduit. Witha new and improved design, 12 mlong wire conduits are used.When starting, only the free wireneeds to be accelerated, therebyreducing the wear on the driverollers. The straight wire is a ma-jor benefit in different situationswhen the wire has to be posi-tioned carefully (e.g. welding innarrow gaps) or when welding inthin plate, for example. When us-ing robot welding, joint trackingis critical and the straight wiremakes this much more accurate.

The most important benefit ofMarathon Pac is, however, the op-portunity to increase productivity.The number of bobbin changes isreduced significantly, repairs andrejects are reduced and it is pos-sible to run unmanned shifts dur-ing the night.

Further improvements on thepackaging side are expected. Atpresent, Marathon Pac is avail-able in two sizes. The serial con-nection of several MarathonPacs, to reduce the number ofchanges, has also been testedwith promising results.

The most important factor fora fabricator using robotic weldingis that the robot can run continu-ously. This in turn leads to re-quirements being imposed on theequipment and consumables, to-gether with high and consistentquality to create the conditionsnecessary for problem-free oper-ation.

For the wires at a robot weld-ing station, feedability and easeof arc striking are essential prop-erties. The new robotic wire,PZ6105R, from Filarc is one ex-ample of this development.

Most robots are designed forsolid wires, but they can be chan-ged relatively simply to coredwires and the different parametersettings that are needed. The ad-vantages of metal cored wirescompared with solid wires arethe higher welding speeds thatcan be attained, the improvementin penetration and the reductionin spatter.

As soon as a robot is installed,the handling time is more or lessconstant, independent of thechoice of process. So, the onlyway to increase productivity stillfurther is to increase the weldingspeed (e.g. use of cored wires).The higher and broader penetra-tion in fillet welds produces a

Nya Svetsaren 1, 1999. 1999-06-24 10.32 Sidan 5

6 Svetsaren No.1 1999

larger safety margin for the con-struction and the opportunity forwider tolerances in the fit-up.There are also discussions aboutwhether it is possible to take ac-count of the penetration whencalculating the throat thickness.This would add a further benefitto the cored-wire process andwould also be a significant cost-reduction factor. Another impor-tant factor is the bead shape,which is much smoother for thecored-wire process. The transitionbetween the weld metal and thebase material is also muchsmoother with cored wires, some-thing that is very important forconstructions subjected to fluctu-ating loads. The low spatter re-duces the need for post-cleaningto a minimum, thereby enablingwelded parts to be immediatelytransported to the next link inthe manufacturing chain.

There are some further devel-opment in the MAG process(twin-arc MAG and tandemMAG) which may be of signifi-cant interest for the future. Intwin-arc MAG, two wires are fedinto the same torch and connect-ed to a sophisticated power sour-ce. The wires have the same volt-age, but different feeding rates.By pulsing, disturbances betweenthe arcs are avoided. This processproduces extremely high deposi-tion rates. The process has alsobeen tested with metal coredwires (PZ 6105R and OK Tubrod14.13) with good results.

Submerged arc welding hashad a fairly stable share of themarket over the years. It is ahigh-productivity process and theapplications are therefore oftenassociated with heavy industry. Anumber of improvements havebeen made for even higher pro-ductivity, such as increasing thenumber of welding wires. Onerelatively new development in-volves using a tubular wire in-stead of a solid wire. This increas-es the deposition rate, improvesthe penetration profile andmakes the adaptation of chemicalcomposition much easier. Theprocess is now being further op-timised, with the joint develop-ment of the cored wire and theflux, to provide a better process.One further example of develop-

ment within this field is the useof a cold wire, which is fed separ-ately but in synchronised form,into the weld pool. This featureboth increases productivity sig-nificantly and helps to cool theweld, thereby preventing exces-sive grain growth. A patent forthis process has now been filedby Esab.

In the future, it is expectedthat, in the case of assemblywelding, especially for heavyequipment, covered electrodeswill still be used. The use of tubu-lar wires will increase significant-ly, especially in Europe. Tubularwires will replace covered elec-trodes, as well as solid wires tosome extent. The main develop-ments will be seen in tubular andsolid wires, particularly in con-nection with mechanised welding.For the technically most ad-vanced fabricators, sophisticatedmethods like laser welding willbe introduced. For fabricatorswho cannot invest the very largeamount of money required for la-sers, advanced methods like twin-arc MIG, which is still based onrelatively conventional powersources, but with advanced soft-ware, could be one possible wayof increasing productivity. How-ever, the majority of fabricatorsare small and medium-sized en-terprises and, as a result, conven-tional welding methods will stillbe used. Productivity will then beobtained from using more effi-cient consumables.

Developments in struc-tural steelThe large advance in terms of theweldability of structural steelscame with the introduction of thethermo-mechanically (TM) pro-cessed steels at the beginning ofthe 1980s. Compared with the tra-ditional normalised steels, thenew steels had a much leanercomposition, for the same yieldstrength. The carbon content inparticular was reduced and thestrength was obtained from finergrain size and increased disloca-tion density. Sometimes, acceler-ated cooling was used, adding ex-tra strength as the steel trans-formed to bainite rather than fer-rite.

In addition to the lower carboncontent, the quality of the steelswas improved significantly by areduction in the impurity element(sulphur and phosphorus) con-tent.

It is difficult to envisage a simi-lar major development in steels inthe near future. Slow and contin-uous improvements will probablybe made to TM steels — in termsof their impact properties, for ex-ample — and they may find newapplications, but, as there willprobably be no major changes,there will be no need to makeany significant changes to theconsumables used for weldingthese steels.

In the new European standardEN 10 113-3, TM steels with yieldstrengths of up to 460 MPa arespecified. TM steels can now beproduced at many steelworks.What might differ between sup-pliers is the combination of platethickness and yield strength thatcan be delivered. Many of thesteels supplied with yieldstrengths of up to approximately500 MPa are made using the TMprocess. For the highest strengthlevels in this range, the produc-tion process is determined by theplate thickness. For thinner pla-tes, the TM process can be used,but for heavier plates it is neces-sary to use quenching and tem-pering to obtain the properties.Above approximately 500 MPa,all steels are of the QT type.These steels are also of high qual-ity, with a low impurity contentand good weldability. However,with increasing strength levelsand increased thickness, more al-loying is needed, making preheat-ing necessary.

A trend that has continued forsome years involves using steelsof higher strength. The advantageof this is obvious; structures canbe made with thinner plates, re-ducing the weight and therebyimproving the opportunity forhigher loads. It should be notedthat there are situations in whicha structure cannot take advantageof thinner plates, such as whenbuckling, stiffness or fatiguestrength is the design criterion.

High-strength steels are com-monly defined as steels with a

Nya Svetsaren 1, 1999. 1999-06-24 10.33 Sidan 6

Svetsaren No.1 1999 7

yield strength of more than 350MPa.These steels now have foundtheir way into many areas of con-struction. In several new spectac-ular bridge constructions, TMsteels with yield strengths of 420or 460 MPa have been used. Oneexample is the Great Belt bridgein Denmark which was built dur-ing the mid-1990s and recentlywent into operation. Part of thebridge is made in the form of asteel suspension bridge, usingsome 80,000 tonnes of steel. Halfthis amount is accounted for byTM steels, with a yield strength of420 MPa. Details of the buildingof this bridge are presented in(2).

Another example from thebridge sector, in which a veryhigh-strength QT steel is used, isthe world’s largest suspensionbridge, the 1,990 m long Akashibridge in Japan. The constructionof this bridge was completed in1997 and the bridge is now in op-eration. In the box girders of thisbridge (comprising hundreds oftonnes of the steel), a very high-strength steel, HT780, with a yieldstrength of more than 780 MPawas used. It is particularly inter-esting to note that this steel onlyneeded less than 50°C of preheat-ing, despite its high strength, dueto the elaborate alloying tech-nique, combined with the quench-ing and tempering technique (3).

Examples of applications forhigh-strength steels with yieldstrengths of up to around 500MPa include standard structuralsteelworks, excavator equipment,pipelines, cranes, roof support inmines and, of course, offshoreconstructions.

Steels of higher strength suchas 690 MPa are used for trailersfor heavy haulage work, cranes

with a high lifting capacity, dump-er bodies and so on. For steelswith even higher strength (900MPa and above), typical applica-tions include penstocks, conveyorsystems and mobile bridges.

For steels with a yield strengthof 350-450 MPa, there are usuallyvery few welding problems. Theproblems that can arise here in-clude low toughness in the weldmetals, often associated with in-creased nitrogen content, due tothe use of too long an arc. If low-hydrogen consumables are used,hydrogen cracking is very rarely aproblem. If it arises, it is relatedto the welding of heavy plates.Solidification cracking may occurin very special circumstances, butit should generally pose no prob-lems. Impact toughness in high-dilution welds, such as one-sidedwelding with only one bead, cansometimes be low. This is, howev-er, often due to some incompat-ibility between the base metaland the consumable.

It is not until steels with a yieldstrength of 600 MPa or above areused that welding may becomesomewhat problematic and re-quire more caution. The steels areused in demanding applications,requiring good toughness at lowtemperatures in many cases. Inthis case, two problems may oc-cur. The first involves finding aweld metal with a yield strengthhigher than that of the steel andat the same time possessing goodimpact toughness. There are anincreasing number of consum-ables with these properties, butthere may still be problems whenit comes to combining high pro-ductivity and good mechanicalproperties. This is discussed inmore detail in the paper by L-ESvensson in this issue.

The second problem is relatedto hydrogen cracking. With thesteel developments that have tak-en place, including a lean alloyingcontent, the weldability of thesteels has been increased. In par-ticular, the need for preheatinghas been reduced dramatically.This is especially true of steels oflower strength, such as 350–500MPa steels. For these steels, theweld metals are also lean in alloy-ing content and do not requirepreheating. However, when itcomes to the high-strength steels,the situation is more complicated.The only way to increase thestrength of these weld metals is toincrease alloying. The advancedprocessing routes used for thesteels can naturally not be ap-plied to the weld metal. So, in asituation in which there is lesshardenability in the HAZ than inthe weld metal, there may be sev-eral reasons why hydrogen crack-ing would be more likely to occurin the weld metal. Preheatingmust then be prescribed to pro-tect the weld metal rather thanthe HAZ of the parent plate. Thisis a somewhat new situation and,although fabricators have learnthow to handle it, there is a lack offundamental knowledge aboutweld metal hydrogen crackingwhich must be remedied.

One solution that might appearto an attractive means of resolv-ing this situation is a further re-duction in hydrogen content fromthe consumables. Developmentsin which the hydrogen content ofthe weld metals has been reducedhave already been in progress formany years. As was noted in aprevious paper (4), hydrogen con-tents as specified in Table 1 havebeen obtained as a result of in-tensive research and develop-ment during the past decade.

There are several reasons forbelieving that the rate at whichthis downward trend will contin-ue will be slower in the futurethan it has been in the past. It willbe increasingly difficult to makefurther reductions from the verylow levels that have already beenachieved. The hydrogen contentcan be reduced by a number ofmeasures. Unfortunately, thesechanges often tend to have a neg-ative effect on other properties,

Consumable type Hydrogen content Comments(ml/100 g weld metal)

Basic covered electrodes 5 3 ml for special types

Tubular wires,basic or metal cored < 5

Tubular wires, rutile < 10 often < 5

Submerged arc fluxes < 5

Table 1. Hydrogen content of different consumables.

Nya Svetsaren 1, 1999. 1999-06-24 10.34 Sidan 7

8 Svetsaren No.1 1999

such as welding characteristics.So, a further reduction in hydro-gen will lead to consumableswhich are less attractive to thewelder. This factor has to be tak-en seriously and evaluatedagainst the benefits of a furtherreduction in the hydrogen con-tent. Another important factor ishow accurately the measurementof hydrogen content can be made.Investigations have shown thatthe error is around 0.5–1.0 ml/100g weld metal for the gas chroma-tography method. The relative er-ror at, say, 2 ml hydrogen/100 gweld metal is then 25-50%. Itmust be noted here that the largeerrors are not due to the analyti-cal equipment but instead to vari-ations in the specimen prepara-tion phase.

Apart from hydrogen stemmingfrom the consumable, there areother sources of hydrogen, such asthe surrounding atmosphere, thebase material or dirt and oil onthe plate and joint surfaces.

So, the amount of hydrogen inthe weld pool can differ from thehydrogen content specified by theelectrode manufacturer. Natural-ly, the hydrogen content of theconsumable is also affected bythe possible moisture absorption.Although low moisture absorp-tion electrodes have been devel-oped, some absorption alwaystakes place. This can be avoidedby using vapour-tight packaging,like Esab’s VacPac. In this kind ofpackaging, the electrodes arekept in the same condition aswhen they were manufactureduntil the package is opened.

To benefit fully from the devel-opment of steels, to increase pro-

ductivity during welding, system-atic investigations need to bemade, partly to be able better todefine the preheating necessaryfor safe welding, but also in orderpossibly to develop the weld met-als still further with the aim ofmaking them crack-resistant whi-le maintaining the mechanicalproperties.

Developments in heat-resistant steelsThe steels which are traditionallyused for high-temperature appli-cations within the petrochemicalindustry or the power generatingindustry can broadly be classifiedinto two groups. One group, spec-ified in EN 10 028-2 Steels forpressure purposes, with specifiedelevated temperature properties,contains those steels commonlyfound in high-temperature powerplants. In this standard, there arefirst four unalloyed quality steels,with a yield strength varying from235 to 355 MPa. The properties ofthese steels are specified up to400°C. For use at higher tempera-tures, steels alloyed with molyb-denum and chromium are used.The simplest steel is only alloyedwith about 0.3% molybdenum.The most common steels are al-loyed with either 1.25Cr-0.5Mo or2.25Cr-1Mo. These steels havetheir tensile properties specifiedup to 500°C. The maximum oper-ating temperature is 565°C. Thecreep properties, given as refer-ence in the standard, are specifiedup to 600°C for a 2.25Cr-1Mosteel (10 CrMo 9-10).

There are a number of sugges-tions on how to modify the

2.25Cr-1Mo steel in particular.The most frequent suggestionsare to increase the chromiumcontent, so that the typical com-position would be 3Cr-1Mo in-stead, and to add vanadium. Theaddition of vanadium increasesthe high-temperature strength ef-fiectively, but the cracking risk inthe HAZ is increased.

Consumables for welding thesesteels have much the same com-position as the parent material.The microalloying elements vana-dium and niobium are on a lowerlevel than they are in the steel,thereby reducing the creepstrength of the weld metals some-what. Since the microstructure ofthe weld metal is bainitic, theprior austenite grain boundariesare preserved and may be a sour-ce of embrittlement. In general,the welded joint is annealed afterwelding, to improve toughnessand reduce residual stresses. Incommon with other similar mi-crostructures, the weld metals cansuffer from two types of embrit-tlement. During annealing, whichtypically takes place at 690°C,carbides can precipitate on theprior austenite grain boundariesand this can lead to lower tough-ness. This is called irreversibleembrittlement, as it is difficult toremove the carbides. At lowertemperatures, typically 400-500°C,reversible embrittlement may oc-cur. This is due to the segregationof impurity elements, like phos-phorus, to the prior austenitegrain boundaries. This processmay take place either during slowcooling through the critical tem-perature regime or if the con-struction is operating at this tem-perature, as is common in theprocess industry, for example.

To prevent reversible embrit-tlement, it is important that thephosphorus content is reduced tothe absolute minimum. The de-gree of segregation and embrittle-ment is also influenced by otherelements and formulae have beendeveloped to help control thepermissible content of variouselements. The best-known of the-se formulae is the Bruscato X-factor (5).

For more demanding applica-tions, steels with higher alloyingcontents are used. The steel with

Alloy Minimum preheating Max interpass Post-weldtemperature °(C) temperature °(C) heat treatment (°C)

0.5 Mo 75 250 600-650(t > 15 mm) (t > 30 mm)

1Cr-0.5 Mo 100 300 650-750(t > 15 mm) (all thickness)

2.25Cr-1Mo 200 350 700-750(t > 15 mm) (all thickness)

9Cr-1 Mo 200 350 700-770(all thickness) (all thickness)

12Cr-1Mo 350 450 intercooling to 125-150(all thickness) PWHT 700-770

Table 2 Preheating, interpass and post-weld heat treatment temperatures for Cr-Mosteels. Based on draft for standard “Welding of ferritic steels”.

Nya Svetsaren 1, 1999. 1999-06-24 10.35 Sidan 8

Svetsaren No.1 1999 9

the highest alloying content inthis group is 12Cr-1Mo steel.However, most interest in recentyears has focused on steels withabout 9% chromium-1% molyb-denum, where large-scale devel-opments have taken place.

About 20 years ago, work be-gan in the US on the develop-ment of a steel of the 9Cr-1Motype, with high-temperature char-acteristics like those of a 12Cr-1Mo steel but far better weldabil-ity. Another aim was to be able toincrease the operating tempera-ture of power plants to around600°C, thereby significantly in-creasing efficiency. The modifica-tion from the original 9Cr-1Mosteel lies primarily in the additionof vanadium, niobium and nitro-gen. This modified steel has al-ready found a number of applica-tions, mainly in the form of pipes.

Developments in this field arerapid. There are suggestions fornew steel compositions, like 9Cr-2Mo, or to replace molybdenumwith tungsten. The aim here is

further to improve the creepproperties. These developmentswill call for the further develop-ment of weld metals. It is expect-ed that, if the 9Cr type of steelcontinues to increase, by beingused in the petrochemical indus-try, for example, this will be oneof the most intensive and inter-esting area of materials develop-ment in the years to come.

The weldability of Cr-Mo steelsis limited and weldability deteri-orates as the alloying content in-creases. Preheating and post-weldheat treatment are required tovarying degrees for many of thesteels. A summary of the recom-mendations for welding thesesteels is given in Table 2. For allsteels, consumables with matchingproperties (and often very similarchemistry) exist, for all the com-mon processes. Note that 12Cr-1Mo is an exception. This alloy isnot welded using high-productivi-ty methods. However, consum-ables for welding 9Cr-1Mo modi-fied steels are still being devel-

oped. Some of the characteristicsof these weld metals are detailedin the paper by E-L Bergqvist inthis issue.

Developments in stain-less steelThe use of stainless steels hasbeen increasing worldwide for along time and this trend is expect-ed to continue. Apart from thecommon grades, significant devel-opments have taken place when itcomes to new grades with im-proved characteristics (see Table3). Ferritic-austenitic duplex andsuperduplex, as well as superaus-tenitic steel, have been devel-oped. One of the important driv-ing forces behind the develop-ment of new stainless steel hasbeen the need to improve charac-teristics in chloride-containingenvironments. This harsh environ-ment gives rise to both pittingand stress corrosion cracking.

These types are now beingused in increasing tonnages in theoil and gas industry, in the pulpand paper industry, in other typesof process industry and in appli-cations such as chemical tankers,for example.

Information about some auste-nitic, duplex, superduplex andsuperaustenitic steels is given inTable 3.

The welding of stainless steel iswell established and a range ofconsumables suitable for all thecommon welding processes isavailable.

There is a fairly extensive rangeof consumables for welding du-plex steels using all the differentwelding processes. Representativeexamples are given in Table 4. Atthe present time, it appears thatthe development of the family ofduplex steels has slowed downand that modifications are beingmade to existing types rather thandeveloping new steels. The use ofduplex and super-duplex steelscan be expected to increase stead-ily in the years to come.

Duplex materials are especiallysuitable in environments wherethere is a risk of stress corrosioncracking — in other words, envi-ronments which frequently con-tain chloride. Even the highest-alloyed duplex steels are, howev-

Steel type Chemical composition (%) Tensile PREproperties (N/mm2)

C Cr Ni Mo N Others Rp0.2 Rm *)

AusteniticsASTM 304L 0.02 18.5 9.5 - - 205 520 19ASTM 316L 0.02 17.0 11.5 2.7 - 205 500 27UNS NO8904 0.01 20.0 25.0 4.5 - Cu 220 500 36

Super-austeniticsUNS S31254 0.01 20.0 18.0 6.2 0.20 Cu 300 650 43UNS S32654 0.01 24.2 17.9 7.2 0.45 Cu 430 750 55

DuplexUNS S31803/S32205 0.02 22 5.5 3.0 0.18 480 680 35

SuperduplexUNS S32750 0.02 25 7.0 4.0 0.28 540 780 42

*) PRE = %Cr + 3.3%Mo + 16%N

Consumables Weld metal chemical Tensile FN PRE Impact composition (%) properties toughness

(N/mm2) –60°C (J)

C Cr Ni Mo N Rp0.2 Rm

OK 67.55 0.03 22.0 9.0 3 0.17 645 800 30-45 35 65OK 68.55 0.03 25.5 9.5 4 0.25 700 900 30-50 43 45

Table 3. Examples of stainless steels, with typical compositions and properties.

Table 4 Duplex weld metals for MMA. The composition of the weld metals isrepresentative of other welding processes as well.

Nya Svetsaren 1, 1999. 1999-06-24 10.35 Sidan 9

10 Svetsaren No.1 1999

er, susceptible to crevice corro-sion in certain conditions (highertemperatures, de-aerated water,very high chloride content). Towithstand seawater environments,like the North Sea, with a chlo-ride content of around 21,000ppm, the steels need to be im-proved still further.

Alongside the development ofthe duplex and super-duplex, afamily of steels, known as super-austenitic steels, was developed.Some examples of these steels aregiven in Table 3. In typical cases,they contain around 20% chromi-um, 18% nickel, 6% molybdenumand 0.2% nitrogen. Chromiumand molybdenum produce excel-lent corrosion characteristics, whi-le nitrogen stabilises the austeniteand reduces the risk of sigmaphase formation during welding.The advantage of these steels isthat they have better ductility andimpact strength than the duplexand super-duplex steels. The yieldstress of super-austenitic steels is,however, lower than that of du-plex steels (of the order of 350MPa). The corrosion resistance ofthese super-austenitic steels ismore or less the same as that ofthe super-duplex steels, as isshown by the similar PRE values(Table 3).

In order to comply with ex-tremely rigorous corrosion re-quirements, the super-austeniticsteels have been improved stillfurther. Examples of steels withhigher PRE values include Alloy31 from VDM and 654 SMO fromAvestaSheffield. These materialsare generally included amongstainless steels, but they aresometimes on the borderline ofnickel-based alloys.

Super-austenitic steels are notwelded with consumables of thesame type, as it is not possible toobtain sufficiently high PRE val-ues with these weld metals. Theprincipal problems are caused bythe molybdenum content. Molyb-denum segregates heavily duringsolidification and the areas whichare poor in molybdenum have afar lower PRE value than theparent metal. Nor is it possible tocompensate for the molybdenumwith other alloying elements, asthis leads to a significant risk of

intermetallic phase precipitation.Consumables of the nickel-basetype are used to weld these steels.The most common type is Ni-21Cr 9 Mo 3 Nb, which is used formost welding processes. Potentialproblems with this compositionare hot cracking and the precipi-tation of intermetallic phases. Toavoid this, a low heat input andlow interpass temperature shouldbe used and dilution should berestricted. A better choice may beto use the recently developed al-loy Ni-23 Cr 16 Mo instead (6).

Very recently, the developmentof stainless steels for offshore ac-tivities has taken a different rou-te. For cost-saving reasons, anddue to increasing experience ofthe corrosion potential of the me-dia that are transported, there isan initiative to develop so-calledsuper-martensitic steels and weldmetals. These steels, which have arange of composition of around10-13 % Cr, 2-4% Ni and 0-6%Mo, all with an extremely lowcarbon content, are now the sub-ject of intensive research and de-velopment programmes. More in-formation on these steels is pre-sented in the paper by L Karlssonin this issue.

Another trend that has emer-ged relatively recently is the at-tempt to improve the weldabilityof steels at the lower end of thestainless steel range, namely steelwith a chrome content of around10-12 %. These steels are interest-ing for use in the transport sector.

The most popular method forwelding stainless steel is manualmetal arc, followed by MIG usingsolid wires. However, with solidwires, there is a greater risk ofweld defects, such as lack of fu-sion. Cored wires, which have re-cently been developed for manyof the common stainless steel gra-des, improve this situation signifi-cantly. Productivity is enhancedby about 30% and spatter is sig-nificantly reduced. Cored wireshave been developed for bothdownhand and out of positionwelding.

Developments in aluminiumAluminium is finding more wide-spread use in most engineering

structure segments. The new high-speed ferries for Stena Line bet-ween Sweden and Denmark andacross the Irish Sea are good ex-amples of the way aluminium isbeing utilised to obtain a lighterweight to permit either a higherload-carrying capacity or fasterspeeds. However, the use of alu-minium has also made it neces-sary to redesign the ferry con-struction.

The advantages of aluminiumas an engineering metal are obvi-ous; it is a light and yet compara-tively strong material, with rela-tively good corrosion. It is alsoenvironmentally-friendly, in thatit is recyclable. There are alsosome drawbacks to aluminium;the lower Young’s modulusmakes it less stiff, the high ther-mal expansion coefficient induceshandling problems during weld-ing and straightening operationsand large amounts of energy arerequired for the production ofraw aluminium.

The drawbacks to aluminiummentioned above, combined withother things, like the loss ofstrength in the heat affected zoneduring welding, are making de-sign and fabrication in aluminiumdifferent from that in steel.

The difference compared withsteel can be clearly seen whenwelding aluminium. At present,the principal technical problemsassociated with the welding of al-uminium are

solidification cracks in theweld metalliquation cracks in the heat af-fected zonepore formation andstrength reduction in the heataffected zone

Both solidification and liqua-tion cracks are thought to be duein the main to the occurrence ofintermetallic phases with a low-melting temperature at the grainboundaries. Alloys with a widesolidification range are the mostsusceptible to cracking. Thismeans that it is the hardenablealloys, to which zinc or copperhave been added, which are mostsusceptible to cracking. Some al-loys also contain lead, therebyincreasing the risk of cracking.Solidification cracks can beavoided by selecting silicon-

Nya Svetsaren 1, 1999. 1999-06-24 10.36 Sidan 10

Svetsaren No.1 1999 11

alloyed consumables. It has alsobeen demonstrated that silicon-alloyed consumables reduce therisk of liquation cracks in hard-enable Al-Mg-Si alloys, probablybecause the solidification tem-perature of the weld metal islower than that of the parentmetal and any cracks thereforehave time to heal before stress iscreated across the joint. In thesolid-solution strengthening al-loys, mainly alloyed with magne-sium, it is those with a low mag-nesium content that are the mostsusceptible to cracking. Howev-er, many alloys, in particular thenon-hardnable ones, but also thehardenable magnesium-siliconalloys, have very good weldabil-ity.

Pores in aluminium welds areusually caused by hydrogen frommoisture. There is a very greatdifference in the solubility of hy-drogen between the molten andthe solid state. So, when solidifi-cation of the weld metal occurs,there is large supersaturation ofhydrogen. The hydrogen is thenprecipitated as pores. To keep thepore formation to a minimum,the hydrogen content must beminimised. All sources of hydro-gen (i.e. the shielding gas, parentmetal and consumables) must beclosely controlled. Recent investi-gations (7) have shown that thematerial in the gas hoses has amajor influence on the moisturecontent. Hoses made from PVCor rubber give off moisture in lar-ge quantities and must be flushedwith gas for perhaps 10 minutesafter they have been idle forsome time. Hoses made from PEor PTFE have a much lowermoisture pick-up and the time forflushing can consequently be re-duced.

Higher heat input is anotherway to improve the situation, as itgives the hydrogen longer tomove out of the weld pool. How-ever, despite these actions, it isdifficult completely to suppresspore formation.

The reduction in strengtharound a weld in aluminium al-loys is inevitable, except for alloysin the untreated or room-tempe-rature-aged condition. This loss ofstrength is due to recovery andrecrystallisation in deformation-

hardened alloys and precipitationcoarsening and dissolution in age-hardened alloys. To compensatefor the strength reduction, severalstrategies are used. Most fre-quently, welds are placed in lowstress areas. Other methods in-clude locally increasing the thick-ness of material. Heat-treatablealloys can, in principle, be givenrenewed heat treatment (solutiontreatment and ageing) to restorethese properties, but this ap-proach naturally involves manypractical difficulties.

Aluminium is almost exclusive-ly welded using MIG or TIG.There is a wide range of consum-ables for welding aluminium, ei-ther pure aluminium or solidsolution-hardened alloys. Thewelding wires are mainly alloyedwith magnesium or, in the case ofcertain alloys, silicon. Modifica-tions to the Al-Mg-system aremade by adding manganese invarying amounts, to increase thestrength still further.

The addition of titanium or zir-conium, to act as grain refiners, isalso quite common. However, thedevelopment of new alloys forwelding wires is relatively slow,probably reflecting the demandfrom the market.

ConclusionsThe most important trends whenit comes to materials develop-ment and which will challenge thedevelopment of consumables are:

improved productivity forcommonly used steelsincreased use of steel with im-proved properties

For consumables, future develop-ments will focus on

tubular wires, for both structu-ral and stainless steelsnew consumables with im-proved high-temperaturecharacteristicsnew consumables with im-proved corrosion propertiesthe development of consum-ables with an even lower hy-drogen content, but also animproved understanding ofweld metal hydrogen crackingmechanisms

On the process side, the followingtrends are anticipated:

high-productivity systems

About the authorLars-Erik Svensson, PhD, is man-ager of the Esab Central Labora-tories in Gothenburg. He has wor-ked for more than 15 years withwelding metallurgy, focusing pri-marily on unalloyed and low-alloy-ed steels. He has published onebook and more than 25 papers onthe microstructure and propertiesof welds.

Johan Elvander, M. Sc, (Materialseng.) joined Esab AB in 1982 aftergraduating from The Royal Insti-tute of Technology in Stockholm.He started as development engi-neer for stick electrodes and nowholds a position as head of Re-search & Development, businessarea Consumables in Europe.

better software for processcontrolmore consumables suitable formechanisation

References1 Esab Environmental Report 1997

2 F. Rouvillian, High strength steel in amajor bridge construction over theGreat Belt Svetsaren, V 49, 1, p 15, 1995

3 H. Mabuchi, Recent progress in structu-ral steels for building and bridges, ISIJ,no 159, Feb 1996

4 A Backman, Development within mate-rials technology - Consumables in the21st century, Svetsaren, V 49, 1, p 4,1995

5 R Bruscato, Temper Embrittlement andCreep Embrittlement of 2 ºCr-1 MoShielded Metal-Arc Weld Deposits,Welding Journal, 49, p 148-s, 1970

6 L Karlsson, S L Andersson, S Rigdaland T Huhtala, New Ni-base consum-ables for welding of highly alloyedstainless steels, Proc Stainless steels ’96,Dusseldorf/Neuss, June 3-5, 1996

7 Aga AB, O Runnerstam, private com-munication

Nya Svetsaren 1, 1999. 1999-06-24 10.37 Sidan 11

12 Svetsaren No.1 1999

Close to 10 years of re-search and developmentare culminating in thefirst industrial productin the shape of theTHOR ArcWeld pro-duction system, a systemfor the automatic pro-gramming of welding robots, integrating theentire process from theimport of CAD data tothe execution of robotprograms.During the past year, the R&Dcompany AMROSE A/S inOdense in Denmark has beencollaborating with Ib AndresenIndustri A/S in Langeskov inDenmark in the EU projectknown as TOMATO. The aim of

the project has been to transferthe advanced robot technology(developed by AMROSE in closecollaboration with Odense SteelShipyard Ltd.) to other metal in-dustries.

The first working prototype ofa robotic production system con-trolled by AMROSE technologywas successfully built and in-stalled at Odense Steel ShipyardLtd. in 1994–95 and it is still beingused in the daily production ofship assemblies.

The TOMATO project has fo-cused on developing the userinterface and adapting the techni-cal functionalities in order to en-sure that the system meets thedemands imposed by companiesin the metal industry for a flex-ible production system.

An internal demonstration ofTHOR ArcWeld at Ib AndresenIndustri was scheduled for the

end of 1998 and AMROSE willbe ready to introduce the systemto the rest of the industry duringthe first half of 1999.

The robot works continuallyThe joint venture between thetwo companies in the TOMATOproject has resulted in the iden-tification of a series of technicalsuccess criteria for the introduc-tion of THOR ArcWeld at a man-ufacturing company.

The immediate advantage ofoff-line programming is that therobot can keep working, whilethe programming is handled onoffice computers.

With CAD data as the startingpoint, it is possible to generate ageometrical model of a work celland workpiece. Subsequently, acollision-free trajectory is calcu-lated for the welding robot in in-

by Charlotte Hybschmann Jacobsen and Michael Wehner Rasmussen,AMROSE A/S, Denmark

From prototype to integrated production system

Robot arc welding of industrial mixer at Ib Andresen Industri.

Nya Svetsaren 1, 1999. 1999-06-24 10.38 Sidan 12

Svetsaren No.1 1999 13

tegration with the workpiece ma-nipulator.

The fact that the programmingitself does not demand valuableon-line time makes the robot-wel-ding of small series profitable.Using sensory equipment, real-time corrections can be made tothe welding process, thereby en-suring high weld quality which inturn reduces the post-processingtime.

Finally, costs are minimized forexpensive precision fixtures whichare only made to compensate forthe traditional inability of robotsto compensate for the incorrectposition of the weld groove.

Customer’s own systemThe system has been developedwith a view to incorporating it inthe customer’s daily productionflow; from the construction de-partment to the shop floor.

It is important that the systemrequires as little individual adap-tation as possible—which is alsothe case when it comes to theinterface with the customer’sCAD and robot systems. The cus-tomer must be able to continueusing his own CAD system forthe design of the workpieceswhich are going to be welded. Atthe same time, THOR ArcWeldgenerates robot programs directlyfor the robot system, which thecustomer then uses in production.

The program is modular in de-sign and has an internal languagefor application developmentwhich ensures very simple adap-tation to different customers andapplications. The system is de-signed in such a way that it canwork with workpiece modelsfrom 90% of all “mid-range”CAD systems. In the same way,the system makes it possible togenerate robot programs for dif-ferent robot controllers (e.g. MO-TOMAN, CONOSS and HIRO-BO).

Joint, seam and runTHOR ArcWeld covers the entirecycle of operations for a work-piece — from 3D CAD drawings(which are imported into the sys-tem) to complete robot programswhich are executed through a sys-tem-integrated computer on the

shop floor. THOR ArcWeld alsocontains instructions for the robotoperator to mount workpieceparts during the production pro-cess, for example.

In THOR ArcWeld, any givenweld is split up into its individualelements: joint, seam and run.

Using these elements ensuresthe greatest possible control ofthe automation process. This re-sults in maximum flexibility in theadjustment of welding require-ments to different workpiecetypes. From heavy workpieces,such as a car lifting platform,which demand weld seams withhigh durability, to workpieces,such as industrial mixers, whichdemand visually high weld qual-ity. Using the CAD model as thestarting point, THOR ArcWeldautomatically identifies the fol-lowing three basic elements ofthe welds:

Joints between platesSeams which are placed onthe jointsRuns which make up theseams

The automatic process whichtakes the workpiece from onestep to another is based on custo-mer-defined rules which can sub-sequently be modified and adapt-ed as required.

Between each step of the auto-matic process, it is possible manu-ally to adjust data and therebydeviate from the set rules.

The user operates in a graphi-cal environment which displaysthe workpiece, the robot and thework cell, plus any positionersand fixtures. The user can contin-uously monitor the automaticprocess in the graphical windowand is able at all times to inter-vene with data adjustments.

The real worldOn the basis of actual workingprocedures at IAI, the followingcase illustrates the facilities ofTHOR ArcWeld.

The company receives an orderfor a number of items. Each itemconsists of both robot-welded pla-tes and plates which must be bentbefore being welded onto the al-ready welded parts of the item.

The construction departmentdraws the particular workpiece ina 3D CAD program, whereaftergeometrical data is imported intoTHOR ArcWeld.

The CAD model is enriched bywelding data which is indepen-dent from the place and methodof production (i.e. whether theworkpiece is welded manually orby a robot).

A so-called assembly tree isbuilt. The assembly tree specifiesthe order of assembly for the var-ious parts of the workpiece.

The user specifies joints be-tween plates; seams and runs arethen generated automatically.

The interaction of THOR

A view of the virtual robot work cell in THOR ArcWeld.

Nya Svetsaren 1, 1999. 1999-06-24 10.40 Sidan 13

14 Svetsaren No.1 1999

ArcWeld with a customer-adapt-ed process database may havespecified that outer corner jointsshould be welded vertically, ifpossible. From this information,the program calculates how thepositioner must move the work-piece between welding jobs withrespect to the overall weldingprocess.

Anchor points are specified.These must be taken into accountbefore the welding process is in-itiated. The anchor points aresubsequently converted intorobot-controlled sensings.

It is possible to enter noteswhich can be read on the shopfloor. An example of this is a notespecifying that one in every ten ofa certain type of weld mustundergo quality control. Thismessage will then appear on thecomputer screen on the shopfloor after every tenth executionof the welding program.

Further work with the work-piece is then transferred to therobot programmer.

The work cell in which theworkpiece is going to be weldedis then chosen. Apart from a ro-bot and its environment, the workcell also consists of a manipulatorand a fixture.

A task tree must be set up. Asopposed to the assembly tree,the job graph reflects the orderand type of tasks to be executedon the workpiece on the shopfloor. The jobs which make upthe job graph are very varied:from robot welding and sensingto messages to the work-cell op-

erator about the placement ofworkpiece parts and performingquality control.

In principle, THOR ArcWeldcan automatically translate thelist of weld seams into a completerobot program, but, in reality,some manual adjustment of theautomatically generated data isrequired.

When the robot programmer issatisfied, he releases the program.The workcell operator can nowdownload the program to therobot controller.

Before the robot is activated, itis possible to play back the simula-tion and thereby obtain a compre-hensive view of the entire process.

The workpiece is mounted asspecified on the computer screenand the robot program is started.

There is direct interaction bet-ween the system and the robotduring the entire production pro-cess.

The robot operator monitorsthe messages on his screen andthe robot automatically stopswhen a new workpiece part needsto be placed in the positioner.The robot does not start againuntil it is actively re-started.

Later versions will include areport tool in which various sta-tistical data, such as the numberof workpieces and welded metres,the welding speed and the num-ber of stops, will be collected andpresented in a report.

The maths insideA non-traditional mathematicalapproach, combined with inspi-

ration from the latest researchresults in the field of ArtificialPotential methods, led the AM-ROSE team to create a new andhighly-efficient robotics con-cept.

This new robotics concept in-cludes mathematical techniquesfrom the field of molecular dy-namics. In this case, mathematicalmodels enable the computationof the motion of atoms and mole-cules under the influence of at-tractive and repulsive forces.

Tweaking the formalism a lit-tle, the scientists turned the forcesacting between atoms in natureinto artificial forces, in a comput-er model which actively controlthe movements of robots.

The artificial forces are chosento encourage the robot to movetowards its target area and thereperform its task (e.g. weld), whileat the same time avoiding colli-sions between the robot, theworkpiece and the surroundings.The attractive forces can be visu-alised as rubber bands that dragthe robot towards its goal. In thesame way, the repulsive forcescan be seen as springs that pushthe robot away from obstacles inthe environment.

Artificial forces are not fullyadequate when high-precisioncontrol over the robot tool isneeded. In the THOR motioncomputations, the tool centrepoint is tied to a frame of refer-ence that moves according to thespecifications of the task. In thisway, the tool is dragged along bythe moving frame with the exactrequired (high-precision) motion.

About the authorsCharlotte Hybschmann Jacobsenhas a masters degree in molecularbiology. She is in charge of userinterface design and documenta-tion of the AMROSE products.

Michael Wehner Rasmussen has amasters degree in internationalmarketing, and he is responsiblefor the commercialisation of theadvanced robot technology deve-loped by AMROSE.

Principles from molecular dynamics are used to generate robot motion.

Nya Svetsaren 1, 1999. 1999-06-24 10.41 Sidan 14

Factorías Vulcano S.A,Vigo, is a medium size ship-yard in the north of Spainproducing an extensiverange of civil and maritimeproducts, including chemi-cal carriers in both carbonand duplex stainless steel.Currently, the yard is final-ising the construction ofThe Primo, a duplex chemi-cal tanker for the Swedishshipping company Initia.The fabrication, from theindoor panel lines down tothe final outdoor block assembly, is characterisedby wide scale use of ESABwelding solutions with a keyrole for ESAB OK Tubrodcored wires. This article reviews the production ofchemical tankers at Vulca-no. Special attention is focussed on the role ofFCAW.

AcknowledgementWe would like to thank FactoríasVulcano for their excellent co-operation in preparing this arti-cle. A special word of thank weaddress to Ramón Pérez Vázqu-ez, Production Manager, JesúsFernández Iglesias, Steel SupplyManager, and Javier Peréz, Weld-er Foreman. Their openness hascontributed greatly to this article.In addition, we compliment ourspanish Esab colleagues José LuisSastre, Carmen Herrero and JoséMaría Fernández Vidal on thegreat marketing success achievedat Factorías Vulcano.

IntroductionThe title “Welding duplex chemi-cal tankers the Esab way”, is per-haps a bit over-ambitious, but it isrightly chosen in the sense thatFactorías Vulcano apply ourwelding solutions in practicallyevery stage of the fabrication pro-cess of chemical tankers. Theshipyard has made intelligent useof ESAB’s capability to serve as atotal supplier for stainless steelfabrication, selecting dependableand productive consumable/equipment combinations forpractically all fabrication steps.The yard possesses a high level ofpractical welding knowledge, pro-viding a solid basis for, sometimesdifficult, but often fruitful techni-cal discussions between our com-panies. Over the years, the co-operation in developing and im-plementing new techniques hasdeveloped such that today we feelwe can rightfully claim that Esab’s mission statement to be“the preferred partner for weld-ing and cutting” is fully valid forthis shipyard.

This article presents a bird-eye-view on the fabrication of chemi-cal tankers in duplex stainlesssteel at Factorías Vulcano. Avoid-ing too much technical detail, itwill step by step discuss the fabri-cation process as well as theESAB welding solutions that havebecome established. The FCAWwith rutile cored wires is empha-sised, because it plays a key role inthe fabrication and because theseproducts are relatively new for du-plex stainless steel welding.

Factorías VulcanoStarting out with the repair ofrailway engines in 1919, FactoríasVulcano widened their capabil-ities to what they are today; a fullscale fabricator of civil and mari-time constructions. Today’s prod-uct range comprises civil engi-neering products like boilers, ma-rine fresh water generators, re-fuse incinerators and sewagetreatment plants, whereas theshipbuilding segment fabricatescontainer ships, refrigerated ves-sels and chemical carriers.

Svetsaren No.1 1999 15

Welding duplex chemical tankersthe ESAB way

Wide scale application of ESAB welding solutions atFactorías Vulcano S.A., Spain

By Ben Altemühl, Svetsaren editor, interviewing Factorías Vulcano production management.

Nya Svetsaren 1, 1999. 1999-06-24 10.42 Sidan 15

stainless steel assembly work in-volves the joints numbered 1,connecting the prefabricateddeck plates to construct the tankfloor. Here Factorías Vulcano ap-ply a combination of manualFCAW on ceramic backing stripfor single sided root passes andSAW for the filling layers. ESABOK Tubrod 14.37 has been select-ed as the FCAW consumable, be-cause of its capabilities for down-hand work. With it’s slow freez-ing, fluid slag, it is designed toweld at high travel speed givinghigh productivity (Figure 3). Itgives good penetration and, afterslag removal, the back side of theroot requires no grinding orbrushing. The ceramic backingstrips to be used with this productrequire a rectangular groove toaccommodate the slag and to pro-mote a good bead appearance.OK 14.37 is welded in 85%Ar/15%CO2 gas protection, a mix-ture applied at Factorías Vulcanofor all FCAW (stainless and car-bon steel). Here, and for all otherFCAW, the yard uses simplisticrectifiers without the need forpulsing.

SAW filling is done with theESAB wire/flux combination OK16.86/OK Flux 10.93, a combina-tion widely applied in duplexstainless steel fabrication, andwith an excellent reputation. Theflux is a low-hydrogen, non-alloy-ing, basic agglomerated type(AWS: SA AF 2 DC). OK Autrod16.86 is of the 23Cr-9Ni-3Mo typealloyed with 0.15%N to obtain aweld metal with sufficiently over-matching mechanical properties, agood austenite/ferrite balance,and excellent corrosion resistancewhen welding standard UNS

In 1990 the company com-menced a three year plan to re-structure and modernise the ship-yard, involving a 1200M Pesetasinvestment. What results today isa modern medium-size shipyardwith advanced FORANCAD/CAM design facilities, anESAB NUMOREX NXB9000under water plasma cutting instal-lation connected to the CAD/CAM system. Also, a panel fabri-cation line with two ESAB A6-LAE1250-TAC1000 submergedarc welding machines, mechan-ised welding stations for stiffenerattachment and various systemsfor mechanised SAW and FCAWapplied in sub-assembly and finalassembly. The yard lay-out guar-antees an efficient flow of workthrough production. Along withthe modernisation, the yard im-plemented the ISO 9001 qualityassurance system. Together withan orderbook of specialised pro-jects that reaches well into thenext century, the yard is well posi-tioned to compete in today’s de-manding market.

Construction of chemi-cal tankers at FactoríasVulcanoAlthough fabricated out of twocompletely different base materi-als, carbon steel and duplex stain-less steel, the construction of

chemical tankers at Factorías Vul-cano takes place according to es-tablished, modern shipbuildingpractices involving panel fabrica-tion, the construction of sub-sec-tions, the assembly of block sec-tions, and the final connecting ofblock sections in the dock. Weshall focus on the role of duplexstainless steel cored wires. Sincethese are applied primarily in thedock assembly, we describe thefabrication of The Primo in re-versed order.

Figure 1 gives a schematic viewof a 16000DWT chemical carrierfrequently built by Vulcano, andvery much resembling the Primo.The vessel has 12 tanks in duplexstainless steel and two small tanksserving for storage of cleaningwaste. Parts in duplex stainlesssteel are highlighted in red. Verti-cal assembly welds are indicatedwith yellow dots.

Figure 2 shows the Primosomewhere half way during theassembly of the chemical cargotanks. Prefabricated sections arehighlighted with individualcolours and all assembly weldsare visualised by yellow lines,numbered 1 to 9, and described inthe margin.

For a good understanding ofthe construction, we recommendto first have a look at Figure 4. Itshows the next block section tobe assembled, comprising a decksection and tank assembly, thecorrugated bulkheads. As such, itwill be turned and placed in theconstruction. The yellow lines inFigure 2 may, therefore, indicateready welds or welds to be madewhen the next block section hasbeen positioned.

The first step in the duplex

16 Svetsaren No.1 1999

Figure 1: Top-side view of a chemical tanker with 12 duplexstainless steel tanks. Yellow dots in the magnification representvertical assembly welds.

Figure 3: Root pass in deck joint withOK Tubrod 14.37 seen from above.

Nya Svetsaren 1, 1999. 1999-06-24 10.45 Sidan 16

S31803 types of duplex stainlesssteel. Vulcano use ESAB A2 Mul-titrac SAW machines, guided byrails attached parallel to thejoints. The same machine-consu-mable solution is used all overthe yard, providing a dependablewelding method in many produc-tion steps (see later).

The same method as describedfor the tank floors is used for theconnection of the tank floor tothe carbon steel hull of the bot-tom (2), be it with 309L typewelding consumables. The flux-cored wire for welding the root pass on ceramic strip is OK Tubrod 14.22, also a rutiletype for all positional use, where-as the wire/flux combination applied for filling is OK Autrod16.53/OK Flux 10.93.

The next assembly step in-volves the placement of the twoside wall sections to the bottomof the vessel where first the car-bon steel parts are connected, fol-lowed by weld type number 3between subsequent block sec-tions. Basically, this is the sametype of joint as between the cor-rugated bulkheads (6), but weld-ed with a slight angle. It is a V-joint welded vertically-up, manu-ally or mechanised with rail-trackequipment, with OK Tubrod

14.27. This rutile cored wire withfast freezing slag system is by farthe most productive solution formaking these kinds of assemblywelds, with deposition rates thatreach up to 3kg/h. Single-sidedroot passes are again made on ce-ramic backing strips with a rec-tangular groove

Assembly welds type 4 and 5connect the tank walls to the tankfloor. Both types are treated assemi-positional welds, primarilyperformed with FCAW. Rootpasses are welded on rectangularceramic strips in the case of weld4 and on cylindric ceramics in thecase of weld 5. The back side ofweld 5 has poor accessibility dueto the geometry of the construc-tion. SMAW with ESAB OK67.50, an established acid- rutileelectrode for standard duplexgrades, was found to provide themost practical and secure solutionfor sealing the root.

The next fabrication step con-cerns the placement of the thirdprefabricated block section com-prising a deck section and a crossof longitudinal and transversetank walls; the corrugated bulk-heads. This section can be seenisolated, and upside down, in Fig-ure 4. The prefabrication of thiscomponent will be described later.

After turning and positioning

this section between the sidewalls of the ship, a number of as-sembly welds remain to be made.

Assembly welds type number 6are the ones indicated with yel-low dots in figure 1. They connectthe corrugated longitudinal bulk-head with the previous tank sec-tion, and the transverse bulk-heads with the corrugated partsattached perpendicular to theside walls. The welding methodand consumable used are exactlythe same as described for weldtype number 3 (OK Tubrod14.27), but the welding position istruly vertical-up.

To obtain optimal weldingeconomy, Factorias Vulcano applymechanised welding with railtrack systems for the filler layers.Figure 5 shows a typical exampleof a vertical assembly weld madein this way. Deposition ratesamount to 3kg/h when calculatedat 100% duty cycle, which is high-ly productive for this kind of un-avoidable assembly welds.

Assembly weld 7, between cor-rugated bulkheads and the tankfloor, is carried out manually, be-cause the geometry of the joint istoo complicated to allow mechan-isation (Figure 6). Moreover, theroot gap may show misalign-ments, requiring the welder tomanually build-up the root with avarying number of beads. OK Tubrod 14.27 proves to be a ver-satile and dependable consum-able for this kind of demandingwork. Root passes are made al-most twice as fast as with stickelectrodes, using cylindrical ce-ramic backing, with excellent ab-lity to compensate for misalign-ment of the joint.

Svetsaren No.1 1999 17

Figure 4: Fabrication of a block section consisting of a tank cover with verticalcorrugated walls in duplex stainless steel.

Figure 5: Vertical weld between corru-gated tank walls; mechanised weldedwith OK Tubrod 14.27

Nya Svetsaren 1, 1999. 1999-06-24 10.46 Sidan 17

Connection between corrugated bulkheads and tank floor

Position: PC/2GRoot: FCAW with OK Tubrod 14.27,manually welded onto cylindricceramic backing.Filling: FCAW with OK Tubrod 14.27,welded manually.

18 Svetsaren No.1 1999

1

Figure 2: Principal dock assembly welds in d

Tank floor frompre-fabricated plates.

Position: PA/1GRoot & 1st pass: FCAW with OKTubrod 14.37, welded manually ontoceramic backing strip.Filling: SAW with OK Autrod 16.86/OK Flux 10.93

4 Connection between verticaltank wall and angled side wall

Position: PC/2GRoot: FCAW withOK Tubrod 14.27,welded manuallyonto ceramicbacking strip.Filling: FCAW withOK Tubrod 14.27,welded manually .

3

6

Connection between corrugated bulkheads andbetween tank side walls

Position: PF/3GRoot: FCAW with OK Tubrod 14.27,welded manually onto ceramicbacking stripFilling: FCAW with OK Tubrod 14.27,welded manually.

72 Connection between tank floor and carbon steel hull

Position: PA/1GRoot & 1st pass: FCAW with OKTubrod 14.22, welded manually ontoceramic backing strip.Filling: SAW with OK Autrod 16.53/OK Flux 10.93

5 Connection between angled side wall and tank floor

Position: PC/2GMulti-layer T-joint; full penetration.FCAW with OK Tubrod 14.27,manually.Sealing: SMAW with OK67.50

1

2

3

3

6

5

74

89

9

9

Nya Svetsaren 1, 1999. 1999-06-24 10.55 Sidan 18

Connection between corrugated bulkheads and tankcover

Position: PC/2GRoot: FCAW with OK Tubrod 14.27,manually welded onto cylindricceramic backing.Filling: FCAW with OK Tubrod 14.27,welded manually.

elds in duplex stainless steel

8

9 Connection between tank cover and between tank covers and side walls

Position: PA/1GRoot & 1st pass: FCAW with OKTubrod 14.37, manually welded ontoceramic backing strip.Filling: FCAW with OK Tubrod 14.37

3

4

Assembly weld 8, connecting asmall, extending part of the cor-rugated bulkhead to the deck ofthe subsequent tank section, isdone in a semi-overhead positionwith exactly the same weldingprocedure. OK Tubrod 14.27 isone of the best cored wires avail-able for overhead work, becausethe stiff, fast freezing slag pre-vents sagging of the weld metal.

The last step in the assemblyprocess involves the connectionof the tank cover (weld type 9).This is done in the downhand po-sition with OK Tubrod 14.37(root passes on rectangular ce-ramic backing strips.

SubassemblyGoing back to Figure 4, it can beseen that this prefabricated blocksection consists of two major parts;the tank cover and a cross of twocorrugated bulkheads placed per-pendicular to the tank cover.

Starting with the tank top, it isclear that it is composed of a great number of plates. The smallyellow lines represent weldsmade indoor on the panel lines(described later) to form thepanels out of which the deck iscomposed. The thick yellow lines

are the pre-assembly welds con-necting the panels to form thetank cover. They are made ac-cording to exactly the same weld-ing procedure as described forthe tank floor in Figure 2 (weldtype 1). FCAW is used for theroot and first pass (OK Tubrod14.37 on rectangular ceramicbacking strip) and SAW (OK Au-trod16.86/ OK Flux 10.93) is usedfor filling and capping.

The sketch of Figure 7 de-scribes the basic component ofthe corrugated bulkheads. Assuch, they are supplied by thesteel fabricator, bent to the rightgeometry with welds connectingthe three areas of increasing platethickness. To form a completelongitudinal bulkhead nine weldsare required. Figure 8 shows thefabrication of these welds. Againthe combination of OK Tubrod14.37 on ceramic backing for theroot pass and OK Autrod 16.86/OK Flux 10.93 is applied for thefilling layers.

Two pre-assembly welds re-main to form the block section.The transverse corrugated bulk-heads are connected to the longi-tudinal ones by means of K-jointswelded mechanised in vertical-up

Figure 6: Attachment of a vertical corrugated tank wall to the tank floor; manuallywith OK Tubrod 14.27 (PC position).

Plate thickness

24 mm 15 mm18 mm

19Svetsaren No.1 1999

Figure 7: Corrugated wall segment as purchased from the steel works.

Nya Svetsaren 1, 1999. 1999-06-24 11.08 Sidan 19

position with OK Tubrod 14.27using cylindrical ceramic backingto allow fast root pass deposition.The cross of bulkheads created inthis way is attached to the tankcover in PB position with OK Tu-brod 14.27 using the same weld-ing procedure as applied in thedock assembly for weld type 7.

Panel fabricationPanel fabrication is carried out in-doors on a panel fabrication linewith two ESAB A6-LAE1250-TAC1000 submerged arc weldingmachines. Panels for the tankfloor, the tank cover and for theside walls of the tanks are all pre-fabricated according to the samewelding procedure. The number ofplates comprising a panel varies.

At the moment of our visit,there was no duplex fabricationin progress, so we describe the

welding procedure by means ofthe sketch in figure 9a. Duplexplates are bevelled to a Y-jointwith a land of 4mm and posi-tioned on the panel line with aminimal root gap. To avoid con-tamination of the duplex materi-al, AISI 316L plates are placedbetween the duplex plates andthe carbon steel rollers of thepanel line.

SAW with OK Autrod 16.86and OK Flux 10.93 is applied forthe complete joint. The first layeris carried out with a tandem sys-tem; the two filling layers withsingle-wire SAW. After completingthe above, the panels are turnedand sealed with single wire SAW.

At this moment, Factorias Vul-cano are experimenting with anew ESAB solution aiming atsingle-sided welding of the pan-els, which would provide a sub-

20 Svetsaren No.1 1999

The ESAB OK Tubrod series of cored wires for standardduplex stainless steel consist of an all-position type, OK Tubrod 14.27 and one for downhand use, OK Tubrod 14.37.They provide fabricators with optimal welding characteris-tics and productivity for manual or mechanised welding.

OK Tubrod 14.27 is a very versatile consumable, suitedfor truly all welding positions, including pipe welding incombination with the TIG process for rooting. Very fastvertical-down welding of fillet welds is possible for partsthat allow to be attached without secure root penetration.Many fabricators standardise on this type only, when themajority of the work involves positional welding.

Both types have very clear advantages compared withMMA and GMAW, reviewed below.

Advantages over MMA• higher productivity in general due to higher duty cycle• productivity for positional welding almost 3 times

higher through increased deposition rates• very economic deposition of root passes, with less

welder skill needed• no stub-end waste and therefore higher efficiency

Advantages over GMAW• up to 150% higher productivity in positional welding• excellent performance with conventional power sour-

ces; no expensive pulsed arc equipment needed.• use of normal 80%Ar/20%CO2 shielding gas; use of

expensive high Ar mixtures is avoided. Fabricatorshave an option to standardise on one gas when weld-ing both unalloyed and stainless steels.

• less oxydation of weld surface due to protective action of slag

• no grinding or sealing needed for the back side of rootpasses

• easy parameter setting

ESAB OK Tubrod rutile cored wires for duplex stainless steel

Product dataClassifications

AWS A5.22: OK Tubrod 14.27 E2209T1-1/E2209T1-4OK Tubrod 14.37 E2209T0-1/E2209T0-4

ApprovalsOK Tubrod 14.27 ABS, Controlas, DNV, GL, LR,

RINA, TÜV OK Tubrod 14.37 DNV, GL, LR, TÜV

All weld metal composition (weight %)OK Tubrod 14.27 OK Tubrod 14.37C: ≤0.03 C: ≤0.03Si: 0.50-0.90 Si: 0.60-1.00Mn: 0.50-1.00 Mn: 0.70-1.20Cr: 21.0-23.0 Cr: 21.0-23.0Ni: 8.0-10.0 Ni: 8.0-11.0Mo: 2.75-3.25 Mo: 2.75-3.25N: 0.11-0.17 N: 0.10-0.16P: ≤0.025 P: ≤0.035S: ≤0.025 S: ≤0.025

FN: 30-50 FN: 30-50

Mechanical properties in Ar/CO2OK Tubrod 14.27 14.37

Rp0.2% (MPa) ≥500 ≥480Rm (MPa) ≥690 ≥690A5d (%) ≥25 ≥25ISO-V –20°C (J) ≥60 ≥40

Shielding gas: Ar/CO2 or CO2

Polarity: DC+

stantial time saving. Successfultests have been carried out with abacking rail filled with fine grainOK Flux 10.93 enabling to depos-it a good quality root pass that re-quires no sealing (Figure 9b). Ap-plication of this system, however,requires an investment in stain-less steel rollers, because it doesnot allow protection of the du-plex material in the way utilisedpresently. The feasibility studyhas not yet been completed.