Unit1 lectbyvrk dynofmachinery

-

Upload

vaidyanathan-ramakrishnan -

Category

Education

-

view

652 -

download

0

Transcript of Unit1 lectbyvrk dynofmachinery

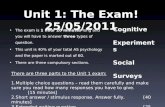

DYNAMICS OF MACHINERYSTATIC FORCE ANALYSIS OF MECHANISMS

Define static force analysis.

It is a force analysis in which inertia forces of the machine components are neglected.

(i.e. “ma” is neglected)

Define static equilibrium.

A body is in static equilibrium if it remains in its state of rest or of uniform motion.

Conditions to be satisfied by a body in static equilibrium are:

Vector sum of all the forces acting on the body is zero. ΣF = 0.

Vector sum of the moments of all the forces about any arbitrary point is zero. ΣM = 0.

What is the condition for a body to be in equilibrium under the action of two forces?

The TWO conditions for a body to be in equilibrium under the action of two forces are

(a) The two forces act along the same line;

(b) The two forces are equal in magnitude and opposite in direction.

1

DYNAMICS OF MACHINERYSTATIC FORCE ANALYSIS OF MECHANISMS

What is the condition for a body to be in equilibrium under the action of two forces and a torque?

The TWO conditions for a body to be in equilibrium under the action of two forces and a torque are

(a) The two forces are equal in magnitude, parallel in direction and opposite in sense;

(b) The two forces form a couple which is equal and opposite to the applied torque.

A body is in equilibrium under the action of three forces, out of which two forces are parallel. What would be the position of third force with respect to the other forces?

If forces F1 and F2 are parallel, the point of concurrence lies at infinity. Therefore force F3 is parallel to F1 and F2 .

2

DYNAMICS OF MACHINERYSTATIC FORCE ANALYSIS OF MECHANISMS

What are the force conventions used in static force analysis of mechanisms?

Force exerted by member “ i” on member “ j “ is denoted by Fij

Consider four members 1,2,3, and 4 connected together as shown. F23 = F32

What are the two principles used in static force analysis?

(a) Principle of super position ; (b) Principle of virtual work.

Define principle of super position.

In linear systems, if number of forces act on a member, the net effect is effect is equal to the superposition of the effects of individual forces taken one at a time.

Define the principle of virtual work.

If a system is in equilibrium and undergoes an infinitesimal displacement from its equilibrium position without any lapse of time, then the net work done is equal to zero.

3

DYNAMICS OF MACHINERYD’Alembert’s Principle – Inertia Force – Inertia Torque

Define D’Alembert’s principle.

D’Alembert’s principle states that when a system (body) is in dynamic equilibrium, the vector sum of all the external forces and inertia forces acting upon a system of rigid bodies is zero.

The vector sum of all the external moments and inertia torques acting upon a system of rigid bodies is also separately zero.

ΣF + FI = 0 ; and ΣT + TI = 0.

What do you mean by inertia force?

Inertia force is a property of matter by virtue of which a body resists any change in linear velocity (v). FI = – m R a G where m R is mass of the reciprocating body in kg and a G is linear acceleration of the centre of mass of the body in m/s 2

The negative sign indicates that the inertia force acts in opposite direction to that of the acceleration. Inertia force acts through the centre of mass of the body.

4

DYNAMICS OF MACHINERYD’Alembert’s Principle – Inertia Force – Inertia Torque

What do you mean by inertia torque?

Inertia torque is a property of matter by virtue of which a body resists any change in angular velocity ( ω). TI = – I G α where I G is mass moment of inertia of the body about an axis passing through the centre of mass in kg m 2 , α is angular acceleration of the body in rad / s 2

The negative sign indicates that the inertia torque acts in opposite direction to that of the angular acceleration.

What do you mean by equivalent offset inertia force?

Equivalent offset inertia force is a force which replaces both inertia force and inertia torque by displacing (Offsetting) the line of action of force from the centre of mass (G) by a perpendicular distance “ h “ such that the torque so produced is equal to the inertia torque acting on the body.

Offset distance h = TI / FI = (– I G α) / (– m R a G ) = k 2 α / a G

5

DYNAMICS OF MACHINERYDYNAMIC FORCE ANALYSIS OF MECHANISMS

What is dynamics of machinery?

Dynamics of machinery deals with forces and their effects while acting upon the machine parts in motion.

What is a dynamic force?

Each component has a mass and it produces a force while accelerating. This force is known as dynamic force.

What is dynamic force analysis ?

Dynamic force analysis is the analysis of various forces acting on the components of machine or mechanism by considering inertia forces due to accelerating parts into account.

Why dynamic force analysis is necessary?

For high speed mechanisms, inertia forces are high and hence dynamic force analysis is very important to determine input torque required for balancing.

6

DYNAMICS OF MACHINERYDYNAMIC FORCE ANALYSIS IN A RECIPROCATING ENGINE

7

DYNAMICS OF MACHINERYDYNAMIC FORCE ANALYSIS IN A RECIPROCATING ENGINE

8

DYNAMICS OF MACHINERYSTATIC AND DYNAMIC BALANCING

9

DYNAMICS OF MACHINERYDYNAMIC FORCE ANALYSIS IN A RECIPROCATING ENGINE

Angular velocity of connecting rod, ω PC = ω cos θ / [ n 2 – sin 2 θ] ½

Angular acceleration of the connecting rod, α = – ω 2 sin θ [ n 2 – 1] / [ n 2 – sin 2 θ] 3/2

Crank Pin Effort (Force), FT = FQ sin (θ + φ) = [FP / cos φ] sin (θ + φ)

Crank Effort (Torque) , T = FT r = {[FP / cos φ] sin (θ + φ)} r

= FP r { sin θ +[sin 2 θ / [2 (n 2 – sin 2 θ)1/2]]}

Piston Effort [ Force on piston or cross head pin], FP =FL ± FI – RF ; where

FL is Net load on piston, FI is inertia force and RF is resistance offered.

Net load on piston, FL = P1 A1 – P2 A2

Inertia Force, FI = – m R a G = m R ω 2 r [cos θ + (cos 2θ)/n] where m R is mass of the reciprocating body in kg and a G is linear acceleration of the centre of mass of the body in m/s 2

10

DYNAMICS OF MACHINERYGAS FORCES – BEARING LOADS – CRANK SHAFT TORQUE

Gas Forces produce the net load on the piston.

Net load on piston, FL = P1 A1 – P2 A2

Inertia Force, FI = m R a G where m R is mass of the reciprocating body in kg and a G

is linear acceleration of the centre of mass of the body in m/s 2

Linear acceleration, a G = ω 2 r [cos θ + (cos 2θ)/n]

where n = l/r = Length of connecting rod / radius of crank

Bearing Loads

Thrust (Force) on crank shaft bearing, FB = FQ cos (θ + φ) = [FP / cos φ] cos (θ + φ)

Normal Force on cylinder wall, FN = FP tan (φ)

Piston Effort [ Force on piston or cross head pin], FP =FL ± FI – RF ; where

FL is Net load on piston, FI is inertia force and RF is resistance offered.

Crank Shaft Torque

Crank Effort (Torque) , T = FT r = [FP / cos φ] sin (θ + φ) r

= FP r { sin θ +[sin 2 θ / [2 (n 2 – sin 2 θ)1/2]]}

11

DYNAMICS OF MACHINERYSHAKING FORCE – SHAKING COUPLE

Engine Shaking Force

Force acting on the crank shaft bearing FB can be resolved into two components,

FB H and FB V . The horizontal component FB H acts along the line of reciprocation and it is equal to FI .

This force is unbalanced and is called shaking force.

Engine shaking Couple

As the lines of action FN and FBV are away by a distance x = PO, it forms a couple known as shaking couple.

Shaking Couple CU = FN x = FBV x

12

DYNAMICS OF MACHINERYEquivalent Masses

What do you mean by equivalent dynamic system?

The motion of connecting rod is not linear. It is difficult to find its inertia. Therefore the inertia is taken into account by considering the mass of connecting rod into two parts acting at two points.

The system in which the entire mass of the body is replaced by two masses placed at fixed distance apart is called equivalent dynamic system.

Conditions to be satisfied by the system to be dynamically equivalent are:

(a) Sum of the two masses must be equal to the total mass of the body.

(b) Centre of gravities of the two masses must coincide with that of the body.

(c) Sum of the mass moments of inertia of the masses about their centre of gravity must be equal to the mass moment of inertia of the body.

13

DYNAMICS OF MACHINERY

14

DYNAMICS OF MACHINERYEquivalent Masses

Let m1 and m2 be the two masses which form equivalent dynamic system (kg)

Let l1 be the distance of mass m1 from G in (m)

Let l2 be the distance of mass m2 from G in (m) on the other side.

Let L be the total distance between the masses m1and m2

The conditions are

(a) m1+ m2 = m

(b) m1l1 = m2 l2

(c) m1l12 + m2 l2

2 = m k2

(d) From the above conditions, we get l1 l2 = k2

15

DYNAMICS OF MACHINERYKLEIN’S CONSTRUCTION DIAGRAM

What is the advantage of Klein’s construction ?

In Klein’s construction, velocity diagram and acceleration diagrams of the mechanism are constructed in the configuration itself. There is no need to draw them separately.

Draw OM perpendicular to PO.Extend PC to obtain M. Draw a circle with CM as radius.OCM is velocity triangle.Draw a circle with PC as diameter.K and L be intersection of the two circles.Join KL. KL intersects PC at Q.CQNO is acceleration polygon.= ω 2

16

DYNAMICS OF MACHINERYCORRECTION COUPLE – CORRECTION TORQUE

Define correction couple. Why is it required?

To convert a two mass system in to equivalent dynamic system (without altering the position of point masses), a couple is applied to the two mass system. The couple which must be applied to the two mass system in the opposite direction to that of the angular velocity to make the system dynamically equivalent to the original system is called correction couple (ΔT) . ΔT = m ( k1

2 – k2 ) α

What is the difference between correction couple and correction torque?

Correction couple may be applied to the system by two equal and opposite forces FY

acting through the small end bearing and big end bearing of the connecting rod.

Correcting torque TC is the torque on the crank shaft due to force FY at big end bearing.

The relationship between correction couple and correction torque is

TC = ΔT (cos θ) / n where n = l/r = length of connecting rod / crank radius

17

DYNAMICS OF MACHINERYTURNING MOMENT DIAGRAM

What is Turning Moment diagram?

Turning moment or crank effort diagram is a graphical representation of the turning moment or torque or crank effort for various positions of the crank. It is also called T- θ diagram where T is the torque and θ is the crank angle.

Draw T- θ diagram for a single cylinder single acting steam engine and single cylinder double acting steam engine.

18

DYNAMICS OF MACHINERY

19

DYNAMICS OF MACHINERYTURNING MOMENT DIAGRAM

Draw T- θ diagram for a single cylinder Four Stroke IC engine.

20

DYNAMICS OF MACHINERYTURNING MOMENT DIAGRAM

Draw TM diagram for 8 cylinder 4 stroke engine and turbine.

21

DYNAMICS OF MACHINERYTURNING MOMENT DIAGRAM

Why does the turning moment of a single cylinder 4 stroke IC engine transfer from negative to positive during second half of suction and exhaust strokes?

During the suction stroke, piston moves from TDC to BDC. The pressure inside the cylinder is less than atmosphere. No work is done. However some work is given to the system for moving the piston from TDC to BDC. Therefore a negative loop is obtained in the first part of this stroke. The fresh incoming charge makes waste gases to exhaust from the cylinder. As some work is done by fresh incoming charge (i.e. by engine) a positive loop is obtained in the second part of this stroke.

During the exhaust stroke, piston moves from BDC to TDC. The piston forces the waste gases to go outside. Work is done on the gases. Hence negative loop is obtained in the first part of the stroke. Some of the waste gases exhaust themselves due to less weight and hence reduces work to be done on the engine. Hence a loop is obtained during the second part of this stroke.

22

DYNAMICS OF MACHINERYFLYWHEEL OF ENGINES

Define Fluctuation of speed.

Variation of speed above and below the mean speed of the flywheel is called fluctuation of speed.

Define fluctuation of energy.

Variation of energy above and below the mean resisting torque line is called fluctuation of energy.

Define maximum fluctuation of energy.

The difference between maximum energy and minimum energy is called maximum fluctuation of energy.

Write the equation for maximum fluctuation of energy.

Maximum fluctuation of energy, ΔE = I ω2 CS = 2 E CS = m k2 ω2 CS

23

DYNAMICS OF MACHINERYFLYWHEEL OF ENGINES

Define coefficient of fluctuation of speed.

It is the ratio of maximum fluctuation of speed to the mean speed.

CS = (N1 - N1) / [(N1+ N1)/2]

Define coefficient of fluctuation of energy.

It is the ratio of maximum fluctuation of energy to the work done per cycle.

CE = ΔE / W , ΔE = E max – E min

Define coefficient of steadiness.

Reciprocal of coefficient of fluctuation of speed is called coefficient of steadiness.

24

DYNAMICS OF MACHINERYFLYWHEEL OF ENGINES

Why small flywheel is used in a multi cylinder engine?

In multi cylinder engine, total turning moment is the sum of the turning moments of each cylinder at any instant. Therefore the fluctuations in the turning moment is low and flywheel required is also small.

Mention the relation between peripheral velocity of flywheel rim and density of material.

‘ v = * σ/ρ ] ½ where σ is hoop stress or tensile stress due to centrifugal force in N/m 2 and ρ is density of rim material in kg/m3

Is work done by IC engine is positive?

In IC engine power is produced only during power stroke. Power is utilised during the other strokes. Work done per cycle is less than work done during power stroke. Hence net work done is always positive.

25

DYNAMICS OF MACHINERYFLYWHEEL OF PUNCHING MACHINE

What is the function of flywheel in a punching machine?

In a punching machine, the torque on the crank shaft is constant and the load varies during the cycle. The function of flywheel is to reduce the fluctuation of speed to a minimum.

26

Differences between Flywheel and Governor

FLYWHEEL GOVERNOR

Flywheel does not

maintain constant

speed.

Governor regulates the

main speed when there

is a variation in load.

Flywheel reduces the

fluctuation of speed

caused by variation in

turning moment.

When load increases,

fuel supply is increased.

When load decreases

fuel supply is

decreased.

Flywheel works

continuously from cycle

to cycle.

Governor functions only

when there is a change

in load.27

28

F

AC

B

Given: Dimensions AB = mm ; AC = mm ; BC = mm ; F = N; Find the Input Torque T in Nm

29

B

F

P

A C

T

Given: Dimensions AB = mm ; AC = mm ; BC = mm ;F = N; P = N;Find the Input Torque T in Nm

30

Given: Dimensions AB = mm ; AC = mm ; BC = mm ; F = N; P = N; Q = N;

F

BQ

T

P

AC

Find the Input Torque T in Nm

31

Given: Slider crank mechanism; Forces acting on links: FP = 4000 N;FQ = 500 N; FR = 2000 N; Lengths of links in mm: AB = 300; BC = 455; BE = 175; AD = 155 and L CAB = 450

To find : Forces F14 ; F34 ; F23 ; F32 ;F14 ; and Driving Torque T2 .

For Torque T4

F 34 = F 14 = T4 / h 4a = 52.2 NF 24 = F 43 = F23= F 32 = F 12 = 52.2 NT2a = F 32 h 2a = 14.3 Nm (CCW)For Torque T3

F 43 = F23= 44.8 NT2b= F 32 h 2b = 1.88 Nm (CCW)T2 = T2a +T2b= 16.18 Nm (CCW)

Given: In a four link mechanism shown here torque T3 and T4 have magnitudes of 30 Nm and 20 Nm respectively. The link lengths are AD = 800 mm, AB = 300 mm, BC = 700 mm, CD = 400 mm. For the static equilibrium of the mechanism determine the input torque T2.

33

Unit-1: Formulae

Parameters involved are x, r, l, l1, θ,φ, p1, p2, A1, A2, FR, mR, mC, k or R

, n = l / r; sin φ = [sin θ] / n; , x = r [ (1-cos θ) + (1/2n) sin2 θ], v p = ω r [ sin θ + (1/2n) sin 2θ], a p = ω2 r [ cos θ + (1/n) cos 2θ], ω pc = (ωcos θ) /n) ; ‘ α pc = – (ω 2 sin θ) /n) ;

FL = [p1 (п/4)D2 ] – [p2(п/4)(D – d )2 ]FI = mR ω2 r [ cos θ + (1/n) cos 2θ]Fp = FL – FI ± m g – FR

FQ = Fp / cos φ ; FN = Fp tan φ ;

FB = FQ cos (θ +φ) ; FT = FQ sin (θ +φ) ;T = FT r

Parameters involved are‘ θ , α, σ, ρ, v, D, A, b, t, m, ω , k or R, T, P, N, I, E, ΔE, Δ ω , ω, W, Cs, CE .‘ v = √(σ/ρ) = п D N/60; ω = 2 п N/60

T mean = Wcycle / θ cycle ;θ cycle = 4 п for 4 stroke IC engine;θ cycle = 2 п for 2stroke IC engine;

Cs = (ω1 – ω 2)/ ω ; ω = (ω1 + ω 2)/ 2Cs = (N1 – N 2)/ N ; N = (N1 + N 2)/ 2 Cs = (v1 – v2)/ v ; v = (v1 + v 2)/ 2

P = Tmean ωWcycle = 60 P /(N/2) for 4 stroke cycleWcycle = 60 P / N for 2 stroke cycleCE = ΔE/ Wcycle

‘ ΔE = m v2 Cs = 2 E Cs = m k2 ω2 Cs

= I ω2 Cs

I α = (T – T mean) = m k2 α

34

Unit-1: Formulae:

Parameters involved are x, r, l, l1, θ,φ, p1, p2, A1, A2, FR, mR, mC, k or R

FL = [p1 (п/4)D2 ] – [p2(п/4)(D – d )2 ]FI = mR ω2 r [ cos θ + (1/n) cos 2θ]Fp = FL – FI ± m g – FR

FQ = Fp / cos φ ; FN = Fp tan φ ;

FB = FQ cos (θ +φ) ; FT = FQ sin (θ +φ) ;T = FT r

35

Problem1: Given Crank radius r = 0.3 mConnecting rod length l = 1 mSpeed of engine N = 200 rpmFind (a) Crank angle θ at which maximum velocity occurs(b) Maximum velocity (c ) Derive the equation

36

Problem1: Given Crank radius r = 0.3 mConnecting rod length l = 1 mSpeed of engine N = 200 rpmFind (a) Crank angle θ at which maximum velocity occurs(b) Maximum velocity

37

Problem 2: Given: Horizontal steam engine; Length of connecting rod l = 1.2 mCrank radius r = 0.3 m; Crank angle θ = 30 o

Acceleration of piston a P = 35 m/s 2 ; Frictional resistance F R = 550 NNet effective pressure P1 – P1 = 5 x 10 5 N/m 2

Diameter of the piston D = 0.3 m ; Mass of reciprocating parts m R = 160 kgFind (a) Reaction on the cross head guide F R ; (b) Thrust on crank shaft bearing F B

(c ) Torque on crank shaft T

38

Problem 3: Given: Horizontal steam engineLength of connecting rod l = 1 mCrank radius r = 0.2 mCrank angle θ = 30 o

Speed of the engine N = 400 rpmNet effective pressure P1 – P2 = 0.4 N/mm 2

Diameter of the piston D = 0.4 mMass of reciprocating parts m R = 100 kgFind (a)Inertia force; (b) Gas Force on piston;(c ) Piston effort; (d) Thrust on cylinder wall; (e) Thrust on connecting rod(f) Crank pin effort and (g) Crank effort

Answers: ω = 41.89 r/s; n = 5; sin φ = 0.1; φ = 5.740; FI = 33.5 kN; FL= 50.26 kN kN; FP = 16.36 kN; FQ = 16.44 kN; FN = 1.64 kN; FT = 9.6 kN; T = 1.921 kNm

39

Problem 4: Given: Horizontal steam engineLength of connecting rod l = 1.2 mCrank radius r = 0.3 mCrank angle θ = 60 o

Speed of the engine N = 250 rpmNet effective pressure P1 – P2 = 0.35 N/mm 2

Diameter of the piston D = 0.5 mMass of reciprocating parts m R = 250 kgFind (a)Inertia force; (b) Gas Force on piston;(c ) Piston effort; (d) Thrust on cylinder wall; (e) Thrust on connecting rod(f) Crank pin effort and (g) Crank effort

Answers: ‘ ω = r/s; n = 4; sin φ = ; φ = 0; FI = kN; FL= kN kN; FP = kN; FQ = kN; FN = kN; FT = kN; T = kNm

40

Problem 5: Given: Vertical double acting steam engineCylinder bore diameter D = 0.3 mStroke length L = 0.45 mSpeed N = 200 rpmMass of reciprocating parts mR = 225 kgPiston rod diameter d = 0.05 mConnecting rod length l = 1.2 mCrank angle θ = 180+125 =305o

Steam pressure above piston P1 = 30 x 10 3 N/m 2

Steam pressure below piston P2 = 1.5 x 10 3 N/m 2

Find (a) Crank pin effort; (b) Effective turning moment on crank shaft

41

Problem 5:

42

Problem 6: Given Suspended connecting rod; h = 0.65 m; l1 = 0.625 m; m = 37.5 kg; t p = 1.87s;Find the masses at small end and big end m1 and m2

43

Problem 7: Given: Petrol engineSpeed N = 1800 rpm; Crank radius r = 0.05 m; Connecting rod length l = 0.2 m;Diameter of piston D = 0.08 m; Mass of reciprocating parts mR = 1 kg;Pressure on the piston P1 = 0.7 N/mm 2

Displacement from IDC = 0.01 mFind (a) net load on gudgeon pin FP; (b) Thrust on connecting rod FQ; Reaction between piston and cylinder FN; Engine speed at which the above values become zero (i.e. FI =FL )

44

Problem 1: Given : Single cylinder single acting four stroke enginePower developed P = 20 kW; Speed N = 200 rpm; Flywheel mass m = 1000 kg;Radius of gyration k = 0.6 m; Work done in power stroke = 3 times work done on compression stroke;

Find Coefficient of fluctuation of speed C S and coefficient of fluctuation of energy C E

Answers: T mean = P/ω = 954.93 NmWork done / cycle = T mean x θ cycle= 60 P / (N/2) = 12 kNmWork done during expansion stroke = 3 (Work done during compression stroke)(i.e.) (п/2 ) T max= 3 (п/2 ) T min

Net work done / cycle = (п/2 ) T max – 3 (п/2 ) T min = 12Hence T max = 11459.16 Nm; C E = ΔE / W; ΔE = (1/2) (T max – T min )2 п / T max

ΔE = I ω 2 C S = m k 2 ω 2 C S = 15125 Nm; C S = 0.096

45

46

Problem 1: Given : Single cylinder single acting four stroke enginePower developed P = 20 kW; Speed N = 200 rpm; Flywheel mass m = 1000 kg;Radius of gyration k = 0.6 m; Work done in power stroke = 3 times work done on compression stroke;

Find Coefficient of fluctuation of speed C S and coefficient of fluctuation of energy C E

Answers: T mean = P/ω = 954.93 NmWork done / cycle = T mean x θ cycle= 60 P / (N/2) = 12 kNmWork done during expansion stroke = 3 (Work done during compression stroke)(i.e.) (п/2 ) T max= 3 (п/2 ) T min

Net work done / cycle = (п/2 ) T max – 3 (п/2 ) T min = 12Hence T max = 11459.16 Nm; C E = ΔE / W; ΔE = (1/2) (T max – T min )2 п / T max

ΔE = I ω 2 C S = m k 2 ω 2 C S = 15125 Nm; C S = 0.096

47

Answer to Problem 1

48

Problem 2: Given : Multi cylinder engine ; Scale: Y axis 1mm = 325 Nm; X axis 1 mm = 3 0

Areas above the mean torque line in mm2 in order are 26, +378, - 256, + 306, - 302, + 244, - 380, +261, - 225

Engine speed N = 800 rpm; Total fluctuation of speed ±1.6% of mean speed.Radius of flywheel R = 0.7 m; Find Mass of the flywheel m

49

Problem 3: Given: Multi cylinder engine; Scale: Y axis 1mm = 500 Nm; X axis 1 mm = 6 0

Intercepted areas between output torque curve and mean resistance in mm2 in order are-30, +410, - 280, + 320, - 330, + 250, - 360, +280, - 260Engine speed N = 800 rpm; Stroke length L = 0.3 mTotal fluctuation of speed ±2% of mean speed.Safe centrifugal stress σ = 7 N/mm2 ; Density of flywheel material ρ = 7200 kg/m3

Find the diameter of flywheel (Radius of flywheel R)

Problem 4: Given: 3 cylinder single acting engine ; Angle between cranks θ = 120 0

Engine speed N = 600 rpm; Turning moment diagram for each cycle is a triangleIn power stroke, T max = 90 Nm at 60 0 ; Torque on return stroke = 0Mass of flywheel m = 12 kg; Radius of gyration of flywheel R = 0.08 mFind (a) Power developed P; (b) Coefficient of fluctuation of speed C S ;(c ) Coefficient of fluctuation of speed C E ; (d) Maximum angular acceleration of flywheel αmax

ω = 2 п N/60 = 62.832 r/s ; Wcycle =3 (1/2)п 90 = 424.115 NmT mean = Wcycle / θ cycle = 424.115 / 2п = 67.5 NmP = Tmean ω = 67.5 x 62.832 = 4241 WEnergy at B = E – (1/2) (п/6)(67.5-45) = E – 5.89Enery at A B C D E F G HE E -5.89 E +5.89 E -5.89 E +5.89 E -5.89 E +5.89 EΔE = E +5.89 – (E -5.89) = 11.78 Nm

ΔE = m v2 Cs = 2 E Cs = I ω2 Cs = m k2 ω2 Cs

11.78 = 12 x 0.082 x 62.832 2 Cs ; Solving Cs = 0.04 CE = ΔE/ Wcycle = 11.78 / 424.115 = 0.028

Maximum angular acceleration of flywheel,I α max = m k2 α max = (T max– T mean) 12 0.08 2 α max = 90 – 67.5 ;Solving α max = 292 rad/s

51

Problem 5: Given: Two stroke engineTorque developed T = 1000 + 300 sin 2θ – 500 cos 2θEngine speed N = 250 rpmMass of flywheel m = 400kgRadius of gyration of flywheel R = 0.4 m

Find (a) Power developed P; (b) Total percentage of fluctuation of speed ;(c ) angular acceleration of flywheel α at θ = 60 0 ;(d) Maximum angular acceleration of flywheel αmax

Answers: Wcycle = 1000 п Nm; T mean = Wcycle / θ cycle = 1000 Nm

P = Tmean ω = 26180 WT = T mean =at θB = 29.5 0 and θC = = 119.5 0

ΔE = 583.08 Nm = I ω2 Cs

Cs = 0.0133; I α = (T – T mean) = m k2 αAt θ = 60 0 , T = ; α = 7.965 rad/s2

Tmax occurs at 2θ = 149.04 0 , 329.04 0

I α = (Tmax – T mean) = m k2 α ; αmax = 9.11 rad/s2

52

53

Problem 6: Given: Electric motor drives a punching machineMaximum speed of flywheel N1 = 250 rpmMinimum speed of flywheel N2 = 230 rpmRadius of gyration of flywheel k = 0.5 m Number of holes per hour = 800Time for punching t = 1.5 sec/holeEnergy required for punching E1 = 12000 Nm

Find (a) Motor power P; (b) Fluctuation of energy ΔE; (c ) Mass of the flywheel m

Motor power P = energy required / sec = = Energy required for punchinga hole x No. of holes punched/hr

= 12000 x 800 /(3600 x 1000)= 2.67 kWEnergy supplied during punching operation E2 = P t = 2.667 x 1.5 = 4 000 NmFluctuation of energy of flywheel ΔE = 12000 – 4000 = 8000 NmWe know ΔE = (1/2) I (ω1

2 – ω22) = (1/2) m k 2 (ω1

2 – ω22)

Solving, m = 607.93 kg

54

Problem 7: Given: Electric motor drives a punching machineMaximum speed of flywheel N1 = 225 rpmMinimum speed of flywheel N2 = 200 rpmRadius of gyration of flywheel k = 0.5 m Number of holes per hour = 720Time for punching t = 2 sec/holeTorque required for punching E1 = 15 kNmFind (a) Motor power P; (b) Fluctuation of energy ΔE; (c ) Mass of the flywheel m

Motor power P = energy required / sec = = Energy required for punchinga hole x No. of holes punched/hr

= 15000 x 720/(3600 x 1000)= 3 kWEnergy supplied during punching operation E2 = P t = 3000 x 2 = 6000 NmFluctuation of energy of flywheel ΔE = 15000 – 6000 = 9000 NmWe know ΔE = (1/2) I (ω1

2 – ω22) = (1/2) m k 2 (ω1

2 – ω22)

Solving, m = kg

59