WARRANTY TRUSTED FOR OVER FOR LIFE 25 YEARS...Plastic Repair Contouring Tape to the back of the...

Transcript of WARRANTY TRUSTED FOR OVER FOR LIFE 25 YEARS...Plastic Repair Contouring Tape to the back of the...

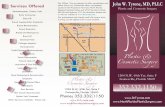

DMB1214

SEALERSPLASTIC REPAIR SOUND DAMPENINGADHESIVES

DMC0416

PARTS & LABOR WARRANTYFOR LIFE SEE DETAILS ON BACK COVER

TRUSTED FOR OVER 25 YEARS

Working Time: 30 MinClamp Time: 2 HrCure Time: 24 HrHeat Cure Time: 1 HrResin Base: Epoxy

39337 Door Skin &SMC AdhesiveA two-component epoxy that quickly bonds any combination of steel, aluminum, fi berglass and SMC.

Working Time: 1 HrClamp Time: 3 HrCure Time: 24 HrHeat Cure Time: 1 HrResin Base: Acrylic

39537 Weld-Bond AdhesiveA non-sag, two-component acrylic adhesive system formulated to bond metal surfaces without the use of an external primer.

Working Time: 10 MinClamp Time: 20 MinCure Time: 30 MinHeat Cure Time: 15 MinResin Base: Acrylic

39897 Patch Panel AdhesiveA two-component, acrylic adhesive for quickly bonding metal panels without the use of an external primer.

ADHESIVES

Working Time: 90 MinClamp Time: 4 HrCure Time: 24 HrHeat Cure Time: 1 HrResin Base: Epoxy

39747 Multi-Purpose Panel AdhesiveA two-component epoxy for panel bonding any combination of steel, aluminum, SMC and fi berglass.

Urethanes, acrylics and epoxies for large and small applications.

• Roof Skins• Door Skins• Applique Panels• Quarter Panels

• Non-sag formula• Excellent corrosion

protection• Bonds multiple

substrates• Long shelf life

• Exceptional impact and peel strength

• Includes glass beads for consistent bond line thickness

• Long working time

• Exceptional impact and peel strength

• Non-sag formula• Quick cure time• Excellent corrosion

resistance

• Long working time• Exceptional impact

and peel strength• Excellent corrosion

resistance• Includes glass beads

for consistent bond line thickness

• Non-sag formula

40207 (7 OZ.) 40202 (1.7 OZ.) Quick Set 20A fast, two-component, opaque, urethane adhesive designed for automotive plastic repair and bonding most small plastic, metal and aluminum parts.

Working Time: 15 SecSet Time: 20 SecCure Time: 15 Min Resin Base: Urethane

• High strength and sandable

• Bonds multiple substrates

• Non-sag formula fi lls gaps

• Colorless• Super fast setting

Working Time: 7 MinSand Time: 15 MinTop Coat Time: 20 MinCure Time: 1 Hr

39847 Multi-PlasticRepair MaterialA two-component epoxy for fast repairs on virtually all plastic bumper covers.

Working Time: 3 MinClamp Time: 7 MinCure Time: 1 HrHeat Cure Time: 15 MinResin Base: Epoxy

39907Non-Sag Fast Set AdhesiveA two-component, epoxy-based adhesive for fast bonds on most surfaces.

PLASTIC REPAIR

Working Time: 5 MinSand Time: 15 MinTop Coat Time: 20 MinCure Time: 1 Hr

39767 Problem PlasticRepair MaterialA two-component, epoxy-based fi ller for repairing olefi n-based plastics and similar rigid and semi-rigid substrates, and SMC.

Working Time: 45 SecSet Time: 50 SecCure Time: 15 MinResin Base: Urethane

40507 (7 OZ.)40502 (1.7 OZ.) Quick Set 50A fast, two-component, black, urethane adhesive designed for automotive plastic repair and bonding most small plastic, metal and aluminum parts.

For repairing fl exible, semi-rigid & rigid plastics with ease.

• Bumper Covers• Interior Plastics• Molded Body Panels

• No adhesion promoter required

• Exceptional sanding and feather edging

• Remains fl exible• Does not shrink or

pinhole• Excellent leveling and

sag resistance

• Superior adhesion• Ideal working time• Bonds multiple

substrates

• No adhesion promoter required

• Superior adhesion• Excellent sanding

and feather edging• Does not shrink or

pinhole• Zero VOC

• High strength and sandable

• Bonds multiple substrates

• Non-sag formula fi lls gaps

Working Time: 3 MinSet Time: 30 MinCure Time: 24 HrResin Base: Urethane

41807 Quick Set 180A general purpose, black adhesive designed for repairing and bonding most plastic, steel, aluminum, glass, SMC and fi berglass parts.

• High strength and sandable

• Bonds multiple substrates

• Non-sag formula fi lls gaps

• Extended 3 minute working time

SEALERS

Working Time: 10 MinSet Time: 15 MinTop Coat Time: 0 MinCure Time: 1 Hr

39377 Seam SealerA two-component, gray, epoxy sealer for sealing interior or exterior seams, joints and voids.

Working Time: 10 MinSet Time: 15 MinTop Coat Time: 30 MinCure Time: 1 Hr

39387 Self LevelingSeam SealerA two-component, epoxy-based, fl owable sealer for use on drip rails, roof and trunk seams.

39477, 40377 & 40477 are not covered under the Dual-Mix Forever Warranty

Working Time: 10 MinSet Time: 15 MinTop Coat Time: 0 MinCure Time: 1 Hr

39477 Beige Seam SealerA two-component epoxy for sealing interior or exterior seams, joints and voids.

Working Time: 10 MinSet Time: 15 MinTop Coat Time: 30 MinCure Time: 1 Hr

39777 High-Build Self Leveling Seam SealerA two-component, controlled fl ow epoxy ideal for use on roof seams, drip rails and trunk seams.

Working Time: 10 MinSet Time: 15 MinTop Coat Time: 0 MinCure Time: 1 Hr

40377 Heavy Bodied Black Seam SealerA high viscosity, two-component epoxy for use on interior or exterior seams, joints and voids.

Flexible sealers that restore OEM appearance while preventing corrosion.

• Roof Skins• Door Skins• Strut Towers• Floor Pans• Fender Wells• Body Pans / Trunk Areas

• Direct to metal• Paintable

immediately*• Excellent adhesion to

bare metal or primed surfaces

• Will not shrink, harden or crack

• Duplicates OEM sealers

• Direct to metal on non-fl exing roof skins

• Excellent self leveling properties

• Flows into crevices• Will not shrink, harden

or crack• Permanently fl exible

• Direct to metal• Paintable

immediately*• Excellent adhesion to

bare metal or primed surfaces

• Will not shrink, harden or crack

• Duplicates OEM sealers

• Direct to metal on non-fl exing roof skins

• Will not shrink, harden or crack

• Permanently fl exible

• Direct to metal• Paintable

immediately*• Holds tool marks

during working time• Non-sag formula• Excellent adhesion

* Paintable immediately with most solvent based paint systems.

* Paintable immediately with most solvent based paint systems.

* Paintable immediately with most solvent based paint systems.

IM

ME D I AT E LY

PAINTABLE

IM

ME D I AT E LY

PAINTABLE

IM

ME D I AT E LY

PAINTABLE

IM

ME D I AT E LY

PAINTABLE

IM

ME D I AT E LY

PAINTABLE

Working Time: 1 HrSet Time: 1 HrCure Time: 1 Hr

39977 Panel Vibration Control MaterialA two-component epoxy and urethane blend for reducing noise and vibration on roof, quarter and door skins.

Working Time: 10 MinSet Time: 15 MinTop Coat Time: 30 MinCure Time: 1 Hr

40477 Heavy Bodied White Seam SealerA high viscosity, two-component epoxy for use on interior or exterior seams, joints and voids.

SOUND DAMPENING

Working Time: 45 SecSet Time: 5 MinTop Coat Time: 15 Min

39997 Rigid Urethane FoamA two-component, urethane, expanding rigid foam for fi lling pillars, posts, and box sections.

Working Time: 10 MinSet Time: 15 MinTop Coat Time: 30 MinCure Time: 1 Hr

40977 Sound & Seal Sprayable CoatingA sprayable epoxy and urethane blend for replacing OEM coatings under rocker panels, in trunks, and on fl oor sections and frame rails.

• OEM recommended• Excellent sag

resistance • Reduces noise

and vibration • Protects against

corrosion • Superior fl exibility

• Direct to metal• Paintable

immediately*• Holds tool marks

during working time• Non-sag formula• Excellent adhesion

• Meets UL 94HB fl ammability tests

• Restores crash parts to OEM condition

• Superior expansion• Reinforces

weak panels• Fast cure

• Will not shrink, harden or crack

• Remains fl exible• Excellent adhesion

to properly prepped surfaces

• Paintable in 30 min

• Excellent sound dampening qualities

• Stops panel fl utter • 10x volume expansion• Does not require

moisture to cure • Will not distort panels• Resists shrinking

Working Time: 15 SecSet Time: 2 MinTop Coat Time: 15 Min

39357Flexible Urethane FoamA two-component, urethane, expanding fl exible foam that stops vibration and dampens sound in most voids.

Reduces noise and vibrations and matches OEM textures.

• Roof Bows• Hoods• Door Intrusion Beams• Rocker Panels / Floor Pans• Quarter Panels• Body Pans / Trunk Areas• Deck Lids• Filler Necks

* Paintable immediately with most solvent based paint systems.

IM

ME D I AT E LY

PAINTABLE

CLEAN & PREP

Clean front and back with Scuff & Clean.

Clean front and back with Plastic & Leather Prep or Zero VOC Surface Cleaner.

SAND & GROOVE

Sand with 80 grit sandpaper.

Using a grinder, dish out damaged area with 36 grit disc at a low RPM.

Grind back of repair area with a 36 grit disc at a low RPM.

REINFORCE & FILL

Reinforce large holes and cracks by applying Plastic Repair Contouring Tape to the back of the repair. Spread a layer of Dual-Mix Multi-Plastic Repair Material to cover all of the tape.

Fill the front side repair with Dual-Mix Multi-Plastic Repair Material. Spread material fi rmly and build up higher than panel to allow for sanding.

1 32

SAND & SKIM

Sand Dual-Mix Multi-Plastic Repair Material with 80 grit sandpaper. Then fi nish with 180 grit sandpaper.

If needed, use a skim coat of Bumper BiteTM Flexible Glazing Putty.

Sand with 180 grit paper, and fi nish with 320 grit paper.

PREP & PRIME

Clean with Plastic & Leather Prep. Dry with a lint-free cloth.

Prime with Flexible Primer Surfacer, High Build Primer Surfacer or World ClassTM Waterborne Flexible Primer.

GUIDE COAT BLACK

Apply Guide Coat Black to dried primer.

4 65

SAND

Sand with 320 – 400 grit sandpaper.

Finish sanding with 600 grit sandpaper.

TEXTURIZE

If texture is needed, apply Texture Coating in light coats.

If texture is not needed, skip to step 9.

PAINT

SEM Bumper CoaterTM and Factory PackTM aerosols are available in many OEM Colors.

7 98 OPTIONAL

DUAL-MIXTM PLASTIC REPAIR

19013+ Factory Pack 16 oz. Aerosol38203 Guide Coat Black 16 oz. Aerosol38331 Scuff & Clean Gallon38338 Scuff & Clean Pint38351 Plastic & Leather Prep Gallon38353 Plastic & Leather Prep 16 oz. Aerosol38354 Plastic & Leather Prep Cone Top Quart39023+ Bumper Coater Aerosols 16 oz. Aerosol39131 Flexible Primer Surfacer Gallon39133 Flexible Primer Surfacer 16 oz. Aerosol

39134 Flexible Primer Surfacer Quart39847 Dual-Mix Multi-Plastic Repair Material 7 oz. Cartridge39853 Texture Coating 20 oz. Aerosol39854 Texture Coating Quart40401 Zero VOC Surface Cleaner Gallon40404 Zero VOC Surface Cleaner Quart40482 Bumper Bite Flexible Glazing Putty 16 oz.Tube42003+ High Build Primer Surfacer 20 oz. Aerosol50184 World ClassTM Waterborne Flexible Primer Quart70007 Plastic Repair Contouring Tape Tape 15’ roll

PRODUCT LIST

TRACE OUTLINE

Using Plastic Repair Contouring Tape, cut enough to fold around both sides of the tab.

A Sharpie® can be used to duplicate broken or missing tabs.

4

FINISH

With a grinder, shape the tab back to its original shape and size.

Re-drill the bolt hole and the job is complete.

6

APPLY QUICK SET

After purging the cartridge, apply Dual-Mix Quick Set 20 to the Plastic Repair Contouring Tape. While wet, fold the tape around torn or missing tab.

After cool down, remove tape.

5

DUAL-MIXTM PLASTIC TAB REPAIR Learn more procedures at www.semproducts.com

AFTERBEFORE

CLEAN & PREP

Clean with Scuff & Clean and a gray scuff pad.

Rinse with water and dry.

Clean with Plastic & Leather Prep wiping in one direction with a clean, lint-free towel.

GRIND

Grind repair area on low RPM or by hand with 36 grit grinding disc.

Drill 1/8" holes around repair area to help “lock in” the repair material.

Blow off and re-clean repair area with Plastic & Leather Prep.

ADHESION PROMOTER

Apply XXX Adhesion Promoter or Plastic Adhesion Promoter per directions to TPO, PP and other similar thermoplastics.

321

38331 Scuff & Clean Gallon38338 Scuff & Clean Pint38351 Plastic & Leather Prep Gallon38353 Plastic & Leather Prep 16 oz. Aerosol38354 Plastic & Leather Prep Cone Top Quart39861 Plastic Adhesion Promoter Gallon39863 Plastic Adhesion Promoter 20 oz. Aerosol39864 Plastic Adhesion Promoter Cone Quart40202 Dual-Mix Quick Set 20 1.7 oz. Cartridge40207 Dual-Mix Quick Set 20 7 oz. Cartridge

70007 Plastic Repair Contouring Tape Tape 15’ roll77721 XXX Adhesion Promoter Gallon77723 XXX Adhesion Promoter 16 oz. Aerosol77724 XXX Adhesion Promoter Cone Quart

PRODUCT LIST

DUAL-MIXTM BONDING & RIVET BONDING

PREPARATION

Remove spot welds with a spot weld cutter; remove rivets by drilling or grinding.

Remove damaged panel and straighten bent fl anges with a hammer and dolly.

DRY FIT

Dry fi t all panels before applying adhesive to ensure proper alignment and clearance.

While dry fi tting the panel during rivet bonding process, drill holes for replacement rivets or mark the location of self-piercing rivets per manufacturer’s instructions.

CLEAN

Clean surfaces to be bonded with SEM Solve or Zero VOC Surface Cleaner per directions.

1 32

GRIND

Grind mating fl anges with a 36 grit grinding disc at low speed to keep marks. Remove any adhesive or protective coating, such as paint, e-coat or galvanized coating.

If rivet bonding, some manufacturers may recommend leaving the OEM e-coat on the surface of the new panel. If so, omit grinding and scuff with a red scuff pad.

RE-CLEAN

Blow off and re-clean surfaces with SEM Solve or Zero VOC Surface Cleaner, if necessary. Always use lint-free towels when cleaning surfaces to avoid particle contamination. Bonding surfaces should be clean, dry and free of debris.

EQUALIZE

Equalize cartridge of Multi-Purpose Panel Adhesive or Weld-Bond Adhesive by dispensing product until both parts fl ow evenly. Install Static Mixer.

Purge a small amount of material to ensure proper mix.

Cut tip to desired size.

4 65

APPLICATION

Apply a 3/8" – 1/2" bead of Multi-Purpose Panel Adhesive or Weld-Bond Adhesive to both bonding surfaces and tool with a spreader or acid brush, covering all exposed bare metal.

Use enough material to completely fi ll the joint when parts are clamped.

BONDING

Clamp panel into place. Wipe away excess material. Do not over clamp.

To assure maximum bond strength, surfaces must be mated within the adhesive’s working time.

RIVET BONDING

Clamp panel into place. Install rivets per manufacturer’s recommendations during adhesive’s working time.

Clamps may be removed after rivets have been installed.

Wipe away excess material.

OPTION 2OPTION 1

38371 SEM Solve Gallon38373 SEM Solve 20 oz. Aerosol38374 SEM Solve Quart39537 Weld-Bond Adhesive 7 oz. Cartridge39747 Multi-Purpose Panel Adhesive 7 oz. Cartridge39847 Multi-Plastic Repair Material 7 oz. Cartridge40401 Zero VOC Surface Cleaner Gallon

40404 Zero VOC Surface Cleaner Quart70011 Integral Nut Square Static Mixers 6 Pack70012 Integral Nut Square Static Mixers 50 Pack

PRODUCT LIST

7 8 8

2K SEAM SEALING Learn more procedures at www.semproducts.com

CLEAN & PREP

Clean joints and seams thoroughly with SEM Solve or Zero VOC Surface Cleaner.

SAND & RE-CLEAN

Bare Metal: Sand bare metal with 80 grit sandpaper.

Primed Surface: Sand primed surface with 400 grit sandpaper or gray scuff pad. Re-clean with SEM Solve or Zero VOC Surface Cleaner.

Blow off and tack clean to remove dust.

3

EQUALIZE & APPLY

Equalize seam sealer cartridge by dispensing product until both parts fl ow evenly. Purge a small amount of material to ensure proper mix.

Install Static Mixer. Cut tip to size.

Apply seam sealer.

DTM OR PRIMER

SEM 2K seam sealers can be applied direct-to-metal over epoxy primer or 2K urethane primers.

Always apply over a primer when fi lling drip rails. Never apply over a self etching primer.

INVERTED SURFACES

Use Dual-Mix High-Build Self Leveling Seam Sealer with a Versa-Tip where a thicker viscosity is needed.

When dispensing allow product to fl ow. Keep tip submerged to minimize air bubbles.

AIR BUBBLE REMOVAL

A heat gun can be used immediately after application to remove any air bubbles that become entrapped. With a steady motion, sweep the heat gun across surface of a self leveling seam sealer at a distance of 2" – 6".

PAINTING

All SEM Seam Sealers are sandable and paintable in 30 minutes at 70°. Scuff with a gray scuff pad prior to priming or painting.

38371 SEM Solve Gallon38373 SEM Solve 20 oz. Aerosol38374 SEM Solve Square Quart39377 Seam Sealer 7 oz. Cartridge39387 Self Leveling Seam Sealer 7 oz. Cartridge39477 Beige Seam Sealer 7 oz. Cartridge39777 High-Build Self Leveling Seam Sealer 7 oz. Cartridge

40377 Heavy Bodied Black Seam Sealer 7 oz. Cartridge40401 Zero VOC Surface Cleaner Gallon40404 Zero VOC Surface Cleaner Quart40477 Heavy Bodied White Seam Sealer 7 oz. Cartridge70011 Integral Nut Square Static Mixer 6 Pack70012 Integral Nut Square Static Mixer 50 Pack70070 Versa-Tip Kit 6 Pack

STANDARD SEAM SEALERS

SELF LEVELING SEAM SEALERS

SEAM SEALER ACCESSORIES

39377Seam Sealer(Gray)

39477BeigeSeam Sealer

40377HeavyBodiedBlackSeam Sealer

40477HeavyBodiedWhiteSeam Sealer

39387SelfLevelingSeamSealer

39777High-BuildSelfLevelingSeamSealer

A Versa-Tip can be used to dispense sealers into wide channels or seams.

Acid brushes may be used to achieve a brushed look.

Spreaders or Versa-Tips can be notched with hole punchers or pinking shears to reproduce OEM appearances.

PRODUCT LIST

1 2

USE ONLY WITH• 39377 Seam Sealer• 39477 Beige Seam Sealer• 40377 Heavy Bodied Black Seam Sealer• 40477 Heavy Bodied White Seam Sealer• 40977 Sound & Seal Sprayable Coating

USE FORTrunks, Doors, Wheel Wells, Etc.

QUICK SPRAY SYSTEM (FOR DUPLICATING OEM TEXTURES)

Clean surface thoroughly with 38373 SEM Solve or 40401 Zero VOC Surface Cleaner.

Sand primed surface with 180 grit sandpaper or sand bare metal surface with 80 grit sandpaper. Blow off and tack clean. Re-clean with SEM Solve or Zero VOC Surface Cleaner. Do not apply 40977 Sound & Seal Sprayable Coating over a self etching primer or a sealer.

Place cartridge into applicator gun and equalize cartridge until both sides dispense equally. Attach 70103 Quick Spray System Static Mixer to cartridge. Attach 70100 Quick Spray System. Do not cut the tip of the static mixer. Modify the air pressure to adjust the spray.

Apply to necessary areas, duplicating existing texture. There is no need to apply in coats.

1 2 3 4

70104 Adapter AssemblyQuantity: 1

70106 Air Baffl eQuantity: 5

70103 Static MixersQuantity: 6

70101 Round Air AssemblyQuantity: 1

70102 Flat Air AssemblyQuantity: 1

A B C D

Our Quick Spray System allows users to duplicate OEM seam sealer textures while utilizing the 2K technology of SEM Seam Sealers.

NOTE70039 Universal Pneumatic Applicator is not included in the 70100 kit. Only use the Quick Spray System with specified SEM products.

A

CB

D

70011 (6 Pack) 70012 (50 Pack)Integral Nut Square Static Mixers

The Integral Nut Square Static Mixers ensure proper mix ratios for the 7 oz. Dual-Mix cartridges.

A sturdy applicator for DIYers and pros alike. It dispenses material quickly and consistently and it’s easy to use because of its ergonomic design. It accepts 2:1 and 1:1 cartridges.

71119 Universal ManualApplicator

70039 Universal Pneumatic Applicator

This applicator is a must-have in body shops. It delivers material quickly and consistently. The lightweight and balanced design means less fatigue for the technician. It accepts 2:1 and 1:1 cartridges.

70070 (6 Pack)Versa-Tip

Versa-Tips allow you to duplicate OEM sealers. Cut them to dispense product from 0.5" – 1.5" wide.

70103 (6 Pack)Quick Spray System StaticMixers

Quick Spray System Static Mixers ensure proper mix ratios. Use with the Quick Spray System.

7 OZ. APPLICATORS & ACCESSORIES

These mixers ensure proper mix ratios for 1.7 oz. Dual-Mix cartridges.

70020 (6 Pack)70021 (50 Pack)1.7 oz. TurboMixers

This is an easy loading applicator for dispensing 1.7 oz. Dual-Mix cartridges. Material is dispensed quickly and consistently.quickly and consistently.

70019 1.7 oz Manual Applicator

1.7 OZ. ACCESSORIES (40202 QUICK SET 20 & 40502 QUICK SET 50)

SEM Products, Inc. 1685 Overview Dr. Rock Hill, SC 29730

WEBSITE

Visit our website for product info,

Technical and Safety Data sheets

semproducts.com

Find us on Facebook to get great tips

facebook.com/semproducts

HOURS

MON – THURS8 a.m. – 5 p.m. EST

FRI8 a.m. – 4:30 p.m. EST

PHONE

TECH SUPPORT 1-800-831-1122

CUSTOMER CARE 1-866-327-7829

TECH SUPPORT [email protected]

CUSTOMER CARE cust_care@

semproducts.com

LEARN AUTOMOTIVE REPAIR & REFINISHING TECHNIQUES

Stay ahead of the competition by learning about the latest automotive refi nishing techniques at SEM School. It’s available for FREE twice a year to professionals who use or sell SEM products.

GET CERTIFIED BY SEM FOR I-CARLEARN MORE & SIGN UP AT

semproducts.com/sem-school

AVAILABLE FOR QUALIFIED COLLISION CENTERS

We’d be happy to meet you for free at your shop. We can demo products, train and answer any

questions. These sessions can be tailored to your needs and anyone is welcome to attend.

CONTACT TECH SUPPORTFOR MORE INFORMATION

800-831-1122

In-Shop Training

When used according to directions, SEM guarantees to the purchaser that all Dual-Mix products will perform to specifi cations forever. This warranty covers reasonable costs for labor, loss of use of the vehicle, parts and materi-als only, and excludes consequential or incidental damages.

MADE IN THE USA