U.S. and Canadian Natural Gas Vehicle Market …...Industries 416, New Flyer Xcelsior, Orion VII...

Transcript of U.S. and Canadian Natural Gas Vehicle Market …...Industries 416, New Flyer Xcelsior, Orion VII...

Heavy-Duty VehicleOwnershipand Production

Final Report

U.S. and Canadian Natural Gas Vehicle Market Analysis:

I

Legal Disclaimer

This report was prepared by TIAX for America’s Natural Gas Alliance on terms specifically limiting TIAX’s liability. Our conclusions are the result of the exercise of our best professional judgment based in part upon materials and information provided to us by our subcontractors and others.

TIAX accepts no duty of care or liability of any kind whatsoever to any third party, and no responsibility for damages or loss, if any, suffered by any third party, as a result of decisions made, or not made, or actions taken, or not taken, based on this document.

This report may be reproduced only in its entirety and only with the prior written consent of TIAX.

Copyrighted items are the property of the respective copyright owners.

II

Table of Contents

1 Introduction

3 Overview of Key Heavy-Duty NGV Applications and Vehicle Types3.1 Heavy-Duty Buses3.2 Vocational and Refuse Trucks3.3 Local-, Regional-, and Line-Haul Trucks3.4 Heavy-Duty Off-Road Vehicles3.5 Marine and Ferry Boat Applications

2 Background on North American Heavy-Duty NGV Production and Use2.1 Diesel Baseline for OEMs and End Users2.2 Urban Air Pollution as the Historical Driver for NGV Deployments2.3 Fuel Cost as a Driver for NGV Deployments

AbbreviationsLower Heating Value Energy Conversion FactorsPrefaceExecutive Summary

Chapter 1

Chapter 3

Chapter 4

Chapter 2

4 Supply Side: Manufacturing and Production of Heavy-Duty NGVs4.1 Current Natural Gas Engine Offerings4.2 Onboard Fuel Storage for Heavy-Duty NGVs4.2.1 CNG Fuel Tank Offerings4.2.2 LNG Fuel Tank Offerings4.2.3 Size and Weight of Natural Gas Fuel Storage Systems4.2.4 Common Onboard CNG and LNG Fuel Systems for HDVs4.2.5 Manufacturer Targets for Heavy-Duty NGV Range4.3 Industry Business Drivers: Profitability and Sales Volumes4.3.1 Heavy-Duty NGVs OEMs4.3.2 Heavy-Duty Engine Manufacturers4.3.3 Heavy-Duty Vehicle Installers/Upfitters4.3.4 CNG and LNG Tank Manufacturers4.4 Other Drivers: Regulatory Compliance and Corporate Responsibility4.5 Manufacturers’ Views on Key Challenges and Barriers4.5.1 Incremental Costs of Heavy-Duty NGVs

and Components4.5.2 Customer Payback Period4.5.3 Refueling Infrastructure4.6 Technology Limitations and Manufacturing Issues4.6.1 Durability/Reliability/Warranty4.6.2 Service, Maintenance and End-of-Life Issues4.7 Manufacturers Views on Future Market Opportunities

III

5 Demand Side: Heavy-Duty NGV Ownership and End Use5.1 Tandem Drivers for End Users: Regulations and Incentive Programs5.2 Other Drivers: Corporate Policies and Green Image5.3 Reduced Lifecycle Costs of HDV Ownership5.4 Payback Period as a Determinant for Fleet Purchase Decisions5.5 Innovative Financial Programs for End Users5.6 End User Operational Considerations5.7 End User Fueling Logistics5.8 Vehicle Procurement Cycles and Near-Term Procurement Choices5.9 Examples of Successful End User Deployments in North America5.9.1 LNG Drayage Trucks at the Ports of Los Angeles and Long Beach5.9.2 CNG and LNG Refuse Trucks5.9.3 CNG and LNG Transit Buses5.9.4 CNG School Buses5.9.5 Canadian Corridors for Heavy-Duty NGVs5.10 Challenges for Expanded Heavy-Duty NGV Deployments5.10.1 Need for Expanded Offerings of Heavy-Duty Natural Gas Engines5.10.2 Competition with Hybrid and Battery- Electric Technologies5.11 Opportunities for Expanded Heavy-Duty NGV Deployments

6 Actions and Opportunities Appendix: Industry and End User Questionnaires

Chapter 5

Chapter 6

Table of Contents

IV

AFV

AGA

ANGA

ATA

BWI

CNG

CARB

CTP

DGE

DOE

DOT

EIA

EPA

GHG

HDV

LNG

NAAQS

NGV

NO

O&M

OEM

PM

PSI

PTO

ROI

SCAQMD

SVM

Diesel

Gasoline

LNG

Natural gas

Alternative Fuel Vehicle

American Gas Association

America’s Natural Gas Alliance

American Trucking Association

BTIC Westport, Inc.

Compressed natural gas

California Air Resources Board

Clean Trucks Program

Diesel gallon equivalent (=131.7 cubic feet of natural gas)

Department of Energy

Department of Transportation

Energy Information Administration

Environmental Protection Agency

Greenhouse gas

Heavy-duty vehicle

Liquefied natural gas (1 gallon LNG = 0.58 DGE)

National Ambient Air Quality Standards

Natural gas vehicle

Oxides of nitrogen

Operation and maintenance

Original equipment manufacturer

Particulate matter

Pounds per square inch

Power take-off

Return on investment

South Coast Air Quality Management District

Small volume manufacturer

129,488 BTU/gal

113,602 BTU/gal

74,720 BTU/gal

983 BTU/cubic foot (=131.4 BTU/gal of volume)

Abbreviations

Lower Heating Value Energy Content Conversion Factors

Source: Argonne National Laboratory, “Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation,” 1.8c

V

The TIAX team has conducted a thorough and independent assessment of the NGV market, with the primary objective of identifying the most productive and effective means to increase the use of natural gas vehicles (NGVs) in the U.S. and Canada, the TIAX team has conducted a thorough and independent assessment of the NGV market. To highlight the major opportunities to spur the market’s development and expansion, this assessment examines the key technical, economic, regulatory, social, and political drivers and challenges that shape this market. TIAX has partnered with The CARLAB, Clean Fuels Consulting, the Clean Vehicle Education Foundation, Jack Faucett Associates, the Natural Gas Vehicle Institute, and St. Croix Research to provide perspective and insights into the development of the future NGV market.

• Segmentation of the vehicle market

• Identification of market decision drivers

• Assessment of market development actions

• Analysis of competing technologies

• Analysis of market scenarios

• Integration of overall market development opportunities

The market perspectives for which decision drivers and opportunities have been identified and assessed are: light- and medium-duty vehicle ownership and production; heavy-duty vehicle ownership and production; compressed natural gas infrastructure; liquefied natural gas infrastructure; and government. Drawing on the respective expertise of each team member, TIAX presents an integrated assessment of the U.S. and Canadian NGV market in a collection of eight reports.

Each report is capable of standing alone while integrating the data, ideas, and themes of the other seven reports. The collection of reports in this TIAX analysis of the NGV market is supported by America’s Natural Gas Alliance and is intended to be transparent and accessible to a broad audience.

A Comprehensive and Independent NGV Assessment

TIAX’s overall approach relies on six key stages

Preface

VI

Executive Summary

The Heavy-Duty NGV Opportunity

Heavy-duty natural gas vehicle (NGV) deployments are a success story for energy diversification of the North America transportation sector (Figure ES-1). Thousands of natural gas fueled HDVs have been put into commercial fleet service, millions of gallons of diesel fuel have been displaced, and major improvements in urban air quality have been realized. The greatest success has been with high fuel use, return-to-base applications, such as transit buses, refuse trucks, vocational trucks, local and regional delivery trucks, and to a lesser extent, school buses. It is difficult to overstate the important role played by air quality based regulations and incentive programs in these heavy-duty NGV deployments.

Major opportunity exists to expand such deployments, including into heavy-duty off-road vehicle sectors. A major advantage of natural gas as a heavy-duty transportation fuel is its relatively low price compared to diesel fuel on an energy-equivalent basis. Moreover, a large “fuel cost differential” between natural gas and diesel has been forecast by the U.S. government over the next two decades. This means heavy-duty fleets should continue to have strong motivation to switch tonatural gas. While regulations and incentive programs have been strong drivers for heavy-duty NGV deployments, these dynamics are evolving. Regulations will need to be restructured towards realization of societal benefits that have not yet been

significantly monetized, such as reduced greenhouse gas emissions and lessoned reliance on conventional fuels from geopolitically unstable regions of the world. Ultimately, however, the sustainability of heavy-duty NGVs depends on their ability to compete “head-to-head” with diesel HDVs and provide low lifecycle costs with a relatively short payback period. This appears achievable given the forecasted fuel cost differential. Additional drivers for fleets to deploy heavy-duty NGVs − in the form of regulations − will further enhance this potential.

To realize the full potential for heavy-duty NGVs, certain challenges must be addressed. Based on input from the North American heavy-duty NGV industry and a limited number of end users across five basic HDV sectors, four general areas of challenge and/or opportunity are identified in this report: 1) vehicle costs, 2) infrastructure costs/access, 3) vehicle performance/ operations, and 4) vehicle/engine availability. However, it is the first two that present the most formidable challenges for expanded commercialization and deployment of heavy-duty NGVs.

Specifically, industry representatives and end users are concerned about the much higher capital costs of heavy-duty NGVs compared to similar diesel HDVs. Onboard natural gas fuel systems contribute 50 to 75 percent of these higher costs.1 To some extent, higher manufacturing volumes for fuel tanks can reduce such price premiums. However, much of the cost premium is inherent to the complex nature and components of onboard natural gas fuel tanks relative to diesel fuel tanks. In addition, responses from industry representatives and many end users indicate high levels of concern that heavy-duty fleets face high costs to build onsite fueling stations, or don’t haveadequate access to offsite fueling stations.

Clearly, strong potential exists to deploy much larger numbers of heavy-duty NGVs in North America; they can provide end users with low life-cycle costs, while also delivering compelling societal benefits. To meet this potential, innovative ways are needed to 1) further reduce deployment costs for end users, accelerating their payback period, and 2) help ensure that end usershave affordable, convenient access to natural gas fuel.

VII

1 According to questionnaire responses from CNG and LNG fuel storage systems; see Section 4.5.1 for details.

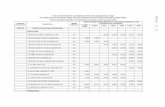

Figure ES-1

Heavy-duty NGVs are commercially offered for a wide array of vehicle sectors, although some sectors (e.g., mining equipment) essentially remain 100 percent fueled by diesel. This report highlights ways in which heavy-duty NGVs are manufactured and used in North America, and applications that have the best potential for expansion.

VIII

Heavy-DutyApplication

Example Natural Gas

Vehicles

CommonRefuelingLocations

Typical DailyRange

Average Age at First

Replacement

Package Delivery Car

Freightliner customchassis (recently

discontinued)Fleet Yards 65 Miles

20 Years/Drive to Scrap

Telecom/UtilityTruck

International 4300 with Emissions Solutions DT466

Conversion, Freightliner M2-112 with OEM Equipped

Cummins ISL-G

Fleet Yards 50 Miles Varies

Flat/Stake Beds,Beverage, Vans,

and Other

International 4300,Freightliner M2-112, FordE-450, Chevrolet Express

Fleet Yards,Public Fueling

Stations55 Miles Varies

School BusThomas Built Type D,

Blue Bird Type DFleet Yards 30 Miles Varies

Transit BusNorth American Bus

Industries 416, New FlyerXcelsior, Orion VII

Fleet Yards 130 Miles12 Years/

Drive to Scrap

RefuseAutocar Xpeditor, Mack TerraPro, Heil RapidRail,

Peterbilt 320Fleet Yards 85 Miles

10 Years/Drive to Scrap

Local/RegionalPickup and

Delivery

Freightliner M2-112,Peterbilt 384, Kenworth

T800

Fleet Yards,Public Fueling

Stations(Truck Stops)

200 Miles

6 years for NewTrucks, Drive to Scrap for Used

Trucks

Long HaulPeterbilt 386, Kenworth

T800 (limited service)

Fleet Yards,Public Fueling

Stations (Truck Stops)

300+ Miles 4 Years

Ground SupportEquipment

Autocar Xspotter Terminal Tractor, Toyota

8-Series forkliftFleet Yards

8 Hours-12Hours of

OperationDrive to Scrap

Locomotives:Switchers or

Specialty

Custom Built viaAftermarket/Upfitters

Rail Yards8+ Hours ofOperation

TBD (Operate to Scrap for

Diesel Switcher)

Construction/Mining

EquipmentNone (Currently) Job/Mine Sites Varies Drive to Scrap

1 Introduction

This report provides a broad “snapshot” of the manufacturing and end use of heavy-duty natural gas vehicles (NGVs) in the North American transportation sector. Its major sources of information are the direct inputs of knowledgeable representatives from the heavy-duty NGV industry and fleets that purchase and deploy heavy-duty NGVs. To obtain such inputs, TIAX directly queried high-level representatives from key manufacturers and end users of heavy-duty NGVs, using a multi-step process. It is important to note that this methodology inherently relies on inputs from those individuals who were willing and able to respond. Thus, there are limitations regarding the degree to which summarized results in this study should be considered “representative” of the companies involved with manufacturing heavy-duty NGVs or the fleets that deploy them. In particular, there are uncounted heavy-duty fleets across North America; obtaining feedback from a high percentage of these fleets was not feasible for this study.

To determine the list of individuals to contact, TIAX first prepared lists of companies that manufacture and supply heavy-duty NGVs and/or their components. Specific types of companies included: 1) original equipment manufacturers (OEMs) and small volume

manufacturers (SVMs) of heavy-duty vehicles and engines; 2) manufacturers and suppliers of natural gas fuel tanks; 3) NGV aftermarket companies and fuel system installers/upfitters; and 4) other companies involved in the heavy-duty NGV business, such as dealers, finance institutions, and service providers.

Next, TIAX telephoned high-level representatives (e.g., managers, directors, and executives) at these supply-side organizations. Repeated attempts were made to contact the individuals (or their recommended surrogates), until 1) contact was successfully made, or 2) further calling did not seem to be productive. Preliminary discussions were held with all individuals who could be reached. The primary objective was to obtain inputs that could help design effective written questionnaires having strong potential to elicit high response rates from manufacturers and end users. A secondary objective was to expand the list of OEM and end user representatives, to help facilitate a wider andmore-fruitful distribution of questionnaires. TIAX staff also visited a large heavy-duty NGV installer / upfitter operation and a transit district to take photographs and better visualize key issues.

Using information provided by the OEM contacts and other available sources, TIAX prepared its “end user contact list” from prominent companies, organizations, and agencies in North America that operate heavy-duty vehicles (HDVs), with a focus on fleets with 25 or more NGVs. TIAX then prepared five different automated questionnaires geared toward these types of supply- or demand-side heavy-duty NGV entities. Questionnaires (Figure 1-1) were emailed to all organizations and individuals on the contact lists. The five questionnaires (provided in the Appendix) are entitled 1) Questionnaire for Heavy-Duty Vehicle/Engine OEMs, 2) Questionnaire for Heavy-Duty Engine OEMs, 3) Questionnaire for Heavy-Duty Vehicle/SVMs and Upfitters, 4) Questionnaire for OEMs of Onboard Natural Gas Storage Tanks, and 5) Questionnaire for Heavy-Duty Natural Gas Vehicle End Users. Questionnaires were emailed up to four times to each organization, in TIAX’s attempt to get a strong response. In most cases, follow-up telephone calls were also made.

Input received from manufacturers (supply side) and end users (demand side) of heavy-duty NGVs provides a broad “snapshot” for their current and potential use as alternatives to conventional gasoline and diesel vehicles in the North American transportation sector.

1

Figure 1-1

The primary information sources for this report were responses to questionnaires by key players in the heavy-duty NGV industry. Telephone interviews were also major sources of information.

2

Your name: Your Title: Date:Phone: Fax:Name of Your Comapny:

Primary target niche of customer(s) (e.g. public transit, refuse, package delivery, etc.): Please check this box if you would like your answers reported without specific references to you or your agency.

Note: The purpose of this automated questionaire is to obtain/confirm input from heavy-duty (H-D) vehicle original equipment manufacturers (OEMs) about their current and potential future product offerings involving Natural Gas Vehicles (NGVs). Your input will help the natural gas industry understand how to best assist HDV manufacturers in expanding NGV markets.

Type ofHDV

ConventionalDiesel orGasoline

CNG LNG PropaneHybridElectric

Approx. Total Number of

HDVs Models You Offer

Semi Tractors

TransitBuses

SchoolBuses

ShuttleBuses

UtilityTrucks

Misc. MD/HDVocational

Trucks

DumpTrucks

RefuseTrucks

Off-RoadHDVs

StreetSweepers

Other:

America’s Natural Gas Alliance (ANGA)Questionnaire for Heavy-Duty Vehicle/Engine OEMs

1. A. Please characterize your current Heavy-Duty Vehicle offerings by filling in the number of HDV models you sell by fuel/technology type, for all applications that apply.

1. B. If H-D Natural Gas Vehicles are included in the table above, what is the approximate volume of vehicles that your company currently manufactures (units per year)?

2 Background on North American Heavy-Duty NGV Production and Use

In defining the challenges faced by heavy-duty NGV technologies to achieve sustainable and widescale commercialization, it is important to understand their competition. Over the last fifty years, the vast majority of the world’s HDVs have been powered by one particular fuel and technology combination: diesel fuel burned in compression-ignition internal combustion engines. This relatively simple, inexpensive, and robust technology2 has long dominated the HDV sector because it provides essential attributes sought by HDV manufacturers and their main commercial customers (municipal and private fleets). Table 2.1-1 summarizes these attributes desired by HDV fleets and the enabling characteristics of diesel fuel and engines.

Simply stated, diesel-fueled internal combustion engines have long dominated the HDV sector because they enable fleets to effectively and reliably transport goods and people at relatively low direct costs. Diesel fuel’s high energy content (per mass and volume) is a

particularly strong attribute; it enables fast refueling times and long driving ranges for HDVs – both of which are highly valued by fleets. Historically, these many positive characteristics that define diesel-fueled HDVs have made it difficult for heavy-duty NGVs (or other types of alternative vehicles) to gain major market share and “displace” large percentages of diesel use.

Despite these strong attributes of diesel engine technology, alternative fuels and propulsion technologies have gradually gained market share in the HDV sector. For several reasons, HDVs are especially attractive candidates for large-scale use of natural gas or other alternative fuels. On a pervehicle basis, diesel HDVs burn large volumes of diesel fuel and historically emit disproportionately high levels of two harmful air pollutants: fine particulate matter (PM) and oxides of nitrogen (NOX). Large return-to-base municipal HDV fleets (e.g., transit and refuse operations) are particularly conducive to the use of alternative fuel technologies, as they offer favorable logistical, operational, policy, and economic characteristics.

Heavy-duty natural gas engines began to emerge as a technologically and commercially viable alternative to diesel engines in the late 1980s. In today’s North American HDV market, an array of commercial heavy-duty NGVs are offered by numerous OEMs. These various types of heavy-duty NGVs run on either compressed natural gas (CNG) or liquefied natural gas (LNG). Both types of fuel systems have distinct advantages and disadvantages and are used in specific HDV applications, with some overlap.

Conventional fuel displacement is an inherent attribute of NGVs because they replace a traditional fuel with natural gas. However, this attribute has not historically driven OEMs to make and sell heavy-duty NGVs, nor fleets to purchase them. By comparison, another inherent characteristic of heavy-duty engines fueled by natural gas – their relatively low emissions of PM and NOX – has provided a distinct advantage that has motivated OEMs to sell and fleets to purchase NGVs. The importance of this advantage is addressed in the next subsection.

Diesel-fueled engines have long been the dominant power plant of the HDV sector, for both on- and off-road applications. However, over the last two decades, natural gas engines have emerged as technologically and commercially proven alternatives to diesel engines that can address environmental issues while also providing lower lifecycle costs for end users.

2.1 Diesel Baseline for OEMs and End Users

3

2 Diesel engines are sometimes called “million-mile” engines, referring to their typical useful life (with rebuilds).

Table 2.1-1

Diesel fuel and engines are the incumbent power plant for HDVs and define the competition for heavy-duty NGVs, offering characteristics meeting the attributes desired by OEMs and end users.

4

Attributes ofHeavy-Duty Vehicles Desired by

OEMs and End Users

Enabling Characteristics ofDiesel Fuel and Engines

Sufficient Torque/Power to MoveLarge Vehicles and Heavy Loads3

• Fuel: enables engines to operate at high compression ratios• Engine: high power density (power per volume and mass)

High Fuel Economy/Good Driving Range• Fuel: high energy content per volume and mass• Fuel Tanks: low in weight per energy stored• Engine: high thermal efficiency

Fast, Convenient, Easy Refueling

• Fuel: liquid at ambient temperatures and pressures; high energy content per volume of fuel pumped• Fueling Stations: widely dispersed network; no special training or protective equipment required

Low Lifecycle Costs/Good Affordability

• Fuel: relatively cheap• Engine/Onboard Fuel System: low capital costs, low maintenance costs (good durability/reliability)• Fueling stations: low capital and operational costs; existing network of mechanics and technicians

Durability/Reliability• Engine: “million mile” capability; relatively low failure rate of components

Ability to Meet ExistingEnvironmental Standards

• Fuel: reformulation over time enabling aftertreatment systems to help meet criteria pollutant emissions standards• Engine and Emissions Controls: evolution over time help meet criteria pollutant emissions standards

Ability to Meet Existing SafetyRegulations, Codes, and Standards

• Engine and Fuel: long histories of experience by regulators and emergency response professionals• Fuel Transport/Storage: ambient pressure and temperature helps minimize requirements

3 It is important to note that most heavy-duty applications do not require engines with as much horsepower and torque as is often equipped in today’s heavy-duty vehicles. In general, “downsizing” of diesel engines may be an important approach to meet future environmental goals while still meeting vehicle performance requirements of HDV fleets.

2 Background on North American Heavy-Duty NGV Production and Use

The key factor in the successful commercialization of heavy-duty NGVs in North America has been the existence of governmental regulations and incentives, which in tandem have created strong end user demand. In the U.S., the primary driver of such governmental efforts has been concern about meeting health-based federal National Ambient Air Quality Standards (NAAQS) for six criteria pollutants: carbon monoxide, lead, sulfur dioxide, ozone, nitrogen dioxide, and PM. California,which has some of North America’s most unhealthful air quality, has been especially aggressive about accelerated deployment of low-emitting HDVs to meet NAAQS.

This pressing need to reduce vehicle emissions has created a compelling niche for commercialization of heavy-duty NGVs. Over the last two decades, a variety of HDV engines fueled by natural gas and other alternative fuels have been certified at NOX and PM emissions levels significantly below similar diesel-fueled engines. Because these NOX and PM emissions reductions have been considered “surplus,”4 some government agencies have been able to subsidize

deployment of qualifying heavy-duty Alternative Fuel Vehicles (AFVs) in their jurisdiction. This historical emissions advantage was the impetus for creation of California’s landmark Carl Moyer Program, which provides incentive funds for fleets to help pay for the incremental cost of qualifying low-emissions HDVs. Now in its eleventh year, it is difficult to overstate the role played by the Carl Moyer Program (and other similar programs that followed) in creating: 1) demand among large California HDV fleets to purchase alternative fuel HDVs, and 2) supply from manufacturers to meet that demand. By far the greatest number of alternative fuel HDVs that have been sold and deployed under Moyer Program funds have been fueled by natural gas.

Complementary to these programs, regulations have also been very significant drivers for NGV deployments in North America. For example, California’s adoption in 2000 of an Urban Transit Bus Fleet Rule helped to accelerate manufacturing and deployment of CNG and LNG transit buses over the last decade. A local California agency, the South Coast Air Quality Management District (SCAQMD), adopted six different “fleet rules”5 applicable to heavy-duty fleets within its four-county jurisdiction (see Figure 2.2-1). The Ports of Los Angeles and Long Beach have adopted tariffs that have accelerated introduction of new trucks into port drayage6 service, including NGV versions. In New York, state agencies and other affected entities that operate medium- and heavy-duty vehicles must implement strategies to reduce conventional fuel consumption and emissions by using alternative fuels and improving vehicle fleet fuel efficiency (see Executive Order 111). It is important to note that such regulations have been viable and effective in part because there have been financial incentives to help end users buy down the incremental costs of heavy-duty NGVs. Historically, regulations and incentives that have helped deploy heavy-duty NGVs have been justified on the basis of their lower emissions relative to conventional HDVs. This important point is further discussed in subsequent sections.

For nearly two decades, low-emitting heavy-duty natural gas engines have provided air quality regulators with a key weapon to combat urban air pollution. Inherently low emissions from heavy duty NGVs have enabled adoption of both regulations and incentives for their deployment.

2.2 Urban Air Pollution as the Historical Driver for NGV Deployments

4 “Surplus” emissions reductions are generally defined as those obtained early and/or in excess of what is required by regulation.5 SCAQMD fleet rules require public agencies and certain private entities with fleets of 15 or more vehicles to purchase alternative fuel vehicles when replacing or

purchasing new vehicles.6 For this report, “port drayage” refers to heavy-duty Class 8 trucks that haul into and out of seaport terminals.

5

Table 2.2-1

Figure 2.2-1

Nearly 8,000 alternative fuel HDVs have been deployed since 1995 in California’s South Coast Air Basin under local air district fleet rules that seek to improve urban air quality. At least 90 percent of alternative fuel HDVs are estimated to be fueled by natural gas.

A combination of regulations and incentives have helped deploy heavy-duty NGVs in New York State, including CNG school buses for the Long Beach City School District.

6

1192: Clean On-Road Transit Buses

1193: Clean On-Road Residential Refuse Collection Vehicles

1195: Clean On-Road School Buses

1194: Clean Commercial AirportGround Access Vehicles

(Shuttle Buses, Taxis)

1196: Clean On-Road HD Public Fleet Vehicles

1116.1: Clean Street Sweepers

4,217

1,450

908

567

359

232

Source: South Coast Air Quality Management District, Mobile Source Division, October 2010*SCAQMD staff estimates that at least 90% of the deployed AFWs are/were fueled by CNG or LNG**Refers to estimated cumulative AFV deployments since adoption of wach corresponding fleet rule

Estim

ated N

umb

er of M

edium

-/Heavy-D

uty AFV

s* D

eplo

yed** U

nder SC

AQ

MD

Fleet Rules

Estimated Number of Medium-/Heavy-Duty AFVs* Deployed** Under SCAQMD Fleet RulesAQMD Fleet Rule

2 Background on North American Heavy-Duty NGV Production and Use

The Market Segmentation report of the overall TIAX market assessment includes a detailed discussion about the importance of fuel price in the North American transportation sector. HDVs account for just over two percent of the U.S. vehicle population, but they consume more than 21 percent of the transportation fuel.7 Diesel is by far the dominant fuel used for HDVs, for the reasons described in Section 2.1. Because fuel costs constitute a large portion of the total cost of ownership for HDVs, user fleets have strong motivation to operate their HDVs on the lowest-cost fuel that meets their rigorous operational needs.

A major advantage of natural gas as a transportation fuel is its relatively low price. As discussed in the Market Segmentation report, on an energy equivalent basis, CNG and LNG have historically been priced in the U.S. at one-third and two-thirds the price of diesel fuel. As this so-called “fuel cost differential” between natural gas and diesel increases, so does the financial incentive for end users to purchase heavy-duty NGVs as a means to reduce vehicle lifecycle costs. Table 2.3-1 shows a “snapshot” in 2012 to date of the fuel cost differential for CNG in selected U.S. states. As shown, the price of CNG vs. diesel (per diesel gallon equivalent, or DGE), varies widely by region. In addition to state-by-state, regional, and supplier differences in pricing structures, the volume purchased by a given end user can heavily influence prices of heavy-duty transportation fuels.

Looking ahead, an increasing trend appears to be on the horizon for the North American fuel cost differential of natural gas compared to diesel. Figure 2.3-1 shows historical and projected data by the U.S. government for the price of diesel and natural gas transportation fuels. It shows that the price of diesel is expected to rise significantly over the next two decades, while the price of natural gas is expected to stay fairly constant. By this projection, the fuel cost differential for natural gas transportation fuels (CNG and LNG) should significantly widen in the future, reaching over $2 per DGE. The importance of having a significant and sustained fuel cost differential to the future of heavy-duty NGV deployments in North America are discussed in subsequent sections.

A major advantage of natural gas as a heavy-duty transportation fuel is its relatively low price compared to diesel on an energy-equivalent basis. When a large fuel cost differential exists between natural gas and diesel, heavy-duty fleets can have strong motivation to switch to natural gas.

2.3 Fuel Cost as a Driver for NGV Deployments

7 According to the 2010 U.S. DOE Transportation Energy Data Book, an estimated 44.6 percent of all vehicles in the U.S. are trucks. Of those trucks, approximately 5.2 percent are Class 4 or greater.

7

Table 2.3-1

Average diesel-CNG fuel cost differentials8 in the U.S. varied widely by region in 2008 and will be important for the future viability of heavy-duty NGVs. In addition to state-by-state, regional, and supplier differences in pricing structures, the volume purchased by a given end user can heavily influence prices of heavy-duty transportation fuels.

8

State Average Fuel Cost Differential ($/DGE)

California 2.23

New York 1.95

Arizona 1.03

Texas 2.00

Georgia 2.14

Massachusetts 1.24

District of Colombia 2.17

Utah 1.22

Colorado 1.31

Figure 2.3-1

The U.S. government predicts that prices for diesel and natural gas transportation fuels will show an increasingly favorable fuel cost spread over the next 25 years, reaching over $2 per DGE.9

8 Based on data from American Petroleum Institute, “July 2012 Summary Reports,” http://www.api.org/Oil-and-Natural-Gas-Overview/Industry-Economics/~/media/Files/Statistics/gasoline-diesel-summary.ashx, July 2012; EIA, “Natural Gas Prices,” http://www.eia.gov/dnav/ng/ng_pri_sum_dcu_SAL_a.htm, accessed August 23, 2012; EIA, “Refiner Petroleum Product Prices by Sales Type,” http://www.eia.gov/dnav/pet/pet_pri_refoth_dcu_nus_a.htm, accessed August 23, 2012.

9 U.S. EIA. “Annual Energy Outlook 2012, June 2012; U.S. EIA, “Gasoline and Diesel Fuel Update,” http://www.eia.gov/oog/info/wohdp/diesel.asp, accessed September 10, 2012; U.S. EIA, “U.S. Natural Gas Vehicle Fuel Price,” http://www.eia.gov/dnav/ng/hist/na1570_nus_3a.htm, accessed September 10, 2012

2000 2010

History Projections

Fue

l Pri

ce a

t P

ump

(2

01

0$

per

DG

E)

Natural Gas (CNG)

Diesel

2020 2030 2035

3.00

2.00

4.50

2.50

0.00

3.50

1.50

4.00

1.00

0.50

2005 2015 2025

3 Overview of Key Heavy-Duty NGV Applications and Vehicle Types

This report describes existing and potential uses of natural gas as a transportation fuel in the HDV sector. Numerous HDV platforms operating on natural gas have been successfully launched throughout North America over the last twenty years. The result has been that thousands of non-diesel HDVs have been put into commercial fleet service, millions of diesel gallons have been displaced, and major improvements in urban air quality have been realized. While the greatest success has involved on-road HDVs (e.g., trucks, buses, and refuse haulers), significant NGV deployments have also occurred in off-road applications, such as locomotives, cargo-handling equipment, and large forklifts.

While this gradual phasing in of heavy-duty NGVs has been quite significant, HDV applications continue to be dominated by diesel fuel and engines. As summarized in Figure 3-1, there are approximately twenty broad classifications of HDV applications (Class 3 to Class 8). Within these on-road applications, there are about seven major applications that currently offer natural gas HDVs. Similarly, in the off-road sector, there are numerous broad classifications of commercially available diesel-fueled HDVs, as depicted in Figure 3-2. Natural gas alternatives to diesel HDVs are also offered in the off-road sector, although to a lesser degree than in the on-road HDV sector.

The Market Segmentation report of the overall TIAX assessment provides extensive discussion about each type of heavy-duty vehicle application. A brief overview is provided below of the various fleet applications that deploy the greatest numbers of heavy-duty NGVs fueled by CNG or LNG. Specific examples of successful deployments by end user fleets are provided in Section 5.9.

NGVs are successfully used today in several HDV applications, including transit, refuse, goods movement, and off-road applications.

9

Table 3-1

The on-road HDV sector consists of approximately 20 broad types of diesel-fueled HDV applications; about half offer natural gas alternatives.

10

Light-Duty

0-6,000

Type

Bus

es

Shuttle

Intercity

School

Transit

Short Haul

Port

Long Haul

Regional

Van

Tow

Moving

Divided

Beverage

Refuse

Dump

Cement

Car Hauler

Utility Truck

Reefer

Tank

Steet Sweeper

Sem

i-Tra

cto

rsH

eavy

-Dut

y V

oca

tio

nal T

ruck

s

Application Example Class 1 Class 2 Class 3 Class 4 Class 5 Class 6 Class 7 Class 8 Major Fuels in Use

6,001–10,000

10,001–14,000

14,001–16,000

16,001–19,500

19,501–26,000

26,001–33,000

33,001ormore

Medium-Duty

Gross Vehicle Weight: Rating (GVWR)in bs.

Heavy-Duty

Gasoline Diesel Natural Gas LNG

Source: Product literature

> 25 25–50 51–75 76–100 101–175 176–300 301–600 601–750 751+

Dump Truck

Bull Dozer

Grader

Earth Mover

Yard Truck

Self Loader

Baggage

Belt Loaders

Fork Lift

Off

-Hig

hway

Engine Horsepower

Major Fuels in Use

Table 3-2

The off-road HDV sector also consists of diverse vehicle types powered by diesel fuel, with natural gas options emerging.

Gasoline Diesel Natural Gas LNG

11

3 Overview of Key Heavy-Duty NGV Applications and Vehicle Types

Numerous types of heavy-duty buses are ubiquitous throughout North America. The function of buses is to transport people rather than cargo (goods and materials). By their very nature, buses are operated near populations, normally in urban areas that place high importance on improving air quality and reducing human exposure to diesel PM. Many, if not most applications, for heavy-duty buses involve return-to-base operations with central fueling and trained fueling personnel. These features make several specific heavy-duty bus applications ideal for using natural gas. Threeapplications in particular are described below (Figure 3.1-1).

Transit buses have been one of the most successful segments for adoption of NGVs, in large part due to their high fuel use and high priority as targets for reducing diesel engine emissions. About 11,000 natural gas transit buses (roughly 20 percent) have been placed into operation in North America over the past fifteen years. Because of their high fuel usage (an estimated 12,800 DGE per year10) and typical operating cycles,

natural gas transit buses can offer significant reductions in operational costs (fuel and maintenance) compared to conventional diesel buses. U.S. transit agencies have maintained or slightly expanded NGV inventories in recent years, and natural gas fuel consumption has increased. Canadian transit agencies were among the world’s first to deploy natural gas transit buses, and Canadian-based transit bus OEMs have been leaders in commercializing this technology. While current use of natural gas in Canada as a transit bus fuel is extremely limited,11 potential exists for expanded deployments.

School buses have been a targeted niche for use of natural gas engines due to the importance of reducing impact to children from harmful air pollutants. An especially compelling attribute is that natural gas school buses eliminate exposure of children to diesel particulate matter, which has been identified by the California Air Resources Board as a potential cause of cancer. Today, there are roughly 1,800 natural gas school buses deployed in North America. With more than 500,000 school buses deployed in North America today, this market segment has potential for expanded use of natural gas. However, school districts are generally cost-constrained and heavily reliant on incentives to offset the incremental capital costs of natural gas buses. Thus, this is among the most important HDV sectors to retain, or even expand, financial assistance mechanisms.

Shuttle buses are operated throughout North America by airports, hotels, universities, and other end user fleets. Heavy-duty buses in these applications can often be designed for relatively low volumes of onboard fuel storage because long driving ranges are generally not required. Shuttle buses operate under return-to-base conditions and can be refueled onsite at the fleet’s central location or at public fueling stations that are located near the fleet. While unknown numbers of diesel-fueled vehicles are operating throughout North America in various shuttle bus niches today, the population is likely to be quite significant. For example, the U.S. has several hundred major airports, most of which are heavily supported by shuttle bus networks.

Buses are distinguishable from most other types of HDVs; they transport people rather than goods and materials. Yet, buses share a number of key characteristics with other types of HDVs, such as high fuel use and operation in urban areas with poor air quality, that have made them attractive candidates for operation on natural gas.

3.1 Heavy-Duty Buses

12

10 Based on data from the American Public Transportation Association “61st Public Transportation Fact Book,” 2010.11 Canadian Natural Gas Vehicle Alliance. http://www.cngva.org. Accessed November 2010.

Figure 3.1-1

Heavy-duty buses operate throughout North America and are strong applications for natural gas. Specific end users of natural gas buses include transit and school districts, and shuttle buses operated by airports, universities, and hotel chains. (See Market Segmentation Report for details and sources for “segment statistics”)

13

Transit Buses

Segment Statistics

Total Vehicles 68,000

Natural Gas Vehicles 10,000

Petroleum Fuel Use (DGE) 650,000,000

Natural Gas Fuel Use (DGE) 150,000,000

Typical Daily Range (Miles) 90 to 130

School Buses

Segment Statistics

Total Vehicles 500,000

Natural Gas Vehicles 1,800

Petroleum Fuel Use (DGE) 550,000,000

Natural Gas Fuel Use (DGE) 2,200,000

Typical Daily Range (Miles) 30

Other Bus Applications Include:

Airport Shuttle Buses

Hotel Shuttle Buses

University Shuttle Buses

Over the Road Coach Buses

3 Overview of Key Heavy-Duty NGV Applications and Vehicle Types

Vocational trucks are a strong market in North America for the use of natural gas fuel, primarily CNG. “Vocational” in this context generally refers to a category of HDVs designed for very specific end uses with specialized bodies. Examples of vocational trucks include cement mixers, dump trucks, and a wide array of trucks used in the waste management industry. Such trucks are typically ordered from HDV OEMs with only the cab attached to the vehicle chassis. They are thenshipped from the chassis OEM to a body builder that installs a customized body to the vehicle chassis. This is the same basic process used in the medium-duty market when specialized truck bodies are required. However, in the heavy-duty market the vehicle purchaser typically has many more choices for configuring the vehicle chassis, cab, and engine.

Because of this ability to customize the body and chassis on vocational trucks, it is possible for purchasing fleets to specify almost any vocational truck as a natural gas truck, assuming at least one vehicle OEM offers a suitable natural gas option. For example, Freightliner

currently offers its M2-112 chassis with the Cummins ISL-G natural gas engine; this chassis can support a wide variety of vocational truck bodies as well as a semi-truck configuration. However, this chassis is designed for Class 7 and Class 8 applications and would not be ideal for Class 4 to Class 6 vehicles. Where natural gas options are not available from the vehicle OEM on a chassis in the proper weight class for a particular application, vocational truck purchasers must utilize upfitters / installers to provide natural gas engine conversions. As with medium-duty vehicles, the standard practice of customizing heavy-duty vehicles provides an opportunity to integrate natural gas engines and fuel systems without significantly altering the typical HDV purchase process.

Refuse trucks are a special type of vocational application with especially high fuel use (Figure 3.2-1). Fuel costs are significant for this sector due to their stop-and-go operation and the fact that engines must frequently provide “power take off” (PTO) operation. In the PTO mode, refuse trucks power special functions such as hoisting trash cans and compacting trash as it is dumped onto the truck. Use of PTO greatly increases fuel usage and reduces fuel economy (mpg).

The refuse hauling/solid waste sector is among North America’s fastest growing applications for heavy-duty NGVs. Two of the largest solid waste companies, Waste Management and Republic, collectively operate about 40,000 HDVs in North America, of which about 1,400 (3.5 percent) are fueled by natural gas (LNG or CNG).12 To keep up with natural gas fueling needs and further expand these NGV fleets, one major fuel supplier now operates natural gas stations for refuse trucks in at least twelve different states. In three years, growth of natural gas fueling stations specifically for the refuse hauling application has increased by an order of magnitude.13 Much of the growth in natural gas refuse truck deployments has been driven by local and regional regulations requiring cleaner vehicles.

Heavy-duty vocational trucks offer many characteristics conducive to natural gas, including high fuel use and return-to-base operation over well-prescribed service routes Refuse haulers are special vocational trucks that make up one of the fastest growing NGV segments.

3.2 Vocational and Refuse Trucks

12 Based on questionnaires completed by refuse companies.13 Showtimesdaily.com. “Clean Energy Likes Refuse Sector.” http://showtimesdaily.com/news-articles/clean-energylikes-the-refuse-sector. August 17, 2010.

14

Figure 3.2-1

Refuse haulers are special types of vocational trucks that are especially conducive to adoption of natural gas because they use high volumes of fuel per vehicle and employ return-to-base operation with well-prescribed service routes.14

Autocar Xpeditor Crane Carrier

Peterbilt 320

Mac TerraPro

Heil Rapid Rail

14 See Market Segmentation report for sources of sector information.

15

Side-loading and Rear-loading Refuse Trucks

Example Natural Gas VehiclesAutocar Xpeditor, Mack TerraPro, Crane Carrier, Heil RapidRail, Peterbilt 320

Common refueling locations fleet yards

Typical daily range 85 miles

Average age at first replacement 10 years/drive to scrap

3 Overview of Key Heavy-Duty NGV Applications and Vehicle Types

Local and regional delivery trucks are another high fuel use sector that can be well suited for the use of natural gas fuel. Trucks with detachable trailers, known as semi-tractors, are the most common type of Class 7 and Class 8 trucks on the road. Approximately 65 percent of the miles traveled by these trucks can be accommodated by a driving range of 200 miles or fewer.15 This market segment includes a wide array of “goods movement” HDVs, such as port trucks, food distribution trucks, and other short-haul trucks. Natural gas trucks in this market can provide significant fuel cost reductions compared to diesel trucks. Their localized area of operation allows these trucks to rely on a single onsite fueling station and/or a nearby public fueling station. Recent growth in these NGV deployments has been strongly driven by combinations of regulations, mandates, and incentive programs (e.g., California’s Carl Moyer and Proposition 1B Goods Movement programs.)

Line-haul trucks consume the largest volume of fuel per vehicle in the North American transportation sector. A single Class 8 semi-truck hauling one or two trailers on North American highways can travel more than 500 miles and consume nearly 100 DGE per day. This makes the economics of line-haul trucking highly sensitive to fuel costs. As such, strong potential exists to significantly reduce lifecycle costs for line-haul trucking operations through the use of natural gas, primarily LNG. At present, no truck manufacturer offers a natural gas powered truck with sufficient horsepower intended for high-mileage line-haul operation (Figure 3.3-1), as truck and engine OEMs are hesitant to invest in HDVs with large LNG engines unless and until there exists a suitable infrastructure to support them. However, at least two manufacturers offer Class 8 trucks with the Westport GX LNG engine that can serve well for the lower horsepower range of this duty cycle, where sufficient LNG fueling infrastructure exists. As discussed later in Section 5.9, there are important emerging deployments (especially in eastern Canada) for this line-haul use of heavy-duty NGVs, with very significant potential benefits.

Local-, regional-, and line-haul trucks are high fuel use applications in which end users can realize significant fuel cost benefits when switching to natural gas. While some return-to-base operations occur, many fleets in this segment are reliant on publicly available fueling infrastructure. In certain regions of North America, significant deployments of CNG and LNG trucks are underway for local and regional delivery trucks. Line haul trucks present unique challenges and opportunities for deployment of heavy-duty NGVs.

3.3 Local-, Regional-, and Line-Haul Trucks

15 U.S Census Bureau. “Vehicle Inventory and Use Survey.” 2002.

16

Table 3.3-1

Class 8 tractors drive local-, regional-, or limited line-haul operations throughout North America. In addition to diesel trucks, a variety of truck OEMs offer LNG versions that may work well in these applications, though no current LNG truck is planned for the highest mileage applications.

17

Class 8 TruckOfferings

Cab TypeEngine and

Horse PowerImages

FreightlinerColumbia(Diesel)

Day Cab

Detroit DieselSeries 60

410 HP

Mack CXU613(Diesel)

48” ExtendedCab

Mack MP7-395C

395 HP

Volvo 64T300(Diesel)

Day CabVolvo D13

405 HP

Freightliner M2-112 ISL-G

(LNG) Day Cab

Cummins-Westport ISL-G

320 HP

Kenworth T800ISX-G(LNG)

Extended CabWestport ISX-G

400 HP

Peterbit 384ISL-G(LNG)

Day Cab

Cummins-Westport ISL-G

320 HP

3 Overview of Key Heavy-Duty NGV Applications and Vehicle Types

Heavy-duty construction vehicles and equipment include highly specialized equipment ranging in size from less than 50 horsepower to more than 1,000 horsepower (Figure 3.4-1). Despite the availability of natural gas engines in many common horsepower ranges used in construction equipment, few if any natural gas options are currently available for construction equipment. Two key challenges, fuel tank integration and changing regions of operation, have made transitions from conventional diesel-fueled equipment difficult. As for drivers toward natural gas, some public agencies do require lower emission construction equipment to be used at local job sites. However, these requirements can generally be met by repowering the equipment with newer diesel engines.

Mining equipment and vehicles are similar to their counterparts in the construction industry but tend to be larger in size, due to a focus on maximizing throughput of material. This requires larger engines, some of which range from 1,000 to 4,000 horsepower. Currently, there is very limited availability of natural gas engines suitable for this market segment. However, high fuel consumption per vehicle and other use logistics make this niche attractive for engine and vehicle OEMs to consider for introduction of NGV offerings.

Locomotives can operate on natural gas; North America programs to develop low-emissions locomotives go back as far as the early 1980s. Recent focus has been on “switcher” locomotives that are used in urban rail yards to move freight cars. These locomotives typically have 1,200 to 2,000 horsepower diesel generator set engines that power electric drive systems. On a demonstration scale, LNG switchers have been created by repowering with a natural gas generator set engine and adding an onboard LNG fuel system. Also, at least one company (Energy Conversions, Inc.) upfits existing locomotives to run on either CNG or LNG, for use in specialty applications (e.g., the Napa Valley, California wine train).

Currently, with the exception of forklifts, North American use of natural gas in heavy-duty off-road vehicles has largely been limited to niche or demonstration uses such as aircraft support vehicles, terminal tractors, and switcher locomotives. These sectors, and a variety of other heavy-duty off-road applications, have potential to introduce or expand the use of CNG and/or LNG systems. In some cases, these vehicles are used continuously for eight or more hours per day at the same “captured” location, making it possible to achieve attractive economics for a switch to natural gas. For all off-road sectors, tougher emissions regulations are being introduced, which may serve as an impetus for OEMs to commercialize natural gas platforms. Specific off-road sectors are discussed below.

Terminal tractors (also known as yard hostlers or yard goats) are a promising heavy-duty off-road application for use of natural gas. These vehicles, which often use the same engines as similar on-road HDVs, are ubiquitous at North American seaports and other areas where cargo containers are moved. While natural gas configurations of terminal tractors are already commercially available, to date deployments in North America have been minimal.

Market penetration of NGVs in the heavy-duty off-road sector has largely been limited to forklifts and demonstrations for vehicles such as terminal yard tractors, ground support equipment, and switcher locomotives. The potential for expanded use is large, however, in part because more stringent emissions regulations are now taking effect. Potential new off-road niches for natural gas include construction and mining equipment.

3.4 Heavy-Duty Off-Road Vehicles

18

Figure 3.4-1

Construction and mining equipment have characteristics that are conducive to the use of heavy-duty NGVs, including high fuel use and centralized fueling. New emissions regulations in these sectors are likely to help drive commercialization of natural gas platforms, and engine manufacturers have expressed interest in entering such markets with large-displacement LNG engines.

19

Scraper Back-Hoe Excavator

Underground Mining Loader Large Rubber-tire Loader

Large Dump Truck (up to 400 ton payload)Underground Mining Truck

Skid Steer Loader Track-Type Tractor

Example Natural Gas Vehicles None

Common refueling locations Job sites

Typical daily range Varies (8+ hours of operation)

Average age at first replacement Drive to scrap

3 Overview of Key Heavy-Duty NGV Applications and Vehicle Types

Merchant ships, ferries and other marine applications are emerging as potentially major markets for natural gas engines. Among the drivers are new and stringent emissions regulations, including emerging “Emissions Control Areas” (ECAs) in the world’s more air polluted coastal areas.

3.5 Marine and Ferry Boat Applications

Some shipping industry representatives now believe that marine diesel oil is not sustainable as the fuel for ships within ECAs.17 One possible solution under consideration by the shipping industry, especially in Scandinavian countries and the Baltic Sea region, is to phase out marine diesel oil and replace it with LNG for “short sea shipping” applications. Worldwide today, approximately 100 merchant ships use LNG fuel for propulsion. Some predict that this will grow significantly given the push to reduce shipping-related emissions and implement ECAs in highly impacted regions across the globe. Marine engine maker Waertsilae OYG estimates that 10% of ships calling at ECAs will be running on LNG by 2015. That would represent a tenfold increase in vessels currently using the fuel. Some in the industry have predicted that LNG will become the dominant fuel source for all merchant ships within 40 years.18

Ferry boats are another emerging marine application for LNG fuel. For example, in countries bordering the Baltic Sea region (e.g., Norway and Poland), LNG-fueled passenger ferries are now being deployed. Like merchant ship applications, this switch requires infrastructure changes and entails additional capital costs, but it can result in lower lifecycle costs. The resulting emissions reductions can be compelling: according to Rolls-Royce Marine, ferry boat emissions of SOX, NOX, and PM are each reduced by at least 80% when such vessels are repowered from diesel engines to lean-burn natural gas engines.19 Use of LNG for marine vessel propulsion in North America has not yet been attempted on a significant scale, but good potential appears to exist for short sea shipping and ferry boat applications.

Currently, the dominant fuel for the merchant shipping industry is high-sulfur-content marine diesel oil. Largely due to sulfur content that averages about 2.7%, marine vessels are major sources of sulfur oxides (SOX) emissions and other harmful pollutants.16 Under new rules adopted by the International Maritime Organization, ships must cut SOX emissions by nearly 90% over the next decade. In the most air-pollution-impacted locations designated as “Emissions Control Areas” (ECAs), SOX emissions must be cut by 98%. In addition, NOX emissions from certain marine vessels must be reduced under IMO requirements. To address global climate change, shipping companies are also now facing pressure to reduce carbon emissions.

16 A sulfur content of 2.7% is equivalent to 27,000 parts per million (ppm). By contrast, on-road diesel fuel in the United States cannot exceed sulfur content of 15 ppm. High sulfur in diesel fuel increases emissions of SOx and other pollutants, while also prohibiting the use of emissions after treatment systems such as diesel particulate filters.

17 Tor Svensen, President of DNV, The Age of LNG is Here: Most Cost Efficient Solution for ECAs, presentation dated June 8, 2010, downloaded from http://www.dnv.com, 18 Maritime News, “LNG to Displace Oil as Dominant Ship Fuel within 40 Years, Det Norske Says,” November 25, 2010, accessed online at http://bestshippingnews. com/uncategorized/lng-to-displace-oil-as-dominant-ship-fuel-within-40-years-det-norske-says/.19 As cited by Per Magne Einang, Research Director, Marintek, “LNG as Fuel for Marine Application”,presentation , http://www.cimac.com/cimac_cms/uploads/ explorer/other_events_2009/presentation_marintek.pdf, November 2009.

20

Figure 3.5-1

Merchant ships and ferry boats powered by LNG are being deployed in environmentally sensitive areas of Europe such as the Baltic Sea region. While not yet a significant marine fuel in North America, some in the shipping industry have predicted that LNG will become the dominant fuel source for all merchant ships within 40 years.20

21

BERGENSFJORD

20 Maritime News, “LNG to Displace Oil as Dominant Ship Fuel within 40 Years, Det Norske Says,” November 25, 2010, accessed online at http://bestshippingnews.com/uncategorized/lng-to-displace-oil-as-dominant-ship-fuel-within-40-years-det-norske-says/.

The LNG-fueled Norwegian passenger ferry, “Bergensfjord”, first deployed in 2007 for Baltic Sea service.

One of two Rolls-Royce lean-burn natural gas engines used to power the Bergensfjord.

4 Manufacturers’ Views Supply Side: Manufacturing and Production of Heavy-Duty NGVs

Currently, most heavy-duty NGV platforms are designed for one of two engines. The smaller of these engines, the Cummins Westport ISL-G, has emerged as the workhorse of heavy-duty NGVs in North America. However, the ISL-G’s power and torque ratings are not optimal for larger HDVs. Other natural gas engines with higher horsepower and torque are being introduced into the market to fill this void.

4.1 Current Natural Gas Engine Offerings

The smaller, dedicated natural gas Cummins ISL-G engine has emerged as the prevailing power plant for North American HDVs that operate on natural gas. For example, approximately 23 commercially available transit bus models (thirteen CNG and ten LNG) can be purchased with this engine today.21 The ISL-G also powers a variety of other heavy-duty NGV types across various on- and off-road applications, including lower horsepower port drayage trucks, school buses, shuttle buses, and street sweepers. The larger Westport GX heavy-duty natural gas engine was designed primarily for non-transit HDV applications that require higher horsepower and torque. Targeted applications include port drayage trucks, heavy-haul trucks, refuse transfer, dump trucks, roll-offs, line-haul, and other vocational applications. The GX is currently available in factory-assembled LNG truck platforms that include the Kenworth T800 and three different Peterbilt models.22 Approximately 300 GX-equipped HDVs have been deployed in North America to date.

The heavy-duty NGV market has heavily relied on the Cummins Westport ISL-G engine. However, at least three new heavy-duty natural gas engines are now emerging as in-demand power plants for the North American HDV market: the Doosan Infracore 11.1 liter GK12, the Emissions Solution 7.6 liter Phoenix, and the Cummins Westport 11.9 liter ISX-G. Figure 4.1-2 lists all available engines and their applications. Over the longer term, heavy-duty engine OEMs are pursuing additional new commercial offerings, with support from North American governmental agencies. For example, the U.S. Department of Energy is spearheading a $21 million public-private partnership to support the development of new natural gas engine and vehicle platforms. Reportedly, numerous heavy-duty engine OEMs have expressed interest in participating. Canadian federal and provincial governmental agencies are also supporting OEM efforts to expand heavy-duty natural gas engine and vehicle offerings.

As of late 2010, most commercially offered heavy-duty NGV platforms are designed for one of two engines: the Cummins Westport 8.9 liter ISL-G, or the Westport 14.9 liter GX. Figure 4.1-1 shows their engine specifications. Other than displacement and horsepower, the primary difference is that the smaller ISL-G is a “dedicated” (100 percent) natural gas engine that uses stoichiometric, spark-ignited combustion combined with a three-way catalyst to achieve the U.S. federal 2010 heavy-duty engine emissions standards. By contrast, the larger GX uses high-pressure direct injection of natural gas into a compression-ignited engine. The GX relies on pilot injection of diesel fuel to ignite natural gas, resulting in diesel-equivalent power and vehicle range. However, this technical approach has made it necessary for Westport to equip the GX with essentially the same emissions controls used on its diesel-fueled engine.

21 NGVAmerica. “Guide to Available Natural Gas Vehicles and Engines.” http://www.ngvamerica.org/pdfs/marketplace/MP.Analyses.NGVs-a.pdf. May 21, 2010.22 Westport. “LNG Engines for Heavy-Duty Trucks.” http://www.westport-hd.com. Accessed November 2010.

22

Figure 4.1-1

Examples of heavy-duty natural gas engines available in North America today.

23

CWI ISL-G Natural Gas Engine

Type: 8.9L, 4-cycle spark-ignited inline 6-cylinder, turbocharged, CAC

• Advertised HP: 250 to 320• Peak Torque: 1,000 lb-ft @ 2,200 rpm

Doosan GK-12 Natural Gas Engine

Type: 11.1 L, 4-cycle spark-ignited inline 6-cylinder, turbocharged

• Advertised HP: 250 to 320• Peak Torque: 1,000 lb-ft @ 2,200 rpm

Westport GX Natural Gas Engine

Type: 14.9L 4-cycle compression-ignited HPDI with diesel plume, inline 6-cylinder

• Advertised HP: 400 to 475• Peak Torque: 1,750 lb-ft @ 1,200 rpm

ESI Phoenix Natural Gas Engine

Type: 7.6 L, 4-cycle spark-ignited inline 6-cylinder, turbocharged

• Advertised HP: 300• Peak Torque: 860 lb-ft @ ~1,700 rpm

Table 4.1-1

An array of HDV applications.

Class Supplier Engine

HD Converter

Emission Solutions Inc.

7.6 LNGPhoenix

HD OEM

CumminsWestport

8.9LISL G

HD OEM

Doosan Infracore

America 11LGK12

HD OEMCummins Westport

11.9L ISX G

HD OEM Navistar 13L

HD OEMWestport

Innovations15L GX

Ligh

t-D

uty

Pass

enge

r C

ar

Taxi

Ligh

t-D

uty

Truc

ksPa

ckag

e D

eliv

ery

Vehi

cle

Uti

lity

Truc

ksSh

uttl

e B

uses

Oth

er M

ediu

m-D

uty

Truc

ks

Tran

sit

Bus

esSc

hool

Bus

esD

raya

ge T

ruck

s Sh

ort-

Hau

l Tru

cks

Long

-Hau

l Tru

cks

Refu

se H

aule

rsO

ther

Hea

vy-D

uty

Truc

ks

24

4 Supply Side: Manufacturing and Production of Heavy-Duty NGVs

There are four basic types of design for CNG tanks. Today’s heavy-duty CNG vehicles are mostly equipped with the lightest-weight Type III or Type IV systems, generally requiring three to six CNG tanks per vehicle to store sufficient fuel for a heavy-duty NGV.

4.2 Onboard Fuel Storage for Heavy-Duty NGVs4.2.1 CNG Fuel Tank Offerings

CNG cylinders for motor vehicle applications are manufactured and commercially offered in a wide array of weights and sizes. There are four basic tank types, designed to meet specific requirements of different NGV applications. As indicated in Table 4.2.1-1, the most suitable type of CNG tank for a given vehicle depends largely on a cost vs. weight tradeoff. The heaviest all-metal Type I tanks store the least fuel per pound of system weight, but they are relatively inexpensive. Lighter composite tanks, Types II, III, and IV, store more fuel per pound of system weight but also cost more. Today’s heavy-duty CNG vehicles are mostly equipped with the lightest-weight Type III or Type IV systems. These NGV applications generally require onboard fuel storage ranging from 40 to 80 DGE, with transit buses carrying as much as 150 DGE. Thus, it typically takes three to six Type III or IV CNG cylinders (of varying sizes) to comprise a practical heavy-duty NGV fuel system (Figure 4.2.1-1).

It is important to note that all CNG cylinders used on NGVs in North America must meet the same basic and comprehensive safety standards. Moreover, end users are required to conduct periodic safety inspections on all tank types. This is an important issue because typical road conditions can present a very severe environment for CNG tanks.23 Section 4.6.2 discusses end-of-life concerns regarding CNG tanks and field inspections.

25

23 Gambone, L. “CNG Cylinders 101.” Powertech presentation, Natural Gas Transit Users Group Meeting. October 2005.

Cylinder Type

General Description Characteristics Example NGV Uses

I Entirely made of metal (either steel or aluminum)

• Lowest cost• Heaviest

OEM and aftermarket on- or off-road applications that are cost- rather than

weight-sensitive, and/or where additional weight can be helpful

(e.g., forklift counterweight)

II

Metal liner reinforced withcomposite wrap

(e.g., glass or carbon fiber) in epoxy of resin around the

tank’s middle (“hoop wrapped”)

• Lighter than Type I cylinders, but more expensive

OEM and aftermarket on-road LDV and MDV applications

III

Metal liner reinforced withcomposite wrap

(either glass or carbon fiber) around the entire tank

(“full wrapped”)

• Lightweight, more expensive than Types I and II

OEM on-road MDV and HDV applications that are cost sensitive but focused on weight reduction and maximizing fuel

efficiency/range

IV

Plastic gas-tight liner reinforced by composite wrap around the

entire tank (“full wrapped”);entire strength of cylinder is

composite reinforcement

• Lightweight• Best for higher working pressures• Most expensive

OEM specialty MDV and HDV applications that are less cost sensitive while focused on weight reduction and

maximizing fuel efficiency/range

Table 4.2.1-1

Overview of CNG Cylinder Types and Example NGV Uses

26

27

Figure 4.2.1-1

Type III and IV CNG tanks dominate the heavy-duty NGV sector. Shown here are:

A. A 5-tank pack of Type III cylinders, designed to hold 90 DGE for refuse trucks. B. The cross-section of a Type III tank, showing reinforcing. C. A 3-tank pack of Type III cylinders, encased for installation on a vocational truck, holds 82 DGE. D. A single Type IV cylinder is needed here to hold 82 DGE; this is a relatively low-weight system that takes up less space but entails higher costs.

A.

C.

B.

D.

4 Supply Side: Manufacturing and Production of Heavy-Duty NGVs

LNG tanks are more complex than CNG tanks but hold more natural gas per weight and volume. Two basic tank types are being installed on heavy-duty NGVs in North America, with total system capacities of 65 to 170 DGE per vehicle.

4.2 Onboard Fuel Storage for Heavy-Duty NGVs4.2.2 LNG Fuel Tank Offerings

Currently, there are two companies manufacturing and marketing LNG fuel tanks in North America for heavy-duty NGVs: NexGen Fueling, Inc. and BTIC Westport, Inc. Both make LNG tanks that are refilled at LNG stations using the same procedure. However, the two types of LNG tank technology vary somewhat in their design, as noted below.

NexGen Fueling, Inc. (also known as “Chart”) has reportedly manufactured more than one million LNG and cryogenic liquid cylinder tanks. NexGen will manufacture LNG tanks to “fit any application” of heavy-duty NGV. They offer ten core LNG tank products with fuel volumes that range from 25 to 86 DGE. Currently NexGen’s worldwide annual sales of LNG tanks for NGVs are about 1,000 units.24 Customers that have purchased and utilized NexGen Fueling’s vehicle tanks include most major bus, truck, and engine manufacturers. In the NexGen LNG tank technology, coolant fluid from the engine is used to warm the LNG from the fuel tank into a gaseous phase for introduction into the combustion cylinders.25

BTIC Westport, Inc. (BWI) is a joint venture formed in 2006 between Canadian company Westport Innovations and BTIC of Beijing, China. The company’s objective is to “market and sell more cost-effective, custom-engineered” LNG tanks for the transportation market. In addition to making LNG tanks, BTIC claims to be the largest CNG cylinder manufacturer in Asia. BTIC has reportedly “built a sophisticated new assembly line” that will be used to manufacture BWI LNG tanks. Currently, for applications to LNG trucks using the Westport fuel system, there are two core LNG tank products, with fuel volumes that are believed to be approximately 65 and 85 DGE. Currently BWI’s annual worldwide sales of LNG tanks for the Westport system are about 600 units.26 The Westport LNG fuel system is diagrammed in Figure 4.2.2-1. A key difference from the NexGen system is that, in the Westport system, a unique, engine-driven LNG pump pressurizes liquid natural gas to high pressure and then subsequently the liquid natural gas is vaporized to a warm, high-pressure gas.27

LNG is stored as a cryogenic liquid at temperatures as low as -260°F (-162°C). Fuel pressure within the storage vessel remains relatively low, ranging from 50 psi (3.5 bar) to 150 psi (10.3 bar). The advantage of liquefying natural gas into LNG instead of compressing it into CNG is that much greater energy can be contained in a given size and weight of fuel storage. However, this higher energy density brings greater storage system complexity. Specialized, highly insulated storage tanks are needed to keep LNG fuel in its cryogenic state in heavy-duty NGVs. If LNG vehicles are not regularly operated, onboard LNG fuel will revert to its gaseous state and must be vented to the atmosphere. LNG tanks are designed with a special vacuum layer of insulation that keeps the fuel cold, provided it is used within one to two weeks. Due to the physics and dynamics of cryogenic natural gas as it is stored in these systems, roughly 10 percent of the LNG in a full tank is not usable to power the NGV that carries it.

28

24 Questionnaire response received from NexGen Fueling, Inc.25 NexGen Fueling, Inc. http://www.nexgenfueling.com/p_ofs_specs.html. Accessed November 2010.26 Questionnaire response received from Westport Innovations.27 Westport Innovations, Inc. http://www.westport-hd.com/complete_system.php. Accessed November 2010.

Figure 4.2.2-1

A. Two different single-tank LNG configurations from NexGen: 68 DGE (foreground) and 86 DGE (background) B. NexGen’s 86 DGE LNG tank installed on the frame rail of a Class 8 port truck C. Complete Westport LNG fuel system as specially designed for use with Westport’s GX engine D. LNG tanks for the Westport LNG fuel system manufactured by the BWI joint partnership

29

A.

C.

B.

D.

Fuel Injectors(Under Valve Cover)

Diesel FuelPump

HydraulicPump

Warm,High-Pressure

CompressedNatural Gas

Control Units(Chassis Mounted)

High-Pressure Accumulator(Chassis Mounted)

LNG Tank(Chassis Mounted)

Fuel ConditioningModule

4 Supply Side: Manufacturing and Production of Heavy-Duty NGVs

Manufacturers work with end users to build heavy-duty NGVs with enough onboard natural gas for typical operational needs, without unacceptable tradeoffs in cargo weight or volume.

4.2 Onboard Fuel Storage for Heavy-Duty NGVs4.2.3 Size and Weight of Natural Gas Fuel Storage Systems

Diesel is a heavy-duty transportation fuel with exceptional energy density. A typical truck fuel tank filled with 100 gallons of diesel fuel weighs about 850 pounds and takes up about 14 cubic feet of space on the chassis frame rails. By contrast, alternative fuels such as CNG, LNG, and propane have lower energy density than diesel. An advanced all-composite (Type IV) CNG fuel storage system with four tanks holding 100 DGE would weigh approximately 1,600 lbs and take up about 62 cubic feet of chassis space.28 A single onboard LNG tank carrying approximately 100 DGE of natural gas29 would weigh about 1,300 lbs and take up about 30 cubic feet of chassis space.

Figure 4.2.3-1 compares the weights and volumes per energy stored (in DGE) of full fuel tanks for five transportation fuels: diesel, gasoline, propane, LNG, and CNG. OEMs work with end users to ensure their heavy-duty NGVs have enough onboard natural gas for typical operational needs, without incurring unacceptable reductions in the weight or volume to be transported. OEMs were specifically asked about how this issue of fuel system weight and size affects their NGV products and use by purchasing fleets. Comments received are itemized in Table 4.2.3-1.

30

28 Based on literature from CNG and LNG fuel tank OEMs, online or provided directly to TIAX.29 Note that this is a hypothetical LNG fuel tank because the largest commercially offered single tank holds 86 DGE.

Figure 4.2.3-1

Onboard storage tanks for alternative fuels are heavier and take up more space than typical diesel and gasoline fuel tanks, requiring special planning by manufacturers to build heavy-duty NGVs for customers that store enough natural gas onboard for typical operational needs, without incurring unacceptable reductions in the weight or volume to be transported.

31

Size of Fuel Tank per Energy Stored(ft3 per DGE)

CNG Type I (3.6k PSI)

CNG Type II (3.6k PSI)

CNG Type III (3.6k PSI)

CNG Type IV (3.6k PSI)

Typical Gasoline

Typical Diesel

LNG

Propane (Various Applications)

0.4

0.3

0.5

0.8

0.7

0.6

0.2

0.1

0

0 5 10 15 20 25 30 35 40 45 50

Heavier per Amount of Energy Carried

Larg

er

pe

r A

mo

un

t o

f E

ne

rgy

Car

rie

d

Weight of Full Fuel Tank per Energy Stored (Pounds per DGE)

Table 4.2.3-1

Heavy-duty NGV industry representatives perceive weight and volume issues for onboard fuel storage to be challenging.

32

Input From:Comments Regarding Weight and/or Volume

of Onboard Natural Gas Fuel Storage

Class 8 Truck OEM #1• Weight/size is important, but fleet customers know tradeoffs well and optimize accordingly

Class 8 Truck OEM #2

• Tank weight and size are big issues because payload and volume are big industry drivers

• Truck weight (front axle, overall tare weight) critical, especially vocational/delivery applications

Class 8 Truck OEM #3• NGV weight can be “close to neutral.” Even though NG fuel storage adds weight, some diesel components (e.g., certain emissions control systems) are not needed on NGVs

Class 8 Truck OEM #4

• CNG is difficult to package on trucks; 60 DGE requires two large tanks on frame rails

• Many return-to-base trucking applications need “every bit of frame space”

Refuse/VocationalTruck OEM

• Fuel tank packaging “a very big deal,” but refuse and vocational applications can work very well