US2128620 - Bending Machine

-

Upload

devheadbot -

Category

Documents

-

view

1 -

download

0

description

Transcript of US2128620 - Bending Machine

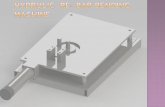

2,ì28,620 D. A. LYoNsï BENDING MACHINE

Aug. SQ, E938.;

/

,zi-mg. so, ww - D», A. MONS ¿www BENDING MACHINE '

Filed Aug. 25, 1957 2 Sheets$heet 2

Patented Aug. 30, 1938

UNITED sr'rs

2,128,629

ATE'Í‘ GFFIE 2,128,620

BENDING MACHINE

Daniel A. Lyons, Los Angeles, Calif., assigner to Consolidated Steel Corporation, Ltd., Los An geles, Calif., a corporation of California

Application August 23, 1937, Serial No. 160,359

6 Claims.

This invention relates to machines for bending elongated members, such as rods, strips, pipes, etc., and has as a broad object to provide a power actuated bending machine that is simple and in

5 expensive to construct and operate. A more speciñc object is to provide a bending

machine adapted to be operated by compressed air, steam or other fluid under pressure with maximum economy of the fluid employed.

10 Still another specific object is to provide a bending machine having a simple and effective structure for quickly and accurately `adjusting the range of movement of the movable bending element. ‘

15 The manner in which the foregoing objects are achieved, and the essential features of the invention, will now be explained by describing in detail a particular embodiment of the invention with reference to the drawings.

..20 In the drawings: Fig. 1 is a plan View of a bending machine in

accordance with the invention; Fig. 2 is a front elevational view of the machine

shown in Fig. 1, with portions broken away to 25 show the construction;

Fig. 3 is a detail vertical sectional view, taken substantially in the plane III-III of Fig. 1;

Fig. 4 is a detail sectionalk view, taken substan tially in the plane IV-IV of Fig. l; and

30 - Fig. 5 is a perspective view of a stop element employed in the machine. Referring first to Figs. 1 and 2, the bending

machine therein disclosed comprises a frame in cluding a top plate I constituting a table, a bot

35 tom plate 2 and an intermediate plate 3 posi tioned in spaced relationship between plates I and 2. The bottom plate 2 is supported from >a flooring by a pair of I-beams d and 5, respectively. The intermediate plate 3 is supported on the bot

40 tom plate 2 in spaced relation thereabove by a plurality of channel section members 6, "I, 8 and 9, and the top plate I is supported from the in termediate plate 3 in spaced relation thereabove by channel section members I9, II, I2, I3 and

4,5 I4, the members I9, I I, I2 and I4 being positioned immediately above the members 6, "I, '8 and 9, respectively. All of the parts described may be rigidly interconnected together by welding into a strong frame. Positioned above the top plate I

50 and rotatable in a horizontal plane thereabove , is a bending arm I5 having a shaft It projecting upwardly therefrom and positioned coaxially with . the aXis of rotation of the arm I5. The arm is also provided with a plurality of spaced apertures

55 I'l, any one of which is adapted to receive a pin

`point of contact with the shaft I9.

(Cl. 153-15) I8 supporting a roller I9 adapted to engage and bend a rod or other elongated member to be bent in the machine.` On the front and rear edges of the top plate I constituting the table of the machine, there are mounted relatively rigid sup porting members 2B and 2l, respectively, for supporting a rod laid thereacross in a suitable ' plane to be intercepted by the shaft I6 and roller I9 of arm I5. The member 29 is provided with a plurality of spaced apart holes 22 any one of 10 which is adapted to receive- a pin, and the mem ber 2l is also provided with holes 23 any one of which is adapted to receive an upstanding pin, which pins may constitute fixed guide means for supporting a rod being bent. ’ >

I also preferably provide another rigid guide supporting member 25 positioned above the top plate l and between the edges of the plate I. The upper surfaces of the members 20, 2| and 25 pref erably all lie substantially in the plane of the 20 upper surface of arm I5. Themember 25 is pro vided with a plurality of holes 26 therein, any one of which is adapted to receive a pin 21 supporting a roller 28. ,I One method of bending a rod with the machine 25

described is shown in Fig. 1, in which a rod 29 to be bent is laid across the‘members 29, 25 and 2I against the stationary roller 28 and the shaft I6 on arm I5. Arm I5 normally extends straight to the left (with reference to Fig. 1). The ma- 30 chine is then actuated in a manner to be described later, causing the arm I5 to rotate about the aXis of the shaft I6 in a counterclockwise direc tion, thereby causing the roller I9 to intercept

Ul

the rod 29 and bend it about the shaft I6, as 35' shown in dotted lines at 29a. If only a single bend were to be placed in the rod, there would be no stop means inserted in any of the holes 23 in member 2 I, and the front end of the rod would swing around as far as necessary depending upon 40 the angle of the bend placed in the rod at its

However, with the particular setup of Fig. l, an arrange ment is shown for placing a double bend in the rod 29. To this end a rigid bar or channel mem- 45 ber 35 is laid across the table on the members 29 and 2l and supported against horizontal move ment to the right by a pin 36 inserted in one of the holes 22 in member 20 and a pin 31 inserted in one of the holes 23 in the member 2l. There- 50 fore, as the front end of the bar swings around >theshaft I6, it contacts the stop member 35 and is thereafter bent around the roller I9,_as indi cated >at 29h, the motion continuing until the rod at bend 29h contacts the stop member 35, under 55

15

20

30

60

2 which condition the resistance afforded to further movement of the arm I5 by the stop member 35 stops the arm. The net result of the bending operation described is to form the rod 29 into two parallel sections interconnected by a diagonally extending section.

If desired, the stop member 35 can be removed and a double bend placed in the bar 29 by merely inserting the pin 31 in .a suitable aperture» 23 in member 2l, bar 29 then bearing directly against the pin 3l instead of against the stop bar 35. Under such conditions the angle of the bends placed in the rods is determined by the extent of movement of the arm I5, and such movement is limited by a stop mechanism associated with the arm, to be described later.

Referring now to the mechanism forrotating the arm I5, the arm is rigidly attached to the shaft I6 which extends a substantial distance be low the arm and is journaled in an upper bushing 45 positioned within an upper bearing member 4 I, (Fig. 3) supported by the upper plate I and the intermediate plate’ 3, and in a lower bushing 42 in a lower bearing member 43 supported by the lower plate member 2. Shaft I6 has keyed thereto at a point thereon

intermediate the lower bearing bushing 42 and the upper bearing bushing 40, a pinion 44 which meshes with a rack 45 extending horizontally be tween plates 2 and 3. A roller 45, mounted on .a shaft 4l supported between the plates 2 and 3, bears against the back face of the rack 45 to maintain the rack in positive engagement with pinion 44 at all times. Referring now to Figs. l and 2, the rack 45 is

rigidly connected at its right end to a relatively large piston rod 48 extending from the left end of a cylinder 49, the rod 48 connecting at its inner end to a piston 50 mounted within and sealing with the walls of the cylinder 49. A suit able stuiîing box 5l is provided on the left end of the cylinder 49 for sealing about the large piston rod 43. Pipes 52 and 53, respectively, lead from the opposite ends of the cylinder 49 through a control valve 54 which also connects to a pipe 55 leading to a source of ñuid under pressure, such as compressed air or steam. The valve 54 is a valve of conventional construction which may be actuated into a plurality of posi tions to connect either pipe 52 or pipe 53 with the pressure fluid supply pipe 55 and simultane ously exhaust the other pipe 53 or 52 to the at mosphere or to an exhaust line. It will be obvi ous that by admitting pressure fluid to» pipe 53 and venting the pipe 52, fluid pressure will be admitted to the right end of cylinder 49 to move the piston 56, the piston rod 48, and the rack 45 to the left, thereby rotating the shaft I5 and the arm I5 thereon in counter-clockwise direction, whereas, by admitting pressure fluid from pipe 55 to pipe 52 and venting the pipe 53, the piston 56, piston rod 48 and rack' 45 will be moved to the right to restore the shaft I6 and arm I5 to normal position. Since it is intended that the arm l5 perform work in bending a rod only when moved in counter-clockwise direction, it is necessary to apply substantial force to the arm I5 when rotat

' ing it in counter-clockwise direction, whereas the l only force required to retract the arm back to

<5170" normal position is that necessary to overcome the i ff'riction of the parts. It is‘for this reason that @fthe piston rod 48 is made of relatively large di î'ariieter so that the effective area of theV left face f Z'Óf't'he piston 56 is relatively small and the dis “placement volume of the cylinder on the left side

rber 60.

2,128,620 of the piston 50 is relatively small, and only a relatively small amount of fluid pressure is con sumed in moving the piston from left to right position. On the other hand, the effective area of the right end of the piston 50 is the full area of the cylinder, thereby providing the necessary surface to develop a powerful force for movement to the left in response to fluid admitted to the cylinder under moderate pressure.

It has been previously mentioned that it is often desirable to determine the extent of a bend placed in a rod by limiting the angle of rotation of the .arm I5 by an adjustable stop means in corporated in the mechanism for actuating the arm. This mechanism comprises a stop member

` 60,' (Fig. 4) adapted to intercept a cross head 6I on the left end of the rack 45 and thereby limit the length of the stroke of the rack. Obviously limitation of the stroke of the rack 45 limits the arc of rotation of the shaft I6 and the arm I5. The cross head 6I is guided for longitudinal movement by a slotted tubular stationary- mem ber 62 supported at opposite ends by the channel member l, and the channel member 6, the ends of the cross head 5I being slidably fitted within the slots in tube 62 and the channel member I hav ing a suitable aperture therein for receiving the end of the member 62 and passing the rack 45. The stop member 50 comprises a tubular member of internal diameter slightly larger than the eX-, ternal diameter of the guide tube 62 so vas to slide freely therealong. Thel member 60 has-di ametrically opposite cuts in its right end at spaced intervals thereabout to provide three sets of abutting faces adapted to contact the cross` head 6I.

'I‘hus referring to Fig. 5, there area pair of diametrically opposite high faces 63, a pair of diametrically opposite low ' faces 64, a lpair of diametrically opposite intermediate faces 65.` Each of the »faces extends circumferentially through an angle of 60° so that by rotating mem ber 60 through a total angle of 160° anyone of the three sets of faces 63, 64 and 65 may be pre sented to the cross bar 6I. Such rotation of the stop member 66 may be effected by a handwheel 66 mounted on a shaft lIì'l having a sprocket wheel 68 keyed thereto, which sprocket wheel is coupled by a chain 59 to a sprocket wheel ‘I6 on the mem

three adjustments for large variations in the stroke of the rack 45 and the arm I5. However, in accordance with the present invention, I pro vide further means for effecting adjustment of the longitudinal position of the stop member 60. 'I'o this end there is provided a cross head 1I extending across through the slots in the tubular member 62 back of the stop member 66 and cou pled thereto for simultaneous longitudinal move ment, but in such way as to permit rotation of member 6I) without rotation ’of the cross head 'I I. Thus the member 50 may be provided with an annular'groove ‘I2 therein adapted to receive the inwardly projecting ends ̀ of ñngers 'I3 secured to the ends of cross head 1I. Cross head 'Il is pro vided with a threaded central aperture which re ceives the threaded inner end of a shaft ‘I4 which is rotatably mounted in-a bearing member ‘I5 rigidly secured to the channel member 6. Shaft 14 has mounted on its rear end a handwheel 'I6 which bears against the end of’bearing member 'l5 and limits inward movement of the shaft 14. A collar 'I'l on the shaft 'I4 bears against the right end of the bearing member 'I5 and prevents out ward movement of the shaft.

Rotation of the handwheel 66 permits

20

25

30

35

'145

"50

55

10

15

20

25

30

35

40

45

50

55

60

2,128,620 It will be apparent that the shaft 74 restrains

the cross head 'll and the stop member 6U from longitudinal movement in response to abutment of the cross head 6l on the rack 45 against the member 60, but that longitudinal adjustment of the stop member 60 may be had by rotating the handwheel 16.

' When it is desired to move the arm l5 through a definite arc, the handwheel 66 is first rotated to rotate the sleeve 6E! into such position as to aline one of the three sets of faces 63, 64 and 65 with the cross head 6l, which will limit move ment of the rack ¿l5 so as to stop the arm I5 in approximately the position desired. Final ac curate adjustment of the limiting position _of the arm l5 can then be had by rotating the hand wheel 'l5 to adjust the stop member 6B longitudi nally by the action of the screw lila. The machine as described can be operated very

rapidly with relatively small consumption of com pressed air or steam by virtue of the fact that the limiting position of the arm is effectively ñxed irrespective of the pressure of fluid employed to move the piston. Therefore the pressure can be sufficiently high to move the arm very rapidly and positively through its stroke. At the same time full pressure fluid can be admitted to restore the arm to normal position quickly without waste of fluid by virtue of the small area of the back face of the piston.

Obviously many minor variations can be made in the particular embodiment of the invention disclosed, which has been described in detail for purposes of explaining the invention;` the inven tion is therefore to be limited only to- the extent set forth in the appended claims.

I claim: 1. A shaping machine comprising fixed mem

bers for engaging a workpiece, a movable member for engaging a workpiece at a point spaced there along from said fixed members, means for mov ing said movable member through an adjustable distance comprising an oscillatable member, and means for oscillating it, said oscillating member having a stop-engaging member thereon, a stop member in the path of movement of said stop engaging member, said stop member having a plurality of faces thereon spaced from each other in the direction of movement of said oscil latory member, means for moving said stop mem ber in a plane perpendicular to the path of movement of said oscillating member for selec tively bringing different ones of said faces into the path of movement of said stop-engaging member, and means for restraining said stop member against longitudinal movement by said stop-engaging member.

2. A shaping machine of the type described comprising fixed members for engaging a work piece, a movable member for engaging a work piece at a point spaced therealong from said ñxed members, means for moving said movable mem ber to shape a workpiece, and means for adjusta bly limiting the distance through which the

3 movable member moves comprising: a stop-en gaging member connected to said movable mem ber for movement therewith, a stop member mounted in the path of movement of said stop engaging member, said stop member having a plurality of faces thereon spaced from each other in the direction of movement of said stop-en gaging member, means for moving said stop member in a plane perpendicular to the path of movement of said stop-engaging member for selectively bringing «different ones of said faces into the path of movement of said stop-engaging member, and means for moving said stop» mem ber directly toward and away from said stop engaging member by small increments.

3. A shaping machine of the type described comprising fixed members for engaging a work piece, a movable member for engaging a work piece at a point spaced therealong from said fixed members, means for moving said movable member to shape a workpiece, and means for adjustably limiting the distance through which the movable member moves comprising: a stop engaging member connected to said movable member for movement therewith, a stop mem- ber comprising a tubular member positioned in the path of movement of said stop-engaging member, said tubular member having a plurality of circumferentially spaced, stepped faces on said one end thereof, and means supporting said tubu lar member against longitudinal and radial movement while permitting rotary adjustment thereof to present different ones of said stepped faces to said stop-engaging member.

4. A shaping machine as described in claim 3, in which said means for supporting said tubular member comprises a stationary tubular guide coaxial with and slidably engaging said tubular member.

5. A shaping machine as described in claim 3, in which said means for supporting said tubular member comprises a stationary tubular guide co axial with and positioned within said tubular member for slidably supporting the latter for rotary and longitudinal motion thereon, said guide having longitudinal slots therein and said stop-engaging member comprising a cross head extending through said slots.

6. A shaping machine as described in claim 3, in which said means for supporting said tubular member comprises a stationary tubular guide coaxial with and positioned Within said tubular member for slidably supporting the latter for rotary and longitudinal motion thereon, said guide having longitudinal slots therein and said stop-engaging member comprising a cross head extending through said slots, a second cross head extending through said slots back of said tubular member and engaging the rear end of said tubu lar member for longitudinal movement therewith,

10

20

25

30

35

40

50

and means for adjustably anchoring said second ' cross head against longitudinal movement.

DANIEL A. LYONS.