W >EE /E' Z WKZd r^ d/KE ðXñò WW >/ d/KE dK DK /&z íôïlõï ...

Transcript of W >EE /E' Z WKZd r^ d/KE ðXñò WW >/ d/KE dK DK /&z íôïlõï ...

PLANNING REPORT - SECTION 4.56 APPLICATION TO MODIFY DA183/93 - REDBANK POWER STATION Land and Environment Court Proceedings 2021/00128111 Prepared for

VERDANT TECHNOLOGIES AUSTRALIA 10 August 2021

1

Page 1

URBIS STAFF RESPONSIBLE FOR THIS REPORT WERE:

Director Clare Brown

Project Code P0035055

Report Number FINAL

Urbis acknowledges the important contribution that Aboriginal and Torres Strait Islander people make in creating a strong and vibrant Australian society. We acknowledge, in each of our offices, the Traditional Owners on whose land we stand.

All information supplied to Urbis in order to conduct this research has been treated in the strictest confidence. It shall only be used in this context and shall not be made available to third parties without client authorisation. Confidential information has been stored securely and data provided by respondents, as well as their identity, has been treated in the strictest confidence and all assurance given to respondents have been and shall be fulfilled. © Urbis Pty Ltd 50 105 256 228 All Rights Reserved. No material may be reproduced without prior permission. You must read the important disclaimer appearing within the body of this report. urbis.com.au

2

Page 2

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

CONTENTS

1. Introduction ....................................................................................................................................... 1 1.1. Overview .............................................................................................................................. 1 1.2. Expert Witness Code of Conduct ......................................................................................... 1 1.3. Information Relied On In Preparing this Report ................................................................... 1

2. the Site and Locality ......................................................................................................................... 2 2.1. The Site ................................................................................................................................ 2 2.2. Surrounding context ............................................................................................................. 2

3. The Proposal ...................................................................................................................................... 4 3.1. The Consent ........................................................................................................................ 4 3.2. Redbank Power Station ....................................................................................................... 4 3.3. The Proposed Modifications ................................................................................................ 5

3.3.1. Addition of Biomass as a Fuel Source ................................................................. 5 3.3.2. Modifications to the Operations and Plant..........................................................11 3.3.3. Modifications to the Consent ..............................................................................12 3.3.4. Substantially the Same Development ................................................................13

4. Updated Impact Assessments .......................................................................................................18 4.1. Transport ............................................................................................................................18 4.2. Operational Traffic Management Plan ...............................................................................20 4.3. Air Quality ..........................................................................................................................20 4.4. Greenhouse Gas Emissions ..............................................................................................21 4.5. Stormwater .........................................................................................................................22 4.6. Acoustic .............................................................................................................................22

5. Project Benefits ...............................................................................................................................23

6. Conclusion .......................................................................................................................................24

Disclaimer ........................................................................................................................................................25

Appendix A CV – Clare Brown Appendix B Site Survey Appendix C Power Station Site Layout

FIGURES

Figure 1 - The Site ............................................................................................................................................. 2

Figure 2 - Regional Context ............................................................................................................................... 3

Figure 3 – Power Station viewed from the south ............................................................................................... 5

Figure 4 - Existing site access points .............................................................................................................. 18

TABLES

Table 1 - Summary of Project Modifications .................................................................................................... 14

3

Page 3

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX INTRODUCTION 1

1. INTRODUCTION 1.1. OVERVIEW An application under section 4.56 of the Environmental Planning and Assessment Act 1979 (EP&A Act) was submitted to Singleton Council (the Council) seeking the modification of the development consent granted to DA183/93 (the consent). The applicant, Hunter Development Brokerage Pty Ltd (the Applicant) filed an appeal to the Land and Environment Court of NSW against the deemed refusal of the modification application, Land and Environment Court Proceedings 2021/00128111 (the proceedings). The modification application sought to modify the terms of the consent for the construction and operation of the Redbank Power Station.

This Planning Report has been prepared to provide a summary of the modification application including additional information and updated environmental assessments prepared following the section 34 Conference held on 22 July 2021. This Planning Report and referenced technical reports and plans also seek to address the contentions filed by the Council in the proceedings.

1.2. EXPERT WITNESS CODE OF CONDUCT I have read, understood and agree to be bound by the Expert Witness Code of Conduct in the Uniform Civil Procedure 2005 Rules (Code of Conduct).

I have prepared this report in accordance with my obligations as an expert witness under the Code of Conduct. I have made all inquiries which I believe are appropriate (save for matters identified in my report). There are no matters of significance which I regard as relevant that have been withheld from the Court.

A copy of my curriculum vitae detailing my qualifications and experience is Appendix A to this Planning Report.

1.3. INFORMATION RELIED ON IN PREPARING THIS REPORT This Planning Report has considered where relevant following documents:

1. Site Layout Plan – Biomass Unload and Storage Area by HDB numbered 21017 Revision B dated 29 July 2021

2. Redbank Power Station Plant Biomass Conversion Drawing by B&PPS numbered C12181-000-100 Rev A, C12181-000-111 Rev A, C12181-000-112 Rev A, C12181-000-113 Rev A, and C12181-000-114 Rev A

3. Site Plan by Alstom numbered 80034-001-M-GA-000-5001 A0 and 80034-025-M-GA-000-9176 A1 4. B&PPS Biomass Handling Plant Concept Study (C12156-03) dated 18 June 2021 5. Redbank QA/QC Supply Chain and Material Handling dated 11 August 2021 6. Noise Impact Assessment by Muller Acoustics Consulting dated 11 August 2021 7. Stormwater Management Plan Report by RGH Consulting Group dated July 2021 8. Air Quality Impact Assessment by EMM dated 9 August 2021 9. Transport Assessment by Ason Group dated 10 August 2021 10. Operational Traffic Management Plan by Ason Group dated 10 August 2021 11. Sustainable Biomass Energy Survey by Verdant dated 16 July 2021 12. Relevant legislation and guidelines

5

Page 5

2 THE SITE AND LOCALITY

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

2. THE SITE AND LOCALITY 2.1. THE SITE The Redbank Power Station is located at 112 Long Point Road West Warkworth (the site) . The legal property description of the site is Lot 450 DP1119428. The site is located in the Singleton local government area (LGA).

The location of the site is shown in Figure 1 below and its regional context in Figure 2. A survey of the site is included in Appendix B.

Figure 1 - The Site

Source: Google Maps

The site has an area of 18.03 hectares and is zoned RU1 Primary Production under Singleton local environmental plan 2013 (the LEP). The site is located to the north of the Golden Highway/Jerry’s Plains Road and vehicle access into the site is from Long Point Road.

2.2. SURROUNDING CONTEXT The site is located within the Hunter Valley to the west of Singleton township and surrounding suburbs. To the north, northwest and south are a number of open cut and underground coal mines.

The broader locality also supports a range of agricultural activities, industrial service facilities including those at Mt Thorley to the south of the site and the Singleton Army base to the south-east of the site.

6

Page 6

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE SITE AND LO 3

Figure 2 - Regional Context

Source: Google Maps

7

Page 7

4 THE PROPOSAL

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

3. THE PROPOSAL 3.1. THE CONSENT On 27 March 1997 the Land and Environment Court issued Orders in Proceedings 10217 of 1994 (Greenpeace Australia Limited v Redbank Power Company Pty Limited and ANOR) permitting an appeal for the modification of the development consent of 10 November 1994 subject to the imposition of 45 conditions (noting that conditions numbered 17 and 40 were deleted).

Order 2 stated that:

Development consent is granted to the construction and operation of a power plant on land being part lots 1-3 DP 247820 and lots 4-5 DP 247820 at Long Point Road and Jerrys Plains Road, Warkworth, and to the construction and operation of ancillary tailing collection, preparation and transportation facilities and ancillary water and ash transportation facilities on adjacent land including land within consolidated coal lease 753 as specified in development application No. 183/93 as modified in the information contained in the prepared statements of Roy Alper and Thor Hibbler of February 1997, and subject to the conditions annexed hereto and marked “A”.

The consent when read together with the referenced documents requires the Redbank Power Station (Power Station) operator to source the majority of its fuel as coal tailings from the Warkworth Mine located approximately 7km (via road) to the south of the site. The consent permits road haulage of fuel to the site based on certain upgrades to the road network being undertaken. These upgrades were completed prior to the operation of the Power Station commencing in 2001.

When operational (between 2001 and 2014) the predominate fuel used was coal tailings which was delivered to the site primarily via conveyor direct from the Warkworth mine and run of mine coal which was used as a backup fuel. The conveyor which transported the fuel is still in-situ and available for the transport of coal based fuel as may be required. The circled area on Figure 3 below indicates the area around the culvert which carries the original overland conveyor from the Warkworth Mine.

3.2. REDBANK POWER STATION The Power Station was constructed over a 14-month period in 2000/2001, with the Power Station commencing operation in October 2001. The Power Station was in continual service until October 2014.

The major features of the Power Station include:

(a) a nominal rating at Maximum Continuous Rating (MCR) of 146 megawatts (MWe) (gross) with an overload capacity of 151 MWe gross.

(b) The existing Redbank Power station is equipped with Fines Circulating fluidised bed combustion technology (FiCirc®1) which was developed to operate with a wide range of fuel such as coal tailings, biomass and other such fuels. The plant is currently configured to handle beneficiated dewatered tailings (BDT) as its main fuel and run of mine (ROM) coal an alternative back up fuel. The layout of the Power Station is shown in the site layout plan at Appendix B.

(c) When in operation, the site generally operated 24 hours a day, seven days per week. There were typically two shifts over this period, starting at 6 am and 6 pm.

The Power Station has been in care and maintenance mode since October 2014 and Verdant Energy are planning to restart the plant in 2021 drawing on either BDT and RoM coal or alternatively biomass.

The FiCirc® fluidised bed combustion system installed in the Power Station could be considered the best available technology for a power station seeking the flexibility to operate on a variety of fuel types such as BDT and biomass.

8

Page 8

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE PROPOSAL 5

Figure 3 – Power Station viewed from the south

Source: BPPS 2021

3.3. THE PROPOSED MODIFICATIONS

3.3.1. Addition of Biomass as a Fuel Source

OVERVIEW

The development as proposed to be modified will introduce biomass as a fuel source. This will comprise quality fuels that are considered residual materials in forestry operations, sawmilling and from urban sources (e.g., timber manufacturing) to provide a new sustainable fuel source for the power Station.

The Power Station’s FiCirc® fluidised bed combustion system is designed to operate with a wide range of fuels such as coal tailings and biomass fuels. Investigations by BPPS have been performed to scope minor changes to the fuel delivery and handling systems with in the Power Station to enable the plant to receive biomass fuels that have been fully prepared, tested and validated for storage and use as an alternate and additional fuel in the plant.

The use of waste biomass from sustainable forestry to generate energy is widely accepted at state, federal and international level. It is recognised as a tool in the transition towards a net zero carbon emissions future and is supported by:

(a) the Intergovernmental Panel on Climate Change (IPCC)

(b) the International Energy Agency (IEA)

(c) the Federal Government

(d) the Australian Renewable Energy Agency (ARENA), a Federal Government agency.

(e) The NSW EPA and the NSW Department of Industry (DPI).

The National Greenhouse Accounts Factors state the emission factor for CO2 released from the biogenic carbon fuels is zero. This is in accordance with the position of the IPCC. The reason for this is, in simple terms, that the carbon emissions from the combustion of biomass from sustainable forestry are offset by the carbon capture from the regenerating biomass within the managed forestry system.

9

Page 9

6 THE PROPOSAL

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

FUEL SOURCES

Eligible Waste Fuels

The NSW EPA Eligible Waste Fuels Guidelines (the Guidelines) identify eligible waste fuels suitable for use in a facility that proposes to thermally treat waste or a waste-derived material.

The Guidelines identify that

Eligible waste fuels are those the EPA considers to pose a low risk of harm to the environment and human health due to their origin, composition and consistency. These are listed in this part and in Section 3 of the NSW Energy from Waste Policy Statement. The EPA may update the list of eligible waste fuels from time to time. Facilities proposing to use eligible waste fuels must meet the following criteria: 1. be able to demonstrate to the EPA that the proposed waste consistently meets the definition of an EPA approved eligible waste fuel

2. ensure there are no practical, higher order reuse opportunities for the waste

3. fully characterise the waste and/or undertake proof of performance (where required), and

4. meet the relevant emission standards as set out in the Clean Air Regulation.

The listing of a waste or waste-derived material as an eligible waste fuel does not constitute an approval to use that material at a particular facility. Proponents must first apply to the EPA for a resource recovery order and exemption in accordance with Part 4 of these guidelines.

Relevant to the proposed modifications to the consent Section 3 of the NSW Energy from Waste Policy Statement lists the wastes categorised by the EPA as eligible waste fuels. For convenience the relevant definitions and categorisations are provided as follows:

1. Biomass from agriculture

Definition

Weeds, plant or crop residues that are free of any physical contaminants, produced directly from agricultural practices; for example, non-putrescible natural organic fibrous materials and organic residues from harvest activities. These residues may include fibres, roots, stalks, stubble, leaves, seed pods, nut shells and some waste from agricultural processing such as cotton and cane trash.

2. Forestry and sawmilling residues

Definition

Uncontaminated, organic fibrous wood residues and natural wood wastes that result from forestry and sawmilling operations such as, heads, tree thinnings, sawmill sawdust, shavings, chips, bark and other offcuts.

Sawmilling operations are the primary processing of round wood into non-round wood products such as planks, boards, beams and other cut and processed wood products.

Additional information

Forestry and sawmill residue materials must be demonstrated to have no risk of contamination; for example, there must be no presence of treated, preserved, lacquered, glued, laminated or coated timber or wood products.

Native forest biomaterial is specifically prohibited from use for electricity generation in accordance with the Protection of the Environment Operations (General) Regulation 2009. The Regulation exempts some native forest residues from forestry operations authorised by a private native forestry property vegetation plan, integrated forestry operations approval or an invasive native species order.

Native forest biomaterial

The use of native forest biomaterial for electricity generation is regulated through the Protection of the Environment Operations (General) Regulation 2009, clauses 96 to 98. These

10

Page 10

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE PROPOSAL 7

clauses expressly prohibit the use of native forest biomaterials in electricity generation, but also provide exemptions for certain types of native vegetation or woody waste from the definition of native forest biomaterials.

The material exempted from the definition is able to be burned for the purpose of electricity generation. Native forestry biomaterial can be used in electricity generation if it is:

▪ invasive native species cleared in accordance with property vegetation plans that have been approved under the Native Vegetation Act 2003 or an invasive native species order under the Native Vegetation Regulation 2013

▪ pulp wood logs and heads and off-cuts from clearing carried out in accordance with a private native forestry property vegetation plan or forestry operations carried out in accordance with an integrated forestry operations approval under the Forestry Act 2012

▪ trees cleared as a result of thinning carried out in accordance with a private native forestry property vegetation plan or an integrated forestry operations approval.

3. Uncontaminated wood waste

Definition

Wood waste that is generated in primary and secondary manufacturing processes at facilities with demonstrated quality control over the uncontaminated wood waste stream.

Additional information

Uncontaminated wood waste includes pre-consumer manufacturing and processing waste materials such as off-cuts, saw dust, wood shavings, untreated packaging crates, untreated pallets and engineered timbers made with urea formaldehyde or phenol formaldehyde resins only….

Uncontaminated wood waste does not include wood waste recovered from highly variable streams, such as mixed municipal solid waste or construction and demolition waste, due to their potential to contain a large number of chemical and physical contaminants over time. Applicants wanting to pursue the use of this material as a fuel should refer to Section 4, Energy recovery facilities, of the NSW Energy from Waste Policy Statement.

Treated timber means wood treated with water, solvent and/or oil-borne preservatives. This includes but is not limited to copper chromium arsenic (CCA), light organic solvent preservative (LOSP), creosote and envelope treatments for preservation, insecticides and fungal treatments.

While the Guideline identifies other forms of Eligible waste such as:

▪ Recovered waste oil,

▪ Organic residues from virgin paper pulp activities,

▪ Landfill gas and biogas, and

▪ Tyres

the relevant treatment required by these other eligible waste fuels cannot be accommodated under the current operations of the Power Station. Verdant Earth, the proposed operator of the Power Plant has identified sources of eligible biomass feedstocks to utilise as an alternative biomass fuel for supplying heat to the boiler to operate the Power Plant. The sources are located across New South Wales as described in the Redbank QA/QC Supply Chain and Material Handling Report dated 9 August 2021 (Supply Chain Report).

FUEL TYPES

The following fuel types are proposed.

BIOMASS

The proposed biomass fuel for electricity generation proposed to be introduced as an additional fuel source to that presently approved include the following which are consistent with the Eligible Waste Fuel Guidelines and the Protection of the Environment Operations (General) Regulation 2009:

11

Page 11

8 THE PROPOSAL

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

▪ pulp wood logs and heads and off-cuts from clearing carried out in accordance with a private native forestry property vegetation plan or forestry operations carried out in accordance with an integrated forestry operations approval under Part 5B of Part A of the Forestry Act 2012;

▪ trees cleared as a result of thinning carried out in accordance with a private native forestry property vegetation plan or an integrated forestry operations approval;

▪ sawdust or other sawmill waste;

▪ uncontaminated wood waste includes pre-consumer manufacturing and processing waste materials such as off-cuts, saw dust, wood shavings, untreated packaging crates, untreated pallets and engineered timbers made with urea formaldehyde or phenol formaldehyde resins only; and

▪ biomass from agriculture being weeds, plant or crop residues that are free of any physical contaminants, produced directly from agricultural practices.

Note that the use of any Eligible Waste Fuel requires an application to the EPA for a Resource Recovery Order and Exemption under the Protection of the Environment (Waste) Regulation 2014. This application would allow a full and separate assessment and approval of the use of any waste fuels, including any fuels approved as Eligible Waste Fuels in the future. The use would also require variation of the Environment Protection Licence for the facility. Any different impacts, or minor variation to conditions relating to receival, storage and use, could be considered as part of that assessment.

While these fuel sources are available across New South Wales the preference is to source the biomass material within generally a 300 km radius of the site that comply with the NSW EPA’s Eligible Waste Fuel Guidelines (EPA Guidelines) and clauses 96, 97 and 98 of the Protection of the Environment Operations (General) Regulation 2009 (in relation to the use of native forestry biomass for electricity generation) (the POEO Regulations):

The DPI North Coast Residues: A project undertaken as part of the 2023 North Coast Forestry Project 2017 report (DPI Report) has identified that there is an estimated one million tonnes of available eligible waste fuels from forestry and sawmill residues in the North Coast region of New South Wales. In addition to this it is estimated that there is a further two million tonnes of available residues per annum from harvesting of private native plantation operations that are otherwise left and burnt in mass in-situ.

The DPI Report estimated that produced sawmill residues (green) were estimated to range between 46,000 tonnes/year from around Bulahdelah to 118,000 tonnes/year for facilities around Kempsey (100 km radius). Green offcuts represented approximately 68% of the total volume of green residues produced.

The Supply Chain Report (page 6) identifies that:

▪ Further residues are available to Verdant Earth and estimated at minimum 500,000 tonnes per annum through land clearance, bushfire zoning and other activities carried out in accordance with an integrated approval under the Forestry Act 2012

▪ Verdant Earth staff have been working with recognised producers of boiler fuels and woodchip manufactures across the industry and have signed MOU’s to supply with eligible fuels.

▪ It is important to note that the woody waste biomass feedstock materials will be recovered from forestry and sawmill sites in many parts of regional NSW. Verdant Earth is working with key companies that operate within the industry to establish centralised manufacturing facilities with in a 300km radius of the Power Station to process the materials to the required Redbank specification in accordance with the Specific Resource Recovery Order issued by the EPA (post approval). Suppliers may or are likely to vary and change from year to year as market conditions dictate.

The biomass from forestry operations that meet the EPA Guidelines, POEO Regulations and operational specifications will be transported directly to the Power Station. It is proposed that the biomass will be sized reduced and stockpiled at locations in the forest compartment in accordance with existing approved management plans. Stockpiles will be sampled, tested for compliance with the Specific Resource Recovery Order and then bulk transported to the Power Station.

12

Page 12

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE PROPOSAL 9

While the Regulation permits the use of pulp wood logs it is noted that such logs would be those that meet the relevant specification and regulatory provisions. Uncontaminated waste wood would be sourced from manufacturers of wood products truss and pallet manufacturers and laminated beams amongst others that have a large volume of off cuts.

Uncontaminated wood waste that will be sourced for fuel at the Power Station will be from primary and secondary manufacturing processes with demonstrated quality control over the uncontaminated waste stream. Uncontaminated wood waste does not include:

▪ Post-consumer waste;

▪ Wood waste extracted from the mixed waste streams, such as construction and demolition waste.

The Supply Chain Report estimates that approximately 70% of the biomass to be sourced for the plant can be obtained from approved forestry residues, 15% from sawmill operations and 15% from uncontaminated wood wastes by weight.

Biomass delivered to the site will meet the operational specification meaning that no processing of the material including grinding, screening or sorting will be required to be undertaken on site.

COAL TAILINGS AND RUN OF MINE COAL

While the proposed modifications to the plant and equipment within the Power Station facilitate the use of biomass as a fuel source the changes are minor and will not preclude the Power Station from burning coal products as has historically occurred on site.

The Power Station will retain the ability to use coal tailings as a fuel. This material will not be blended or co-fired with biomass. If the plant after using biomass as fuel chooses to use coal tailings, all biomass in the approved storage location will be fully utilised, and the area cleared before coal tailings are then introduced.

While there are minor modification to the plant and equipment required as described below to enable the use of biomass as a fuel source it is expected that no changes to the plant will be required to re-commence the use of coal tailings. Operational controls of the plant can be adjusted to ensure that the fuel / air mixing ratios are maximised for plant efficiency in accordance with approved operational conditions.

SUPPLEMENTAL AND START-UP FUELS

As provided for in the original EIS (sections 2.5 and 2.6) it will be necessary to keep a store of supplemental and start up fuels on site for circumstances where unexpected conditions arise or when start up after a maintenance or other shut down is required.

This was provided for in the terms of condition 16 as granted and this is retained under this proposed modification.

QUALITY CONTROLS

Quality controls measures will be implemented at the source site as well as when loads are received at the Power Station in order to establish an auditable chain of custody. This process will be implemented for all suppliers to the Power Station and will include the following actions as detailed in the Supply Chain Report:

▪ Each vehicle load of feedstock despatched from the supplier’s facility will be assigned a transport certificate

▪ On arrival at the site each load will be weighed over a weighbridge and the relevant data recorded

▪ Each month a reconciliation will be made between the supply facility delivery data and the arrival data received at the site to confirm a match-up of delivered and received loads.

▪ At least one vehicle load of feed stock per supply facility will be visually inspected by suitably trained Verdant Energy staff each day where deliveries are received, and a grab sample collected.

▪ The visual check is to confirm, as far as practicable, that prohibited materials are not included in the load.

13

Page 13

10 THE PROPOSAL

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

▪ The grab sample will be checked for grading and moisture content in a small laboratory on site.

▪ Only deliveries of feed stock from approved suppliers carrying the necessary transport certificate and evidence of compliance with site specific Resource Recovery Order will be permitted to discharged into the feed stock storage and handling system on site.

▪ A register of pre-approved delivery vehicles will be maintained on site and only pre-approved vehicles will be permitted to weigh-in on site.

▪ All delivery drivers will be required to successfully complete the relevant site safety and operations induction to weigh-in and discharge feed stock on site.

▪ On arrival of a load of feed stock to the site the transport certificate will be checked prior to the biomass being discharged into the feed stock storage and handling system. Automatic interlocks or barrier systems will be installed to prevent discharge without prior authorisation.

▪ Records of daily inspections will be maintained at the site.

▪ In the case where the feedstock is rejected the vehicle will be directed to a dedicated quarantine area, the source facility will be notified, and the load will be directed to return to the supplier. Records of disputed/rejected loads will be included in a reject loads register which is stored on site.

▪ The point of discharge of feed stock from the delivery vehicle into the feed stock storage and handling system will be monitored by video camera and the image will be displayed in the central control room located on site. Where discharged loads are observed or suspected to contain prohibited materials, this material will be transferred to a designated quarantine area until the suspect material has been checked and approved by site personnel.

▪ Vacant storage capacity will be maintained within the feed stock storage area to cater for the storage of up to 200 m3 of quarantined feed stock.

Sampling protocols to be implemented in the supply chain will be carried out in accordance with the sampling and testing protocol in Appendix 1 of the Supply Chain Report.

In addition to the site specific quality assurance mechanism designed for the proposed operations it will be necessary that the Power Station keep the records required under the POEO Regulation and the Guidelines for the Burning of Bio-material - Record-keeping Requirements for Electricity Generating Facilities (2013).

RESIDUAL ASH MANAGEMENT

The burning of waste woody biomass in the Power Station will produce a residual ash of approximately 3%-5% of the feedstock. Utilising the worst-case scenario of 5% it has been calculated that there will be a requirement to remove 134 tonnes of the ash per day or the equivalent of three transport loads. This ash generation has been calculated as follows

▪ Biomass burnt - 112t/h x 24 hours = 2,688 tonnes per day

▪ Ash generated - 2688 x 5% = 134.4 tonnes

There will be 70 B-double configured semi-trailers delivering biomass to the site and those vehicles will be capable to back load the ash to an approved site(s) where the ash will be used as a soil amendment. The ash bunker is large enough to hold 2.5 days ash production.

It is noted that the application of ash from the burning of biomass as a soil or fertiliser amendment on land is permitted under the NSW EPA’s The Ash from Burning Biomass Order 2014. Ash from the burning of biomass will be sampled and tested in accordance with the Order to confirm it meets the chemical requirements under Table 1 of the Order This Order permits the reuse of ash when fuels used biomass from “…agriculture, forestry and sawmilling residues, uncontaminated wood waste and/or organic residues from virgin paper pulp activities.” This Order would apply to the proposed operations.

The burning of BDT and RoM coal in the operation of the Power Station will also produce ash. Historically the ash was returned to tailings dams. Under the NSW EPA’s The Coal Ash Order 2014 permits the use of this ash as a soil or fertiliser amendment on land. This Order applies to coal ash and coal ash blended with

14

Page 14

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE PROPOSAL 11

other materials (blended coal ash). In this order, coal ash means coal combustion products (CCPs), fly ash or furnace bottom ash from burning Australian black coal - coal tailings are derived directly from Australian black coal.

Ash from the burning of the coal will be sampled and tested in accordance with the Order, to confirm it meets all chemical requirements under Table 1 of the Order, and when compliant will be provided to a contractor for use as a soil amendment in accordance with The Coal Ash Exemption 2014.

The Supply Chain Report identifies that:

Should the ash not comply with the requirements of the EPA’s The Coal Ash Order, a Specific Resource Recovery Order and Exemption will be applied for from the NSW EPA to enable the beneficial reuse of ash in appropriate applications to ensure that human health and the environment are protected at all times.

3.3.2. Modifications to the Operations and Plant

The primary modification proposed to the consent is the introduction of biomass as an additional and alternate fuel source for the operation of the Power Station on site. However, there are also modifications to plant and equipment to facilitate the delivery of biomass fuel to the site.

A high-level summary of the material elements of the consent, the proposed modifications and the nature of any change to the elements of the operation as a result of using biomass as an alternate waste stream is presented below. As can be seen, the only change to the material elements of the proposal is the change to fuel feed stock (nature, volumes received, and waste generated) with some minor operational elements to deliver the feed stock to the site and its delivery from onsite storage to the furnaces.

Biomass will be delivered to the site six days per week (excluding Sundays and public holidays) between the hours of 6am to 6pm.

In order to facilitate the delivery of biomass fuel by road and its delivery into the Power Station operational system it will be necessary to undertake minor modifications to plant on site. These refinements will not alter the central operation of the fluidised bed combustion technology on which the Power Station relies, but to ancillary equipment and machinery.

Most equipment components will be reused and modified where necessary to accommodate the use of biomass as an additional fuel source and some new equipment will be required. The changes are summarised as follows and shown on the nominated drawings

▪ Site Layout Plan – Biomass Unload and Storage Area by HDB numbered 21017 Revision B dated 29 July 2021.

▪ Redbank Power Station Plant Biomass Conversion Drawing by B&PPS numbered C12181-000-100 Rev A, C12181-000-111 Rev A, C12181-000-112 Rev A, C12181-000-113 Rev A, and C12181-000-114 Rev A. and

▪ Site Plan by Alstom numbered 80034-001-M-GA-000-5001 A0.

▪ Extension of Conveyor CV 76 from the existing crusher house to feed existing conveyorCV34.

▪ Modify conveyors CV34 to feed unit 1 only and CV 35 to feed unit 2 to provide better availability and silo filing efficiency.

▪ Replace chutes with reversing conveyors in boiler silo area.

▪ Modification to the boiler storage silos by removing the bottom section and trouser legs and replacing them with a cylindrical section inclusive of rotating discharge augers.

▪ Modify the furnace fuel feeders removing the current Stock feeders and replacing with screw feeders as well as reopening the pneumatic fuel distributors to their original dimension.

▪ Removal of the tailings crushing plant on site as BDT and ROM received in the future will be required to comply with site specifications.

15

Page 15

12 THE PROPOSAL

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

▪ Additional/extension to the existing fire detection and protection system.

▪ Additional dust collection as required and upgrading of the existing dust suppression system.

▪ Installation of incoming and outgoing weigh bridges and installation of mobile equipment to facilitate the unloading of B-Double trucks adjacent to the tailings stockpile area.

▪ The tailings stockpile area will be used New B-double truck unload and stock pile facility.

The design parameters of the modifications to the plant and installation of mobile plant required in order to facilitate the use of biomass as a fuel source for the Power Station is set out in the BPSS Biomass Handling Plant Concept Study.

The proposed modifications to the operational parameters of the Power Station will also require a modification of the current Environment Protection Licence (EPL11262). This will follow the modification of the consent.

3.3.3. Modifications to the Consent

In order to enable the use of both BDT and RoM coal product and biomass as fuel sources as now proposed, it is necessary to amend the terms of the development consent. Principally this relates to:

▪ the description of the development,

▪ the terms of condition 1 and the documents on which the consent as amended relates, and

▪ condition 16 in terms of the fuel type and source to be used in the operation of the Power Station.

The modifications to the terms of the consent are detailed below and are as a direct consequence of the introduction of the use of biomass as an additional fuel source.

DESCRIPTION OF DEVELOPMENT

The amendments to the development description is shown by strike through where details are being deleted and italics and underline where text is inserted.

Development consent is granted to the construction and operation of a power plant on land being part lots 1-3 DP 247820 and lots 4-5 DP 247820 at Long Point Road and Jerrys Plains Road, Warkworth, and to the construction and operation of ancillary tailing collection, fuel delivery and storage, preparation and transportation facilities and ancillary water and ash transportation facilities on site and adjacent land including land within consolidated coal lease 753 as specified in development application No. 183/93 as modified in the information contained in the prepared statements of Roy Alper and Thor Hibbler of February 1997, and as modified in the information referenced in condition 1 and subject to the conditions annexed hereto and marked “A”.

CONDITION 1 – SCOPE OF DEVELOPMENT

The amendment to the condition is shown by strike through where details are being deleted and italics and underline where text is inserted.

The development being carried out generally in accordance with the Amended Environmental Impact Statement prepared by the National Power Company and ESI Energy Inc. dated November 1993 and the additional clarification contained in the responses to comments prepared by the National Power Company and ESI Energy Inc. dated 21 February 1994 and the information regarding improvements to the development contained in the prepared statements of Roy Alper and Thor Hibbler of February 1997 as amended by the following documents:

1. Planning Report prepared by Urbis dated 10 August 2021 2. Site Layout Plan – Biomass Unload and Storage Area by HDB numbered 21017 Revision B

dated 29 July 2021 3. Redbank Power Station Plant Biomass Conversion Drawing by B&PPS numbered C12181-000-

100 Rev A, C12181-000-111 Rev A, C12181-000-112 Rev A, C12181-000-113 Rev A, and C12181-000-114 Rev A

16

Page 16

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE PROPOSAL 13

4. Site Plan by Alstom numbered 80034-001-M-GA-000-5001 A0 and 80034-025-M-GA-000-9176 A1

5. B&PPS Biomass Handling Plant Concept Study (C12156-03) dated 18 June 2021 6. Redbank QA/QC Supply Chain and Material Handling dated 30 July 2021 7. Noise Impact Assessment by Muller Acoustics Consulting dated 11 August 2021 8. Stormwater Management Plan Report by RGH Consulting Group dated July 2021 9. Air Quality Impact Assessment by EMM dated 9 August 2021 10. Transport Assessment by Ason Group dated 10 August 2021 11. Operational Traffic Management Plan by Ason Group dated 10 August 2021

Where there is any inconsistency between the Amended Environmental Impact Statement and Associated documents and those submitted with the modification application dated 2021 the latter documents will prevail.

CONDITION 16 – FUEL SOURCE

Condition 16 has been previously modified to delete reference to the Lemington operation and identifies the source of the coal tailings to be utilised in the operation of the Power Station.

As discussed above it is proposed to modify the operation of the Power Station to permit it to operate using coal tailings or biomass. The amendment to the condition is shown by strike through where details are being deleted and italics and underline where text is inserted.

At least the majority of the fuel burnt at the power plant in any one year after commercial operation, on a dry tonnes basis, is to be derived from either:

(a) coal washery tailings obtained either directly from the Warkworth mine washery or indirectly from tailings storage dams on the Warkworth mine lease. Coal washery tailings are not to be obtained from mines other than the Warkworth without the further approval of Council, or

(b) Biomass fuel classified as Biomass from Agriculture, Forestry and Sawmill Residues or Uncontaminated Wood Waste in the EPA’s Eligible Waste Fuel Guidelines.

3.3.4. Substantially the Same Development

CONSIDERATION

The modification application the subject of the Land and Environment Court Proceedings was submitted under section 4.56 of the EPA Act which contains a power to modify a development consent granted by the Court where the consent as modified is, amongst other things, substantially the same development as that for which consent was originally granted.

Viewed holistically, the development as proposed to be modified retains its essence. That is, the development remains first and foremost a Power Station powered by waste fuel supplying electricity to the grid. There is no significant qualitative change to the structure or components of the plant other than in respect to fuel loading.

The proposed introduction of biomass as an additional waste fuel with changes in equipment to facilitate efficient fuel loading, does not change the material essence of the Power Station. The power to modify a consent is not limited to modifying the details of a consent.

Having regard to the body of case law around the assessment of “substantially the same development” it is clear that the answer to that question will depend on fact and degree in the context of a specific development.

An analysis of the essential elements must focus on a holistic approach to determine the essence of the development. Table 1 above sets out the quantitative and qualitative difference between the development as modified and the development for which consent was originally granted.

17

Page 17

14 THE PROPOSAL

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

MODIFICATIONS TO MATERIAL ELEMENTS

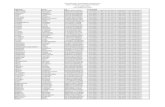

Table 1 - Summary of Project Modifications

Project Item The Consent/The

Operation

Modification

Application

Change

Land description 112 Long Point Road

West, Warkworth.

112 Long Point Road

West, Warkworth.

No change.

Project Operation of a power

plant at Long Point

Road and Jerrys Plains

Road, Warkworth, and

operation of ancillary

tailing collection,

preparation and

transportation facilities

and ancillary water and

ash transportation

facilities.

Operation of a power

plant at Long Point

Road and Jerrys Plains

Road, Warkworth, and

operation of ancillary

tailing collection,

preparation and

transportation facilities

and ancillary water and

ash transportation

facilities.

No change.

Technological Design

Capacity

Operation of Fines

Circulating fluidised bed

combustion technology

(FiCirc®1) and a

single151MW steam

turbine which was

developed to operate

with a wide range of fuel

such as coal tailings,

biomass and other such

fuels.

Operation of Fines

Circulating fluidised bed

combustion technology

(FiCirc®1) and a

single151MW steam

turbine which was

developed to operate

with a wide range of fuel

such as coal tailings,

biomass and other such

fuels.

No change.

Fuel source and

volumes

Use of 700,000 tonnes

of BDT and ROM waste

per annum.

Use of 700,000 tonnes

of BDT and ROM waste

per annum.

Alternative is to use up

to a maximum of

850,000 tonnes per

annum of biomass as a

fuel source.

No change to volumes

of BDT and ROM.

Introduction of biomass

as an additional waste

fuel source.

The calorific value

entering the plant

remains the same as

the previously operating

plant.

Waste Outputs Coal ash from BDT and

ROM at 100 tonnes per

hour (or 2,400 tonnes per

day).

Coal ash from BDT and

ROM at 100 tonnes per

hour (or 2,400 tonnes per

day).

No change in ash

production when BDT

and ROM are used.

Major reduction in ash

generation, reducing from

2,400 tonnes per day to

18

Page 18

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE PROPOSAL 15

Project Item The Consent/The

Operation

Modification

Application

Change

Ash from biomass at 134

tonnes per day.

134 tonnes per day (or

94% reduction).

Waste output – reuse. Coal ash from BDT and

FOM returned to mine

sites for deposition into

tailings dam.

Ash from BDT and ROM

will no longer be sent to

tailings dams, rather it

will be used as a soil

amendment in

accordance with The

Coal Ash Exemption

2014.

Ash from burning

biomass will be used as

soil or fertiliser

amendment on land is

permitted under the

NSW EPA’s The Ash

from Burning Biomass

Order 2014.

Positive environmental

change to the disposal

of coal ash and biomass

ash as permitted under

relevant guidelines and

regulations.

Transport Delivery of BDT and

ROM predominantly by

conveyor and by road if

required.

Coal ash delivered by

conveyor and truck.

Delivery of BDT and

ROM predominantly by

conveyor and by road if

required.

Coal ash delivered by

conveyor and truck

Biomass to be delivered

by B-double truck up to

70 per day. Biomass

ash to be disposed by

back-loaded trips of B-

double trucks

approximately three

trucks per day.

Delivery of biomass fuel

and disposal of ash by

truck only.

140 truck movements

per day to transport the

biomass.

Commuter, contractor

and service deliveries

remain consistent.

Greenhouse Gas

Emissions

Emissions from BDT

and RoM 1,011,320 t

CO2-e/annum

Emissions from BDT

and RoM 1,011,320 t

CO2-e/annum

Emissions from biomass

(direct and indirect)

35,465 t CO2-e/annum

Reduction from

1,011,320 t CO2-

e/annum to 35,465 t

CO2-e/annum when

biomass rather than

coal is used as the fuel

source

Power Generation Nominal rating at

Maximum Continuous

Rating (MCR) of 146

megawatts (MWe)

Nominal rating at

Maximum Continuous

Rating (MCR) of 146

megawatts (MWe)

No change.

19

Page 19

16 THE PROPOSAL

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

Project Item The Consent/The

Operation

Modification

Application

Change

(gross) with an overload

capacity of 151 MWe

gross.

(gross) with an overload

capacity of 151 MWe

gross.

Hours of Operation and

Shifts

24 hours a day, seven

days per week. Two

shifts over this period,

starting at 6 am and 6

pm.

24 hours a day, seven

days per week. Two

shifts over this period,

starting at 6 am and 6

pm.

No change.

Grid Connection Electricity generated at

the Power Station

converted and fed into

the grid adjacent to the

site.

Electricity generated at

the Power Station

converted and fed into

the grid adjacent to the

site.

No change.

The supply to the grid

remains the same. The

supply to the grid was

and will be a

commercial contract.

The comparison makes clear that the proposed development remains for a Power Station generating electricity using Fines Circulating fluidised bed combustion technology (FiCirc®1) and a single151MW steam turbine for supply to the grid. With respect to environmental impact, the modification results in a beneficial outcome over that which was originally approved, particularly having regard to greenhouse gas emissions.

Turning to the ‘proper context’ for the consent, the EIS is instructive. The three major objectives of the approved Power Station Project are :

1. Efficient utilisation of natural resources (i.e., fuel resources);

2. Introduction of an alternative, environmentally responsible method of tailing disposal;

3. Design and operation in a manner that minimises environmental impacts.

The establishment and operation of the Power Station has historically met Objective 2 - The Project retains the ability to deal with coal tailings however, coal tailings are not currently available from the Warkworth mine due to changes to process and technology at that mine. However, the objectives in relation to coal tailings are not precluded in the future even with the introduction of the biomass as a fuel source. Disposal of the Warkworth tailings is now subject to a separate process and environmental impacts reduced by alternative means. This is not an essential element of the approved development and the ability to fire on coal tailings has not been removed.

The introduction of biomass as an additional and alternative fuel source meets Objective 1 providing for the efficient use of natural resources that would otherwise be burnt, left to decay or disposed of at landfill without delivering a beneficial outcome or the efficient utilisation of that resource.

The design and operation of the Power Station has inherent flexibility which enables the use of a variety of fuel types to generate electricity while managing emissions with limited adverse environmental impacts. The technical assessments of the proposed modifications as presented in Section 4 of this Planning Report identify the manner in which the operations will be managed to limit environmental impact in terms of traffic generation, air quality emissions, greenhouse gas emissions, stormwater and water quality and acoustic impacts. The development as proposed to be modified is able to meet relevant controls parameters for the operation of the Power Plant.

The combustion of the tailings from an adjacent mine site is not an essential element of the approved development but rather an aspect offsetting the impact of the combustion of coal. The ability to fire on coal tailing has not been removed.

CONCLUSION

20

Page 20

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX THE PROPOSAL 17

As demonstrated in Table 1 above:

▪ There is no significant qualitative change to the structure or components of the plant other than in respect to fuel receival and fuel loading. This change of nature of the waste fuel, and fuel receival and loading, does not change the material essence of the Power Station.

▪ The introduction of biomass as a fuel source does not result in any material increase in environmental impact – in fact, the modification would have a significant beneficial impact in terms of greenhouse gas emissions as discussed in Section 4 of this Planning Report.

▪ The objectives set out in the original EIS includes an objective to …improve the utilisation of natural (fuel) resources… and this continues.

The power to modify a development consent is not limited to modifying the details of a consent and contemplates modifying the nature of the development itself provided the change is not a radical transformation. The proposed modification to the consent is well within those limits.

21

Page 21

18 UPDATED IMPACT ASSESSME

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

4. UPDATED IMPACT ASSESSMENTS 4.1. TRANSPORT The Ason Group has prepared a Transport Assessment of the proposed modifications to the consent to enable the use of biomass as a fuel source.

The transport of biomass is to be undertaken by 70 x B-double vehicles over a 12 hour period, 6 days / week (Monday to Saturday).

The Transport Assessment reviewed the traffic modelling to confirm that the proposed routes do not detrimentally impact on the design and operation of the intersections and access arrangements along the intersection of Long Point Road West / Golden Highway (the Intersection). The assessment assumed a 50/50 split of heavy vehicles in the north and southern direction of Golden Highway during both morning and afternoon peak periods.

The Ason report also reviewed the site and access arrangements have been reviewed to determine if there is sufficient area on-site for the manoeuvring of the B-double vehicle is possible and that all queueing associated with the proposal is accommodated on-site.

Vehicle access to the site is via Long Point Road via two driveways at the eastern and western boundaries of the site as shown in Figure below

Figure 4 - Existing site access points

Source: Anson Traffic Impact Assessment

Anson Group undertook an assessment of the performance of the key intersections has been analysed using RMS’ approved SIDRA intersection modelling software and found that the level of service (LoS) for the intersection of the Golden Highway and Long Point Road in the am peak was LoS A and in pm peak was LoS B. The intersection was considered to currently operate at good level of service, with low delays and queues, while retaining significant spare capacity.

22

Page 22

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX UPDATED IMPACT 19

In addition to undertaking the SIDRA modelling Anson Group examined the crash data for the key intersection, which indicated generally good intersection / road geometry and turning infrastructure; sight distances; and relatively moderate flows through the road network.

In terms of traffic generation for the delivery of biomass the following assumptions have been made:

▪ The employment of up to 35 operational and maintenance staff per day shift and five staff per night shift.

▪ Primary day shifts for staff being 6:00am – 6:00pm and night shift 6pm to 6am.

▪ Biomass would be delivered Monday to Saturday between 6:00am-6:00pm.

▪ A 50/50 split of heavy vehicles in the north and southern direction of Golden Highway during both morning and afternoon peak periods.

▪ A wide range of sites would be used to source the appropriate biomass, including forestry and sawmilling residues, uncontaminated wood waste from primary & secondary manufacturing processes. Suppliers are likely to vary and change from year to year as market conditions dictate.

▪ The biomass fuel unloading process on site will be undertaken as follows:

‒ A truck arrives at the site and travels over an incoming weigh bridge;

‒ The truck traverses to the fuel unloading area and tips its load into the drive over hopper

‒ The capacity of the hopper and feeder conveyors will be designed to accommodate up to two B-double truck loads.

‒ The hopper floor is swept by a feeder conveyor or chain conveyor;

‒ Once empty, the truck continues to the departure weigh bridge and then exits the site.

▪ In terms of trip generation, the following assumptions are made:

‒ The facility has been designed to have capacity of 850,000 tonnes of biomass per annum,

‒ Deliveries of biomass shall be undertaken by B-doubles with a conservative capacity of 40T this equates to 21,250 loads required per year,

‒ Seventy load deliveries to arrive 6 days per week would result in 140 truck movements per day, as (one inbound movement & one outbound movement per truck);

‒ Based on 12-hour delivery window, the resulting trip generation is 12 truck movements per hour.

▪ Daily ash production from the burning of the biomass would be in the order of 134.4 tonnes per day. The ash material is proposed to be backloaded onto the trucks delivering the fuel to the facility.

The impact on the performance of the intersection of Golden Highway and Long Point Road was undertaken using the above assumptions and found that in the am peak the intersection achieved a LoS B and in the pm peak a LoS B. While there is a reduction in level of service in the am peak the Ason Report (page 14 &15) identifies the SIDRA analysis indicated that … the additional traffic generated by the Proposal will have no significant impact on the operation of the Golden Highway/ Long Point Road West intersection, with the intersection predicted to continue to operate at good levels and with spare capacity and that … post development, the Jerry Plains Road x Long Point Road West intersection would operate at a good level of service during peak periods, with only minor increases in the delays experienced (in the order of 5 seconds).

The Ason Report identified that in order to accommodate the proposed truck movements that … that a BAL turn treatment would also be warranted for vehicles turning left into Long Point Rd from Golden Highway. the BAL treatment on the major road has a widened shoulder, which assists turning vehicles to move further off the through carriageway making it easier for through vehicles to pass. The existing shoulder width on the approach to the intersection would seem to be in excess of 4m, therefore would be acceptable for a left turn treatment to be constructed.

23

Page 23

20 UPDATED IMPACT ASSESSME

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

The undertaking of this intersection upgrade can be conditioned with the works to be completed prior to commencement of the delivery of biomass to the site.

In order to regulate the deliveries of the biomass material the Ason Report recommended that… that a schedule of all biomass deliveries be established prior to each day and be site-specific, and that radio contact is maintained with haulage vehicles at all times.

This recommendation can be actioned as part of the procedures to be adopted in the final Operational Site Management Plan.

4.2. OPERATIONAL TRAFFIC MANAGEMENT PLAN The Ason Group has prepared an Operational Traffic Management Plan (OSMP) to support the proposed modifications to the consent to introduce biomass as a fuel source.

The OSMP identifies ingress and egress points for heavy vehicle deliveries, commuter and delivery traffic, staff and contractor parking areas, pedestrian circulation and potential pedestrian vehicle conflict points.

The OSMP presents a series of recommendations to control vehicle speed and reduce/remove potential for pedestrian vehicle conflict including refinements to onsite road intersections and introduction of speed limiting and other signage throughout the site.

The recommendations of the OSMP will be actioned and the OSMP will be subject to regular review during the operation al phase of the Power Station.

4.3. AIR QUALITY EMM have prepared an Air Quality Impact Assessment Report that seeks to respond to the contentions raised by Council in the Land and Environment Court Proceedings 2021/00128111 in relation to air quality and greenhouse gas emissions.

In relation to the air quality contentions EMM undertook additional CALPUFF modelling including approved operations (firing using coal tailings) and proposed operations with 100% firing on biomass. The outcomes of the new modelling found that:

▪ The fugitive emission estimates for biomass handling are higher than for coal handling, however, when combined with emissions from the furnace stack, the total emissions to air for biomass are less than for coal.

▪ The incremental PM10 concentrations for the furnace stack alone are lower for biomass compared to coal, however when fugitive emissions are included, the highest incremental 24-hour average PM10 concentration is 2.6 μg/m3 for biomass and 1.0 μg/m3 for coal. The highest incremental annual average PM10 concentration is 0.4 μg/m3 for biomass and 0.1 μg/m3 for coal. The incremental ground level PM2.5 concentrations for the furnace stack alone are slightly higher for biomass compared to coal. When fugitive emissions are included, the highest incremental 24-hour average PM2.5 concentration is 0.6 μg/m3 for biomass and 0.3 μg/m3 for coal. The highest incremental annual average PM2.5 concentration is 0.1 μg/m3 for biomass and 0.04 μg/m3 for coal.

▪ When background concentrations are added to the proposal increment, there are no additional days above the 24-hour average impact assessment criterion for PM10 or PM2.5. The existing background for annual average PM10 and PM2.5 is already above the impact assessment criteria; however, the contribution from the proposal (biomass firing plus fugitive emissions) to annual average PM10 and PM2.5 is approximately 1% of the impact assessment criteria and can be considered insignificant (based on criteria used in other jurisdictions for screening out insignificant impacts [DWER 2019; Environment Agency 2011]).

▪ For biomass firing, the incremental ground level concentrations of CO and SO2 are minor. For example, the maximum 1-hour average concentration of CO and SO2 is less than 2% of the impact assessment criteria, while the 24-hour average and annual average concentration of SO2 are less than 1% of the impact assessment criteria. When assessed as a percentage of the impact assessment criteria, the largest risk occurs from NOx, which is 43% of the 1-hour average impact assessment criterion and 2% of the annual average impact assessment criterion.

24

Page 24

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX UPDATED IMPACT 21

▪ However, it is noted that this comparison uses NOx concentrations to compare against the impact assessment criteria for NO2. For coal firing, the ground level concentrations of CO and NOx are comparable to biomass, however the predicted ground level concentrations of SO2 are significantly higher for coal.

▪ Cumulative modelling predictions for NO2, SO2 and CO demonstrate that there would be no exceedances of the respective impact assessment criteria for NO2, SO2 and CO.

▪ For trace elements and organic compounds, the modelling predictions for biomass and coal firing are comparable. All modelling results are less than 10% of the impact assessment criteria and can be screened as insignificant.

4.4. GREENHOUSE GAS EMISSIONS EMM has prepared an Air Quality Impact Assessment Report which examined the air quality and greenhouse gas emissions outcome from the introduction of biomass as an alternate fuel source for the Power Station. The EMM report is based on updated CALPUFF modelling of approved (coal) and proposed alternative operations (biomass) of the Power Station and the key conclusions of the assessment are extracted and presented below:

Under a business as usual (BAU) scenario (ie if biomass fuel was not used at Redbank), forest residues would remain in place and would either decompose naturally or be burnt onsite. A life-cycle assessment of GHG emissions associated with the use of biomass for energy found that when avoided emissions due to the displacement of fossil fuels are taken into account, the net GHG emissions associated with the use of biomass for electricity generation results in approximately 70% less GHG emissions than the BAU scenario (DPI, 2017). For a sustainably managed harvest system, the CO2 released from the combustion of biomass waste will be reabsorbed by growing trees. As reported in the National Greenhouse Accounts Factors (NGAF) workbook (DISER 2020), under the IPCC Guidelines for National GHG Inventories (IPCC 2016), the emission factor for CO2 released from combustion of biogenic carbon fuels is zero, with emissions and removal of CO2, based on changes to carbon stocks, estimated and reported under land-use change categories. …

When emissions of CO2 from the combustion of biomass are taken as zero, the total estimated scope 1 (direct emissions such as combustion in a furnace) and scope 3 (indirect upstream and downstream emissions from transport and fuel preparation i.e. chipping) GHG emissions represent a small percentage (3.5%) of the GHG emissions associated with burning coal (as shown detailed in Table 8.2 of the EMM Report). Notwithstanding, even when CO2 emissions from the burning of biomass are accounted for, a full life cycle assessment of GHG emissions found that there are benefits associated with energy production from biomass (DPI 2017).

The DPI 2017 Report notes that:

One of the common concerns raised in utilising biomass from native forests for bioenergy generation is the impact on climate change. The analyses carried out here clearly shows that, from a climate perspective, the use of biomass that would have otherwise been left in the forest to burn and/or decay for bioenergy generation results in positive outcomes, especially if biomass is used to produce electricity displacing the use of coal. This is consistent with a previous study (Ximenes et al 2012), where the positive contribution of increased biomass usage for energy generation from native forests for climate mitigation was also clearly demonstrated.

At the times that the Power Station operates using biomass as a fuel source rather than BDT or RoM coal there will be improved environmental outcomes in terms of greenhouse gas emissions in the generation of electricity from the Power Station.

25

Page 25

22 UPDATED IMPACT ASSESSME

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

4.5. STORMWATER The RGH Consulting Group (RGH) has prepared a Stormwater Management Plan Report that considers the potential impacts on the operation of the onsite stormwater management systems as a result of introducing biomass as an additional and alternate fuel source for the operation of the Power station. In undertaking the assessment RGH considered the requirements for biomass fuel stockpile management in regard to stormwater.

The Stormwater Management Plan Report found that the proposed biomass fuel conversion …will not alter the current hydraulic characteristics of the site…and… it was deemed that no augmentation of the current site drainage network is required as part of the conversion. Similarly, the existing on-site detention system will function as normal and was also deemed satisfactory for the development modification.

Modelling was undertaken using MUSIC software to evaluate the performance of the ‘treatment train’ on site to determine if the future Power Station operation using biomass would meet the Council’s pollution reduction targets.

The model included of the existing sediment basin and detention basin as the water quality improvement devices to treat stormwater runoff and factored in other devices such as oil skimmers utilised on the site to achieve council’s pollutant reduction targets.

It was determined that the use of biomass fuels will not result in any net change in water pollutant runoff from the site as the volume of stormwater that is captured and reused on site greatly limits the amount of stormwater that leaves the site.

Further, the Stormwater Management Plan Report found that the pollution reduction achieved by the existing stormwater treatment train is significantly higher than Council’s minimum requirements.

In terms of sediment runoff from the biomass stockpile when compared to a tailings stock pile is expected to be less than that for the tailings stockpile due to the material properties of the biomass in comparison to coal. The existing sediment basin servicing the tailings stockpile area is therefore considered adequate for sedimentation control with the introduction of biomass.

4.6. ACOUSTIC Muller Acoustic Consulting Pty Ltd (MAC) has prepared a Noise Impact Assessment (NIA) to quantify potential emissions from the proposed introduction of biomass as a fuel source for the operation of the Power Station. The NIA was based on the results of unattended and attended noise monitoring activities carried out by MAC.

The NIA found that:

▪ Emissions from additional items of plant and processes associated with waste biomass haulage and handling on site would satisfy the relevant project noise trigger levels (PNTL) at all assessed receivers during each of the assessment periods;

▪ Cumulative noise levels from the additional items of plant and the predicted noise levels from the operation of the Power Station, as provided in the historic assessment, would also satisfy the relevant noise policy for industry (NPI) criteria at all assessed receivers during each of the assessment periods;

▪ Sleep disturbance is not anticipated to occur, as emissions from impact noise are predicted to remain below the EPA maximum noise trigger levels; and

▪ Project related road traffic noise levels will meet the objectives of the road noise policy (RNP) for the nearest residential receivers on the Golden Highway.

26

Page 26

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX PROJECT BENEFIT 23

5. PROJECT BENEFITS The proposal involves modification of the existing consent to allow for the Power Station to utilise biomass fuel as an additional fuel source.

This provides the opportunity for the proponents to generate electricity with Net Zero CO2 emissions in a cost-effective manner.

The introduction of biomass as a fuel source will enable the generation and delivery of reliable green baseload energy reducing the risk of blackouts and provides downward pressure on the cost of power, for both the residential and commercial/industrial markets.

The broad public benefits that the proposed modifications to the consent will deliver include:

▪ A fully operational the power plant would produce a million megawatt hours of electricity per year, equivalent to supplying around 200,000 homes.

▪ The project will drive significant progress towards the NSW Government’s Net Zero Plan Stage 1: 2020-2030, being the foundation for NSW’s action on climate change and goal to reach net zero emissions by 2050. The introduction of biomass as an alternate fuels source for the Power Station operation will result in the first major green baseload power station for the country and is an important step towards the development of a 100% green grid.

▪ Achieving Pillar 4 of the NSW Forestry Industry Roadmap which encourages new investment, innovation and environmental sustainability which is vital to the future of the NSW forestry industry, including biomass and bioenergy products.

▪ Delivery of an alternative and sustainable energy source that is based on sustainably produced biomass contributing broadly to climate change mitigation and supporting decarbonisation through expansion of intermittent renewables consistent with the precautionary principle.

▪ A reduction in indefinite warming through decarbonisation which reduces the absolute quantity of CO2 in the atmosphere which reduces future warming and minimise impacts on natural ecosystems and food security.

▪ Positive outcomes for biodiversity and ecological integrity that are managed through forestry regulations requiring sustainable forest management practices to be applied. No additional trees will be harvested as the biomass is obtained from harvest and mill residues.

▪ The opportunity for the Power station to generate broader interest and opportunities to pursue renewable energy outcomes and encourage additional investment in the region.

▪ A diversification of energy generation away from coal mining.

▪ The establishment of the largest green baseload generator in Australia (excluding hydrogeneration) when using eligible biomass fuel by generating more green power over a year than the largest existing solar farm in Australia. It will provide much needed firming capacity to the grid assisting and supporting the adoption of more weather or time of day dependent intermittent power sources of solar and wind.

▪ Enable the potential production of products which require green energy such as Green Hydrogen production through the operation of the Power Station which would be as Net Zero CO2 emissions so leading to the further decarbonisation of the economy.

27

Page 27

24 CONCLUSION

URBIS

DRAFT PLANNING REPORT FINAL (002).DOCX

6. CONCLUSION This Planning Statement provides a description of the proposed modifications to the consent to enable the Power Station to operate with the introduction of biomass as an alternate and additional fuel source.

This Planning Statement incorporates the reviews of key operational elements which are relevant to the introduction of biomass as a waste stream. These reviews have provided additional information to address the concerns raised by the Council and the community in relation to the use of biomass and have demonstrated that:

▪ The development as proposed to be modified will be substantially the same development when modified as when approved.

▪ It will not require a change to the technology installed and previously used in the operation of the Power station;

▪ There is adequate supply of eligible biomass available to enable the operation of the Power Station as proposed;

▪ It will not change the overall water management and stormwater strategy for the site;

▪ Biomass as a fuel type can be accommodated in the operation of the Power station as the fluidised bed technology has the designed flexibility to accommodate both coal and biomass a fuel type. The Power Station has been designed to safely operate using a range of fuel types and is able to comply with specified emission limits noting that only one fuel type will be burnt at any one time;

▪ It does not give rise to any uncertainty around the performance of the air pollution technology installed within the Power Station;

▪ Minor modifications will be required to some ancillary plant and equipment and the introduction of new weighbridges and mobile plant to convey the fuel into the Power station operational areas;

▪ When emissions of CO2 from the combustion of biomass are taken as zero, the total estimated scope 1 and scope 3 GHG emissions from the operation of the Power Station represent a small percentage (3.5%) of the GHG emissions associated with the burning coal; The road network will continue to operate at a good level of services and that there is capacity to accommodate the truck movements delivering material to the site and removing waste from the site; and

▪ The operation of the Power Station using biomass will comply with the relevant operational and road noise criteria and compliance with the relevant EPA policies, without additional ameliorative measures being required.

28

Page 28