UConn IMS Newsletter2014

-

Upload

institute-of-materials-science -

Category

Documents

-

view

227 -

download

1

description

Transcript of UConn IMS Newsletter2014

MATERIALS A UNIVERSITY OF CONNECTICUT institute of materials science NEWSLETTER

Faculty Focus:ProfessorRampiRamprasad

Well Equipped:Small Angle X-Ray Scattering Machine

Student and Alumni News

Meet the Director of IMS

Research Notes:Implantable

Biosensor to Monitor

Blood Sugar

Volume 1, issue 1

DirectorDr. Steven L. Suib

Associate DirectorDr. Mark Aindow

IMS Polymer ProgramDr. Douglas Adamson, Director

IMS Industrial Affi liates ProgramDr. Edward Kurz, Director

Dr. Fiona Leek, Associate Director

Materials Science and Engineering DepartmentDr. S. Pamir Alpay, Department Head

EditorRhonda M. Ward

Lead WriterRhonda M. Ward

Contributing WriterZachary Johnson

Additional ContributionsUConn Today

IMS Faculty MembersMaria Mejias

Courtney Whittle

Institute of Materials ScienceUniversity of Connecticut

97 North Eagleville Road, Unit 3136Storrs, CT 06269-3136

P: 860-486-4623F: 860-486-4745

CONTENTSFACULTY FOCUS

SPOTLIGHT

OUTREACH

STUDENT AND ALUMNI NEWS

WELL EQUIPPED

1 Meet the Director of IMS2 Dr. Rampi Ramprasad3 Former IMS Director Retires3 IMS Professor Chosen for Young Scientist Exchange4 Four IMS Faculty Members Elected to CASE5 Two IMS Faculty Members Awarded Tenure in Chemistry Department

7 Small Angle X-Ray Scattering Machine Arrives in IMS8 The IMS Thermal Analysis Laboratory8 The IMS Microscopy Laboratory

RESEARCH NOTES5 A Novel Approach to Malaria Vaccine6 Implantable Glucose Sensor6 A New Way to Create Porous Materials

9 The IMS Industrial Affi liates Program10 Industrial Affi liates Program Welcomes Industry Partners to Annual Meeting11 KX Technologies Sponsors IMS Students for Capstone Senior Design Project

13 IMS Graduate Working with Naval Research Laboratory13 IMS Undergrad Receives Presidential Scholar Enrichment Award14 IMS Graduate Working with UTRC15 Alumni News

17 IMS Polymer Program18 Meet YoungHee Chudy, Administrative Assistant for the IMS Polymer Program19 Founding Director of IMS Dies

In July 2013, Dr. Steven L. Suib was appointed director of UConn’s Ins tute of Materials Science. The son of an entomologist, Dr. Suib developed an early interest in science but considered a career in music before deciding on chemistry. A professor and former head of the Department of Chemistry, Dr. Suib has made signifi cant contribu ons to his fi eld and has been the recipient of numerous honors, including the Connec cut Medal of Science, the state’s highest award for science. He currently holds the tle of Board of Trustees Dis nguished Professor.

Environmental impact is at the root of much of Dr. Suib’s research. He developed this interest during his junior and senior years in college. Projects analyzing water and soil samples from streams and streambeds led Suib to develop a method to trace fl y ash, a coal-burning by-product, which appeared to be pollut-ing streams that fed into Lake Erie. Suib’s interest in environ-mental science was fueled from this work and con nues to guide his research today.

A long me member of the Ins tute of Materials Science, Dr. Suib welcomes the challenges of his posi on. Among his goals as director, he hopes to increase awareness of the Ins tute’s presence and its capabili es with regard to its educa onal programs, scien fi c research, and industry outreach through increased communica on within and outside UConn’s campuses.

No ng a close link between research funding and real-world outcomes, Dr. Suib envisions even closer rela onships with indus-try. “I think the role of industry is cri cal to the future of IMS,” he says.

Suib seeks to further strengthen the link between industry and the educa onal process within IMS through the Department of Materials Science & Engineering’s Capstone Design Project. The program pairs industry partners with UConn students to collaborate on projects that benefi t both our students and industry. “Most of our students end up in industry,” says Suib. “Why shouldn’t we be train-ing them to learn about industry in their academic programs?”

The IMS Industrial Affi liates Program, the Ins tute’s industry outreach program, provides unique opportuni es for IMS to assist industry partners in bringing products to market by providing short-term, materials-related research, development and produc on projects.

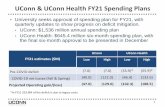

The interdisciplinary nature of IMS uniquely posi ons the Ins tute to play a signifi cant role in the future of UConn’s scien fi c programs. Because the Ins tute’s faculty members are based within a range of departments, the research carried out in IMS echoes beyond the walls of the Ins tute. With the major fi nancial investment the State of Connec cut has commi ed to the sciences at UConn, Dr. Suib believes IMS will make major contribu ons through NextGen CT, Jackson Laboratories, the coming Technology Park, and other scien fi c ini a ves.

All of this will keep Dr. Suib extremely busy. Indeed, his schedule is already fi lled with teaching and advising, research, and mee ngs. At the end of the day, though, Suib takes strength in family and a con nued love of music as balance to a schedule few would envy.

Meet the Director

IMS AT A GLANCE 150 Graduate Students

33 Faculty Members

5 Emeritus Faculty

60 Affi liated UConn Faculty

13 Administrative Staff

11 Scientifi c/Technical Staff1

Dr. Steven L. Suib

Dr. Rampi RamprasadDr. Rampi Ramprasad is passionate about science. Growing up in India, he developed an interest in science during high school and went on to the Indian Ins tute of Technol-ogy, Madras, one of India’s top universi es, for his undergraduate educa on. He a ended graduate school in the U.S., earning his Ph.D. from the University of Illinois at Urbana-Cham-paign where he began his research in materials science.

Upon comple on of his PhD, Dr. Ramprasad, began a career in industry at Motorola, in Tempe, Arizona. He spent two of six years there working primarily on a project in his area of exper se, namely, materials modeling, and later on found himself involved in several developmental projects some of them unrelated to materials research.

While at Motorola, Ramprasad had the opportunity to co-teach a graduate level course in his area of exper se at the Arizona State University. The posi ve experience he had with this part- me assignment made him think seriously about an academic career. This led to a New Year’s resolu on in 2004 to explore such opportuni es, and brought him to UConn later that year.

While Dr. Ramprasad thinks that academia is the right place for him, he nonetheless values the me he spent at Motorola. “It made me more fl exible and adaptable,” he explains. He also gained a perspec ve on the connec on between research and real-world applica on. “For the most part, I think science should be useful to society.” All of these things, he says, contributed to his success in academia; and he encourages his students to develop a big picture view with regard to their research and to be able to communicate beyond the academic level.

VIRTUAL EXPERIMENTATIONDr. Ramprasad’s research is in the area of materials modeling aimed at materials discovery. Computer simula ons are performed in his group both to determine the proper es of a given material, and to iden fy materials with a desired set of proper es. “Virtual materials design has become much more popular in recent years,” he explains. This is because computers

have become much faster and theore cal methodologies have matured to a high level, making it possible to reliably simulate materials behavior rapidly in silico (i.e., in the computer). More-over, it is much more cost eff ec ve (and safer) to perform virtual experimenta on versus doing the same in the real world. In short, materials modeling is effi cient, reliable, fast, and cheap, and is increasingly becoming a vital component of most materials research por olios.

Specifi cally, Dr. Ramprasad’s research focuses on the virtual design of materials of interest to the electronics, energy storage, and catalyst industries.

MURIA recent highlight of Dr. Ramprasad’s research relates to his work on capacitors for energy storage. This work, funded by the Offi ce of Naval Research through a Mul disciplinary University Research Ini a ve (MURI), is part of a larger eff ort spanning eight researchers from fi ve educa onal ins tu ons: UConn, Penn State, Columbia University, University of Akron, and Rensselaer Polytechnic Ins tute (RPI). The en re eff ort is aimed at guiding the design and synthesis of new classes of polymeric fi lms for electrical energy storage, using a variety of materials modeling, synthesis, processing and tes ng eff orts.

For Dr. Ramprasad, the MURI has been a learning experience, providing a more in-depth view of the many aspects and challenges involved in the path from fundamental research to the real-world.

OUTSIDE THE LABDr. Ramprasad has many interests outside of science. Family plays a big role in his life, and he is very much into music. Specifi cally, he enjoys western as well as Indian classical music; the la er he describes as “old and sophis cated although not very universal.” He enjoys travel and is also an impressive sketch ar st. He is a huge fan of the Dutch ar st, M.C. Escher, and has visited the Escher museum in the Netherlands.

Science, though, is truly his passion. Dr. Ramprasad has recently begun to explore the area of data mining to increase the effi ciency of his own brand of calcula ons. He sees value in examining the commonali es and diff erences between previously discovered materials and situa ons to predict the a ributes of new ones more quickly. The ques on he poses with this new direc on in his research is “Rather than start fresh every me, how can scien sts make use of prior knowledge eff ec vely?”

FACULTY FOCUS

2

Dr. Rampi Ramprasad

Dr. Anson Ma, assistant professor (IMS/CBE), par cipated in the dis nguished U.S.-Japan Young Scien st Exchange Program, a program launched in 2003 by The Na onal Science Founda- on (NSF) and the Ministry

of Educa on, Culture, Sports, Science & Technology (MEXT) in Japan. The exchange encourages partnerships

among U.S. and Japanese researchers and focuses on bio-nano-micro technologies, as well as other various themes including manufacturing, sensing and energy.

Ma was selected to a end the exchange for his contribu- ons in understanding the fl ow behavior and processing

of complex fl uids for biomedical and energy applica ons. During the exchange, he presented his research on rheology and processing of nanofl uids. Along with other scien sts selected for the exchange program, he presented his research at several universi es, including the University of Tokyo, Osaka University and Kyoto University.

The group also visited the Na onal Ins tute for Materials Science in Tokyo and rode the high-speed Shinkansen train (known as the “Bullet Train”) from Tokyo to Kyoto for a tour of the 17th-century Kodaiji Temple. One of the many highlights that Ma was impressed by was the ultra-high voltage Hitachi-electron microscope at Osaka University, which is more than 13 meters high.

“The goal is to unveil areas of mutual interest and to build collabora ve research bridges in transforma ve research arenas,” says Dino Di Carlo, an associate professor of bioengineering at UCLA. He and Alexander Revzin, a program director in the Biosensing Division at the Na onal Science Founda on and professor at the University of California-Davis, both coordinated the research trip.

IMS Professor Chosen for Young Scientist Exchange

Dr. Harris Marcus joined the Ins tute of Materials Science in 1995 as director. He came to the University of Connec cut from the University of Texas, Aus n, where he was a member of the faculty. In the 19 years of his tenure, Dr. Marcus was witness to many changes in the world of materials science. Among those that stand out for him, Marcus notes that the increase in the storage capaci es of computers has allowed for more precise materials modeling, making accurate predic on of experimental outcomes much more likely. Dr. Marcus points out that, in recent years, many funding agencies have required that modeling and analysis be part of applica ons for research resources.

In the future, Dr. Marcus predicts a return to basics. As materials science con nues to advance research with computer modeling and analysis, and as older metallurgists re re and leave the fi eld, a void is being created that must be fi lled. Dr. Marcus believes this phenomenon will create a renewed emphasis in tradi onal metallurgy at the undergraduate level, and possibly at the graduate level.

As he looks over his tenure as director of IMS, Dr. Marcus refl ects on his accomplishments. Asked about his most signifi cant accomplishments, he spreads his arms to indicate the space where we are si ng. The annex to IMS brought addi onal labs, offi ce space, mee ng space and a student lounge. He takes no credit for the clean room that was created during his tenure by former associate director, Dr. Fo os Papadimitrakopoulos. Nor does he take credit for the excellent facili es and equipment. He gives credit for that to current associate director, Dr. Mark Aindow. He does, however take pride in bringing talented people to IMS. A majority of the current faculty and staff members were hired by Marcus.

Since ending his tenure as director, Marcus con nues to come into the offi ce on a daily basis and does not see that changing with re rement. He looks forward to more me for research and seeking funding for his research.

c s jj ioi dd hth IIns t t fof MM t iialls SS ici

Former IMS Director Retires

3

Four IMS Faculty Members Elected to CASE

Dr. Richard Panas

Dr. Rampi Ramprasad

Dr. Gregory Sotzing

Dr. Barrett O. Wells

Professors Richard Parnas (IMS/CBE), Rampi Ramprasad (IMS/MSE), Gregory Sotzing (IMS/Chemistry), and Barre Wells (IMS/Physics) were all elected to membership in the Connec cut Academy of Science and Engineering (CASE) in 2014.

CASE is a private, non-profi t organiza on which selects members based on “scien fi c and engineering dis nc on achieved through signifi cant contribu ons in theory or applica ons, as demonstrated by original published books and papers, patents, the pioneering of new and developing fi elds and innova ve products, outstanding leadership of na onally recognized technical teams, and external professional awards in recogni on of scien fi c and engineering excellence.”

The Academy was established in 1976 to provide expert guidance on science and technology to the people and the state of Connec cut, and to promote the applica on of science and technology to human welfare and economic well-being.

Dr. Parnas’ research focuses on biofuels produc on and separa ons, renewable polymers and composites, and interface engineering. He holds a patent on a biodiesel reactor which makes biodiesel and separates the resul ng glycerol in a one-step process. Parnas has been widely published and his honors include a Fulbright Scholarship, the UConn Environmental Achievement Award, and the Department of Commerce, Na onal Ins tute of Science and Technology (NIST) Bronze Medal.

Dr. Ramprasad focuses his research on fi rst principles materials computa ons and materials informa cs aimed at ra onal materials design, func onal and designer polymeric materials, catalysis using complex oxides, point defects and interfaces involving metal oxides, band gap engineering through strain, and polariza on and ferroelectric phenomena in nanowires. Dr. Ramprasad has published extensively and has been honored with the United Technologies Corpora on Professorship in Engineering Innova on, the Alexander von Humboldt Founda on Fellowship, the Max Planck Society Fellowship, and the Motorola Silver Quill Award for excellence in publica on. He has also been recognized for his dedica on to teaching with the UConn MSE Program Teaching Excellence and Outstanding Faculty Member awards.

Dr. Sotzing’s research focuses on heterocyclic synthesis, polymer synthesis, op cally transparent conduc ve polymers, nanofi bers, and nanolithography. He currently holds 16 patents related to his research. Sotzing’s honors include the Na onal Science Founda on’s CAREER Award and the American Ins tute of Chemists Award. Sotzing’s research has been published in numerous journals including ACS Applied Materials & Interfaces, Advanced Materials, and Polymer Chemistry.

Dr. Barre Wells’ research interests include studies of high tem-perature superconductors, magnets, and ferroelectrics in transi on metal oxide compounds where strong electron correla ons dominate the physics. He has been awarded the Na onal Science Founda on CAREER Award, Research Corpora on’s Co rell Scholarship, and the Sloan Founda on Research Fellowship. His publica on credits include the journals Physics Review, Nature Materials, and Applied Physics.

4

Dr. Peter Burkhard and Colleague Develop Novel Approach to Malaria Vaccine

Dr. Peter Burkhard (IMS/MCB) and Dr. David Lanar, chief of the Department of Molecular Engineering at Walter Reed Army Ins tute of Research are working on a novel approach to malaria vaccines. Their research seeks to develop a vaccine at the molecular level by engineering a protein that is a clone of the parasite’s own defensive protein (which masks itself from the host). They would make the protein visible to the host, thereby triggering an immune response capable of killing the parasite.

Using computer modeling, Burkhard and Lanar were able to construct the building blocks of the DNA of the parasite’s protec ve protein. Then, using a computer program they determined the DNA sequence of the gene encoding the fi nal protein. The approach required the design of a protein monomer that combines with iden cal monomers to form a self-assembling protein nanopar cle or SAPN.

Burkhard and Lanar have tested their vaccine in mice and are confi dent that their research will lead to future advances in human malaria vaccine development.

Dr. Peter Burkhard

Two IMS Faculty Members Awarded Tenure in Chemistry DepartmentDr. Douglas Adamson and Dr. Yao Lin were both recently awarded tenure in the Chemistry Department. Dr. Lin was also promoted to Associate Professor. Congratula ons!

Dr. Douglas Adamson Dr. Yao Lin

RESEARCH NOTES

Graduate ProgramsMaterials Science

Materials Science & EngineeringPolymer Science

Degrees OfferedM.S.

M. Eng.Ph.D.

IMS AT A GLANCE

5

A New Way to Create Porous MaterialsDr. Steven L. Suib, Board of Trustees Dis nguished Professor and Director of IMS and his research team, have found a new way of crea ng a class of porous materials that enables be er developed controls and broader

applica ons than the industry standard.

This research is the fi rst major work to come out of the University’s Green Emulsions, Micelles and Surfactants Center of Excellence (GEMS). The process has resulted in the forma on of more than 60 new families of materials and is believed to a ract industry because of its approach to be simple, cost-eff ec ve, and green.

“This is defi nitely the most exci ng project I’ve been involved in over the past 30 years,” Suib says. “What we’ve done is similar to discovering a new insect, only now there is a series of fami-lies of these things that can be discovered. That’s pre y cool.”

In the last few decades, scien sts have relied on a long-stand-ing water-based procedure for making mesoporous materials, which was fi rst developed by Mobil Oil. However, the proce-dure has limita ons. The size of the pores in the material is hard to manipulate, the structure of the mesoporous walls are

amorphous, and the solidity of the core system weakens when exposed to intense heat. The process also only works well when using silicon or tanium, which opposes the use of other metals.

Suib’s research consists of crea ng uniform, or monomodal, mesoporous metal oxides by using transi on metals such as manganese, cobalt, and iron. Mesoporous describes the size of the pores in the material, which are between two and 50 nanometers in diameter and evenly distributed across the material’s surface. The process allows scien sts to use nitric oxide chemistry to alter the pore size. The approach contains chemical reac ons and provides an extraordinary control and fl exibility. Materials with uniform microscopic pores allows for molecules of a par cular size to fl ow in and out of the material. This is vital in adsorp on, sensors, op cs, magne c, and energy products.

The research team also chose to replace the water-based process with a synthe c chemical surfactant to create mesopores. By reducing the use of water and introducing the surfactant, as well as subjec ng the nanopar cles to heat, the research team discovered that it could manufacture uniform mesoporous materials with strong crystalline walls. The mesopores are formed by the gaps that are created be-tween the organized nanopar cles when they’re clustered together. The size of those gaps could be increased or decreased by adjus ng the nanostructure’s exposure to heat.

Dr. Steven L. Suib

Former IMS Associate Director Among Team Developing Implantable Glucose Sensor

Former Associate Director of IMS, Fo os Papadimitrakopoulos (IMS/CHEM), Board of Trustees Dis nguished Professor of Pharmaceu cs, Diane Burgess, and ECE professor Faquir Jain, along with a team of postdocs and graduate students are working to develop an implant-able, wireless biosensor to monitor blood sugar levels in diabe c pa ents. The device is designed to be placed beneath the skin and eliminate the use

of pricking devices to extract blood samples for monitoring glucose levels.

“In my opinion, this device will be a dream come true for diabe cs,” says Papadimitrakopoulos. “It is not only going to improve their standard of living but it will also help educate

people on how to go about living with this disease.”A major challenge of the project is fi nding a method to minimize ssue damage as the body generally reacts to the implanted device with pain, redness, and swelling. The body will then a empt to cover the device in scar ssue (fi brosis). To prevent this reac on, the team developed a polymer hydrogel containing ny microscopic beads fi lled with an -infl ammatory medica on which is released as the gel breaks down around the sensor.

While the project is currently in the pre-clinical tes ng stage, the research team is hopeful they will soon be working on clinical trials and enter the market in the upcoming decade. Dr. Fotios Papadimitrakopoulos

6

Small Angle X-Ray Scattering Machine Arrives in IMSThe Small Angle X-Ray Sca ering Machine (SAXS) can be applied to determine the representa ve structures of nanomaterials. The applicable forms of samples are solu ons, gels, amorphous solids to crystals. Detailed structural informa on can be revealed by the sca ering intensity as a func on of the sca ering angles – through either modeling or scaling laws.

“The SAXS machine is a powerful tool for researchers on campus to study nano-structure of materials,” says Dr. Mu-Ping Nieh, associate professor of Chemical and Biomolecular Engineering and faculty member of IMS. He is the PI of the Self-Assembled Func onal Nanomaterials laboratory. He also cites the SAXS as a good complimentary tool for electron microscopy, which provides important local structural informa on.

The fact that the sca ering of X-ray depends on the distribu on of the electron density in the materials allows researchers to iden fy the spa al arrangement of molecules, which have diff er-ent electron densi es. The sca ering intensity as a func on of angle provides informa on in the reciprocal space, i.e., smaller angles corresponding to larger lengths. In order to obtain a length scale around 100 nm, the accessible angle has to be smaller than 0.1o. This means the footprint of incident X-ray has to be extremely small and highly collimated while enough sca ering

signal is required. The current SAXS machine (Bruker NANOSTAR) employs rota ng anode to generate high-fl ux incident X-ray, two small sca erless pinholes (300 ~ 550 m) to collimate the X-ray and a high-resolu on posi on-sensi ve 2-D detector (pixel size: 68 x 68 m2). All these features allow us to probe nano-struc-tures from Å to 100 nm. The instrument is also equipped with a variety of sample stages for samples under temperature control, in-situ measurements under fl ow or shear condi ons as well as thin-fi lm geometry. It can also perform grazing-incident SAXS.

A er earning his Ph.D. at the University of Massachuse s, Amherst, Nieh began his career as a post-doctoral researcher at the Na onal Ins tute of Standards & Technology (NIST) with a cross appointment with Pennsylvania State University, becoming an expert in small angle neutron sca ering (SANS). He later joined the Na onal Research Council of Canada (Canadian Neutron Beam Centre) as a research offi cer, designing the fi rst SANS instrument using thermal neutrons on a triple-axis spectrometer in Canada. In 2010, he joined the UConn faculty as an associate professor at the Department of Chemical and Biomolecular Engineering with a cross appointment at IMS. In 2013, Nieh also became a member of the Department of Biomedical Engineering (BME).

WELL EQUIPPED

Photo/Heike Brueckner

7

Dr. Mu-Ping Nieh (right) and Jack Gromek with the SAXS)

The Microscopy Laboratory contains a suite of advanced instruments that sup-port the research, educa on and outreach missions of the Ins tute. These instru-ments include: Transmission Electron Microscopes (TEMs), Scanning Electron Microscopes (SEMs) and associated sample prepara on equipment. The most sophis cated microscope in the suite is an FEI Strata Dual-Beam Instru-ment in which high-resolu on SEM and Focused Ion Beam (FIB) columns are inte-grated into a single unit. The SEM column has an in-lens secondary electron detector that gives very high-resolu on images of sample surfaces, while the gallium ion beam produced by the FIB column is used to modify the surfaces at the sub-micron scale. Other features of this instrument include a fl ipstage/STEM assembly that facilitates site-specifi c sample prepara on for TEM, and an X-ray spectrometer that can be used to characterize local chemical composi ons. The power and versa lity of the instru-ments in the Microscopy Laboratory make

this a key resource for the Ins tute. The Laboratory serves mainly as a user facility with over 100 graduate students and sci-en fi c staff making regular use of the mi-croscopes in their research programs. The instruments are also used in inves ga ons to support local industry, mainly through the Industrial Affi liates Program, and to provide demonstra ons for our teaching and educa onal outreach ac vi es.

“Because of the many diff erent kinds of instruments in this lab, a wide variety of requests is addressed,” says Dr. Roger Ristau, who manages the Microscopy Laboratory. “Most deal with characterizing materials by obtaining high magnifi ca on images and chemical data.” One aspect of the Microscopy Laboratory that keeps Roger interested is the diversity of ways in which electron microscopes can be applied to examine material proper es. “I also have the opportunity to work with the con nually changing graduate student popula on. There is always something new to learn and to pass on to the stu-dents,” Roger states. Dr. Ristau earned his Ph.D. at Lehigh Uni-versity in Materials Science and Engineer-ing. His interest in the capability of the TEM to obtain informa on at the atomic scale as an undergraduate infl uenced his career path of working in Electron Micros-copy.

Transmission Electron Microscope

The IMS Microscopy Laboratory

The IMS Thermal Analysis Laboratory

The Thermal Analysis Lab at IMS examines thermal proper es of polymers as a func on of me and temperature. Two important instruments in this lab that work to iden fy heat fl ow and weight loss are the Diff eren al Scanning Calorimeter (DSC), and the Thermo-Gravimetric Analyzer (TGA) respec vely.

Dr. Laura Pina , is the manager of the thermal analysis lab.“We o en receive requests for characteriza on of materials

because something has gone wrong in the manufacturing process causing an undesired result in the product,” she states.

“We can observe how a material is processed, the amount of vola les in a sample, and how much organic material is within a sample among other things, with the help of these instru-ments.”

The DSC measures the heat fl ow (crystalliza on, mel ng, and glass transi ons) and can be used to iden fy types of polymers, how polymers have been processed, and can determine how changes in process aff ect the fi nal product.

The TGA is used to measure weight loss as a func on of me or temperature. This is achieved in inert or oxidizing atmospheres. Based on the decomposi on profi le and the temperature at which the polymer decomposes, the results will determine the rela ve stability of the material and how much fi ller exists within it.

Laura received her Ph.D. in Polymer Chemistry right here at UConn’s Ins tute of Materials Science. She worked at American Cyanamid in Stamford, CT for four years before taking me off to raise her children. She returned to IMS in 2000 and became manager of the Thermal Analysis Lab in 2002.

8

Dr. Laura Pinatti in the Thermal Analysis Lab

Exci ng new developments are in store as the IMS Industrial Affi liates Program (for-merly known as the IMS Associates Program) con nues to build the capacity and resources necessary to support manufacturing and industrial research in Connec cut and the region. Partnerships with the UConn Industrial Park and the increasing depth of faculty ex-per se enabled by NextGen UConn will allow the Program to con nue to provide businesses with access to state-of-art research, exper se and facili es. The Industrial Affi liates Program was estab-lished in 1974 to fulfi ll the Ins tute’s industry outreach mission and has provided convenient access to resources at IMS to assist industry with short-term, materials-related research, development and produc on projects. The Program currently has 28 members. The Program accepts requests on a case-by-case basis; however, many companies have found membership in the Industrial Affi liates Program to be an invaluable resource which fosters a more in mate, long-term working rela onship. Through membership, IMS grows to become an integral part of the company’s technical team and a problem-solving partner. Typical requests include: analysis of product and process diffi cul es; troubleshoo ng of raw materials; iden fi ca on of contaminants and failure analysis. Assistance typically involves materials tes ng and faculty counsel. Small feasibility studies of research pla orms are also possible and easily transi oned into longer-term research projects.

The Industrial Affi liates Program’s director, Dr. Edward Kurz, sees a bright future for the Program; “Having completed forty years of service to industry, we look forward to the next 40; con nuing to support increasingly di-verse industry, to expanding the Program and working with new ini a ves of the University and the state, including NextGen CT, the Tech-nology Incubator Program (TIP) and of course

the new tech park.”Both the Director of the program, Ed Kurz, and the Associate Director, Fiona Leek, had signifi cant experience in industry before joining the Program at IMS. Dr. Kurz was an applica ons engineer at Galileo ElectroOp- cs and Manager of Materials Research and

Development at Scho Fiber Op cs. Dr. Leek was a Consul ng Senior Research Scien st at Millipore and an Applica ons Scien st at T.A. Instruments. Both understand the diff erences between typical academic research and the needs of industry and bridge the gap between the two.

In addi on, the program off ers short courses on topics including failure analysis, conduc ve polymers, mechanical tes ng, electron micros-copy, and sta s cal design of experiments. Its annual mee ng, generally held during late spring, is well a ended by both member and non-member companies.

The Industrial Affi liates Program maintains a mailing list for those interested in its services. Please contact [email protected] to be added to the list.

Color Enhanced SEM of Fibrous Material

OUTREACH

40 Years of Supporting Growth and Innovation: The IMS Industrial Affi liates Program

Dr. Edward Kurz, DirectorIMS Industrial Affi liates Program

Dr. Fiona Leek, Assoc. DirectorIMS Industrial Affi liates Program

9

IMS Industrial Affi liates Program Welcomes Industry Partners for 2014 Annual MeetingThe Ins tute of Materials Science Industrial Affi liates Program welcomed its members, affi liated industry partners, and other members of industry to its 2014 Annual Mee ng on June 4. Over 60 industry partners represen ng 36 companies a ended the mee ng and luncheon where presenta ons covered programs, departments, research, and facili es.

Dr. Douglas Adamson, director of the IMS Polymer Program, provided an overview of the program, for which he has been director since 2011. Dr. Pamir Alpay, head of the Materials Science and Engineering Department gave an overview of his department. Dr. Yang Cao, a former IMS student who was recently hired as director of the Electrical Insula on Research Center (EIRC) presented “EIRC: Embracing Grid Moderniza on.” Dis nguished Professor Dr. Harold Brody, and Dr. Rainer Hebert, director of the Pra & Whitney Addi ve Manufacturing Innova on Center gave insight into the Materials Science and Engineering Department’s Capstone Senior De-sign Project, which is supported by many of the Industrial Affi liates Program members and other IMS-affi liated industry partners. Dr. Mu-Ping Nieh, associate professor of Chemical and Biomolecular Engineering spoke about the new Small Angle X-Ray Sca ering instrument in a presenta on en tled “Small Angle X-Ray Sca ering: A New Capability for Structural Characteriza on at UConn”. And Dr. Rampi Ramprasad, professor of Materials Science and Engineering, discussed the breadth of the computa onal modeling cluster at IMS in his presenta on, “Materials Modeling at IMS.”

The events of the day included a luncheon in the Student Union Ballroom where Dr. Steven Suib, Board of Trustees Dis nguished Professor and director of IMS, presented an overview of the Ins tute as well as informa on about the Technology Park. Dr. Fiona Leek, associate director of the Industrial Affi liates Program, provided a highly impac ul look at the IAP membership program, welcoming new members GKN Aerospace, Ul mate Wireforms, Swi Tex le Metalizing, and Luvata Waterbury; highlight-ing partnership milestones including Roger’s Corpora on’s 40 years and Smiths Medical’s 20 years as members; and outlining the many services of the Industrial Affi liates Program, including characteriza on services, its short course off erings, and the variety of programs within IMS available to member companies.

The IMS Polymer Program and the Materials Science and Engineering Department presented a joint poster session organized by Polymer Program Administra ve Assistant, YoungHee Chudy. The joint venture with the IAP Annual Mee ng featured nearly 60 post-ers and presented an excellent opportunity for industry partners to meet and talk to IMS students about their current research and their outlook for the future. IMS students were also on hand to off er tours of selected IMS laboratories to industry par cipants.

The IMS Industrial Affi liates Program holds its annual mee ng every spring as an opportunity to thank its members for their support, introduce new faculty, highlight research being conducted in IMS, and provide a networking vehicle for its industry partners.

Photo/Jack GromekIndustry Partners Listen to Presentation by IMS Director, Steve Suib

10

Seniors William Li and Nicholas Cerchia count the Capstone Senior Design Project among the most infl uen al experiences of their me at UConn. The two were paired for a project sponsored by IMS Industrial Affi liates Program Member, KX Technologies, a Connec cut company specializing in water fi ltra on systems. The project challenged Cerchia and Li to fi nd a non-destruc ve technique for tes ng fi lters for defects. Prior to the Capstone project, the company used bubble-point tes ng, an eff ec ve but destruc ve method as any fi lter tested using the method needed to be discarded a er tes ng.

Li and Cerchia tested a variety of methods before iden fying thermal imaging as a simple but very eff ec ve method for discovering defects. The method passes hot air through the fi lter while a thermographic imaging camera monitors the heat diff eren al throughout the fi lter, showing hotspots in areas where defects are present.

A er iden fying an eff ec ve method, Li and Cerchia went one step further to determine just how small a defect could be detected u lizing thermal imaging. They found that they were able to iden fy defects as small as .226 mm.

In addi on to the opportunity to partner with KX Technologies, the students were excited to be working toward a solu on to an

exis ng problem. Both were impressed with the support they received from KX Technologies. “They were ready for us and we hit the ground running,” recalls William Li. “They let us take what we learned in the classroom and apply it to the real world.”

“Overall it was a great learning experience,” says Nicholas Cerchia. “Blake Savoy from the manufacturing side of KX Tech provided samples with quick turnaround.”

Li was off ered a posi on with the company and started a er gradua on. He is the second UConn grad to be hired by the company.

Dr. Pamir Alpay, head of the MSE Department and Dr. Fiona Leek, Associate Director of the IMS Industrial Affi liates Program served as advisors for the project, mee ng weekly with the students to off er guidance and feedback.

Bruce Taylor and Andrew Lombardo from KX Technologies said their company was excited to par cipate in the Capstone Senior Design Project as they wanted to tap into the young talent and interact with faculty to take their involvement with UConn beyond IMS. “It’s an ongoing process,” said Taylor. “We were already contempla ng next year’s interac on with UConn before this project was over.”

Industrial Affi liates Program Member, KX Technologies, Sponsors Students for Capstone Senior Design Project

11

from l-r: Bruce Taylor, William Li, Nicholas Cerchia, Andrew Lombardo, Jinwen Wang (KX Tech)

12

Student and Alumni News

Margo Staruch, PhD., 2013, was a Physics Ph.D. student. Her adviser in IMS was Dr. Menka Jain. She received the pres gious NRC postdoctoral fellowship and is currently an NRC postdoctoral fellow at the Naval Research Laboratory, Washington DC. She answered ques ons for the fi rst issue of MATERIALS:

Please describe the focus of your research and why you are interested in this fi eld.The area of my current research is both single phase magnetoelectric mul ferroics as well as biphasic composites. In these materials, the electric and magne c orders are coupled so a ferroelectric polariza on can be induced by an applied magne c fi eld or vice versa. This eff ect makes mul ferroics promising candidates for non-vola le random access memory, sensi ve magne c fi eld sensors, or vibra onal energy harves ng. There is not yet a complete understanding of all of the factors that can infl uence this coupling

In what ways did your work as a student within the Ins tute of Materials Science prepare you for the work you are currently doing with Naval Research Laboratory?As a student in IMS, there is access not only to a wide range of equipment for materials char-

acteriza on and tes ng, but also many great faculty and staff members who are willing to spend me training you and helping with any problems you might have. The understanding I developed of what techniques can be u lized for the problem I am trying to solve has been incredibly helpful. In par cular, I learned so much from my advisor Dr. Menka Jain – everything from materials synthesis to how to give an engaging presenta on of my research – that I will con nue to use in my career.

What do you hope to be doing within the next fi ve years with regard to materials science? For the next fi ve years, I hope to s ll be doing research synthesizing and studying new materials and op mizing the desired prop-er es by varying the processing parameters. I also hope to work on integra ng these new materials into devices to help solve concrete problems.

How would you describe your experience as an IMS student?My experience as a student working in IMS was great! The faculty, staff , and fellow students were always friendly and people are very willing to help you if you have any problems. A wide variety of seminars allowed me to learn more about my fi eld, but also about other exci ng research topics that I didn’t know much about. By having access to this wide range of research, I had the ability to study the problems that I found interes ng.

IMS Grad Working with Naval Research Lab

Margo Staruch

IMS Undergraduate Receives Presidential Scholar Enrichment Award

Rodney Sutherland, an undergraduate researcher working with CBE assistant professor Dr. Anson Ma (IMS/CBE), is the benefi ciary of a Presiden al Scholar Enrichment Award.

The University of Connec cut established the Presiden al Scholars Program to sup-port a wide range of academic endeavors during a researcher’s four years at the

university such as internships, study abroad, travels to profes-sional conferences and research. The program can provide up to $2,500 in funding for undergraduate students.

The grant will support Sutherland’s study on crea ng an ex-perimental pla orm for understanding the essen als of inkjet and 3D prin ng. The research seeks to advance the solidity and the resolu on of exis ng prin ng technology for digital manufacturing. Rodney began working with Dr. Ma in July this year. “While the idea of 3D inkjet prin ng is exci ng to me, at this point I’m more of the guy who draws out blueprints and turns the wrenches,” Rodney says. Now that he has recently completed a separate project, Rodney has begun construct-ing the device. “It’s been quite an experience going through papers of other lab’s previous work and ordering/assembling all the components to the device!” continued on next page

Rodney Sutherland

13

Numerous prac cal applica ons will be impacted, primarily the possibility for fl exible electronics. With these refi nements, it may be possible to print organs in the future, meaning that vital organs can be contrived in the lab and pa ents requiring a transplant won’t have to wait long periods of me.

It may be possible for sensors to be printed on the skin of pa ents almost like a “short-term ta oo,” to monitor their physical condi on. Likewise, skin gra s may also be printed to speed up the recovery process of burns or deep wounds.

IMS Grad Working with UTRC

Neal Magdefrau completed his Ph.D. in 2013 under the supervision of IMS’ associate director, Mark Aindow. In the process of working toward his degree, Neal was employed by UTRC. Neal agreed to answer ques ons for the fi rst issue of MATERIALS.

Please describe the focus of your re-search and why you are interested in this fi eld.My research was related to solid oxide fuel cell (SOFC) materials development specifi cally as it related to interconnects and interconnect coa ngs. I ini ally be-came interested in this fi eld while working at United Technologies Research Center (UTRC). The metallic interconnects are the electrical connec ons between the individual fuel cells. Over me the metal interconnects oxidize and a non-conduc- ve oxide layer leads to performance

degrada on of the fuel cell stack. I was looking specifi cally at ways that we could tailor the ceramic interconnect coa ngs to react with the metallic interconnect and produce an oxida on product that

was s ll electrically conduc ve. While my por on of the project is complete, there is another student carrying on the work and we hope that this research will give us more insight into what the next genera- on of SOFC interconnect coa ngs will be.

In what ways did your work as a student within the Ins tute of Materials Science prepare you for the work you are cur-rently doing with UTRC?IMS gave me the hands-on tools that I needed to make a smooth transi on into an industrial research environment. I can’t stress how important it is as both an undergraduate and graduate student to get in the lab and learn how to run experi-ments and analy cal equipment. I started working in IMS as an undergrad a er my freshman year and it opened up doors for me. By my sophomore year I was running SEMs and TEMs rou nely and even got the opportunity to write and publish a pa-per as part of a DARPA research program. It didn’t seem like a big deal at the me, but learning how to work in the lab early on made my graduate work much easier as I went in knowing how to run a lot of the equipment I needed. I was able to use all of those acquired lab skills immedi-ately upon star ng with UTRC and having that hands-on experience defi nitely helped me land the job that I did.

What do you hope to be doing within the next fi ve years with regard to materi-als science and research?While my current work at UTRC no longer involves SOFC materials research, the knowledge I have gained in ceramics pro-cessing and characteriza on is s ll valu-able. I’m currently working on a ceramics program for turbine applica ons which is a very challenging materials development

project. I hope that 5 years from now I can point to ceramic components in a jet engine and be able to say “I helped de-velop, test and validate those materials”.

How would you describe your experi-ence as an IMS student?Being an IMS student was really a lot of fun and I never felt like it was a “job”. My biggest regret is that I stopped being a full- me graduate student a er get- ng my Master’s degree. A er working

full- me for a year I decided I wanted to get my PhD which meant I had to go the part- me route. This was challeng-ing logis cally as I had to complete my regular job du es at UTRC, a end class and complete my research and thesis. If I could go back and do it all over again I would have defi nitely stayed in IMS full- me and completed my PhD. I think being in an environment like IMS where you have such easy access to both equip-ment and the technical exper se of the professors is something I really missed as I was pursuing my degree part- me. Current students should be grateful for every day they have the opportunity to spend in IMS. Depending on where you end up in your career, it’s very unlikely that you’ll ever have access to the level of materials science exper se in addi on to the millions of dollars in research labs and equipment that IMS has. I’m certainly thankful for everything IMS has done for me and my career and I look forward to giving back by con nuing to collaborate with UConn and IMS whenever possible.

Neal Magdefrau

Presidential Scholar Award continued from previous page

14

Dr. Zhigang Ban, Ph.D. , ‘03, “Thermodynamic Modeling of Fer-roelectric Epitaxial Films and Polariza on-Graded Ferroelectrics.” Has worked at Argonne Na onal Laboratories, KennaMetal Inc., and is currently Development Engineer at First Solar Inc., Perrysburg, OH. He received the School of Engineering Outstanding Ph.D. Thesis Award, UConn (2004) and Outstanding Graduate Student Award, Department of Materials Science and Engineering, UConn (2003).

Mr. Anuj Sharma, M.S., ‘04, “Eff ect of Internal Stresses on Pyroelectric Response of Ferroelectric Thin Films.” Anuj is the Manager for Strategic Accounts in IT Services Business, NIIT Technologies, Amsterdam, Netherlands.

Dr. Burc Misirlioglu, Ph.D., ‘05, “Stress Relaxa on, Phase Transforma ons, and Disloca ons in Ferroelectric Heterostructures.”Burc is Assistant Professor at Sabanci University, Istanbul, Turkey. Burc had an Alexander von Humboldt Post-Doctoral Research Fellowship (Max Planck Ins tute, Halle, Germany), Outstanding Graduate Student Award, MSE, UConn (2005), ASM Har ord Chapter Student Speaking Contest First Prize (2005), and School of Engineering Outstanding Doctoral Student Award, UConn (2007).

Dr. Shan Zhong, Ph.D., ‘07, “Ferroelectric Mul layers and Heterostructures for High Performance Tunable Microwave Devices Applica ons.” Shan is Senior Packaging Engineer at Intel Corp., Phoenix, AZ. Outstanding Graduate Student Award, MSE, UConn (2006).

Dr. Gürsel Akcay, Ph.D., ‘08, “Strain Engineering of Epitaxial Ferroelectric Thin Films on Anisotropic Substrates.” Gürsel is working at Smiths Medical. He received the Outstanding Graduate Student Award, MSE Program, UConn (2008).

Dr. Bamidele S. Allimi, Ph.D., ‘08, “Metal-Insulator Transi ons in Epitaxial V2O3 Films.” Bamidele was Senior Produc on Engineer at, Intel Corp., Hillsboro, OR, and is currently Development Engineer, Global Foundries Corp., East Fishkill, NY.

Dr. Dianying Chen, Ph.D., ’08. Dianying just started a GE Avia on in Ohio a er holding another posi on at Sulzer Metco in Westbury NY.

Dr. Jing Dong. Ph.D., ’09, is an Assistant Program Manager, at Saint-Gobain in Worcester, MA.

Dr. Si-Yu Li., Ph.D., ’10. Si-Yu is currently an Assistant Professor of Chemical Engineering, Na onal Chung Hsing University, Taiwan.

Dr. Arif Mubarok, Ph.D., ’11. Arif started in January at Deringer-Ney in Bloomfi eld. Before this he was at the University of Amherst as a post-doc.

Dr. M. Baris Okatan, Ph.D., ‘11, “Interlayer Coupling in Ferroelectric Mul layers: Domain Structures and Eff ect of Space Charges.” Baris was a Postdoctoral Research Associate, School of Materials Science and Engineering, University of New South Wales, Australia, and is currently Research Scien st at Oak Ridge Na onal Laboratories, TN.

Dr. Sudsiri Hemsri, Ph.D., ’11. Sudrisi is an Assistant Professor of Polymer Science, in Thailand.

Dr. Yong Liu, Ph.D., ‘11, “Ni-Ru Alloys for Electrical Contact Applica ons.” Yong is R&D Yield Enhancement Engineer, Micron Corp., Boise, ID. China Scholarship Council Chinese Government Award for “Outstanding Self-Financed Students Abroad.”

Dr. Dharma Maddala, Ph.D., ’11. Dr. Maddala works at ALCOA’s Technical Center in New Kensington, PA in their surface science and tribology group. He is heavily involved in ASM Interna onal and serves on the execu ve board of the ASM Pi sburgh Golden Triangle chapter.

Dr. Claire V. Weiss, Ph.D., ‘11, “Op miza on of the Solu on and Processing Parameters for SrTiO3 Thin Films for Electronic Devices.” Claire is a Scien st at the Army Research Laboratory, Aberdeen Proving Ground, MD. She received the Gold Medal at the Army Research Laboratory Summer Student Research Symposium for “Novel Thin Film Materials for Tunable Device Applica ons,” Aberdeen Proving Ground, MD (August 2008); Science, Mathema cs, and Research for Transforma on Pro-gram (SMART) Doctoral Scholarship, Naval Postgraduate School (NPS) and The American Society for Engineering Educa on (ASEE), (August 2009-2011); The Connec cut Technology Council, 2010 Women of Innova on-Collegian Innova on and Leadership Award, Jan. 2010.

Dr. Josefi na Arellano-Jimenez, Postdoctoral Associate, ’12. Josefi na started a new posi on in Spring 2014 as a Research Associate in the Kleberg Advanced Microscopy Center which is located in the Department of Physics and Astronomy at The University of Texas at San Antonio. Josefi na will be looking a er the EMs in the Center including their aberra on-corrected TEM.

Dr. Adam A. Heitmann, Ph.D., ’12. Adam is currently an Engineer at the Naval Undersea Warfare Center (NUWC) in Newport, RI. He received a B.S. from Rensselaer Polytechnic Ins tute in 2007. Prior to his full- me employment, he carried out post-doctoral work at NUWC in the area of piezoelectric materials development. His current research focuses on domain-engineered relaxor ferroelectric single crystal transducers and the infl uence of crystallographic orienta on on electromechanical behavior under naval opera ng condi ons.

Dr. Girija Marathe, Ph.D., ’11. Girija works at IBM’s Watson Research Center as a senior process engineer.

Alumni News

15

Mr. Michael Pomykala, M.S., ’12. Michael is a Research Engineer, Henkel Loc te in CT.

Dr. Jonathan Winterstein, Ph.D., ’12. Jonathan le FEI in the Fall of 2013 and began a staff posi on at NIST. He is very involved with operando TEM using one of NIST’s aberra on-corrected Titan instruments.

Ms. Julie A. Wi enzellner, M.S., ‘13. Julie is an Engineer at United Technologies Research Center, East Har ord, CT.

Dr. (Mr.) Liang Dong, Ph.D., ‘13, “First Principles Study of Band Off sets and Band Bending of InxGa1-xN/GaN and Zn1-xBexO/ZnO Heterostructures and Quantum Wells.”

Mr. Shawn Fonseca, M.S., ‘13, “Electrocaloric Cooling Effi ciency of Perovskite Ferroelectric Thin Films.” Shawn is a Design Engineer at GE Energy – Industry Solu ons, Plainville, CT.

Dr. Neil Spinner, Ph.D., Dec. ’13. Neil has a new postdoctoral posi on at the Naval Research lab and is working on Li Ion Ba ery Cathodes.

Dr. Jialan Zhang, Ph.D., ‘13, “Electrothermal Proper es of Perovskite Ferroelectric Films.” Jialan was a Post-

doctoral research associate at the University of Illinois Urbana-Champaign. She was twice recipient of the Research Fellowship Award for Foreign Ci zens of the Scien fi c and Technological Research Founda on of Turkey (June-September 2011 and June-September 2012); Best Oral Paper Prize at the 22nd Connec cut Microelectronics and Optoelectronics Consor um, Mar. 2013. She is currently a postdoc at Rutgers University.

Dr. Olumide Adebolu, Ph.D., 13. Olumide is a Process Engineer at Intel Corpora on.

Dr. Michael Bellos, Ph.D., ’13. Mike is now a postdoc with Professor David DeMille, Physics, at Yale University.

Dr. Jayita Banerjee, Ph.D., ’13. Jayita is now a research scien st at Intel Research Laboratory, Hillsboro, OR.

Dr. Prashant Deshmukh, Ph.D., 2013. Prashant started a new job at Elemen s Speciality in NJ as senior research scien st in January 2014.

Dr. Ila Sivarajah, Ph.D., ‘13. Ila is a Post-doctoral Research Fellow in Ion-Trap Quantum Compu ng at the Center for Quantum Dynamics, Griffi th University, Nathan (Brisbane area), Queensland,Australia. Ila received the R. Earl Mar n Award for Outstanding Physics Major at

his undergraduate school, Hanover College (Indiana) in May 2003.

Dr. Margo Staruch, Ph.D., ’13. Margo won a pres gious NRC postdoctoral fellowship and is currently working at the Naval Research lab in Washington DC.

Dr. Shayan Ahmadian Ph.D., ’14. Shayan just started a posi on at Pra and Whit-ney.

Dr. Ching-Chang Chung, Ph.D., ’14. Ching-Chang is currently a Postdoctoral Re-search Scholar in the Department of Materials Science and Engineering at North Carolina State University. He received B.S. and M.S. degrees from Na onal Cheng Kung University, Taiwan in 2004 and 2006, respec vely. His research focuses on phase equilibria, processing science, and microstructure evolu on in piezoelectric ceramics.

Dr. Jus n Roller, Ph.D., ’14. Jus n now works at FEI as a TEM applica on scien st. He received a GAAN Graduate Fellowship and a NASA Space Grant fellowship while at UCONN.

Alumni News (continued)

Alumni, We Want to Hear from You!Send us your news and we will include you in the next IMS Newsle er!

Please Send Info to:

Rhonda WardIns tute of Materials Science

University of Connec cut97 North Eagleville Road, Unit 3136

Storrs, CT 06269-3136

16

The fi eld of polymer science is concerned with large, generally organic molecules, which are mostly carbon based, but might also be based on other elements such as silicon and phosphorous. The word polymer com-monly conjures images of plas cs but protein is a polymer and so is DNA. Polymers are also used as coa ngs and par cles (i.e. nanopar cles for drug delivery).

The Ins tute of Materials Science’s Polymer Program was established in 1965 and has been recognized na- onally and interna onally as a center of excellence for interdisciplinary research and educa on in the fi elds

of polymer science and engineering. Its faculty conduct substan ve academic research related to the synthe-sis, classifi ca on, manufacture, and molecular structure of polymeric materials. Dr. Douglas Adamson, associ-ate professor of chemistry, has been director of the IMS Polymer Program since 2011. He joined the Depart-ment of Chemistry in August 2008, with a combined appointment in the IMS Polymer Program. Adamson’s

research focuses on polymer synthesis, bio-inspired materials, block-copolymer self-assembly and polymersomes and graphene.

The program is comprised of 15 faculty members represen ng various areas of research including nanomaterials, biomaterials, sen-sors, electronic and photonic polymers, and polymers for energy genera on.

Dr. Andrey V. Dobrynin, professor of physics, and Dr. Elena E. Dormidontova, associate professor of physics, focus on computa onal work, a process which uses computer algorithms to predict possible outcomes of experimenta on.

Dr. Peter Burkhard, professor of molecular and cell biology, works extensively with several bio-polymers. He is working on self-assembled proteins which mimic a virus to trigger an immune response within the body.

Dr. Yao Lin, assistant professor of chemistry, researches polymers, bioinspired materials, macromolecules with complex architecture, supramolecular polymeriza on, molecular coopera vity, mul cataly c enzyme-polymer assemblies, and polymeriza on motors

Dr. Rajeswari Kasi, associate professor of chemistry, researches responsive polymers, new self-assembling polymer architectures including blocks, brushes and liquid crystalline units, protein-polymer conjugates, and polymer nano composites

Dr. Alexandru Asandei, associate professor of chemistry, focuses his research on controlled radical polymeriza on, block copolymers, fl uoropolymers, catalysts, biodegradable polymers, and organometallic chemistry

Dr. Mu-Ping Nieh, associate professor of chemical & biomolecular engineering, among his research pursuits, Dr. Nieh uses light scat-tering, x-ray sca ering and neutron sca ering to determine polymer structures

Asandei Burke Burkhard Dobrynin Dormidontova Kasi Lin

Ma Nieh Papadim Parnas Seery Shaw Sotzing Sun

Douglas AdamsonHead, IMS Polymer Program

SPOTLIGHT: IMS POLYMER PROGRAM

continued on next page

17

Meet YoungHee Chudy: Administrative Assistant for the IMS Polymer Program

If you have occasion to work with the IMS Polymer Program, likely the fi rst person you will meet is YoungHee Chudy. YoungHee has been the administra ve assistant for the program since 1986 when she was hired to support the Liquid Crystalline Polymer Research Center (LCPRC) which had received a DOD grant and used funding from that grant to hire her. She also supported the IMS Polymer Program half- me. Her husband, Bob Chudy, was already

working with the university as Director of the Interna onal Offi ce.

Prior to joining the staff at IMS, YoungHee was a high school teacher in her na ve South

Korea. She has also worked as a bookstore manager and managed a travel agency. Dr. Leonid Azaroff , the founding director of IMS, hired YoungHee and at the me that she joined the program, Bob Weiss was director.

YoungHee’s posi on includes a wide variety of tasks including coordina ng special projects, maintaining student records, processing student payroll and travel reimbursements for postdocs.

She has built a reputa on over the years as a source of informa on about the program and its history. She has known every director of both IMS and the IMS Polymer Program to serve since the incep on of the Ins tute nearly 50 years ago.

Among the changes that have impacted the program over the years, YoungHee notes that technology, from word processing to scien fi c advances eff ec ng research, has had a major impact on the program.

YoungHee’s integrity is evident in the fact that she is even willing to take her job home with her, literally. She has opened her home to stu-dents who arrive before housing arrangements have been completed, off ering them a warm bed in her guest bedroom.

She has seen many people come and go. One thing that seems a constant, though, is that YoungHee Chudy has the respect of students, faculty and staff .

YoungHee Chudy

Spotlight: IMS Polymer Program continued from previous page

Dr. Anson Ma, assistant professor of chemical & biomolecular engineering, has been researching liquid to air interface and liquid to solid interface. He also works with carbon nanotubes and ink jet prin ng.

Dr. Gregory Sotzing, professor of chemistry works largely with conduc ve polymers. Among his varied research interests, he is work-ing with a conjugated system to make electrons travel across polymers.

Dr. Richard Parnas, professor of chemical & biomolecular engineering, seeks to formulate polymer membranes to clean up unwanted bio-diesel. Parnas also constructs fi ber board out of cheap waste products, such as coconut shells, to make building supplies.

Dr. Fo os Papadimitrakopoulos, professor of chemistry, among his research is the development of a glucose monitor which is in-serted in the body to measure blood sugar levels in diabe cs.

Dr. Luyi Sun, associate professor of chemical & biomolecular engineering, research interests includes polymer composites and nano composites. He is also interested in polymer processing, nanostructured materials and green science.

Dr. Thomas Seery, associate professor of chemistry, his research includes surface ini a ve polymeriza on and light sca ering. Seery is working on a process to make unclear solu ons transparent for light sca ering.

Dr. Montgomery T. Shaw, emeritus professor of chemical engineering, has a research focus in rheology, primarily polymer melts and solu ons. Shaw also studies the aging of polymers, polymer processing and biomedical applica ons of polymers.

Dr. Kelly Burke, assistant professor of chemical & biomolecular engineering, is a new faculty member of the Polymer Program. Burke is currently examining spider-silk to see if it can be used for ssue healing, as well as seeking a way to use man-made polymers to replicate the proper es of silk.

18

19

Leonid (Lee) V. Azaroff , an interna onally known crystallographer and founding director of UConn’s Ins tute of Materials Science, died in Naples, Fla. on July 3. He was 88.

A graduate of Tu s University and the Massachuse s Ins tute of Technology, Azaroff later affi liated with the facul es of the Armor Research Founda on and the Illinois Ins tute of Technology. He was a guest physicist at the Brookhaven Na onal Laboratory from 1961 to 1964. In 1965, he was appointed director of UConn’s newly opened Ins tute of Mate-rials Science, and held the posi on un l he re red from UConn in 1992.

Azaroff was also a faculty member in the physics department, and an expert in X-ray diff rac on, in par cular X-ray powder diff rac on, which he wrote about in his book The Powder Method in X-ray Crys-tallography (McGraw-Hill, 1958).

He oversaw the development of grad-uate-level interdisciplinary research programs in polymer science and crystal science, and in 1970 supported the establishment of an x-ray laboratory for the atomic-level defi ni on of biomacro-molecules, one of the early such facili es in the country.

Azaroff was the author of more than 60 journal ar cles, and numerous textbooks and books. Several of the scien fi c books he authored remain standards in the fi elds of solid-state physics and X-ray analysis. These books include Electronic Processes in Materials (McGraw-Hill, 1963); Elements of X-ray Diff rac on (McGraw-Hill, 1968); X-ray Spectroscopy (McGraw-Hill, 1974); and Introduc on to Solids (McGraw-Hill, 1984).

In his re rement, he con nued wri ng and produced a small book tled Physics Over Easy: Breakfasts with Beth and Phys-ics (World Scien fi c Publishing, 1996),

which relates the principal features of physics through easy-to-understand conversa ons with his wife. Chapter tles include “Breakfast of Hard-boiled Eggs with Iner a” and “Breakfast of Apple-gravity Pancakes.”

Azaroff was the fi rst president of the Con-nec cut Academy of Sciences and Engi-neering (CASE); a member of the Ameri-can Associa on of the Advancement of Science; Sigma Pi Sigma; Sigma Kappa Xi; Sigma Xi; American Crystallographic As-socia on; American Society of Engineer-ing Educa on; Mineralogical Society of America (Fellow); American Ins tute of Metallurgical Mining Engineers (Fellow); American Physical Society (Fellow); and the Ins tute of Electrical and Electronic Engineers (Senior Member).

He received the UConn Alumni Associa- on Dis nguished Leadership Award in

1984. Azaroff served as associate director of the Connec cut Economic Develop-ment Corp. from 1977 to 1989, and director of Connec cut Innova ons Inc. from 1990 to 1992.

He is survived by his wife Beth Sulzer-Azaroff , his sister, three children, two nieces, two grandchildren, a grandniece, and a great-grandniece.

Founding Director of IMS Dies reprinted from UConn Today

You Can Help Secure Our FutureThe Ins tute of Materials Science (IMS), over the past 50 years, has invested in scien fi c development throughout the State of Connec cut, the United States and the world. Our students, faculty and staff members, and alumni con nue to contribute to a world made more exci ng due to the educa onal, outreach, and research eff orts of IMS. Please help us to make strides towards a richer future by making a contribu on to the Ins tute.

Your dona on to the fund(s) of your choice will enable us to con nue our eff orts in keeping our gradu-ate educa on and research infrastructure strong. Please help by assis ng us with your contribu on to the fund(s) of your choice.

An unrestricted IMS General Fund Account (20312)This account supports all IMS Ac vi es.

IMS Equipment and Maintenance (21753)This account is used to provide equipment and maintenance of IMS Facili es.

IMS Polymer Mixture Thermodynamics (20334)This account is used for studies of polymer mixtures.

Julian F. Johnson Alumni Fellowship Fund (22177)This account is used to provide fellowships for graduate students in the Polymer program.

Materials Science and Engineering (MSE) General Fund Account (22156)This account supports MSE Departmental Func ons.

Please make checks payable to The UConn Founda onIn the memo line, please note the fund(s) of your choice

Mail payment to:Steven L. Suib, Director

Ins tute of Materials ScienceUniversity of Connec cut

97 North Eagleville Road, Unit 3136Storrs, CT 06269-3136

Alumni, We Want to Hear from You!Send us your news and we will include you in the next IMS Newsle er!

Please Send Info to:

Rhonda WardIns tute of Materials Science

University of Connec cut97 North Eagleville Road, Unit 3136

Storrs, CT 06269-3136

20

Ins tute of Materials ScienceUniversity of Connec cut97 North Eagleville Road, Unit 3136Storrs, CT 06269-3136

NON-PROFIT ORG.U.S. POSTAGE PAID

PERMIT 3STORRS, CT 06269