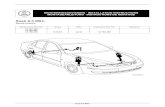

TVP09 RA-3 Chassis

-

Upload

miteshjangam -

Category

Documents

-

view

203 -

download

0

Transcript of TVP09 RA-3 Chassis

S® Lab Manual

RA-3 Chassis and Direct ViewWEGATM Television AlignmentCourse

Alignment Lab

Course: TVP-09

Sony Service CompanyA Division of Sony Electronics Inc ©1999

All Rights ReservedPrinted in U.S.A.

S is a trademark of Sony Electronics

Alignment Lab

Prepared by: National Training Department Sony Service Company A Division of Sony Electronics Inc.

Course presented by _____________________________________

Date___________________________________________________

Student Name ___________________________________________

Models: KV-20FV10KP-43T70

Table of ContentsLab A (Based on model KV20FV10) 1Objective 11. Pre-Lab Preparation 12. Precautions 23. Rear Panel Removal and GeneratorConnection 24. Yoke Support Removal 25. Beam Landing / Purity 36. Picture Geometry - Yoke Adjustment 57. Convergence 6Convergence - Presetting the TV video levels and yoke controls 7

Convergence - Adjusting the Electrical VStat Control 7

Convergence - Adjusting the Yoke Tabs 8

Convergence - Adjusting the Yoke Controls 11

Convergence - Corner Convergence 14

8. Picture Geometry - Service Mode Adjustments 14Vertical Adjustments 14

Horizontal Adjustments 15

9. Using the Memory Transfer Reader / Writer 17Addendum 1 - 27”-32” Adjustments 20Addendum 2 - Service Mode Item List 22Addendum 3 - Service Bulletin 387R2 24

Lab B (Based on model KP43T70) 31Objective 311. The New Service Mode 312. Positioning the Yoke 343. Focus Adjustment 35Spot Shape 35

Electrical Focus 36

Mechanical Focus 37

4. Coarse Convergence 37Setting the Video Levels 38

Check of Internal Reference Data 38

Set the Green Geometry 39

Superimpose the Red over the Green 42

Superimpose the Blue over the Green 46

Making the Cursor Data Visible 47

Enter the Fine Convergence Mode 47

Converge Red in the Cursor Area 48

5. Defocusing the Blue Color 48Change the Picture Mode to VIVID 49

Shut Off the Red and Green Colors from the Service Mode 49

Adjust the Blue Electronic Focus Control so the Dot is a Specified Diameter 49

Return the Red and Green Colors 50

6. Updating the Flash Focus Memory 50

Appendix:Convergence Using Default Data iInstall the Preset Convergence Data i

Install the Coarse Green Geometry Data i

Installing the Fine Green Geometry Data ii

Sony’s Authorized Service Website iv

1

TVP-09 Lab A (Based on model KV20FV10)

Check off the box as you begin to read each step. This will help you follow along during

the adjustment procedure.In this lab you will check the set, remove the previous class’ convergence parts and con-verge the set. Convergence will be performed in this order:Center of the screenSides of the screenCorners of the screenThis direct view TV adjustment lab is divided into nine parts:1. Pre-Lab Preparation – a checklist2. Precautions – what not to do3. Rear Panel Removal and Generator Connection4. Yoke Support Removal5. Beam Landing / Purity6. Picture Geometry - Yoke Adjustment7. Convergence8. Picture Geometry – Service Mode Adjustment9. Using the Memory Transfer Reader / Writer

1. Pre-Lab PreparationThe following equipment is necessary to perform this lab:

Equipment needed:Test Equipment Spare Parts

1. Insulated tip driver for yokeadjustments P/N = 7-700-731-04

1. Magnet for purity P/N = 1-452-032-00 (1-452-094-00 for 27 or larger screen TVs)

2. Color / Hatch Generator or VCR for R,G, B colors and cross hatch tape PB.

2. Permalloy Strips for Convergence P/N = 4-048-133-01 (4-051-734-21 for larger TVs)

3. TV s Remote Control for service access 3. Rubber yoke wedges P/N = 4-053-005-014. Hexagon alignment tool P/N 7-700-733-

014. TLH convergence plate P/N = 4-057-714-01(2-163-920-01 in 27 and 32 WegaTM TV sets).

5. Not Magnetized + tip screwdriver6. NVM Reader/Writer P/N = T-9350-109-1

Three technicians per TV. The first person reads while the second per-forms the adjustments. The third will assist both partners. Later wheninstructed in the text, the lab partners will rotate positions.

ObjectiveThe purpose of this lab is to teach you about the new flat screen TV adjustment proce-dures. You will apply these procedures when you replace a picture tube or yoke. Afterreplacement, degaussing, beam landing, geometry and convergence will be necessary.Degaussing is done with the internal degaussing coil.

A 20” direct view TV flat screen WEGATM TV will be used to teach these adjustment proce-dures. The Sony 27” and larger WEGATM TVs have an additional HTRP yoke control andring magnets on a WA board. Procedures are given in this lab for those larger screen TVadjustments in the addendum that follows lab A. The larger screen TV adjustments arelinked to lab A by step numbers so the adjustment sequence is maintained.

2

2. PrecautionsIf the reasons for the following precautions are not understood, you must see your instructorbefore proceeding.· Do not wear a metal watch or rings. Physical and electrical damage to both you and the TV

could occur.· Do not disconnect the high voltage anode. A loose anode lead may come off.· Do not manually degauss the picture tube (leave that to the internal degaussing circuit). Some

picture tubes are pre magnetized to aid in purity and convergence.· Do not touch any exposed contacts or yoke wires. The highest voltage measured on the

exposed yoke contacts of this 20” TV was 8.6Vdc (to cold ground). This was measured on anew working set. The set you have could still have a defect.

· Do not scratch the CRT glass neck. A scratch weakens the glass considerably and a danger-ous implosion is possible. Do not use if scratched.

· Do not remove the tape around the neck. The cloth tape prevents the yoke from scratching theCRT neck and weakening the glass structure. The tape also provides friction to grip the yoke.If the tape is missing tell your instructor ASAP.

· Use demagnetized tools to avoid magnetizing parts of the TV. A magnetized TV part canmake convergence impossible.

3. Rear Panel Removal and Generator Connection

Step 1. Remove the seven rear cover screws (three in the back) and the rear cover.

Step 2. Set the pattern generator for a green only raster and connect it to the TV’s

video 1 input.

Step 3. Plug in and turn ON the TV. Select the video 1 input to verify the presence of

a green raster. The speakers have been removed so there will be no sound.

Step 4. Switch to a crosshatch pattern. Your objective is to improve the convergence

performed by the last class.

Step 5. Turn OFF the TV and unplug the AC cord.

4. Yoke Support Removal

Step 6. - For 27” and larger WEGATM sets - see Addendum 1 on page 20.

Step 7. In the following step a NON-magnetized + screwdriver must be used. A magnetized

screwdriver will magnetize the clamp when you touch it and leave a magnetic field that will make purity or convergence difficult or impossible. With a demagnetized + tip screwdriver, loosen the yoke clamp screw that holds the yoke in place. Slide the yoke back to free the rubber supports.

1

2

3

4

Remove 4 yokewedges

Back ViewSide View

Yoke

Yoke clamp screw

Back

Yoke

3

RubberWedge

PermalloyStrips

Step 8. Remove the four wedge type rubber yoke supports, the Permalloy strips and

the disc magnets on the picture tube bell. Set them aside.

Picture of a yoke in a 20” WEGATM series Sony TV.

5. Beam Landing / Purity

Step 9. Reset the six rings on the yoke by moving tabs to the initial position as shown:

Note that all four of the small points, one on each ring, should line up when the tabs arein the initial position.

Yoke Side View Yoke Back View – Initial Position

In this initial position, the purity rings are both at noon position. The two H/VStat tabs areat 7 and 10 o’clock positions. The BMC tabs are on the opposite side at the 2 and 5 o’clockpositions. At the left side of the rings, four small points of the plastic BMC and H/VStatrings should be aligned in a row.

Step 10. - For 27” and larger WEGATM sets - see addendum page.

Step 11. Slide the yoke up to the bell (wide part) of the picture tube.

Step 12. Plug in the TV and turn it ON. Input a green raster pattern. You should see a

green colored screen with color impurities.

Yoke

BMC rings

H/VStat Purity rings

H/VStat

H/VStat

BMC

BMC

4 Small points

Purity tabs together

CRTneck

4

BEAM

CONTROLSPURITY

RGB

RGB

GREEN

PULLED BACKYOKE

TV screen with yoke pulled back.

With the yoke back about 3/4 away from the bell (over the velocity modulation coil), the

green electron beam misses the green phosphor at the screen’s left and right sidesbecause of insufficient deflection.

Green Beam striking the wrong phosphors at the sides

.

Step 14. Spread the top purity tabs until there is an equal amount of red and blue at

each side.

Step 15. Slowly slide the yoke toward the bell of the picture tube. There will be one

point where the screen is entirely green. KEEP THE YOKE LEVEL. Tighten the yoke-mounting clamp temporarily.

GREEN

REDBLUE

Step 13. Slide the yoke about ¾” away from the bell of the picture tube so there is a color on each side of green.

5

Step 16. Switch the input signal to a red and then to a blue color to make sure these

colors are uniform.

Step 17. - For 27” and larger WEGATM sets - see Addendum 1 on page 20.

Step 18. If the screen is not a uniform color, place a disc magnet at the bell near the

impurity. Move the magnet about until the TV screen’s impurity is affected. Thenrotate the magnet until the TV screen is pure green in that area. Stick the magnetthere. In a larger TV an impurity is more pronounced and more magnets may beneeded so you may have to repeat this step.

Caution: If the magnet is too strong (large) or too close to the yoke there will be geometricdistortion. Keep the magnets as far away as you can.

6. Picture Geometry - Yoke AdjustmentMechanically adjusting the yoke is new to flat screen TV sets. It is crucial to straighten benthorizontal lines at the top and bottom of the picture.

Step 19. There is a black picture rotation coil about the yoke. To ensure your yoke

adjustment is true, you will need to unplug the rotation coil. Trace the wires to the Cboard and unplug the coil from the C board.

Step 20. Input a crosshatch pattern.

Green

Redimpurity

Yoke

CRT Rear

Addmagnet

Bent

BlackRotationCoil

Yoke

6

Step 21. Rotate the yoke so the crosshatch

pattern is straight at the middle.

Step 22. Never touch any exposed wires or terminals. Only touch the plastic

parts of the yoke at the front of the yoke by the picture tube bell. You may touch theinsulated black picture rotation coil to move the yoke.This is the most important step in straightening the top and bottom lines. You must tiltor bend the yoke front to get the top and bottom cross hatch pattern horizontal linesstraight. Grasp the front of the yoke to move it up and down and side to side, whilewatching the crosshatch pattern on the TV screen. Position the yoke for straight topand bottom horizontal lines. You will use the wedges in the next step to hold the yokein the bent position.

Step 23. Locate the rubber yoke wedges (P/N 4-053-005-01) you removed. Insert the

top wedge first because the yoke tends to tilt down. Insert the remaining three wedges.Normally you would permanently stick the wedges down now. Since this lab will berepeated, you will just insert the old wedges. Permanently sticking the wedges is tricky.This is done by peeling back a little of the adhesive cover at a corner so you can stillgrab the cover when the wedge is upright. Position the wedge upright under the yokeand then slide the remainder of the cover off the wedge.

Step 24. - For 27” and larger WEGATM sets - see Addendum 1 on page 21.

7. ConvergenceIn this part you will converge the three colors into white at the center of the screen using yokerings, the sides using the yoke controls, and the corners using Permalloy strips. The convergenceconsists of five parts:

· Presetting the TV video levels and yoke controls· Adjusting the electrical HStat control· Adjusting the yoke tabs· Adjusting the yoke controls· Corner convergence

TV Screen

Straight horizontal lines

7

Convergence – Presetting the TV Video Levels and Yoke Controls

In the steps to follow you will preset the picture level to 20% and brightness level to 50%.Then you will preset the two yoke controls to mid rotation.

Step 25. On the remote, press the MENU button.

Step 26. Press the center “SELECT” button to enter the video adjustments. Use the

down button to go to the “PICTURE” adjustment and press SELECT again

Step 27. Use the left button to reduce the picture level to about 20%. Press the

center SELECT button to return to video adjustments.

Step 28. Use the down button to go to “BRIGHTNESS” and press the center SE-

LECT button.

Step 29. Press the or button to adjust the brightness to 50% (½). Press the MENU

button to exit. This presets the video adjustments.

Step 30. On the 20 and 24” WEGA TV sets, the yoke has two controls on top. Preset

the TLV and YCH controls to the middle of rotation.

Convergence - Adjusting the Electrical HStat Control

The H Stat control is used to converge the three beams into a single white line at the centerof the picture.

Step 31. Locate the black R1750 HStat control on the CRT board

Step 32. While observing the center vertical line(s) on the screen, rotate the HStat

control in both directions to see the effects. What lines are affected and how are theyaffected when the HStat control is turned clockwise at the shaft? Use the box below todraw what you observe on the screen.

Selectbutton

Menubutton

C Bd

CRT Board

H StatCCWrotation

H StatCWrotation

DeflectionYokeTOP VIEW

TLV

YCH

20 & 24WEGATM

TV YokeControlsLocations

8

Adjust the HStat control until the red and blue vertical lines merge onto the green line toproduce a white line. The control should be at or near mid rotation. The following willcause the HStat control to be incorrectly adjusted to the end of rotation:

1. The yoke rings are not at the initial positions.2. The yoke is defective.3. The picture tube or its socket is defective.4. The H Stat control is broken or not grounded.

R G B

HStat Adjustment

R G B

C R T

H.V.Resistor

H.V.H.Stat

Convergence - Adjusting the Yoke Tabs

You will require the following information to assist you in adjusting the rear yoke tabs.There are three pairs of ring magnets at the back of the yoke. They are connected to tabsfor adjustment. Read the following information before adjusting the ring magnets:

WA board on 27” or larger TV sets only.

Rotating the tabs moves the red and blue beams. The following chart and diagram showthe red and blue beam movement.

Yoke Ring Magnets

Magnet Tab Shape # Magnets Beam movement

Blue Mis-Convergence(BMC)

1 Notch 6 Poles Red and blue beams move in thesame direction.

Horizontal/Vertical Static(H/V Stat)

3 Notches 4 Poles Red and blue beams move inopposite directions.

From the chart you can see in this set that the four pole rings have three notches on theirtabs and the six pole rings have one notch. During manufacture, these two rings aredistinguished by the number of notches. A different manfacturer may use a different num-ber of notches.

H Stat Control(R1750)

9

From the diagram, you can see the four pole rings move the beams in opposite directionsand the six pole rings move the beams in the same direction.

The distance the beams move is dependent upon the magnetic strength. Using a secondring to cancel or extend the magnetic fields can control the magnetic strength. Thereforespreading or closing the tabs on each ring controls the beam distance.

The direction of movement can be controlled. Rotating both rings together changes the mag-netic direction.

Initially the rings are preset with the south poles facing on top (4 & 6 pole diagram, left). Fromthis initial position, spreading the tabs has the opposite effect in the 4 pole and 6 pole rings.Spreading the H/V Stat tabs causes vertical (up/down) beam movement but spreading the BMCtabs causes horizontal (left/right) beam movement. Generally, rotating both rings togetherperforms the same beam movement in the other axis.

Step 33. The H/V Stat ring magnets are used in pairs. Spreading these tabs apart controls

the amount of red and blue beam movement. Moving both rings together controls how much the beams are moved in the other axis.

While looking only at about 6” around the center of the 20” screen, spread or close the yoke’sthree notch H/V Stat tabs so the red and blue horizontal lines are distinctly apart from thegreen line. This is performed in preparation for the next ring adjustment. If the vertical linesare spreading apart too, rotate both rings together until the vertical lines become a single line.

S

N N

S

R

G

B

S

N

N

S

RG

B

SN

N

S

R G BS

N

S

N N

S

R G B

S

N

4 Pole -H/V Stat

6 Pole -BMC

B

RG

white

H/V Statbeamseparation

10

Step 34. The BMC ring magnets are also used in pairs, but their affects are the opposite of the

HVStat magnets. Moving both rings together controls the amount of red and blue beammovement. Spreading the tabs apart controls how much the beams are moved in the otheraxis.

The yoke’s single notch BMC rings move the red and blue beams in the same direction. If onecolor is closer to the green than the other, move both BMC rings together to make the horizon-tal lines equidistant to the green. Spread or close the tabs to keep the vertical lines white.

Rotate both one notchBMC tabs to move the R &B lines up so the spacing isequal (a=c)

BG

R

a

c

H/V Stat Ring Adjustment

Spread H/VStat Tabs apart

RGB

R G BRotate both tabs together(use H Stat control if presentinstead of the tabs).

H/V Stattabs

Spread BMCTabs apart

RGB

R G B

BMC Ring Adjustment

Rotate bothtabs together

BMCtabs

11

Step 35. It is now time to switch places with your lab partner.

Step 36. Switch to a dot pattern.

Step 37. Rotate both H/V Stat tabs so the dots are aligned vertically (up and down).

Step 38. Spread or close the H/V Stat tabs to converge the dots into one.

Step 39. Switch back to the crosshatch pattern.

Convergence - Adjusting the Yoke Controls

The WEGATM TVs have new adjustments on the deflection yokes. These controls distort thepicture at the ends of rotation.

R/BGB/R

New WEGATM TV Series Yoke Convergence Adjustments

Name Affected Areas Effect

TLV Top and bottom red/blue horizontallines

The red lines move apart from the blue.

HTRP (27 &larger TVs)

Top and bottom red and bluehorizontal lines. Leave at midrotation.

The top red and blue lines movetogether while the bottom ones moveapart.

YCH All red and blue vertical lines The red line tilts left while the blue tiltsright.

TLH Plate Left OR right vertical lines Theaffected area depends on the plateentry side.

The red and blue lines move apart ortogether.

RB

RB

HTRP (only 27 & 32 )TLV

BR

RB

TLH plate slot 2

TLH plate slot 1

DeflectionYokeTOP VIEW

TLV

YCH

20WEGATM

TV YokeControlLocations

12

The best adjustment of the TLV and YCH yoke controls are performed without the green lines soyou can see the blue lines clearly. In the next three steps the green color will be turned off from theservice mode.

Step 40. Enter the service Mode by first turning OFF the TV set. Then turn the TV back ON

pressing the following buttons on the remote control: Display, #5, Vol +, Power ON.

Step 41. Use the remote control numbers 1 (up) or 4 (down) to move to service item GON.

There is a partial list of service items in addendum 2 after lab A. GON is item number 36 outof 96 items.

Step 42. While in the service mode item GON, press the remote control number 6 (data down).

This changes the data from 1 to 0. The green color is shut OFF in preparation for the TLV andYCH adjustments.

Step 43. The TLV control is one of two controls on the yoke. While looking at the top and

bottom horizontal lines, adjust the TLV control so the red and blue lines merge (superimpose).Disregard the other line movements.

B R B R B R

YCH

R G B B G R

TLH Plate

BR

RB

TLVAdjustment

B RYCHAdjustment

TLH plate slot 2

TLH plate slot 1

DeflectionYokeTOP VIEW

TLV

YCH

20WEGATM

TV YokeControlLocations

13

Step 44. The YCH control is the other control on the yoke. Observe the vertical lines at the

middle of the screen. Adjust the YCH control so the top and bottom of these vertical linesmerge. You will notice that the blue color does not show as much when the lines merge.

Step 45. Restore the green color by pressing number 3 to change the GON data back to 1.

Step 46. The TLH plate is not normally needed on small TV sets. However, there are provi-

sions in the yoke frame for this plate insertion. Ask your instructor for a TLH plate and insert itinto the compartment at the left or right side of the yoke. Notice that it moves the very outer leftor right red and blue vertical lines in opposite directions.

Step 48. Step back and determine where colors peek out from the white cross hatch lines

(misconvergence). Touch up the adjustments. To make this easier, look through this lab forall the adjustments and list them below:

Controls that affect Vertical Lines Controls that affect Horizontal Lines

1. 1.

2. 2.

3. 3.

4. 4.

5.

6. HTRP Yoke control in 27” or larger WEGATM TV sets

7. Y Axis Separation ring magents in 27” or larger WEGATM TV sets

B R

TLHPlateAdj

R B

Right insertion Left insertion

TOP VIEWYoke

Right THL plateinsertion point.

Left TLH plateinsertion point.

Step 47. - For 27” and larger WEGATM sets - see Addendum 1 on page 21.

14

Convergence – Corner Convergence

Convergence at the corners is corrected by using Permalloy Strips. These strips contain bits ofmetal or ferrite fused onto a plastic adhesive strip. The metal inserts alter the yoke’s magneticfields. The strips come in different lengths. Order the right length for the size of the yoke.

Permalloy Corner Convergence Strips

24 TV sets and smaller Part number = 4-048-133-01

27 TV sets and larger Part number = 4-051-734-21

Step 49. At each corner of the screen where convergence is needed, insert a Permalloy strip

between the yoke and picture tube. For example, the illustration shows a TV screen with theupper right corner misconverged. The red line is not straight.

Step 50. Insert a Permalloy strip between the yoke and picture tube. As the strip is inserted,

the screen crosshatch will distort. Move the strip so the distortion is in the area ofmisconvergence. Pay particular attention to the bottom of the screen where lettering occurs.Position the strip so either the red line moves to merge with the green and blue lines or thegreen and blue lines both move to merge with the bent red line. Either way there should be asingle white line. On large screen TV sets sometimes two or more strips are required in asingle corner. Have your instructor check the convergence before proceeding to geometry.

8. Picture Geometry – Service Mode AdjustmentsIn this section you will straighten the picture so the cross hatch pattern forms a rectanglewith uniform size boxes. It is easier to perform all the vertical adjustments as a group.

Vertical Adjustments

Step 52. While still in the service mode, use the #1 and #4 remote control buttons to

locate the name of each vertical register. At each register name use the #3 and #6buttons to change the data and correct the picture geometry. When finished, save thedata by pressing the remote control MUTE button followed by the ENTER button. Thenext picture below the chart illustrates the effects of the data change to the VLIN andSCOR registers.

G/BR

Insert strip here tocorrect upper rightcorner

Yoke

Step 51. It is now time to switch places for the last time in thislab.

15

Service Mode Vertical Adjustment Registers

Name Tools Purpose / Adjustment procedure

VPOS Up/down picture positioning

Center the picture.

VSIZ Height of the picture.

Overscan the picture top and bottom byapproximately 5%.

VLIN Overall Linearity. Adjust for equal spacing ofthe boxes at the middle and bottom.

SCOR(VSCO)

1. Crosshatchgenerator

2. Remote control

S signal correction. Adjust the height of thetop row of boxes to equal the others

Note: You must not have a curved horizontal line along the bottom. Only yoke positioningand Y splitting axis correction ring magnets (27” and larger TV sets) on the CRT neck caneliminate a curved horizontal line. Reposition the yoke if the bottom horizontal lines are notstraight.

Step 53. Store the vertical adjustment information by pressing the remote control’s

MUTE button, followed by the ENTER button.

Horizontal Adjustments

Step 54. While still in the service mode, use the remote control #1 (up) and #4 (down)

buttons to locate the name of each horizontal register listed in the next chart. At eachregister use the #3 or #6 button to adjust the data. The changes in data result in thechanges to the crosshatch geometry. When finished, save the data by pressing theMUTE button followed by the ENTER button.

You can make the left and right vertical lines perfectly straight with these eight registers.The trick is to equalize the distortion on both the left and right sides of the screen, theneliminate it using another register. The pictures below the chart illustrate the effects of thedata change to all of the registers except the simpler HPOS and HSIZ registers.

VLIN & SCOR adjustments:

CORRECTVertical lines must be equidistant

INCORRECTVlinbottom must = middle

INCORRECTSCORTop must =others

16

Service Mode Horizontal Adjustment Registers

Name Tools Purpose

1. HPOS Left/right picture positioning

Center the picture so the center line is betweenthe SO and NY of the SONY emblem.

2. HSIZ Width of the picture

3. PAMP Vertical lines at the center bow in/out

4. VBOW Vertical lines at the center bow left or right

5. UPIN Vertical lines at the top bend left or right.

6. LPIN Vertical lines at the bottom bend left or right.

7. VANG Rotates the picture left or right

8. TRAP/PPHA

1. Crosshatchgenerator

2. TV remotecontrol

Keystones the picture *

3. PAMP adjustment:

4. VBOW adjustment:

5. UPIN adjustment. Correct for upper bends

6. LPIN adjustment. Correct for lower bends

7. VANG adjustment. Correct for picture tilt

17

8. TRAP/PPHA adjustment. A Keystone shape is narrow at the top and wide at the bottomor vise versa:

Keystone

Shapes

Step 55. Store the horizontal adjustment information by pressing the remote control’s

MUTE button followed by the ENTER button.

Step 56. The new yoke has a XCV coil adjustment that affects the straightness of the

left vertical lines. The XCV coil is under the Yoke Board. The effect is more pro-nounced on the larger 27” TV sets. Using tool P/N 7-700-733-01, adjust the coil untilthe left vertical line is straight.

The TV crosshatch pattern should now be straight, converged, and rectangular.

Step 57. Touch up the focus. The control is located on the flyback transformer.

Step 58. Turn OFF and unplug the TV. Disconnect the video input from the TV.

Step 59. The black rotation coil around the yoke is still unplugged. Plug it back into the

CRT board at connector CN707.

9. Using the Memory Transfer Reader / WriterIn this last section of lab A you will learn how to use the Non-Volatile Memory Reader/Writer Jig. As an exercise, you will copy memory information from the TV, then alter theTV’s data. Later if everything goes well, you will restore the original TV information.

Step 60. In the TV set, there is a catch that holds the main board. The catch is

located at the left side of the main board by the letter H. Pull out the catch and slide outthe main and power supply boards to reach the rear power supply connectors.

Step 61. On the main board unplug power supply connectors CN120 and CN 550 to

permit the main board to flip up.

Step 62. Behind the tuner is the Micro, IC001. Underneath IC001 is the NVM (memory)

IC003. Slide the main board out and flip it up on its side to expose the memory IC.

Pullcatch

Main bd PS

XCV

YokeAssembly

sideview

straighten

TV screenYokeBoard

18

Step 63. Locate the Non-Volatile Memory (NVM) Reader/Writer Jig.

Step 64. The cable that plugs into the top of the NVM jig has two connectors and one

clip lead. The clip lead is always grounded (connected to the white/orange ground @connector pin 4). The two connectors connect to the memory IC.

Memory IC003 in this set is an 8 pin flat pack IC. Locate the Pomona model 5250 SOIC flatpack IC clip and put the connectors on so that the White/blue wire is pin number 1 and theWhite/green wire is pin number 8.

Step 65. Set all the NVM Jig rocker switches to OFF. No damage to our knowledge

has occurred with the switches in the wrong position. Experiment at your own risk.Switch 1 = Memory size

Switch 2 = Unknown

Switch 3 = Adds pull up resistor to BClk (connector pin 6)

Switch 4 = Adds pull up resistor to Bdata (connector pin 5)

Step 66. Connect the ground clip onto the Micro IC001/pin 30. This is the reset pin.

Your instructor has soldered a wire at pin 30 so you can make the connection.This ground (reset) connection keeps the Micro inactive while the “NVM” is powered bythe Jig. The ground prevents the Micro from accessing the memory IC while the NVMJig is reading or writing to the same memory.

Step 67. Locate memory IC003 and clip the Pomona clip onto it, observing pin outs.

Step 68. Slide the NVM Jig power switch ON and press the READ button. One of three

things will occur:· The Green Read light comes ON in three seconds – Normal. Memory information was

copied. The time is dependent upon the memory size.

Operation/Error lightPower switch

Read button

Read completion light

Write button

Write completion light

NVM Reader/WriterJigT-9350-109-1

4 switches

NVM Jig

White/blue = pin 1

White/green = pin 8

1

45

8

Gnd

19

· The Red Operate/Error light blinks immediately – Failure to copy the memory informa-tion. Recheck the memory connections, verify ground pin. Unplug the TV. Reset theERROR light by turning the Jig OFF.

· The Red Operate/Error light blinks after a while – Failure to copy the memory informa-tion. Turn memory size switch 1 to the ON position and try again.

Step 69. Unplug the NVM Jig from the TV board and turn OFF the NVM Jig. The

information has been saved in the jig and will remain there even when the Jig is OFF.The data will remain in the Jig until new information is read into it.

Step 70. Reinstall the main TV board. Reconnect the two power supply connectors.

Slide the boards in and plug in the TV set.

Step71. Turn the set ON in the service mode by pressing the DISPLAY, 5, VOL +, then

the Power ON button on the remote control.

Step 72. The first service adjustment is horizontal size. Press the remote’s # 6 button

and hold it until the data (upper right corner) is 0. Press MUTE, then ENTER to savethis incorrect data.

Step 73. Press category change button #5 on the remote once. This should bring you

to the ID codes that tell the Micro what features this model should have.

Step 74. Press remote button #6 repeatedly to decrease ID-0 data from 89 to 17. Data

17 corresponds to a European TV. Press MUTE, then ENTER to save this incorrectdata.

Step 75. Turn the TV set OFF and then back on (not in the service mode). Is the

picture still shrunken? ________

Step 76. Press the MENU button. Is the menu in English? _____________

Step 77. Turn the TV OFF and unplug it so the Micro does not get power.

Step 78. Slide out the main board to access the memory IC003 again.

Step 79. Clip the NVM Jig onto memory IC003 and the ground clip.

Step 80. Turn the NVM Jig ON and press WRITE. After about three seconds, the write

light will illuminate indicating a successful transfer of data. If the red error light blinks,recheck your connections, turn OFF the NVM Jig to reset the red error light and tryagain. The original information is still in the NVM Jig.

Step 81. Disconnect the NVM Jig and reinstall the main board with the power supply.

Step 82. Plug in the TV and turn it ON. Is the width reduced? _____________

Step 83. Press the MENU button. Is the menu in English? ___________

Step 84. Turn OFF the TV and unplug it.

Step 85. Reinstall the rear cover and fasten with five large screws and two small ones.

Unplug and coil up the TV line cord. Place the remote control on top of the TV.

20

ADDENDUM 127” TV Set Adjustments:

Step 6. Before removing the yoke, note the WA board’s position on the CRT neck.

Notice that the edge of the V board clamp is mounted just above the G3 cylinder grid.Return the V board to this position if it is moved.

Step 10. Reset the two rings on the WA board to the initial position. The ring’s tabs should be

together and both face to the right as shown:

Step 17. On 27” and larger flat screen WEGATM TVs you must remove the side wedges

and tilt or bend the sides of the larger yoke to straighten the left and right vertical linesof the picture. Reinsert the rubber wedges.

Yoke Position

Adjustment Tool Purpose

Tilt front of yoke Add wedges P/N =4-053-005-01

1. Straighten bent horizontal (left to right) lines.

2. Reduce bent vertical lines at thesides of the screen.

cathode

G1

G2

G3 G4 G5

WA board / clamp edge

CRT

Clamp location

Both tabs should face tothe right.

Vertical lines

21

Step 24. Located on the neck assembly between the yoke and CRT pins are “Y splitting axis”correction ring magnets. Rotate the tabs of these ring magnets to straighten the pincushiondistortion to the top and bottom horizontal lines.

Step 47. On the top of the 27” and 32” WEGATM TV yokes there is an H-TRP control for

trapezoid correction. Use the non-metallic 2.5mm flat blade type driver (P/N = 7-700-731-04) to adjust control H-TRP. Make the left and right vertical lines of the picturestraight. If the line cannot be made straight, equalize the distortion at both sides of thepicture.

New Controls on 27 and larger WEGATM TV sets

Name Tool Purpose

Y axis ring magnets Fingers Top and bottom pincushion

H-TRP Non-metallic2.5mm flat blade

Make the left and right vertical lines asstraight as possible. The final positionmust not be at the end of rotation.

Balance Top and BottomBalance Top and Bottom

OK OK

No goodNo goodY splitting ringIncorrect adj. =

StraightenStraighten

Adjust the H-TRP control

DeflectionYokeTOP VIEW

TLV

YCH

27 & 32WegaTM

TV YokeControlsLocations HTRP

27 & 32WEGATM

TV YokeControlsLocations

22

ADDENDUM 2

PALM/DATA PALN AVERAGE

NO. ITEM FUNCTION RANGE 20" 25" 20" 25" DATA1 HSIZ HORIZONTAL SIZE ADJ. 0-63 35 382 HPOS HORIZONTAL POS. ADJ. 0-63 33 213 VBOW VRT LINE BOWING ADJ. 0-15 5 94 VANG VRT LINE BOW SLANT ADJ. 0-15 7 55 TRAP HORIZ. TRAPEZOID ADJ. 0-15 7 76 PAMP HORIZ. PIN DISTORTION ADJ. 0-63 7 327 UPIN UPPER PIN DISTORTION ADJ. 0-63 36 398 LPIN LOWER PIN DISTORTION ADJ. 0-63 36 399 VM VELOCITY MODULATION ON/OFF 0, 1 0

10 BLK VERTICAL BLANKING ON/OFF 0, 1 011 VMLV VELOCITY MODULATION LEVEL 0-3 2 212 AGN2 AGING 2 0, 1 013 REFP REFERENCE PULSE POSITION 0, 1 014 VBLK VERTICAL BLANKING ON/OFF 0, 1 015 JPSW 0, 1 016 VSIZ VERTICAL SIZE ADJ. 0-63 47 4917 VPOS VERTICAL POSITION ADJ. 0-63 32 3218 VLIN VERTICAL LINEARITY ADJ. 0-15 619 SCOR VERTICAL "S" CORRECTION ADJ. 0-15 820 VZOM 16:9 CRT Z MODE ON/OFF 0, 1 021 EHT VRT HI-VOLT. CORRECTION 0-15 622 ASP ASPECT RATIO CONTROL 0-63 4723 SCRL 16:9 CRT Z MODE TRANS SCROLL 0-63 3124 HBLK HORIZONTAL BLANKING ON/OFF 0, 1 125 LBLK LEFT BLANKING AFJ. 0-15 1226 RBLK RIGHT BLANKING ADJ. 0-15 527 VUSN V SAW WAVEFORM COMPRESS 0, 1 028 HDW H. DRIVE PULSE WIDTH 0, 1 129 EWDC "PARABOLA’ EW/DC ADJ. 0, 1 030 LVLN LOWER SCREEN BTM VRT LIN ADJ. 0-15 031 UVLN UPPER SCREEN BTM BRT LIN ADJ. 0-15 032 RDRV R OUTPUT DRIVE CONTROL 0-63 3633 GDRV G OUTPUT DRIVE CONTROL 0-63 25 21 2634 BDRV B OUTPUT DRIVE CONTROL 0-63 25 21 2535 RCUT R OUTPUT CUTOFF CONTROL 0-15 836 GCUT G OUTPUT CUTOFF CONTROL 0-15 7 6 637 BCUT B OUTPUT CUTOFF CONTROL 0-15 738 DCOL DYNAMIC COLOR ON/OFF 0, 1 139 SHUE SUB HUE 0-31 14 12 1540 SCOL SUB COLOR 0-31 1541 SBRT SUB BRIGHTNESS 0-31 15 13 1542 RON R OUTPUT ON/OFF 0, 1 143 GON G OUTPUT ON/OFF 0, 1 144 BON B OUTPUT ON/OFF 0, 1 145 AXPL AXIS PAL 0, 1 046 AXNT AXIS NTSC 0, 1 047 CBPF CHROMA BPF ON/OFF 0, 1 148 CTRP Y TRAP FILTER ON/OFF 0, 1 149 COFF COLOR ON/OFF 0, 1 050 KOFF SET COLOR KILLER 0, 1 051 SSHP SUB SHARPNESS 0-15 6 7 752 SHPF SHARPNESS CIRCUIT FO 0, 1 153 PREL PRE/OVR SHOOT SWITCHING 0, 1 154 Y-DC DC TRANS RATIO SWITCHING 0, 1 1

14

11

0

0

NTSC VIDEO

INITIAL DATA

35

00

00

047326806

47311

125010

335777

3636

00

31

10

60

1

0

11

010

1

0

Palette mode controls this register

23

PALM/DATA PALN AVERAGE

NO. ITEM FUNCTION RANGE 20" 25" 20" 25" DATA55 GAMM GAMMA CORRECTION AMNT 0-3 1 156 ABLM ABL MODE SWITCHING 0, 1 157 VTH ABL CD VHT SWITCHING 0, 1 158 YDEL Y DELAY TIME CONTROL 0-15 759 NCOL NO COLOR ID 0, 1 160 FSC FSC OUT ON/OFF 0, 1 161 K-ID KILLER ID CONTROL SW 0, 1 062 HOSC H VCO OSCILLATION FREQ 0-15 763 VSS V SYNC SLICE LEVEL 0, 1 1 0 064 HSS H SYNC SLICE LEVEL 0, 1 065 HMSK 0, 1 066 VTMS SELECT SIGNAL VTIM PIN 0-3 067 CDMD V CNT DWN MODE SWITCHING 0-3 068 AFC AFC LOOP GAIN SWITCHING 0-3 069 FIFR FIELD FREQUENCY 0-3 1 370 SBAL SUB BALANCE 0-15 771 SBAS SUB BASS 0-15 972 STRE SUB TREBLE 0-15 973 BBEL BBE LOW 0-15 1274 BBEH BBE HIGH 0-15 975 SRND SURROUND 0-63 1376 BBE BBE ON/OFF 0, 1 177 DISP O.S.D. DISPLAY POSITION 0-63 22 5 1578 TROT TILT CORRECTION 0-63 3179 HCLW HORIZONTAL COUNT LOWER LIMIT 0-127 16 1680 HCHG HORIZONTAL COUNT HIGH LIMIT 0-127 64 6481 ABLO 0, 1 182 ABL0 0-7 783 SYSC COLOR SYSTEM 0-7 684 VENH VERTICAL ENHANCEMENT 0-7 4 485 CBPC 0, 1 086 BYCF 0, 1 087 KILC 0, 1 088 LDOT 0, 1 089 CORE 0, 1 090 ID0 0-255 See ID Map91 ID1 0-255 See ID Map92 ID2 0-255 See ID Map93 ID3 0-255 See ID Map94 ID4 0-255 See ID Map95 ID5 0-255 See ID Map96 ID6 0-255 See ID Map

Palette mode controls this register

30

64

17343

2510

00

20119

000

64006

1

3116

912913

0379

0000

107

117

1

NTSC VIDEO

INITIAL DATA

Palette mode controls this register

24

Sâ

ADDENDUM 3

CONFIDENTIALService BulletinTV Products

Sony Service CompanyNational Technical ServicesA Division of Sony Electronics Inc.Park Ridge, New Jersey 07656

CSV-1

Model: KV-36FV1, KV-36XBR200 No. 387R2

Subject: Geometric Distortion Date: June 21, 1999

Symptom:(1335) Geometric distortions, such as; shoulder rolloff (rounding of the horizontal lines at

the top and bottom corners of the screen), or trapezoidal picture, etc.

Solution: If the customer complains of this symptom please follow the adjustment proce-dure in this bulletin. Before doing so, please check the serial number of the set.ONLY early production units require a new improved Yoke to be installed.

Parts: This procedure may require the following items, Rotatable Magnets P/N 1-452-094-00 Permalloy Strips P/N 4-062-047-01, Core Alignment tool P/N 7-700-733-01

Model: KV: Ser.# Range Description Part #

36FV1 1 9017656 Defl. Yoke 8-451-506-11

36XBR200 1 9017263 Defl. Yoke 8-451-506-11

Distinguishing the New Yoke: The new yoke contains 4 bar magnets added to the outside of thehousing (white arrows). Electrical changes were also made to the windings. (Fig. 1 below)

Fig. 1 Important Note: Many experienced technicians have reported difficulty in obtain-

ing good geometry with proper purity. Please read and perform all the steps in thisprocedure. The tilting and positioning of the yoke is critical to this procedure. Sonyrecommends the use of a large stand mirror for the geometric and purity adjust-ments. Adjustments are made to equalize the distortion (make even top tobottom or left to right). Don’t try to correct only one position on the screen,therefore it is necessary to perform the entire adjustment procedure toobtain the best results.

25

Procedure for readjusting the Yoke1. Set customer menu Tilt Correction adjustment to zero Use the remote to enter the menu and

select the toolbox icon, then select tilt and set this to 0.2. To be performed only if the yoke is the old type. First, mark the Neck Assembly position

before removing. Remove the old yoke and all the rubber wedges. Also, remove the THLplate (Fig. 11, right side picture) from the original yoke, since this does not come with thenew yoke.

3. Mount the new yoke and the Neck Assembly (at the previously marked place). If the neckassembly was not marked before it was removed, then position as illustrated below. The backof the metal clamp is positioned over the spot indicated by the dashed line.

4. Set Yoke rings to their zero position. See Fig 2

Neck Assembly Position

End of this element

Back of metal clamp is posit ion over the element indicated by thedashed l ine.

Fig 2

The points of theH/V magnets,and the bumps ofthe BMCmagnets shouldalign at this pointon the yoke,when set to thezero position

H/V tabs:Ridges ontop of tab

BMC tabs:V shapednotches

Tall Purity tabs: Bothtabs together pointingup to top of set (cutoffin this picture)

26

Purity Adjustments

If the set is being adjusted in the shop, it is extremely important to face the CRT towards either the Eastor West direction, which reduces the influence of the earth’s magnetic field. Later you will be asked tocheck adjust it in a North to South position. This only reduces the possibility of readjustment upondelivery to the customer’s home. however, due to the large flat CRT, some readjustment in thecustomers home is likely.If the set is adjusted in the customer’s home, please face the set in the direction that the customer willwatch it. This will optimize the adjustment. Note: For optimum adjustment, the set should be on for 20minutes.5. Remove all purity magnets, permalloy strips and rubber wedges (DY spacers).6. Do not use an external degausser to degauss the CRT. Turn the set off and on to use the TV’s own

degausser circuit. Please note proper degausser operation: If the set is on for several minutes thedegausser (relay activated) will have had time for the thermistor to cool so that it will degauss properly.However if the set was just turned on for a short while and then turned on and off, the degausser maynot work properly. In this case, turn the set off and wait 3 to 4 minutes for the thermistor to cool andthen turn the set back on.

7. Make sure the Purity ring tabs are at the zero position. See Fig 2.8. Loosen the deflection Yoke mounting screw, using a non-magnetized screwdriver.( a standard screw-

driver, one that does not have a magnetized head able to pickup screws).9. Input a green flat field pattern.10. Move the deflection yoke backward, and adjust with the purity tabs so that the green is in the center

and red and blue are even on both sides. See Fig. 3 for tab location.11. Move the entire deflection yoke forward, and adjust so that the entire screen becomes green.12. Switch the raster signal to Red and Blue and confirm the purity condition. Readjust yoke and rings as

required.13. Lightly tighten the yoke holding screw with a non-magnetized screwdriver, so that it does not move

back and forth.14. Input a crosshatch pattern. Adjust the neck assembly rings (See Fig 4 ), so the top and bottom

vertical pincushion is minimized. The purity may be affected by this adjustment. Therefore, a touchup of the Purity Rings may be required.

15. If after readjusting purity there is slight impurity in the picture, place a disc magnet, P/N 1-452-094-00,on the CRT bell to correct for the mislanding. Standard purity magnets are not effective, use only thistype.

16. If adjusted in the shop, face the set North to South, turn unit on and off to degauss, and confirm thepurity is correct. If not, readjust.

Location of Ring Magnets (on Yoke) Neck assembly magnets (on WA board- behind yoke)

Neck AssyRings ForGeometricAdjustment

Adjusting for best geometric picture.Input a crosshatch pattern.In the service mode turn off the Blue and Red guns. To enter the service mode, start with the setoff and then press the following buttons on the remote in this order in quick succession: Display, 5, VolumeUp, Power. Set will then come on in the service mode.

27

The RON & BON are approximately 40 registers after the last ID code. Once selected by using the “1” (up)and “4” (down) buttons, press the “6” button to turn off. Green pattern is only displayed.1. Hold the yoke and tilt it up, down, or sideways to obtain the best over all geometric pattern. The yoke

can be held by the rotation coil that surrounds the yoke, when positioning it while viewing the effect onthe screen. When the best position is obtained, place 4 rubber wedges (spacers), part number 4-053-005-01, between the yoke and CRT to maintain the yoke position. Check that the Horizontal lines arestill as straight as possible. This is one of the most important adjustments to improve ShoulderRoll off. (Fig. 5)

Lift the yoke up/down and side toside for the best over all geometricpattern.

Fig. 5

2. Using the Core Alignment tool (Fig. 6) P/N 7-700-733-01. Adjust the XCV core (Fig.7) to obtain thestraightest lines on the X-axis. (Vertical lines bend in on either the top or bottom as this coil is ad-justed) Use the crosshatch pattern.

(Right Side View of Yoke – Located near the Bottom ofYoke)

P/N 7-700-733-01

XCV coreadjustment

Core Alignment tool (Fig.6) XCV core to adj X-axis (Fig. 7)

3. Adjust the HTRP adjustment (Fig.11), which is one of three potentiometers located on the top of theyoke. Adjust for the least amount of trapezoidal distortion while viewing a crosshatch pattern. (Philipsslotted)

4. Geometric Service Adjustments: Next adjust the following geometric registers in the Service Mode:(Display, 5, Volume up, power) The sequence of adjustments below are written in the order as theyappear in the service mode. Some adjustments should not be changed, thus they are marked, “Do notAdjust”.

5. VPOS: Moves pix up and down6. VSIZ: Increase/decrease vertical size7. PVSZ: Do not adjust8. VCOM: Do not adjust9. VLIN: Vertical Linearity10. VSCO: Vertical Linearity (Top bends in)11. HPOS: Moves pix left or right12. HSIZ: Increase/decrease Horizontal size13. PHSZ: Do not adjust

14. PAMP: Pincushion on the sides15. UPIN: Upper Pin (Top)16. LPIN: Lower Pin (Bottom)17. PPHA: Trapezoidal – Sides Angle in/out18. AFC: Do not adjust19. VBOW: Bows vertical lines on the side20. VANG: Angles both sides in/out21. Write Data (Muting then Enter)

Note: Repeat steps as necessary : Equalize Distortions

28

Convergence

Turn the Red and Blue Guns back on. Go to the RON (press 3) & BON (press 3)Before adjusting set the brightness control to minimum and the Picture control to themid-position.Use either the crosshatch or dot pattern from the generatorCenter the H. Stat control. The H Stat control should not be positioned to either side, but should be some-what centered. (Plastic knob on side of C-Board, RV:1761). The following order is recommended foradjustment: e V-Stat , BMC and then H-Stat.

1. Adj. the V. Stat rings by opening or closing the tabs to converge red, green, and blue bars in thecenter of the screen. (See Fig. 8) The H Stat control should be adjusted to fine-tune the convergenceand should never be set to either side. (Diagrams below illustrate beam dot movement during ringadjustment)

A d j. th e V . S ta t m ag ne t and ad jus t s ta tic conve rge nceby ope n in g , c los in g o r ro ta tin g the tabs to co nverge theR G B do ts o r c rossha tch lines .

V . S ta t m ag ne t e ffec ts o n R G B be am s(R efe r to d iag ram s ins ide the so lidlin es) (Fig 9 :Two diagram s above,on left hand side )

BMC ADJUST: R efe r to the d ia g ram s ins id e th e do tted lines :T he respective be am do t pos it io n resu ltin g fro m m ov ing eachB M C ring , w h ich in te rac ts w ith o th e r rings , so you w ill ne edto go back an d fo rth b e tw ee n V -S ta t a nd B M C r ingassem b lies fo r op tim um cen te r converg ence . (Fig. 10)

Ring Location diagram(Fig. 8)

BMC Rings Operation

29

2. The BMC (Blue Mis-Convergence) magnet rings will also interact with the V Stat magnet.Therefore you will need to go back and forth with these two magnets to achieve the bestvertical and horizontal center convergence. All three magnets along with the H Stat control on the CBoard should be touched up as you do the convergence alignment. Fig. 10

3. Once the adjustments are completed the V Stat and BMC adjustment rings should be locked intoplace with an acrylic latex paint, especially if the unit is being transported.

Location Of the various adjustment on the Yoke

Fig.11

THL Plate (only one)(Must be removedfrom original yoke.)

YCH

THL plate slits are on both sides of the yoke. Theeffect is different on each side, please try mountingand adjusting (sliding in and out) this plate on eachside to determine best adjustment position.

1. Turn off the Green gun from the Service mode (select GON, press 6). Adjust the YCH so that theBlue along the vertical center line (Top to Bottom lines) has the least amount of blue showing. If theblue can not be eliminated then the best compromise between the top and bottom of the screen.

2. Adjust the TLV so that the blue horizontal lines (Lines across the screen) on the top and bottom havethe least amount of blue lines between a & b.

30

THL Plate Adj.

3. THL Plate Adjust: Note: This plate does not come with the new yoke. It must be removed from theoriginal. Slide the THL plate into the slot on either side of the deflection yoke assembly in order toimprove the horizontal convergence at the right and left sides of the screen.The plate can be mounted on either side of the yoke housing. Select the side that gives the bestresults. The plate should be secured with locking paint after the adjustment. (See Fig 11)

4. Corner Convergence should be corrected by use of Permalloy Strips around the Yoke.Part number 4-062-047-01.

5. Turn green back ON by selecting GON in the service mode and pressing “3” on the remote.6. Write this data by pressing “muting” then “enter”.7. Exit Service mode by turning the set OFF and then back ON.8. Return Brightness and Picture control to their previous settings.9. This completes the adjustment procedure. Please verify proper geometry and convergence.

31

TVP-09 Lab B (Based on model KP43T70)

Three people per TV. The first person reads while the second performs theadjustments. The third will assist both. Later when instructed in the text, thelab partners will rotate positions.

ObjectiveThe purpose of this lab is to provide you with practical knowledge about Sony’s new con-vergence procedures. Convergence is necessary after a picture tube or yoke replace-ment. Picture tube aging may also require reconvergence. With Sony’s new microproces-sor controlled convergence stage, merging of the red, green and blue pictures can bealmost 100%.

In this lab you will explore the new convergence service mode, position and adjust thegreen yoke, focus the TV, and then perform coarse and fine convergence of the threepictures. After convergence, you will update the Flash Focus memory.

Check off the box as you begin to read each step. This locates your step as you switchplaces or pause.

Items needed for this lab:· Demagnetized + tip screwdriver· TV remote control· Tape measure to locate the screen center· Ruler that measures in mm

This projection TV adjustment lab is divided into six parts:

1. The New Service Mode steps 1-112. Positioning the yoke steps 12-183. Focus Adjustment steps 19-324. Coarse Convergence steps 33-78,5. Fine Convergence steps 79-906. Defocusing the blue color steps 70-1007. Updating the Flash Focus Memory steps 101-108

1. The New Service ModeThe Sony RA-3 and RA-4 chassis projection TV sets contain an additional microprocessor thatmanages the convergence. You will access this convergence microprocessor information thoughthe normal service mode. In the convergence service mode some of the remote control buttonswill have different functions than the normal service mode.

In this chassis, the last service mode category where you left off is remembered as long as the TVis plugged in. For example, if you turned off the TV in the ID category, the next time you enter theservice mode it will be in the first item of the ID category. If the TV were unplugged the first item ofthe first category will appear in the service mode.

32

Step 1. Plug in the projection TV set into AC and connect an antenna to it.

Step 2. With the TV initially OFF, press the following buttons on the remote control to enter the

normal service mode:Display, #5, Vol +, Power

Step 3. Using the remote control channel up/down buttons only, select a TV channel (one

strong enough so the sync is stable). Then press the TV/Video button to select the unusedvideo 1 input. The TV screen will have a service mode display in green similar to this:The data numbers shown are samples.

Your data number will be different.

Step 4. You can use the remote control #2 (up) and #5 (down) buttons to jump through the

categories. Press the #2 button three times to move from the initial VPNT category to the PJEconvergence category. The convergence mode is distinctive because the letters are white,not green. The screen should look like this:

Step 5. Some remote control buttons perform different functions in the PJE convergence ser-

vice mode:

Press the #6 button to get a white cross hatch pattern on the screen.

What appears on the screen when you press button #6?

1. OFF2. Cross hatch pattern________________3. ________________________________4. ________________________________5. ________________________________6. OFF

Service VPNT 00 VPOS 028000000 00

data

category

1 2 3

4 5 6

7 8 9

#3 = Color change - Green, Blue, Red.

#6 = Crosshatch/dots/hatch/dots/OFF

#9 = Coarse / Fine Convergence Mode

RemoteControlNumbers

PJE 00 00FDIS lWhite letters

PJE Convergence screenVPNTVPNVVPNSPJE3DCMTONEDSPMC

SCICPPDACPIIDCCDOP

Service Mode Categories

33

Step 6. We need to see why there are duplicate patterns. Switch to TV reception temporally by

pressing the remote control TV/video button several times until you see a channel number.Kill the volume so you can hear your partner.With a TV station in the background, press the remote control #6 button several times to cyclethrough the patterns again. What is the difference between the two hatch patterns?

Return to a crosshatch pattern (#6 button) and go back to an unused video input (TV/Videobutton) so you can see the white convergence service mode letters clearly.

Step 7. You can use the #9 remote control button to alternate between the coarse and fine

convergence modes. Press the #9 button. What appears on the screen? Draw in the answer.

Step 8. While in the fine convergence mode, press the #3 button. The cursor color corre-

sponds to the beam color that is moved during fine convergence.What happens on the screen each time the #3 button is pressed?

Green cursor

1st time 2nd time 3rd time 4th time

Step 9. Press the #9 button again to return to the coarse convergence mode.

Step 10. In this step you will electronically remove the convergence signals to all three picture

tube sub yokes. Press the #7 button on the remote control. The word INITIAL will appear.

Press ENTER before the word INITIAL disappears. An unconverged crosshatch pattern willappear with geometric distortion. This convergence reset mode can be saved but you willspend hours performing convergence before returning to the correct convergence unless youuse default data (see Convergence using default Data in the appendix after this lab B).

This mode is useful for yoke centering and can also be used to determine if a convergencesignal line is actually active or just contains noise.

Step 11. Restore the convergence signals by pressing #0, ENTER.

Coarse Conv Mode Fine Conv Mode

PJE 00 00FDIS 1

DrawAnswerhere

INITIAL

34

Screw 1

Screw 2

Screw 3

2. Positioning the YokeIf the yoke is incorrectly positioned, convergence cannot be completed because of insufficient R,G or B color data range. In addition, the Flash Focus feature will show an error code and will notwork. The yokes are positioned after the convergence data is turned off from the convergenceservice mode. You will only position the green yoke in this exercise.

Step 12. The yokes are behind the speaker grille. Loosen the front speaker grille from the

back by removing three screws at the left and right bottom corners. Two screws are recessedinside the hole. The third screw is hidden below the others.

Step 13. Tilt the top of the TV backwards so you can wiggle out the bottom speaker grille. Do

not disconnect the wires from the speaker grill. They contain the remote control’s receiver.

Step 14. The baffle board covers the circuitry where the yokes are. Remove the board’s four

screws and the board itself.

Step 15. While still displaying a crosshatch pattern in the convergence service mode, press the

remote control’s #7, ENTER buttons. The convergence information is disconnected in thismode and the pattern is distorted everywhere except at the center.

Step 16. The picture tube yoke clamps are accessible from the TV front. You will only use a

demagnetized screwdriver to loosen the yoke clamp. A magnetized driver will magnetize theclamp upon contact. The beam will shift position (and its position will vary from day to day),making permanent centering/convergence impossible.Loosen the clamp connected to the middle (green) picture tube yoke. Rotate the yoke whilewatching the picture. With a partner, is it easy to position the yoke so the center horizontallines are straight? ___Yes____

Step 17. Can the yoke be pushed up or slid down? _________________

Re-center the green yoke and tighten its clamp.

Step 18. On the remote control, press #0, ENTER to return to the converged state. .

35

3. Focus AdjustmentSpot Shape, mechanical focus and electrical focus should be performed prior to convergence.Focus is adjusted one color at a time. Only the green focus procedure is shown in this lab: Theothers colors are adjusted similarly.

Spot Shape

The shaping of the electron beam affects the picture sharpness. Each picture tube has two pairsof ring magnets on the yoke for shaping. The 2 pole rings (near the CRT pins) are used to centerthe electron stream. The 4 pole rings centers the beam in the yoke’s magnetic field so the beamspot on the screen is round, not oval. Adjust them after yoke or tube replacement before youperform electrical and mechanical focus.

In this section you will access the yoke and adjust the ring magnets before performing typicalfocus adjustments. Not all these adjustments apply to all colors.

Spot Shape Adjustments

Adjustment Color Focus control Target

2 pole Green, Red Clockwise Center dot in spot

4 pole Green, Red, Blue Counter Clockwise Spot must be round

Defocus Blue only Either Enlarge dot

Step 19. Remove the eight screws from the back of the TV that hold the rear (lower) panel. Lift

out and set aside the rear panel.

Step 20. Cover both the red and blue picture tube lenses with a sheet of paper.

Step 21. Each deflection yoke has two pairs of ring magnets. The 2-pole set is near the CRT

pins. Tabs are connected to the rings to move the magnets.

Step 22. While still in the convergence service mode, press the #6 button on the remote control

several times until you come to a dot pattern.

Step 23. Next you will defocus the green color. Locate the green focus control at the front of

the TV and turn it CLOCKWISE until you can see the dots bloom. Inside the enlarged dot is abrighter spot.

2 pole tabs

4 pole tabs

RingMagnetLocation

Initialtabposition

36

Focus Control Block

Step 24. While looking at the center of the screen, move the 2 pole tabs to place the brighter

spot at the center of the dot.

Step 25. Defocus the green color in the other direction by turning the electrical focus control

COUNTER CLOCKWISE.

Step 26. Move the 4-pole magnet tabs so the spot at the center of the picture is round.

Step 27. You may uncover the red lens and cover the green to perform the 2 and 4 pole

adjustment on the red yoke rings. The 2-pole adjustment is not performed on the blue color.The 2 pole rings for the blue color will remain in the initial position.

Electrical Focus

This focus is performed while looking at snow or the scanning lines. The scanning line method isdescribed here.

Step 28. From the front of the TV set find the electrical block where the red, green and blue

focus controls are located. This block also contains the screen controls for a total of sixcontrols.

Step 29. Place a piece of paper over the red and blue picture tubes lenses to block the light.

Adjust the green focus control on the block for narrowest horizontal and vertical crosshatchlines. The focus adjustment should coincide with the clearest horizontal scanning lines.

Four pole Adjustment

SpotDot

Two pole Adjustment

37

Step 30. Repeat this electrical focus procedure for the other two colors. Shift the paper to

cover the unused color lenses.

Mechanical Focus

This focus is performed from the back of the TV. The internal plastic lens is mounted to a wingnuton the lens housing. The wingnut and lens move on an inclined slot for focus.

Step 31. At the center green lens loosen the wing nut that connects to the lens. While watch-

ing the crosshatch from the back of the screen, slide the loosened wing nut along the incline forthe smallest cross hair width.

Wing Nuts

Step 32. Tighten the wing nut and remove the sheets of paper that cover the lenses.

Step 33. Repeat this procedure for the remaining red and blue colors. To see the blue clearly,

darken the room or have your partner place a piece of paper over the front of the screen toblock the ambient light.

Step 34. Touch up the electrical focus by repeating steps 27-29.

4. Coarse ConvergenceTime spent performing a good coarse convergence will save time in the long run and avoid “maxingout” the fine convergence locations. In this section you will first check the reference information tosee if the internal crosshatch and basic parameter data is correct. Then the green crosshatch isgeometrically set so the picture is straight, rectangular and not bowed. Finally the red and bluecolors can overlay the green pattern. Save frequently.

Scanning lines

Narrow cross hatch

Cross hatch

38

The plan for the coarse convergence is to:

· Set the video levels steps 34-41· Check internal reference data steps 42-43· Set the green geometry steps 44-52· Superimpose the red over the green steps 53-77· Superimpose the blue over the green steps 78-79

Setting the Video Levels

The picture and brightness levels must be reduced to 20% and 50% respectively to prevent dam-aging the CRTs with an unmoving crosshatch pattern.

Step 35. Press the remote control button #6 a few times to turn the patterns off so the menu

can be seen.

Step 36. Press the MENU button. Press the SELECT at the middle of the arrow buttons twice,

once to enter the video mode and a second time to select the mode.

Step 37. Use the down arrow to highlight the MOVIE mode (because Vivid and Standard

modes are not adjustable). Press the SELECT button again.

Step 38. Use the down arrow button again to highlight PICTURE ADJUSTMENT AND

PRESS the SELECT button.

Step 39. Use the down arrow button again to highlight PICTURE and press SELECT.

Step 40. Use the left arrow button to decrease the picture level to about 20% and press

SELECT. This returns you to the PICTURE ADJUSTMENT page to make brightness adjust-ments.

Step 41. Press the down arrow button to highlight brightness. Press the SELECT button.

Step 42. Use the left arrow button to reduce the brightness to 50%.

Check of Internal Reference Data

In this section, you will check the memory data to see if the internal crosshatch and basic param-eter data is correct before beginning convergence. Convergence is not possible if the data iscorrupt or incorrect.

Step 43. While in the “PJE” coarse convergence category, you will use the remote control #1

(up) or #4 (down) buttons to verify the contents of the first 17 service mode items. At eachlocation compare the data with the data listed in the chart. If they are different, use the arrowbuttons to change the TV data to the data listed in the chart.

0

1 2 34 5 67 8 9

RemoteControlArrowButtons

39

Use #1 (up) or #3 (down) to change items and the arrow buttons to change data. Press MUTE andENTER to store the correct PJE convergence data.

Step 44. It is time to switch places. The person who was reading will now perform theadjustments. The person assisting will now read.

Set the Green Geometry

Each item within the convergence menu is numbered except for the last six. The coarse conver-gence is performed using the last six UN-numbered adjustment items. Not all of the colors have alladjustments.

There are only centering, skew and pincushion adjustments for the green color. You will use theseadjustments to straighten the picture and form a green rectangle.

Step 45. You are currently in the PJE convergence service mode item number 16. Press and

hold down the remote control #1 (item up) button while watching the item numbers advance.You will pass Item numbers 17 – 28 that are the Flash Focus memory locations (centering andskew). Stop after item #34.You are at the green centering adjustment screen. If the word GRN does not appear on thescreen, press the #3 button to change color back to green (GRN).

Service Mode PJE Convergence DataItem # Item Data00 FDIS 0101 OSDH 3102 OSDV 2503 FVST 2504 VIST 005 VICU 6206 COHP 007 FIHP 19408 TPHP 6209 DFHP 22510 DFHG -8011 DFVG -1512 PWM 1 013 PWM 2 3214 HBLD 24415 HBLW 2316 BLKP 27

PJE 00 00FDIS

Category Item Item # Data

PJE 16 27BLKP

Category Item Item # Data

PJE service Mode item # 16

RemoteControlnumbers

GRN -063 -084CENT

S O N Y

1 2 3

4 5 6

7 8 9

Item up

Item dwn

Centering Adjustment ScreenPJE ADJ ITEMSVLOW item #33HPR - item #34CENT no item #SKEW no item #SIZE no item #LIN no item #KEY no item #PIN no item #

ItemUP

40

Step 46. Press the remote control #1 button twice more to move from green centering to green

SIZE.

Step 47. Verify that the green size data is –70 and –190. If it is different, use the arrow buttons

to change it to these numbers.

Step 48. Press the remote control #3 button once to move down from green SIZE to green

SKEW.

Step 49. Cover the red and blue lenses so they do not interfere with your judgement.

Step 50. Using the center marks or sides of the bezel for straightness, press the remote’s

arrow buttons to make the center lines parallel to the bezel.

Step 51. Locate the middle of each of the four sides of the screen. Use a tape measure to

identify the middle if your teacher did not mark it on the set.

Locate the vertical cross hatch line closest to the center. If you are not sure where the centeris, press the #9 button to display the center cursor. Press the #9 button again to return to thecoarse convergence mode.

Move the center cross hatch lines so they match the markers on the TV bezel. You can usethe first line of the N in SONY to center the vertical line.

GRN -070 -190SIZE

Horiz data Vert data

0

7 8 9

RemoteControlArrowButtons

Movesthisway

Moves thisway

SKEW Adjustment

x

x

x

x

X = middle

0

7 8 9

RemoteControlArrowButtons

SONY

S O N Y

Center thevertical line Center the

Horizontal line

41

Note: The final H & V centering data should be close to 000 for minimum DC voltage into theyoke. A high number means more current and more stress on the convergence driver ICs. Avery high number also means the yoke is incorrectly positioned. Yoke positioning begins atstep 12. The chart below shows typical data values.

Typical Centering Data

Color H Data V Data

Green 026 021

Blue 059 -070

Red 035 -018

Step 52. Press the remote control #1 button repeatedly so the TV screen changes from

CENTering to the green PINcushion adjustment item.

Step 53. Use the remote control top or bottom arrow buttons to adjust the top and bottom bow

so it is straight.The XXX at the horizontal data location means there is no horizontal pincushion adjustment.The left and right remote arrow buttons have no effect.

This completes the green geometry adjustments.

GRN XXX 250PIN

V DataH Data

Your datanumbers will bedifferent

PJE Adj ItemsCENTSKEWSIZELINKEYPIN

#1button

SONY

GreenVerticalPincushionAdjustment

RemotecontrolArrowbuttons

TV screen

Bowsinward

42

Superimpose the Red over the Green

There are more red geometry adjustments than green geometry adjustments. The size, skew,linearity, keystone and pincushion adjustments will be used to place the red crosshatch over thegreen cross hatch pattern (convergence). The best way to converge a TV set is to use the adjust-ments in pairs. Centering is paired with skew, size is paired with linearity, and keystone is pairedwith trapezoid adjustments.

Red Skew and Centering Adjustments

Step 54. Remove the paper covering the red lens but keep the blue lens covered.

Step 55. The service mode items are listed in the order below. On the remote control, press

the #4 (item down) button until you see the green centering adjustment screen.

Step 56. Press the #3 button until GRN changes to RED.

Step 57. Press the remote control’s up arrow button until the red lines separate from the white

line. Did the red lines move an equal amount over the entire screen or move more in one part?Circle the correct answer.

1. Top only moves more

2. Bottom only moves more

3. Middle only moves more

4. Equally all over

Step 58. While looking only at the center of the picture, use the remote control arrow buttons to

superimpose the red lines over the green lines. Disregard the lines at the sides for now.

Step 59. Press MUTE and then press ENTER to store the centering information.

GRN -063 -084CENT

RED 051 -059CENT

Adj Items ListCENTSKEWSIZELINKEYPIN

down

#4button

RemotecontrolArrowbuttons

up

At thecenter,merge thered linesover thegreen ones.

43

Step 60. Press the remote control button #1 to change from centering to SKEW.

Step 61. Use the arrow buttons to tilt the red center lines and place them over the green lines.

Red Size and Linearity Adjustment

The Linearity adjustment moves the lines more on one side of the screen than the other. You willadjust Linearity so the mis-convergence is equal on both sides of the screen with reference to thegreen. Then you will use the equal movement Size adjustment to converge the red lines onto thegreen reference.

Step 62. On the remote control press the #1 (item up) button (once) until you see the red size

adjustment screen:

Step 63. Press the remote control’s right arrow button until the red lines separate from the

white line. Did the red lines move an equal amount over the entire screen or move more in onepart? Circle the correct answer.

1. Right and left sides move equally to the right

2. Right side moves more

3. Left side moves more

4. Right and left sides move equally outward

You will leave the red size mis-adjusted until you have adjusted the red linearity.

Step 64. On the remote control press the #1 button (once) until you see the red Linearity

adjustment screen.

RED 025 000SKEW

Adj Items ListCENTSKEWSIZELINKEYPINup

#1button

RED -096 -246SIZE

Adj Items ListCENTSKEWSIZELINKEYPINup

#1button

Size Adjustment Screen

Use rightarrow buttonto correct

REDSKEWADJ

Use toparrow buttonto correct

RemotecontrolArrowbuttons

right

44

Step 65. The XXX data on the screen means the remote control’s up and down arrow buttons

do not work. There is no coarse electrical vertical linearity adjustment for this color.Press the remote control’s right arrow button until the red horizontal linearity data decreasesby 50. Did the red lines move an equal amount over the entire screen or move only in onearea? Circle the correct answer.

1. The right moved more

2. The left moved more

3. The middle moved more

4. All the lines move equally right

Step 66. The linearity adjustments move the red at each side an unequal amount. You will

move these left and right lines so they are an equal distance from the green lines. Later, equalmovement adjustments will correct the mis-convergence.Use the remote control left and right arrow buttons to move the outer red lines so they areequidistant from the green lines by the same amount (a = b).

Step 67. Now that the red line is an equal distance from the green line, you will use the size

adjustments to move both left and right red lines equally onto the green line. On the remotecontrol, press the #4 button (once) to return to the red size adjustment.

Adj Items ListCENTSKEWSIZELINKEYPINup

#1button

Linearity Adjustment Screen

Right button

Redline

Greenlines

a b

At the line s centeradjust the horizontallinearity so a = b.

Redline

RED -170 -246SIZE

Adj Items ListCENTSKEWSIZELINKEYPIN#4

button

down

45

The four red cross hatch intersections at the top, bottom and sides must match the four greenintersections. Use the four remote control arrow buttons to shrink or expand the red crosshatch so they match. Disregard any mis-convergence at the corners of the screen.

Step 68. Store the red convergence data by pressing MUTE and ENTER buttons.

This completes the coarse convergence in the area marked with an X. These areas are at thecenter, middle and sides of the screen.

Red Pincushion Adjustment

Next you will adjust the red pincushion, keystone and skew while watching the perimeter of thescreen. The previously converged areas are used as reference (Ref).

Step 69. Press the remote control #1 button (three times) until you see the pincushion screen:

Step 70. Press the remote control down arrow button. How did the top and bottom lines

change?

Step 701. Press the remote control up/down button to straighten the top and bottom red lines:

Red Keystone and Trapezoid Adjustment

These adjustments are also paired. The most effective way to identify and correct a trapezoiddistortion is to first introduce some keystone distortion. The trapezoid distortion is evident andcorrected before restoring the keystone distortion introduced earlier.

Step 72. Press the remote control #4 button (once) to enter the red keystone adjustment. You

will misadjust the keystone adjustment now so you can later perform the skew adjustment.

3

Move the red linesso the lines overlapat these 4 sides.

1

2

4

red

4green

X

XX

X

X

RED XXXX 254PIN

Adj Items ListCENTSKEWSIZELINKEYPINup

#1button

x

xRef

x

x

X X

XX

46

Step 73. Press the remote control up arrow button and increase the data by 30.