VersaFlex 2014

Transcript of VersaFlex 2014

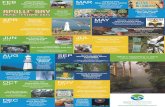

HIGH PERFORMANCE POLYUREA COATINGS

& LININGS

The World’s Leading Provider of Polyurea Technology

About VersaFlex VersaFlex formulates, manufactures and

supplies pure polyurea coatings, liners and sealants for a wide variety of industrial, commercial and maintenance/repair environments

2014 Marks VersaFlex’s 20 Year Anniversary

VersaFlex is a proud Sponsor of Polyurea.com and endorses quality hands on polyurea training through the Polyurea University

Our R&D team are the inventors on over 30 patents covering polyurea technology and processes and continues to develop new and exciting products and applications.

Most Experienced Technical Staff David Cerchie, President

Jeff Downing, VP Sales

Joe Haydu, Bridge Preservation

Roy Harvey, Concrete Repair & Decorative Flooring

Jeff Smith, Oil & Gas Secondary Containment

Lee Bower, Water & Wastewater

Roger Hemp, Technical Service

Dudley Primeaux, Director of Education & Development

Todd Gomez, Inside Sales & Technical Service

Doug Commette, Director of Marketing & Communications

John Winfrey, Lab Director

Jamie House, Director of Operations

Product Development & Technology Director of Development Dudley J. Primeaux II,

PCS, CCI was the original developer of polyurea spray technology Currently holds over 28 US patents

Wide selection of specially designed polyurea formulations (products) for specific application use

Capability to custom design polyurea and non-polyurea formulations to meet any application

Third Party Testing and Performance Credentials

Third Party Testing & System Performance ISO 9001:2008 Quality Management Certification

from SAI Global Certified in Manufacturing and Laboratory Chemical

Design

ASTM E 84-12c Flame Resistant

Infrared Reflective (IRR) Technology

ANSI/NSF 61.5 Approved Potable Water

Anti-Microbial Technology

Direct Food Contact (FDA)

AREMA Bridge Deck Waterproofing Membrane

Lab Capabilities & Testing Titration

Viscosity

Refractive Index

Density

pH

Color determination with spectrophotometer

Tensile properties

Tear properties

Compressive properties

Accelerated UV exposure

Water Vapor Transmission

Durometer Testing

IR Spectroscopy

Abrasion resistance

Materials processing evaluation through proper equipment

Thermal analysis

Modulated stress analysis

Modulated thermal analysis

Elevated and Sub-ambient tensile testing

Elevated and Sub-ambient tear testing

Elevated and Sub-ambient compressive testing

Liquid exposure testing

Pilot Production

The VersaFlex lab has its own pilot production area to create small batch “pre-production” samples for testing and evaluation

Allows verification of formulation design prior to manufacturing integration

Expedites customer/field testing to validate new product designs

State-of-the-Art Demo Facility Assist lab with new

product development and systems testing Identify optimum materials

processing evaluation through proper equipment

Ability to replicate field situations for technical service and quality control

Customized customer training

ISO 9001:2008 Certification VersaFlex was actually the first company in the

United States to receive ISO certification under the newer 2008 standard

In 2013, VersaFlex’s Product Development and Testing Lab achieved ISO 9001:2008 “Design Certification”

VersaFlex is the ONLY polyurea supplier with both Manufacturing AND Design certification

Quality Management System Third party regulatory audits of all product testing,

formulating, and designs Full Spectrum analysis and approval criteria for all

raw materials including field performance characteristics analysis

In depth pre-shipment Quality Assurance process for all products

NIST Traceability and verification on all measurement devices and equipment

Field application verification, bringing the lab to the field

Order Process Analysis In depth Purchase order review process: every

P.O. is reviewed and initialed by two customer service agents before transitioning into processing.

In depth Processing review and traceability process: all orders are processed, reviewed, and signed off on by production personnel. Lot and batch data is recorded for 100% traceability.

Logistic and final inspection process: all transportation documents and order contents are reviewed for accuracy and signed off on. Photos are taken of all freight for evidence of conformity.

Continuous Improvement Nonconformance reporting on all incidents

impacting QMS quality objectives

Root Cause analysis on all system nonconformance

Corrective Action implementation on all nonconformance reporting

Preventive action systems utilized to eliminate nonconformance before it occurs

Manufacturing Capability Modern 100,000 sq. ft. facility

Bulk Raw Materials Storage

Output capacity at only 50% utilization

In house A-side Pre-polymer Manufacturing

In-process and finished good quality control (ISO 9001:2008)Finished Goods Certificate of Analysis (COA)

Massive Inventory & Same Day Shipping Over 95% of all orders

ship same day / next day

Industry Leading Training Polyurea University is the leading

polyurea application and inspection training program/facility in the world

Registered Provider of Continuing Education PDH/CEU’s to Engineers and Architects

Free Technical Resources Instructional Videos

E-Books

Webinars

HIGH PERFORMANCE POLYUREA COATINGS

& LININGS

The World’s Leading Provider of Polyurea Technology