vibratory roller handbook - · PDF filevibratory roller handbook with standardized terms and...

-

Upload

truongkhanh -

Category

Documents

-

view

228 -

download

6

Transcript of vibratory roller handbook - · PDF filevibratory roller handbook with standardized terms and...

vibratoryroller

handbookwith standardized terms

and definitions

SECOND EDITION

Developed by theCompaction and Paving Machinery Technical Committee (CPMTC)

Bituminous and Aggregate Equipment Bureau (BAEB)of the Construction Industry Manufacturers Association

111 East Wisconsin Avenue. Milwaukee, Wisconsin 53202. (414)272-0943

AcknowledgementThis Handbook was developed by the Compaction andPaving Machinery Technical Committee (CPMTC) of theConstruction Industry Manufacturers Association (CIMA),with the support of the Bituminous and AggregateEquipment Bureau (BAEB) - a product-oriented Bureauof CIMA. It represents the cooperative efforts andcontributions of technical experts from the many membercompanies which manufacture, among a broad range ofequipment for the bituminous industry, compactionequipment of all types.

A word about CIMACIMA is the U.S. based international trade grouprepresenting the producers of construction machinery andconstruction-related services used worldwide in thegeneral construction, housing, roadbuilding, mining,energy and forestry fields. For more than 80 years, CIMAhas acted as a forum for its member companies todiscuss and act upon issues of industry-wide concern,including product safety, machine performance standards,government liaison, export and trade activity, parts andservice information, training and the special concerns ofthe smaller and medium-sized manufacturer, amongothers. CIMA also produces the CONEXPO@ InternationalConstruction Equipment Exposition, one of the world'slargest machinery exhibitions.

Copyright@ 1994 - Construction Industry Manufacturers Association

Page

Purpose of Handbook

3Scope of Handbook

History of Compaction

Vibratory Compaction

7Description of a Vibratory Roller

Representative Types of Vibratory Rollers

Recommended Machine Specifications

Standard Specifications Label

Terms & Definitions

Metric Conversion Table

This Handbook on VIBRATORY ROLLERS is designedto serve the following purposes:

To reaffirm, promote and establish uniform, recognized andaccepted terminology, and machine specifications for the guidanceof manufacturers, distributors, buyers and users in comparing,specifying and presenting data relative to vibratory rollers;

To serve as a basis for common language and understandingamong manufacturers, distributors, buyers and users indetermining the basic types, features, operating characteristicsand applications of vibratory rollers;

To provide means for the identification of common types ofvibratory rollers;

To increase the knowledge of individuals involved withcompaction and compaction machines, and to enhance theirability to communicate and carry out their responsibilitiesefficiently and effectively;

To provide useful text and reference material for code-writingagencies, regulatory agencies, engineers, marketing personnel,contractors, equipment operators, schools, students, and othersinterested in, or involved with, the field of compaction.

2

This Handbook provides standardized terminology pertainingto vibratory rollers and their operation, standardized parametersfor designating the specifications and characteristics ofvibratory rollers, and other information of general interest tothose associated with, or interested in, vibratory rollers andtheir operation.

This Handbook is not intended to establish machinerequirements nor to promote the acceptance or use of anyspecific type of compactor - vibratory or otherwise. It is likewisenot intended to be an exhaustive treatise on the subject ofvibratory rollers.

This Handbook covers ride-on, walk-behind and towedmachines.

Excluded from coverage are all static rollers, and all vibratoryplate and rammer compactors.

Also excluded from coverage in this Handbook are safety-related matters, which are covered in manufacturers' manuals,and in CIMA's Roller Compactor Safety Manual, one of a seriesof operator safety manuals developed and published by CIMA,covering various types of construction machines.

Vibratory compaction may seem to some of usto be a recent technological innovation. Whilevibratory compaction is relatively new, thetheory and application of soil compaction is asold as recorded history itself.

road building declined. The construction of an18th-century road in England consisted of mendigging ditches along each side of theproposed road and throwing the excavated dirtinto the middle of the road bed, hoping thatpassing vehicles would act as compactors. Asticky situation existed during heavy rainspells.

In early civilization, soil compaction methodsemployed the dynamic forces of movinganimals and men. The motion of a foot (orhoof) is similar in some respects to the motionof a padded drum.

Around 1815 John London MacAdam, aScottish engineer, introduced a pavingtechnique which greatly advanced roadbuilding in England. MacAdam's method wasto mix small pebbles with clay or rock dust.The surface was then troweled smooth andcompacted. With the proper mixture thismaterial became almost as hard as concrete.

In 1869 a new innovation from England,known as the steam roller, was tried in NewYork. This early type of smooth-wheel rollerproved to be very effective in highwayconstruction for nearly a century.

With the Romans came the advancement ofcivilization and the art of road building. TheRoman method of road construction was tofirst make a cut the width of the planned road,deep enough to hold the fill. The earth at thebottom of the cut was made more solid throughthe use of heavy rammers, and a foundationlayer of stones was laid on this compactedbase. This layer was then covered with a9-inch layer of concrete. Next a 6-inch layerof fine concrete was laid, in which were setblocks of lava or other type of stone. This finalcourse was then rolled, using a cylindricalstone pulled by an attached yoke (the firsttowed-type roller). Some sections of theseRoman roads are still being used today.

The photograph below shows a Chinesemethod of soil compaction which employedthe theory of variable amplitude. It isreasonable to assume that this method iscenturies old.

With the fall of the Roman Empire, the art of

Photo courtesy of Engineering News-Record

4Method of dynamic soil compaction by tamping used in China

Various theories of, and testing methods for,soil compaction evolved in the 1920's, but itwas not until 1933 that R. R. Proctorpublished his basic theories dealing with theeffect of moisture content on compactionresults. Proctor devised testing methods fordetermining the optimum moisture content,and also procedures for determiningcompaction in the field.

in popularity of these vibratory rollerscontinued at a rather steady rate into the1960's, when their popularity rose sharply.The latter sixties saw the introduction of avibratory roller for compacting hot mix asphaltpavements. During the next few years a seriesof rapid advancements produced vibratoryrollers which experienced outstandingsuccess on both granular and cohesive soils,as well as on asphalts. Today, vibratory rollersare widely used and accepted for compactingasphalt pavements because they achieve therequired densities faster and are therebycapable of increasing production. The largedouble drum vibratory rollers, which firstappeared in 1969, provided even furtherproduction capabilities for the main linerolling of asphalt pavements.

Vibratory compaction of soils was firstemployed in Germany in the early 1930's inconnection with the construction of itshighway system. The first type of vibratorycompactor was the 1 ~-ton base plate unit,followed by a crawler type of compactorweighing about 25 tons, manufactured by theLosenhausen Company.

Today many different types and variations ofvibratory rollers are manufactured and used tomeet widely varying soil and field conditions,from granular soils to asphaltic concrete.

The first towed type of vibratory rollers for soilcompaction in the United States wasmanufactured in the 1940's. Self-propelleddesigns followed in the late fifties. The growth

,

An early type of vibratory roller

Tests conducted around the worldcommercially, academically and on the jobhave shown the benefits of vibratorycompaction for achieving density, depthpenetration and economy of compaction. Bothmachine and material factors contribute to itssuccess. Many such factors exist; they areinterrelated; and each varies in effect andimportance with differing material and workingconditions.

Compaction effectiveness also dependsgreatly upon the material being compacted.Typical variables include the type of materialmoisture or asphalt content, lift thickness,temperature, and underlying support. Inaddition, the characteristics of the materialbeing compacted change as the densityincreases.

Comparative rating ofvibratory rollersDue to the many variables mentioned above inachieving compaction performance, there is noknown specification which indicates the overalleffectiveness of a vibratory roller. The bestcomparative rating between vibratory rollers isthe resulting density, surface smoothness andrate of production on a specific application.

A drum's static weight applies a compactingforce; however, by inducing vibration of thatdrum, the compacting force is increased. Themomentary, high cyclic forces of the vibratingdrum overcome frictional and cohesiveresistance of the material being compacted,facilitating greater density.

Machine factors which affect vibratorycompaction efficiency include machineweight, drum weight and construction, sprungweight, machine suspension, vibratoryfrequency, amplitude, the vibration-inducingmechanism, and speed of travel.

6

A vibratory roller is a compactor having adrum* (roll or horizontal cylinder) used todensify (compact) soil, asphalt or othermaterials through the application of combinedstatic and dynamic forces (weight andvibrations) to increase the load-bearingcapacity of the surface.

the drum. The amplitude and frequency ofdrum movements cover a wide range of values.The drum(s) and drive wheels may be smoothor may include projections designed forspecific compaction purposes. Theseprojections vary as to material, size and shape.

Vibratory rollers may be self-propelled ortowed, rigid frame or articulated, andcontrolled by either a riding or walkingoperator, manually or remotely. See page 8for representative types.

The machine may have one or more drums,which mayor may not be powered forpropulsion. The machine may have drivemembers such as rubber tires in addition tothe drums. The centrifugal force is normallyproduced by one or more rotating offcenterweights, which produce a cyclic movement of

'Drum and roll are used interchangeably in this Handbook.

for soil and asphalt compaction

Smooth or multiple projection (padfoot, sheepsfoot or grid) drums

1

a. Articulated Frame b. Rigid Frame2 -

Tandem, double drum, ride - on(One or both drums may vibrate)

a. Single Articulated b. Double Articulated Steering c. Rigid Frame

4 Double drum, walk-behind(One or both drums may vibrate)

a. Articulated Frame b. Rigid Frame

8

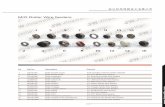

for publication by manufacturersof vibratory rollers

Operating Weight (kilograms, pounds)Shipping Weight (kilograms, pounds)Drum Diameter (millimeters, inches)Drum Width (millimeters, inches)Number of Vibrating DrumsOverall Width (millimeters, inches)Operating Height (millimeters, inches)Overall Length (millimeters, inches)Wheelbase (millimeters, inches)Turning Radius at the outside edge of Drum(s) and Tires if wider than drum (meter, inches)Static Weight at Drum(s) and at Tire(s) (kilograms, pounds)Centrifugal Force at a Stated Frequency (kilonewton, pounds)Vibrating Mass (kilograms, pounds)Eccentric Moment (kilogram meters, inch pounds))Frequency (hertz, VPM)Nominal Amplitude (millimeters, inches)Type of EngineNet Intermittent Power at Installed Full Load Governed Speed per SAE J1349(kilowatts, horsepower @ RPM)Speed Forward and Reverse (kilometers per hour, miles per hour)Fuel Capacity (liters, U.S. gallons)Water Spray System Capacity (liters, U.S. gallons)Curb Clearance (millimeters, inches)Oscillating Angle from Pivot Center (:t degrees)Tire Size and Ply rating

Additional Specifications for Padfoot Machines Only

Diameter Over Pads (millimeters, inches)Pad Area (square millimeters, square inches)Pad Height (millimeters, inches)Number of Pads

Specifications NOT Recommended .'

Total Applied Force and all its derivativesCentrifugal Force Described as Energy or with a time or travel distance factor(Example: tons per second)Any equivalent rating of a vibratory roller to a static roller

GradeabilityDouble Amplitude

NOTES: 1. When a vibratory roller has more than one vibrating drum, the weight and force specifications will be for each drum.

2. For compactors equipped with External (not inside the drum) vibrating mechanism, this must be clearly stated.

3. Specifications do not necessarily apply to all types of machines.

10

51 MetricUnits

! EnglishUnitsSymbol DefinitionTerm

Inches(in.)

Millimeters

(mm)AMPLITUDE, ACTUALDOUBLE

Double amplitude as measured under operatingconditions. This will vary with theconditions of the material being densifiedand the vibration frequency.

ACTUALDOUBLE

AMPLITUDE

I'-

..~-

The total peak to peak vertical movement percomplete vibrating cycle of the drum in a

I freely suspended condition.Double Amplitude is twice the Nominal Amplitude

AMPLITUDE, NOMINAL I A

I Millimeters

(mm)

Inches(in.)

Note: This term is not recommendedfor specifications.

I Nominal amp;~d; is calculated by using the

I f~"~:;~~ f~~';;;'~la:IA= ~ A= _wxr

Mv Mv. g(SI metric units) (English Units)The eccentric moment (m x r) or (w x r) dividedby the vibrating mass (Mv) in SI Units orMv. g in English Units.

jTIME FOR ONE FULL CYCLE

!'.. .' '.

-~--"-

AMPLITUDE,VARIABLE

Nominal Amplitude change accomplished byvarying the eccentric moment.This is independent of frequency.

(continued)

51 MetricUnits

I EnglishI UnitsI DefinitionTerm I Symbol

BALLAST WEIGHT I Material added to increase the weighti of the machine. I ~~~grams

-i-~~--Poundslib)

~~

CENTRIFUGAL

FORCEFc

--

The force generated by thevibration-inducing mechanisms at a statedfrequency. To compute centrifugal force:(81 Metric Units)Fc = 3.948 X 10-2 (m x r) x f2 Kilonewton

(kN)

Pounds(Ib)

~----COMPACTOR

DRUM

---DYNAMIC FORCEAPPLIED

(English Units)Fc = 2.840 X 10-5 (w x r) x f2Note: In calculations, it is customary forthe sake of simplicity to assume that r

I (in the formula) is measured from thetrue bearing center.

--- .A machine designed and used specificallyto compact materials. It densifies materialthrough the application of static force or dynamicforce combined with static force.

--- -A rotating cylindrical member used totransmit compaction forces to soil or othersurface materials.

I The vectorial resolution of all thegenerated forces and the static forces

I at the interface of the drum and thematerial being compacted.

ECCENTRIC MOMENT

I Note: The Dynamic force applied varies with thetypes and conditions of the material being compacted.Therefore this term is not recommended to be usedin rating compactors.

The product of the unbalanced mass (m)/unbalancedweight (w) times the distance (r) from the center ofI gravity of the unbalanced mass to the bearing center.

(m x r) Kilogram-Millimeter(kg-mm)

Pounds-Inch(Ib-in)(w x r

~

~ry

/ "/ CENTEROFGRAVITY

'"- CENTER OF ROTATION

I UNBALANCED MASS = mI UNBALANCED WEIGHT = wDISTANCE = r

I ECCENTRIC MOMENT = m x r ( SI Units)w x r (English Units)

12

(continued)

Hertz(Hz)

Vibrationsper minute

(VPM)

The number of complete cycles of thevibrating mechanism per unit time.

FREQUENCY

To be consistent with SAE and ISO it isrecommended that this term not be used in themachine specifications. The surface and operatingconditions can change the actual gradeabilityof the compactor compared to the theoreticalcalculated numbers.

GRADEABILITY

-~-

The centrifugal force generated per drumdivided by the drum width.

LINEAR CENTRIFUGALFORCE

KilonewtonPerMillimeter)(kN/mm

PoundsPerLinear Inch(PLI)

The static weight divided by the drum width.LINEAR STATIC FORCE PoundsPerLinear Inch(PLI)

KilogramsPerMillimeter(kg/mm)

Kilograms(kg)

The static weight measured at the drum(s)on the ground, minus the vibrating weight.

Pounds(Ib)

NON-VIBRATINGWEIGHT

Kilograms(ka)

Poundslib)

The gross machine weight with full mechanicaloperating systems, a full tank of fuel,one-half sprinkler tank of water, if soequipped, and a 75 kg (165 lb. ) operator.If the operating weight includes a ballast, thelocation, type(s), and weight of the ballastshould be so designated.

OPERATING WEIGHT

A one-way trip or passage of the machine. Around trip in the same path is two passes.

PASS

Hertz(Hz)

VibrationsperMinute(VPM)

RESONANTFREQUENCY

The actual frequency at which the combinationof the drum and material exhibits the greatestamplitude; that is when the generatedfrequency coincides with natural frequency of thematerial being compacted.

ROLL See drum.

I Pounds

lib)

The weight of the machine as shipped bythe manufacturer.

Kilograms(kg)

SHIPPING WEIGHT

Kilograms(kg)

Pounds(Ib)

SPRUNG WEIGHT See non-vibrating weight (mass).

Kilograms(kg)

Pounds(Ib)

That portion of the operating weight (mass)exerted on the ground at the drum(s).

STATIC WEIGHT

(continued)

14