VORAFORCE 5200 fast cure composite epoxy resins€¦ · carbon fiber composite ... Resin Transfer...

-

Upload

phamnguyet -

Category

Documents

-

view

247 -

download

0

Transcript of VORAFORCE 5200 fast cure composite epoxy resins€¦ · carbon fiber composite ... Resin Transfer...

Dow Automotive Systems introduces a state-of-the-art epoxy formulation, designed mainly for carbon fiber composite production using varia-tions of the resin transfer molding (RTM) process.

RTM is a closed mold process enabling high-fiber reinforcement content in the final composite. VORAFORCE 5200 optimizes key processing and performance properties, making them comparable to properties of metal solutions.

THE VORAFORCE™ 5200 EPOXY SYSTEM IS SETTING A BENCHMARK BY MEETING CHALLENGING COMPONENT WEIGHT REDUCTION GOALS WITHOUT COMPROMISING PRODUCTION SPEED, STRUCTURAL INTEGRITY OR DESIGN FLEXIBILITY.

Meeting OEM emissions andfuel efficiency requirements is a difficult challenge when working with materials such as steel or aluminum sheet metal. Significant weight reduction is possible with low-density carbon fiber compos-ite components that can function alongside traditional metal components in an efficient hybrid construction.

VORAFORCE™ 5200 fast cure composite epoxy resins

VORAFORCE 5200 provides a class-leading

balance of long gel and rapid cure times which maximize produc-tion tool output, while maintaining excellent processing flexibility – even for large components with high fiber content. Its ultra-low viscosity reduces filling pressure and clamp force, without sacrificing flow length or fiber wetting.

Composite ResinsStructural AdhesivesStructural Composites

B-pillar VORAFORCE RTM filling simulation.

Filling Times

PREss

Insert preformClose RTM mold

Inject resin system

Comp A Comp B

Curing Open moldRemove part

PREss

Conflicting resinrequirements:

Process requirements (for large volume automotive):

Low viscosity and long gel time

to fill mold and impregnate

fiber mat

Gel time (infusion time) 30-90 sec

Total cycle time < 240 sec

Demold time > 180 sec

Complete/high conversion

Fast cure to reduce

cycle time

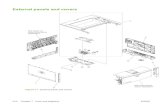

Resin Transfer Molding Process

HM1404das_VF5200_sheet.indd 1 7/11/13 9:27:27 PM

Dow Automotive systems The Dow Chemical Company, 1250 Harmon Road, Auburn Hills, Michigan 48362 USAPhone: +1-248-391-6300 / Toll free: +1-800-441-4369 / Fax: +1-248-391-6417E-mail: [email protected]

Dow Automotive systems Dow Deutschland, Am Kronberger Hang 4, 65824 Schwalbach, GermanyPhone: +49 (0)6196-566-0 / Toll free: 00800 3 694 6367* / In Finland: 990 3 694 6367 / In Italy: 800 783 825 / Fax: +49 (0)6196-566-416*Toll free from Austria, Belgium, Denmark, France, Germany, Hungary, Ireland, The Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and the United Kingdom.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow Dow Automotive Systems is a business unit of The Dow Chemical Company and its subsidiaries. Form No. 299-52216-713 HMC

VORAFORCE™ 5200. THE PERFECT PACKAGE OF ULTRA-LOW VISCOSITY, EXCELLENT FLOW, SUPERIOR FIBER WETTING AND RAPID IN-TOOL CURE.

VORAFORCE™ 5200 offers excellent mechanical properties, complemented by a high glass-transition temperature to boost stability and durability of the composite at the required service temperatures. No post-cure operations are required to achieve these properties.

ABOUT DOW AUTOMOTIVE SYSTEMSDow Automotive Systems, a business unit of The Dow Chemical Company, is a leading global provider of collaborative solu-tions and advanced materials for original equipment manufacturers, tier suppliers, aftermarket customers and commercial transportation manufacturers. Our materials focus includes structural, elastic and rubber-to-substrate adhesive solutions; polyurethane foams and acoustical management solutions; films; fluids; and innovative composite technologies. Offices and application development centers are located around the world to ensure regionalized technical, engineering and commercial support for customers and industry groups. For additional information, visit dowautomotivesystems.com.

NOTICE: No freedom from any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change over time, the Customer is responsible for determining whether products and the information in this document are appropriate for the Customer’s use and for ensuring that the Customer’s workplace and disposal practices are in compliance with applicable laws and other governmental enactments. Dow assumes no obligations or liability for the information in this document. No warranties are given.

VORAFORCE 5200 is ideal for producing large, fiber-reinforced composite articles integrating glass, carbon or aramid fibers that require rapid infusion and cure times for increased build volumes. Depending on process needs – e.g. high- or low-pressure RTM processes, closed mold or open gap injection – the versatility of VORAFORCE 5200 allows easy adjustment of injection and cure profiles as needed, enabling demold time as low as 3 minutes.

Dow Automotive systems brings the smart solutions to your composite bonding challenges.

Dow Automotive Systems is also a market leader in adhesive bonding technologies. As the use of lightweight composites and metals has increased, Dow Automotive Systems has developed innovative adhesives that enable much more design flexibility in the use of these materials. For instance, we’ve pioneered a two-component polyurethane bonding system that links dissimilar materials – especially those with low surface energy – allowing the integration of lightweight materials such as aluminum, glass fiber, aramid, carbon fiber and others into vehicle body design and construction.

HM1404das_VF5200_sheet.indd 2 7/11/13 9:27:29 PM