Vibration Energy Harvesing with PZT Cantilevers and Mxximum Power Point Tracking

-

Upload

tatiana-yeva -

Category

Documents

-

view

29 -

download

0

description

Transcript of Vibration Energy Harvesing with PZT Cantilevers and Mxximum Power Point Tracking

Multifunctional Integrated Circuits and SystemsMultifunctional Integrated Circuits and Systems

Vibration Energy Harvesing with PZT Cantilevers and Mxximum Power Point Tracking

Na Kong (MS or Ph.D.) and Dong S. HaECE Dept, Virginia Tech, VirginiaMotivation:

• Vibration energy is abundant in nature.• Example Sources and Applications

Automobiles, bridges, industry machines, and human body.

Wireless sensor nodes, Portable devices• PZT cantilevers offer high density and scale

well.

Impedance Matching:• The maximum power is transferred under the

complex conjugate matching. However, the required inductance is impractical.

• Resistive matching is adopted.

Maximum Power Point Tracking:• It sets the input resistance of the DC/DC

converter to the optimal value dynamically under varying operation condition.

• A sophisticated algorithm can harvest more energy, but higher power dissipation. The goal is to maximize the net harvested energy. A “Perturb and Observation” algorithm is

simple and effective.

Proposed System:• A microcontroller unit (MCU) implements the

MPPT – flexible.

• Flyback Converter

IAC

Rs

Ls

Cs

CpZL

PZT

Low Power Controller Design:• Adopt constant on-time control for a lower

clock frequency.

• Duty cycle for the MPPT algorithm Execute the MPPT algorithm for 20 ms at 8-MHz clock, and go to the sleep mode for 2 sec at 1-MHz clock.

Conclusion:• The MCU-based approach is flexible and

achieves reasonably high efficiency.• Future improvements, use

a synchronous rectifier. an ASIC for the controller.

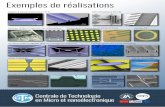

Experiment Set Up: 4 PZT Cantilevers Converter and Controller

Efficiency:• 62 – 73 % under 0.5g base acceleration

• Breakdown of losses

Did power to battery

increase?

Decrease load resistance.

Did power to battery

increase?

NoNo

Yes Yes

Increase load resistance.

Average power

44 45 46 47 48 49 50 51 52 530

2

4

6

8

10

12

Base Vibration Frequency (Hz)

Out

put

Pow

er (

mW

)

Our system

Resistor load

44 45 46 47 48 49 50 51 52 5360

65

70

75

80

85

90

95

100

Base Vibration Frequency (Hz)

Eff

icie

ncy

(%)

MPPT

Conversion

Overall

d

tTon

Ts DToff

d

tTon

Ts

DTon

102

103

104

101

102

103

104

105

DRin ()

Clo

ck f

requ

ency

(kH

z)

Constant Fs, Rin=50k

Constant Fs, Rin=10kConstant Ton

1 MHz

10 MHz

50 MHz

Sleep110 uA for

2 sec

MPPT 2.6 mA for

20 ms

s

Lmmavg T

iLP

2

2max,

Mechanical Model

Equivalent Input Resistance

RectifierEnergy Storage Device

DC/DC Converter

Controller

LoadEnergy

Harvesting Sources

MCU

PZT Cantilever

Constant Frequency Control

Constant On-time Control

max

outoverall P

P

max

inMPPT P

P

in

outconversion P

P