Update on Be Wall Cavity Steve Virostek Lawrence Berkeley National Lab MTA RF Workshop November 15,...

-

date post

21-Dec-2015 -

Category

Documents

-

view

218 -

download

0

Transcript of Update on Be Wall Cavity Steve Virostek Lawrence Berkeley National Lab MTA RF Workshop November 15,...

Update on Be Wall

Cavity

Steve VirostekLawrence Berkeley National Lab

MTA RF Workshop

November 15, 2010

2

•Funding is available (LBNL account) for the design/fab project (~$200k)

•Several design concepts are being developed based on preliminary discussions (R. Palmer, S. Virostek, D. Li)

•A preliminary 3D CAD model of the nominal design concept has been completed by Allan DeMello (LBNL)

•Quotes have been obtained for Be material in various configurations for the different design concepts

•Currently analyzing the manufacturing risks of different approaches: brazing (Be to Cu or Hastelloy), coupling port configuration, bolted RF/vacuum joints, machining processes

•Progress has been delayed by a lack of manpower at LBNL, but expect to move forward soon

Current Status

3

Original Concept (R. Palmer)

4

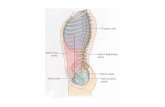

• Common characteristics–Two bolted halves or a center body with two cover plates

–Combined RF and vacuum seal at bolted joints–Main body is copper plated Hastelloy or solid copper

–Cavity inner side walls are beryllium (TiN coated)

–Slotted coupling port in side wall

• Beryllium side wall options1) Thin Be foil (~500 m) brazed to side walls2) Thick Be plates (~6 mm) brazed to side walls3) Solid Be side walls (no brazing)

• An all Be cavity is not likely to be practical

• E-beam welded cavity joints not being considered due to accessibility issues

Concept Descriptions

5

Concept Descriptions

Thin FoilBe wall

Thin PlateBe wall

Thick PlateBe wall

6

3D CAD Model – Cavity Assembly

Cavity body (2 halves)Cavity body (2 halves)

Be wallBe wall

Coupling portCoupling port

7

3D CAD Model – Cavity Half

RF/vacuumseal jointRF/vacuumseal joint

8

3D CAD Model – End & Section Views

9

2D Layout of Cavity Concept

10

•Brazing–Be brazing is only done at select shops–Differential expansion may be a problem for solid Cu body

–May be some issues with brazing to Cu plated Hastelloy

–Transition from Be side walls to rounded corner at cavity OD presents some challenges

•Coupling port–Interface between Be and cavity body material at port needs to be fully brazed

–Need to incorporate a connection flange to RF waveguide

•Cavity joints–Seal(s) between cavity sections needs to provide a good RF connection as well as a vacuum seal

•Machining: relatively few shops capable of Be machining

Manufacturing Challenges

11

Be Material and Fabricator Info

•Quotes obtained from Brush-Wellman for Be material for the three different concepts (for a single cavity)–0.5 mm thick, 330 mm diameter (2 pcs): $6.0k–6.4 mm thick, 330 mm diameter (2 pcs): $13.8k–12.7 mm thick, 445 mm diameter (2 pcs): $31.5k–Lead time is 8 to 10 weeks

•LBNL has had preliminary discussions with Brush-Wellman for the complete fabrication of the cavity (build-to-print)–Company is local to LBNL (<1 hour drive)–Currently fabricating the curved Be windows for MICE

•Another possible vendor is Axsys Technologies (Cullman, AL)–The company has experience with machining Be–Need to determine if brazing capability is adequate

12

Schedule and Manpower

•Next step is to complete the down select of the preferred cavity design concept

•Hope to complete the engineering analysis and detailed design by the end of FY11

•Expect to hold preliminary and final design reviews at LBNL later in FY11

•Long lead material (Be) to be ordered before the end of FY11

•Cavity fabrication to be complete by the end of FY12

•A. DeMello (LBNL) will be available to work on engineering design as MICE RFCC Module design work winds down

•Design oversight to be provided by S. Virostek and D. Li

![MTA - Unopomp · TM01 8522 0300 MTA 3 MTA 4 L[mm] 35 45 TM01 8657 0600 TM01 8658 0600 TM01 9076 1000 10 L 10 125 45 Min. 20 mm General data MTA. 6 Technical data MTA 3 MTA 4 ... 105](https://static.fdocuments.net/doc/165x107/5be789d309d3f246788ca2ff/mta-tm01-8522-0300-mta-3-mta-4-lmm-35-45-tm01-8657-0600-tm01-8658-0600-tm01.jpg)