Tuberia Xt

description

Transcript of Tuberia Xt

-

DRILLING PRODUCTS & SERVICESwww.grantprideco.com

eXtremeRotaryShoulderHandbook

eXtremeRotaryShoulderHandbook

-

CONTENTSSECTION IDrill PipeSECTION IIDouble Shoulder ConnectionsSECTION IIIHeavy Weight Drill PipeSECTION IVDrill CollarsSECTION VKellysSECTION VISubsSECTION VIIWell Control

This handbook is a summary of the technical data from APISpec. 7 Latest Edition, API RP 7G Latest Edition, etc., for the purpose of easier application in the field.

Grant Prideco has produced this handbook forgeneral information only. It is not intended for designand engineering purposes. Although every effort hasbeen made to maintain the accuracy and reliability ofits contents, Grant Prideco in no way assumesresponsibility or liability for any loss, damage or injuryresulting from the use of information and data herein.All applications for the material described are at theuser's own risk and are the user's responsibility.

-

1DR

ILLPIPEProper break-in is probably the most important factor

affecting the life of the tool joint connection. Here aresome recommendations to follow:

1. Proper make-up torque is determined by theconnection type, size, OD and ID and may befound in torque tables.

2. Make up connections slowly, preferably usingchain tongs. (High speed kelly spinners or thespinning chain used on initial make-up cancause galling of the threads).

3. Tong them up to the predetermined torque usinga recently calibrated torque gauge to measurethe required line-pull.Note: Monitor breakout torque. It should be

less than or no greater than make-uptorque. If it is greater, the connectionshould be cleaned, inspected andrepaired, before it is made up again.

4. Breakout, visually inspect, redope and make uptwo more times before running in hole. Alwaysuse backup tongs to make and break connec-tions.

5. Stagger breaks on each trip so that each con-nection can be checked, redoped and made upevery second or third trip, depending on thelength of drill pipe and size of rig.

A new string of drill pipe deserves good surface han-dling equipment and tools. Check slips and masterbushings before damage occurs to the tube. (See theIADC Drilling Manual for correct measurements).Do not stop the downward movement of the drill stemwith the slips. This can cause crushing or neckingdown of the drill pipe tube. The drill pipe can also bedamaged by allowing the slips to ride the pipe on tripsout of the hole.Good rig practices will help eliminate time consumingtrips in the future, looking for washouts or fishing fordrill pipe lost in the hole. For more information refer tothe IADC Drilling Manual.

Drill Pipe

-

2New Tool JointsTorque Chart Drill Pipe Tool Joint

Note: 1. The use of outside diameters (OD) smaller than those listed in the table may be acceptable on Slim Hole (S.H.) tool joints due to special service requirements.

2. Make-up torque values may be lower than those published in API RP 7G LatestEdition. The make-up values are lower due to the combined torsional and tensile loads found in service conditions.

Drill Pipe Type Box Pin Make-upSize Conn OD ID Torque(in) (in) (in) (ft-lb)

N.C. 26 (I.F.) 3 3/8 1 3/4 3,900O.H. 3 1/4 1 3/4 3,700O.H. 3 1/8 2 2,600

2 3/8 S.L. H-90 3 1/4 2 2,700W.O. 3 3/8 2 2,400P.A.C. 2 7/8 1 3/8 2,600

2 7/8 S.H. (N.C. 26) 3 3/8 1 3/4 3,900O.H. 3 3/4 2 7/16 3,100O.H. 3 7/8 2 5/32 4,800S.L. H-90 3 7/8 2 7/16 3,800S.L. H-90 3 7/8 2 5/32 6,800

2 7/8 P.A.C. 3 1/8 1 1/2 3,200W.O. 4 1/8 2 7/16 3,900X.H. 4 1/4 1 7/8 7,000N.C. 31 (I.F.) 4 1/8 2 1/8 6,400N.C. 31 (I.F.) 4 1/8 2 7,100N.C. 31 (I.F.) 4 3/8 1 5/8 4,4003 1/2 S.H. (N.C. 31) 4 1/8 2 1/8 6,400S.L. H-90 4 5/8 3 7,600S.L. H-90 4 5/8 2 11/16 11,110O.H. 4 3/4 3 6,500O.H. 4 3/4 2 11/16 9,300

3 1/2 N.C. 38 (W.O.) 4 3/4 3 6,800N.C. 38 (I.F.) 4 3/4 2 11/16 9,700N.C. 38 (I.F.) 5 2 9/16 10,700N.C. 38 (I.F.) 5 2 7/16 11,700N.C. 38 (I.F.) 5 2 1/8 14,000N.C. 40 (4 F.H.) 5 1/4 2 9/16 14,600N.C. 40 (4 F.H.) 5 3/8 2 7/16 15,600N.C. 40 (4 F.H.) 5 1/2 2 1/4 17,100S.H. (3 1/2 X.H.) 4 5/8 2 9/16 8,100O.H. 5 1/4 3 15/32 11,900O.H. 5 1/2 3 1/4 14,700N.C. 40 (4 F.H.) 5 1/4 2 13/16 12,400N.C. 40 (4 F.H.) 5 1/4 2 11/16 13,500N.C. 40 (4 F.H.) 5 1/2 2 7/16 15,600N.C. 40 (4 F.H.) 5 1/2 2 7/16 15,600

4 N.C. 46 (W.O.) 5 3/4 3 7/16 15,200N.C. 46 (I.F.) 6 3 1/4 17,600N.C. 46 (I.F.) 6 3 20,500N.C. 46 (I.F.) 6 3 20,500N.C. 46 (I.F.) 6 3 1/4 17,600N.C. 46 (I.F.) 6 3 20,500N.C. 46 (I.F.) 6 2 5/8 24,400N.C. 46 (I.F.) 6 2 7/8 21,900

-

3Used Tool JointsTorque Chart Drill Pipe Tool Joint

Box Make-Up Box Make-upOD Torque OD Torque(in) (ft-lb) (in) (ft-lb)

3 1/4 3,000 3 3/16 2,5003 1/16 2,300 3 1/32 2,1003 1,800 2 31/32 1,6002 31/32 2,000 3 31/32 2,0003 1/16 2,000 3 1,5002 25/32 2,500 2 23/32 2,1003 3/8 4,100 3 5/16 3,6003 1/2 3,300 3 7/16 2,7003 19/32 4,300 3 17/32 3,6003 17/32 3,800 3 17/32 3,8003 19/32 4,600 3 17/32 3,8003 1/8 3,500 3 1/16 3,5003 5/8 3,200 3 9/16 2,5003 23/32 4,400 3 21/32 3,7003 11/16 3,200 3 21/32 2,8003 29/32 5,700 3 13/16 4,6004 1/16 7,700 3 31/32 6,5004 6,900 3 29/32 5,7004 3/16 5,500 4 1/8 4,5004 3/8 8,800 4 9/32 7,1004 9/32 5,500 4 7/32 4,6004 3/8 7,000 4 5/16 6,0004 3/8 5,300 4 11/32 4,8004 3/8 5,300 4 11/32 4,8004 19/32 8,800 4 1/2 7,3004 21/32 9,900 4 9/16 8,3004 23/32 10,900 4 5/8 9,3004 15/32 11,400 4 13/32 9,0005 12,600 4 7/8 10,2005 3/32 14,400 4 15/16 11,4004 7/16 8,800 4 11/32 7,4004 31/32 7,500 4 29/32 6,2005 1/32 8,800 4 31/32 7,5004 13/16 9,000 4 23/32 7,3004 15/16 11,400 4 13/16 9,0005 12,600 4 7/8 10,2005 12,600 4 7/8 10,2005 7/32 7,900 5 5/32 6,5005 5/32 10,000 5 7/32 7,9005 7/16 12,800 5 5/16 10,0005 15/32 13,600 5 3/8 11,4005 9/32 9,200 5 3/16 7,2005 9/16 15,800 5 7/16 12,8005 5/8 17,300 5 1/2 14,3005 5/8 17,300 5 1/2 14,300

Note: 3. Make-up torque is based on the use of 40% to 50% by weight of finely pow-dered metallic zinc, applied to all threads and shoulders.

Premium Class 2

-

4New Tool JointsTorque Chart Drill Pipe Tool Joint

Drill Pipe Type Box Pin Make-upSize Conn OD ID Torque(in) (in) (in) (ft-lb)

O.H. 5 7/8 3 3/4 14,600F.H. 6 3 17,600F.H. 6 2 3/4 20,100F.H. 6 2 1/2 22,300N.C. 46 (X.H.) 6 1/4 3 1/4 17,600N.C. 46 (X.H.) 6 1/4 3 20,500

4 1/2 N.C. 46 (X.H.) 6 1/4 2 3/4 23,200N.C. 46 (X.H.) 6 1/4 2 1/2 25,600N.C. 50 (I.F.) 6 3/8 3 3/4 19,800N.C. 50 (I.F.) 6 3/8 3 3/4 19,800N.C. 50 (I.F.) 6 3/8 3 5/8 21,600N.C. 50 (I.F.) 6 3/8 3 1/2 23,400N.C. 50 (I.F.) 6 3/8 2 7/8 30,300N.C. 50 (X.H.) 6 3/8 33/4 19,800N.C. 50 (X.H.) 6 3/8 3 1/2 23,400N.C. 50 (X.H.) 6 1/2 3 1/4 26,800N.C. 50 (X.H.) 6 1/2 3 30,000

5 N.C. 50 (X.H.) 6 5/8 2 3/4 32,9005 1/2 F.H. 7 3 1/2 37,4005 1/2 F.H. 7 1/4 3 1/2 37,4005 1/2 F.H. 7 1/4 3 1/4 41,200F.H. 7 4 29,200F.H. 7 4 29,200F.H. 7 3 3/4 33,400

5 1/2 F.H. 7 1/4 3 1/2 37,400F.H. 7 1/4 3 1/2 37,400F.H. 7 1/4 3 1/2 37,400F.H. 7 1/2 3 44,600F.H. 7 1/2 3 44,600

F.H. 8 5 38,400F.H. 8 5 38,400F.H. 8 5 38,400

6 5/8 F.H. 8 1/4 4 3/4 44,600F.H. 8 1/4 4 3/4 44,600F.H. 8 1/4 4 3/4 44,600F.H. 8 1/2 4 1/4 56,100F.H. 8 1/2 4 1/4 56,100

Note: 1. The use of outside diameters (OD) smaller than those listed in the table may be acceptable on Slim Hole (S.H.) tool joints due to special service requirements.

2. Make-up torque values may be lower than those published in API RP 7G LatestEdition. The make-up values are lower due to the combined torsional and tensile loads found in service conditions.

-

5Box Make-Up Box Make-upOD Torque OD Torque(in) (ft-lb) (in) (ft-lb)5 15/32 12,300 5 3/8 10,0005 3/8 12,100 5 9/32 10,1005 9/16 16,400 5 7/16 13,5005 5/8 17,800 5 15/32 14,2005 13/32 12,100 5 5/16 9,9005 19/32 16,500 5 15/32 13,5005 25/32 21,200 5 5/8 17,3005 23/32 19,600 5 9/16 15,8005 29/32 16,600 5 25/32 13,2005 23/32 11,600 5 21/32 10,0005 13/16 14,100 5 23/32 11,6005 15/16 17,500 5 27/32 14,9006 7/32 25,500 6 1/16 21,000

5 7/8 15,800 5 25/32 13,3006 1/32 20,200 5 29/32 16,7006 3/32 21,900 5 31/32 18,4006 3/16 24,700 6 1/32 22,0006 5/16 27,500 6 3/16 22,9006 21/32 25,500 6 1/2 20,2006 23/32 27,700 6 9/16 22,3006 15/16 35,500 6 3/4 28,800

6 17/32 21,300 6 7/16 18,2006 9/16 22,300 6 15/32 19,2006 5/8 24,500 6 1/2 20,3006 23/32 27,650 6 19/32 23,3506 25/32 29,900 6 5/8 24,5006 25/32 29,900 6 11/16 26,5607 1/32 39,000 6 27/32 32,1007 1/32 39,000 6 7/8 33,200

7 7/16 26,800 7 3/8 24,1007 1/2 29,500 7 13/32 25,5007 5/8 35,100 7 1/2 29,5007 11/16 38,000 7 9/16 32,3007 11/16 38,000 7 19/32 33,7007 3/4 40,900 7 21/32 36,5007 29/32 48,200 7 25/32 42,3008 52,700 7 27/64 45,200

Used Tool JointsTorque Chart Drill Pipe Tool Joint

Premium Class 2

Note: 3. Make-up torque is based on the use of 40% to 50% by weight of finely pow-dered metallic zinc, applied to all threads and shoulders.

-

Performance Properties of Seamless Drill Pipe

6

Cros

s Po

lar

Wal

lSe

ctio

nal

Sect

iona

lSi

zeN

omin

alTh

ick

Are

a M

odul

usO

DW

eigh

tn

ess

IDo

f Pip

eZ

(in)

(lb/ft

)(in

)(in

)(sq

. in)

(cu in

)E7

5X9

5G

105

S135

E75

X95

G10

5S1

352

3 / 84.

850.

190

1.99

51.

3042

1.32

04,

760

6,02

06,

060

97,8

2012

3,90

013

6,94

017

6,07

06.

650.

280

1.81

51.

8429

1.73

46,

240

7,90

08,

740

138,

220

175,

080

193,

500

248,

790

2 7 / 8

6.85

0.21

72.

441

1.81

202.

242

8,07

010

,220

11,3

0013

5,90

017

2,14

019

0,26

024

4,62

010

.40

0.36

22.

151

2.85

793.

204

11,5

3014

,610

16,1

5020

,760

214,

340

271,

500

300,

080

385,

820

3 1 / 2

9.50

0.25

42.

992

2.59

023.

922

14,1

2017

,890

19,7

7025

,420

194,

260

246,

070

271,

970

349,

680

13.3

00.

368

2.76

43.

6209

5.14

418

,520

23,4

6025

,930

33,3

3027

1,57

034

3,99

038

0,19

048

8,82

015

.50

0.44

92.

602

4.30

375.

846

21,0

5026

,660

29,4

7037

,890

322,

780

408,

850

451,

890

581,

000

411

.85

0.26

23.

476

3.07

675.

400

19,4

4024

,620

27,2

2034

,990

230,

750

292,

290

323,

050

415,

360

14.0

00.

330

3.34

03.

8048

6.45

823

,250

29,4

5032

,550

41,8

4028

5,36

036

1,46

039

9,50

051

3,65

015

.70

0.38

03.

240

4.32

167.

156

25,7

6032

,630

36,0

7046

,380

324,

150

410,

590

453,

810

583,

420

4 1 / 2

13.7

50.

271

3.95

83.

6004

7.18

425

,860

32,7

6036

,210

46,5

5027

0,03

034

2,04

037

8,05

048

6,06

016

.60

0.33

73.

826

4.40

748.

542

30,7

5038

,950

43,0

5055

,350

330,

560

418,

700

462,

780

595,

000

20.0

00.

430

3.64

05.

4981

10.2

3236

,840

46,6

6051

,570

66,3

0041

2,36

052

2,32

057

7,30

074

2,24

05

19.5

00.

362

4.27

65.

2746

11.4

1641

,090

52,0

5057

,530

73,9

7039

5,60

050

1,09

055

3,83

071

2,07

025

.60

0.50

04.

000

7.06

8614

.490

52,1

6066

,070

73,0

3093

,900

530,

140

671,

520

742,

200

954,

260

5 1 / 2

21.9

00.

361

4.77

85.

8282

14.0

6250

,620

64,1

2070

,870

91,1

2043

7,12

055

3,68

061

1,96

078

6,81

024

.70

0.41

54.

670

6.62

9615

.688

56,4

7071

,530

79,0

6010

1,65

049

7,22

062

9,81

069

6,11

089

5,00

05

7 / 823

.40

0.36

1 5.

153

6.25

3516

.251

58,6

0074

,200

82

,000

10

5,50

0 46

9,00

0 59

4,10

0 65

6,60

0 84

4,20

026

.30

0.41

55.

045

7.11

8518

.165

65,5

0083

,000

91,7

0011

7,90

053

3,90

067

6,30

074

7,40

096

1,00

06

5 / 825

.20

0.33

05.

965

6.52

6219

.572

70,5

5089

,360

98,7

7012

7,04

448

9,46

061

9,99

068

5,25

088

1,04

427

.70

0.36

25.

901

7.12

2621

.156

76,3

0096

,600

106,

800

137,

300

534,

200

676,

700

747,

900

961,

600

Tors

iona

l Yie

ld S

treng

th (f

t-lb)

Ten

sile

Yie

ld S

treng

th (lb

)

New

Dril

l Pip

e Di

men

sion

al, T

ors

iona

l, an

d Te

nsi

le D

ata

- - -

-

-

Size

Nom

inal

OD

Wei

ght

(in)

(lb)

2 3 / 8

4.85

11,0

4013

,980

15,4

6019

,070

10,5

0013

,300

14,7

0018

,900

6.65

15,6

0019

,760

21,8

4028

,080

15,4

7019

,600

21,6

6027

,850

2 7 / 8

6.85

10,4

7012

,930

14,0

1017

,060

9,91

012

,550

13,8

7017

,830

10.4

016

,510

20,9

1023

,110

29,7

2016

,530

20,9

3023

,140

29,7

503

1 / 29.

5010

,040

12,0

6013

,050

15,7

809,

520

12,0

7013

,340

17,1

5013

.30

14,1

1017

,880

19,7

6025

,400

13,8

0017

,480

19,3

2024

,840

15.5

016

,770

21,2

5023

,480

30,1

9016

,840

21,3

3023

,570

30,3

104

11.8

58,

410

9,96

010

,700

12,6

508,

600

10,8

9012

,040

15,4

8014

.00

11,3

5014

,380

15,9

0020

,170

10,8

3013

,720

15,1

6019

,490

15.7

012

,900

16,3

4018

,050

23,2

1012

,470

15,7

9017

,460

22,4

404

1 / 213

.75

7,20

08,

400

8,95

010

,310

7,90

010

,010

11,0

7014

,230

16.6

010

,390

12,7

5013

,820

16,8

009,

830

12,4

5013

,760

17,6

9020

.00

12,9

6016

,420

18,1

5023

,330

12,5

4015

,890

17,5

6022

,580

519

.50

10,0

0012

,010

12,9

9015

,700

9,50

012

,040

13,3

0017

,110

25.6

013

,500

17,1

0018

,900

24,3

0013

,120

16,6

2018

,380

23,6

205

1 / 221

.90

8,44

010

,000

10,7

4012

,710

8,61

010

,910

12,0

6015

,510

24.7

010

,460

12,9

2014

,000

17,0

509,

900

12,5

4013

,860

17,8

305

7 / 823

.40

7,45

08,

770

9,36

010

,820

8,06

010

,220

11,2

9014

,520

26.3

09,

560

11,5

0012

,410

14,8

909,

270

11,7

4012

,980

16,6

906

5 / 825

.20

4,81

05,

310

5,49

06,

040

6,54

08,

280

9,15

011

,770

27.7

05,

890

6,75

07,

100

7,81

07,

170

9,08

010

,040

12,9

10

Colla

pse

Pres

sure

, psi

E75

X95

G10

5S1

35E7

5X9

5G

105

S135

Inte

rnal

Pre

ssur

e, p

siNew Drill Pipe Collapse and Internal Pressure Data

7

-

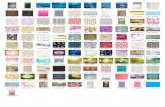

8Tool Joint Bevel Diameters

Internal Flush

&Numbered

Connections

Full Hole&

NumberedConnections

Xtra Hole &Numbered

Connections

H-90

SlimlineH-90

Slimhole &

NumberedConnections

2 3/8 & N.C 26 3 3/8 3 17/642 7/8 & N.C 31 4 1/8 3 61/643 1/2 & N.C 38 4 3/4 4 37/643 1/2 & N.C 38 5 4 37/64N.C. 40 5 1/2 5 1/644 & N.C. 46 6 5 23/324 & N.C. 46 6 1/4 5 23/324 1/2 & N.C. 50 6 1/8 6 1/164 1/2 & N.C. 50 6 1/4 6 1/164 1/2 & N.C. 50 6 3/8 6 1/164 1/2 & N.C. 50 6 1/2 6 1/164 1/2 & N.C. 50 6 5/8 6 1/16N.C. 56 7 6 47/643 1/2 4 5/8 4 31/644 & N.C. 40 5 1/4 5 1/644 1/2 6 5 23/325 1/2 7 6 23/325 1/2 7 1/4 6 23/325 1/2 7 1/2 7 3/323 1/2 4 3/4 4 17/324 1/2 & N.C. 46 6 5 23/325 & N.C. 50 6 1/4 5 59/644 5 1/2 5 17/644 1/2 6 5 23/322 3/8 3 1/4 3 1/82 7/8 3 7/8 3 23/323 1/2 4 5/8 4 7/162 3/8 2 7/8 2 25/322 7/8 & N.C. 26 3 3/8 3 17/643 1/2 & N.C. 31 4 1/8 3 61/644 4 1/2 4 11/324 4 5/8 4 11/324 1/2 & N.C. 38 5 4 37/64

Type Size OD Bev. Dia

-

Fraction Decimal mm Fraction Decimal mm1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 17/32 0.53125 13.4943/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.2885/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.09375 2.381 19/32 0.59375 15.0817/64 0.109375 2.778 39/64 0.609375 15.478

1/8 0.1250 3.175 5/8 0.6250 15.8759/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.66911/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.763 11/16 0.6875 17.46313/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.25615/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.05017/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.84419/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.938 13/16 0.8125 20.63821/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.43123/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.22525/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.01927/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.113 15/16 0.9375 23.81329/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.60631/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 25.400

9

1.000

Decimal and Millimeter Equivalents

1 mm = 0.03937 inch0.001 inch = 0.0254 mm

-

10

Basic Customary SI/Metric ConversionUnit Units Units Customary to

(Abbreviation) (Abbreviation) SI/MetricMultiply by

Length in mm 25.4Area sq in mm2 645.16Volume, capacity cu ft m3 0.028317

U.K. gal L 4.546092U.S. gal L 3.785412

Plane angle deg (0) rad 0.017453Time min S 60Mass lbm kg 0.453592Temperature (traditional) 0F 0C

Pressure lbf/in2(psi) bar 0.068947N/m2 Pa 1.at (kp/cm2) bar 1.0197bar Pa 105

Density (liquids) lbm/U.S. gal kg/m3 119.8264lbm/U.K. gal kg/m3 99.77633lbm/ft kg/m3 16.01846

Density (solids) lbm/ft3 kg/m3 16.01846Throughput (mass basis) lbm/hr kg/h 0.453592Throughput (volume basis) bbl/D m3/h 0.006624

ft3/D m3/h 0.001179U.K. gal/min L/min 4.546092U.S. gal/min L/min 3.785412

Flow rate (volume basis) U.K. gal/min L/min 4.546092U.S. gal/min L/min 3.785412ft3/min m3/min 0.028314

Energy work Btu kWh 0.000293ft-lbf kJ 0.001356lbf-ft kJ 0.001356K N-m kJ 1.

Power hydraulic horse kW 0.746043power-hhphp (electric) kW 0.746Btu/hr W 0.293071

Fuel consumption mile/U.S. gal km/L 0.425144mile/U.K. gal km/L 0.354066

Velocity (linear) speed ft/min m/s 0.005080in/s mm/s 25.4

Rotational frequency rev/s rev/s 1.0rev/min rev/s 0.016666

Weight/length lb/ft kg/m 1.488164Force lbf N 4.448222

kg-m/sec2 N 1.Bending moment torque lbf-ft Nm 1.355818Section modulus cu in mm3

Stress kgf/mm2 N/mm2 9.806650lbf/in2 (psi) N/mm2 0.006895

(0F-32)1.8

2831685

Conversion of Customary Units to SI/Metric Units

-

11

DOUBLE

SHOULDER

CONNECTIO

NS

BoxWeld

Pipe

PinExternal Upset Tool Joint

Elevator Shoulder Internal Upset Internal Coating

Pin BasePin base extendsin spring-like manner when jointis bucked up torecommendedmake-up torque.

SecondaryShoulderWhen joint is handtight, secondaryshoulders do notcontact. When jointis bucked up torecommendedmake-up torque,they do contact.

Primary ShoulderProvides seal andpreload just ason conventionaltool joint.

Box CounterboreSection Box counterboresection compressesin spring-like mannerwhen joint is buckedup to recommendedmake-up torque.

Grant PridecoDouble Shoulder Connection

Pin Nose

Drill Pipe withDouble Shoulder Connections

Hardbanding

-

12

Types of Grant Prideco DoubleShoulder Connections

There are three types of double shoulder connectionsoffered by Grant Prideco.

HI TORQUE (HT) First generation double shoul-der connection providing approximately 40% moretorque capacity than API connections of equivalentdimensions. Not interchangeable with API connec-tions.

eXtreme Torque (XT ) Second generation doubleshoulder connection providing approximately 70%more torque capacity than API connections of equiv-alent dimensions. Not interchangeable with APIconnections. Two primary differences exist betweenHT and XT connections: 1) XT has a flatter taperand 2) XT has increased thread root radii.

o eXtreme Torque with Metal-To-Metal Seal (XT-M) Industry first gas tight pressure rated rotaryshoulder connection achieved through a 15 metal-to-metal (M-T-M) seal on the pin nose. Providestorque capacity similar to that of XT connections.Not interchangeable with API connections.

Grant Prideco Double Shoulder (GPDS) Double shoulder connection which is interchange-able with API connections and provides 20-50%more torque capacity than API connections ofequivalent dimensions.

The below figure illustrates the taper difference betweenHT and XT connections.

XT

HT

-

13

HT Tool Joint Make-up Torque ChartRecommended Maximum

3 3/83 1/83 1/83 1/83 1/43 3/163 1/83 5/83 5/83 5/8 3 1/23 3/84 1/4 4 1/84 1/84 1/84 1/8

4555

4 15/164 7/84 7/84 3/44 3/44 3/45 1/45 1/85 1/8

55

6 1/46 1/46 5/86 5/86 5/86 5/86 1/27 3/87 1/47 1/47 1/47 1/47 1/47 1/47 1/87 1/87 1/8

777778

1.8151 7/161 3/41.9751 1/21 1/21 1/21 1/41 3/81 1/21 1/21 3/41 3/41 7/8

22 1/82 5/322 5/322 5/162 7/162 9/162 9/162 7/162 9/162 7/162 9/162 11/162 13/162 9/162 11/162 7/162 9/16

3 3 1/4

3 3 1/43 1/23 3/43 1/2

43

3 1/43 1/23 3/43 7/8

43 1/43 7/8

43

3 1/43 1/23 3/4

4 5

6,3006,8005,6004,6005,2005,1005,1009,2008,7007,9007,3005,20014,00011,90011,30010,0009,6008,90021,70019,80017,70017,70019,30017,70017,00016,10015,20019,20021,10020,10019,60018,60034,60028,50053,30046,80039,70032,00039,60046,80072,00069,00063,90055,60051,20046,70064,20051,10046,50062,50059,50056,30052,60046,30059,800

2 3/8 HTSLH90

2 7/8 HTPAC

HT26

HT31

HT38

HT40

HT46

HT50

HT55

HT65

TypeConnection

BoxOD(in)

PinID(in)

Make-upTorque(ft-lb)

Note: Applies to drill pipe and HWDP tool joints.

-

14

XT Tool Joint Make-upTorque ChartRecommended Maximum

3 1/8 3 1/2 3 1/2 3 1/2 3 3/4 4 1/8 4 1/8

4 4 4 4

4 7/84 13/16

4 3/44 3/4 4 3/4

5555

4 15/164 15/164 29/324 29/32

4 7/84 7/84 7/8 4 7/8 5 1/45 1/45 1/4 6 1/46 5/86 5/86 1/26 1/26 1/26 3/86 3/86 3/46 5/87 3/8

77 3/87 1/47 1/47 1/47 1/47 1/47 1/4 7 1/87 1/8

7 7 7 7 8

8 1/2

1 1/2 1 1/4 1 1/21 3/4

21 7/8

22

2 1/8 2 5/322 3/8

2 9/162 9/162 7/162 9/162 11/162 9/162 11/162 13/16

2 7/82 9/16

2 13/162 3/4

2 13/162 9/162 11/162 3/4

2 13/162 11/162 13/16

3 3 1/4 3 1/23 3/42 3/4 3 1/2 3 3/43 1/23 3/4

44

3 5/84

3 1/4 3 3/16 3 1/43 1/23 3/4

44 1/43 1/44 1/43 1/23 3/4

44 1/4

55 1/4

5,7009,9008,9006,9009,000

14,00012,70012,20011,20010,8007,900

18,90018,80020,50018,80016,60024,50022,20019,80018,60023,40019,80021,00019,80022,20021,20020,70019,80028,80026,40022,40042,10054,40046,40061,60052,80046,20048,70045,10052,00049,90072,20058,10090,00085,70084,90081,90076,30066,90056,90079,90056,80071,60067,90063,70056,60081,200

100,300

XT24

XT26

XT29

XT31

XT38

XT39

XT40

XT46

XT50

XT54

XT55

XT57

XT69XT65

TypeConnection

BoxOD(in)

PinID(in)

XT Make-upTorque(ft-lb)

Note: Applies to drill pipe and HWDP tool joints.

-

15

XT-M Tool Joint Make-upTorque ChartRecommended Maximum

3 3/8 4 4

3 7/8 4 1/4 4 3/4 4 3/4

5 5 5

4 7/85 1/45 1/45 1/46 1/4 6 5/86 1/26 1/46 1/47 1/4

778

8 1/2

1 3/4 2

2 1/82 1/8

2 9/162 9/162 11/162 7/162 9/16

2 13/162 11/162 11/16

33 1/4

33 1/23 3/43 1/23 5/84 1/44 1/84 1/4

55 1/4

5,80010,8009,7008,5009,500

16,70014,50023,30022,30017,70018,90026,20023,50019,50045,10050,30042,10040,70038,90051,90056,50051,60074,60092,900

XT-M26

XT-M34

XT-M39

XT-M31

XT-M38

XT-M40XT-M43

XT-M46

XT-M50

XT-M57

XT-M65XT-M69

TypeConnection

BoxOD(in)

PinID(in)

XT-MMake-upTorque(ft-lb)

Note: Applies to drill pipe and HWDP tool joints.

-

16

GPDS Tool Joint Make-upTorque ChartRecommended Maximum

3 1/23 1/2 3 1/24 1/84 1/8

55

4 7/84 7/84 3/44 3/45 1/45 1/45 1/4

5 5

6 1/2666

6 5/86 5/86 5/86 1/26 1/26 1/26 3/87 1/47 1/47 1/8

7 77

8 1/488

1 3/41 11/161 5/8

21 7/82 7/162 9/162 7/162 9/162 1/82 1/22 7/162 9/162 11/162 7/162 9/16 3 1/22 3/4

3 3 1/42 3/4

3 3 1/43 1/43 1/23 3/43 1/43 3/44 1/83 3/43 1/2 3 3/4

44 3/4

4 15/164 7/8

5,3005,8006,30010,30010,90017,50015,50017,10015,40016,90014,50022,80021,90019,60017,80016,90018,80036,40031,80025,70054,40049,70043,30043,10036,10028,50041,20053,80040,10053,60053,90050,30044,50071,40061,20064,500

GPDS26

GPDS31

GPDS38

GPDS40

GPDS46

GPDS50

GPDS55

GPDS65

TypeConnection

BoxOD(in)

PinID(in)

Make-upTorque(ft-lb)

Note: Applies to drill pipe and HWDP tool joints.

-

17

Tool Joint Break-inMost drill pipe connections are broken-in during manu-facture. The following break-in procedure is recom-mended for connections which have not been broken-induring manufacture.Step 1: Make the joints up to the maximum recom-

mended make-up torque, and then breakthem out. If the break-out torque is lessthan the make-up torque, the joints do nothave to be separated.

Step 2: Make the joints up again to the samemake-up torque and break them out.Separate the pin and box and reapplythread compound.

Step 3: Make the joints up again to the same make-up torque and they are ready for service.

Note: The break-out torque should be less thanthe make-up torque. If the break-out torqueis more than the make-up torque, separatethe joints and inspect them for damage.

Picking Up Pipe with Double ShoulderConnections for the First Time Visually examine the thread protectors for damage

such as dents or crushing. If any thread protectors aredamaged, inspect the threads on that joint for dam-age.

If the joints were shipped to the rig with rust preventiveon the threads, it must be removed. Use soap andwater, steam or a vapor degreasing solvent such asVarsol. No residue should remain on the threads aftercleaning.

If the joints were shipped to the rig with thread com-pound, it is not necessary to remove the thread com-pound unless there is a problem suspected.

Inspect the threads for damage or for foreign material. Before the joints are put in service, the threads, the pri-

mary make-up shoulders and secondary make-upshoulders must be coated with a good quality rotaryshouldered connection thread compound.

The following sections provide general guidelines for runningand handling double shoulder connections. Connection-spe-cific running and handling procedures are available direct fromGrant Prideco and can be downloaded fromwww.grantprideco.com.

-

18

Special Considerations When RunningXT and XT-M Connections

Check to ensure the counterbalance on the topdrive is working properly and provides a minimumamount of weight applied to the connection duringmake-up.

Ensure the bore through the top drive bell stabbingguide (top drive flipper) is no more than 1/2" largerin diameter than the box tool joint diameter.

Because of the flatter taper, XT and XT-M pins donot stab as deeply into the box as do HT, GPDSand API connections. Alignment of the pin to thebox when stabbing and spinning up is more criticalfor XT and XT-M connections. A stabbing guide isrequired when running XT and XT-M connections,and alignment should be verified before spinningup.

Proper alignment, along with slow initial make-up ofthe starting threads, is necessary with XT and XT-Mconnections. Use chain tongs or slow speed spin-ners when spinning in the starting threads. High-speed spinners may be used after the startingthreads are engaged.

Minor thread damage may occur within the startingthreads. This is not detrimental to the connectionand should be removed with a soft grinding wheelor a file.

-

19

Application of Thread Compound toDouble Shoulder Connections All contacting surfaces, the threads, the primary

shoulders, secondary shoulders and 15 M-T-M seal(XT-M), must be coated with a good quality rotaryshoulder connection thread compound. Copper-based thread compounds are recommended.

Some drilling fluids or drilling fluid additives mayaffect the frictional properties of the tool joint andthread compound. If this is the case, rinse the drillingfluid off the connections before applying thread com-pound.

Remove drilling fluid from the secondary shoulderand 15 M-T-M seal (XT-M) of the box before makingup the connection for the trip in the hole. Trappeddrilling fluid can promote corrosion of the secondaryshoulders.

Racking the pipe will wipe thread compound off thepin nose. If pins are doped coming out of the hole,reapply compound to the secondary shoulder beforethe connections are made up.

NOTE: For XT-M connections, localized corrosion or pittingmay occur on the 15 M-T-M seal if racked back withoutthread compound applied to it. This is more common withcompletion fluids than common drilling fluids. Apply a liber-al and even coat of quality thread compound to the 15 sealwhen racking back XT-M connections.

PrimaryShoulder

Threads

SecondaryShoulder

15 M-T-MSeal

-

20

Tonging, Proper Gripping of the BoxDuring Make-up Tongs should be placed at least 2 inches from the

make-up shoulder on XT boxes size 46 and greater,all HT and all XT-M boxes. These are considered"long" double shoulder connections. This is notrequired for XT boxes less than 46 and all GPDSboxes.

The threads of a long double shoulder box are about1-1/2 inches further away from the makeup shoulderthan the threads of an API box. Tongs or top drivetorque wrenches should engage these long doubleshoulder boxes at the same location in relation to thethreads that they would engage an API joint.

On the Varco BJ PH85 pipe handler torque wrench,this can be accomplished by decreasing the length ofthe saver sub from 7 inches to 5-1/2 inches. This willput the tong dies 2 inches from the box make-upshoulder.

Back-up tongs should always be used

2 inches

RecommendedTonging Area

-

21

Tong Height Buckinguptooljointswithtongscanputhighbend-ingloadsinthepipe.

Review the IADC Drilling Manual Latest Edition,orTongHeightFigureinAPIRP7GLatestEditionabout height of tool joint above slips to preventbendingpipeduringtonging.

Hmax

P

P

-

22

Alignment when Making upConnections Galling and other damage can occur during stab-

bing and spinning connections up. A stand of pipe can weigh between 1,500 lbs and

2,300 lbs. At initial contact, the weight could be supported by the sharp edge of one thread againstthe flank of the mating thread. This can cause highcontact stresses and wipe the thread compound off.

Slight misalignment of the pin and box can cause further increases in the stresses when spinning up.

The whipping action of spinning pipe can causehigh loads on threads.

NOTE: Alignment of the pin to the box when stab-bing and spinning up is more critical for XT andXT-M connections. A stabbing guide is requiredwhen running XT and XT-M connections and align-ment should be verified before spinning up.

Box

Pin

Contact of sharp edge ofpin thread on box flank

Tripping Alternate breaks when tripping so that each joint

will be broken-out every third trip. Monitor break-out torque. The break-out torque should be less than the make-

up torque. High break-out torque is an indication ofdownhole make-up or thread damage.

Do not let the end of the pin strike the box make-upshoulder when stabbing the pin in the box.Stabbing guides are required for XT and XT-M con-nections and recommended for HT and GPDSconnections.

-

23

Standing Pipe Back Using normal drill pipe care and handling practices,

no special care is required to protect the pin nosewhen standing the pipe back. The pin nose is not aseal. Minor damage to the pin nose from standingthe pipe back does not affect the connections per-formance.

It is not necessary to use thread protectors whenstanding the pipe back.

Do not use pressed steel thread protectors whenstanding the pipe back. They could allow theweight of the stand to be supported by the primarymake-up shoulder of the connection on the sharpedge of the thread protectors.

Apply a liberal and even coat of quality thread com-pound to the 15 M-T-M seal when racking backXT-M connections.

Sharp edge of thread protectorcan damageshoulder.

-

24

Downhole Make-up Downhole make-up can be detected by high break-

out torque. The break-out torque should be less thanthe make-up torque.

If downhole make-up is suspected, punch mark thepin and box next to the make-up shoulders when trip-ping into the hole (after the connection is made up).

If downhole make-up occurs, the position of thepunch marks will change.

Downhole make-up can cause Compressed box counterbores Compressed pin noses

Milled Hardness Flat

Punch marks

Apply punch marks in linewith hardness flat to makethem easier to find.

-

25

Make-up Shoulder and Bevel Diameter The primary make-up shoulders provide the seal for

the connection (HT, XT and GPDS). For XT-M,the primary seal is the 15 M-T-M seal and the back-up seal is the primary make-up shoulder.

The primary make-up shoulders and 15 M-T-M seal(XT-M) should be inspected frequently using currentGrant Prideco Field Inspection Procedures for theapplicable connection type.

Proper operation and correct shoulder loads dependon the pin length and box depth of double shoulderconnections being within specifications. The pinlength and box depth are shown on the FieldInspection Drawing for the particular size and typeconnection.

No more than 1/32 inch should be removed fromeither the primary or secondary make-up shoulder atany one refacing. No more than 1/16 inch cumula-tively should be removed from either the primary orsecondary make-up shoulder. The correct pin lengthand box depth must be maintained when resurfacingmake-up shoulders.

The Grant Prideco benchmark is a reference forchecking how much material has been removedfrom make-up shoulders.

The surface finish of the primary make-up shouldershould be 150 RMS or less.

When Grant Prideco double shoulder connectionsare refaced, the bevel does not need to be rema-chined.

The following sections provide information and general guide-lines regarding the field inspection of Grant Prideco doubleshoulder connections and are not intended to replace GrantPrideco Field Inspection Procedures and Drawings.

Connection type-specific Field Inspection Procedures andconnection type and size-specific Field Inspection Drawingsare available direct from Grant Prideco and can be down-loaded from www.grantprideco.com.

-

26

Pin

1 2 3

1 2 3

1 2 3

1 2 3

The pin nose is not a seal, it is a mechanical stop.The pin nose must be free of raised metal or otherimperfections that could prevent proper make up orcause galling. Pin nose damage can be repairedwith a hand file.

Box

-

27

Checking Pin Length The pin length can be checked with a dial indicator

or depth micrometers. If the pin length is short by1/32 inch or less, the pin can be repaired by resur-facing the primary shoulder.

If the pin length is short by more than 1/32 inch, thepin must be recut.

If the pin length is too long by 1/32 inch or less, thepin can be repaired by resurfacing the pin nose.

If the pin length is too long by more than1/32 inch,the pin must be recut.

A Go/No Go gauge can be provided by Grant Prideco tofield check double shoulder connections primary shoul-der to secondary shoulder pin length and box depth. Thegauge does not provide dimensional information on thepin length or box depth.

If the pin nose does not contact the gauge when usedas shown in the figure, the length should be inspectedwith measuring instruments that determine the actualdistance between the shoulders.

-

28

Checking Box Depth The box depth can be checked with a dial indicator

or depth micrometers. If the box depth is short by1/32 inch or less, the box can be repaired by resur-facing the secondary shoulder.

If the box depth is short by more than 1/32 inch, thebox must be recut.

If the box depth is too long by 1/32 inch or less, thebox can be repaired by resurfacing the primaryshoulder.

If the box depth is too long by more than 1/32 inch,the box must be recut.

If the primary shoulder does not contact the gaugewhen used as shown in the figure, the depth should beinspected with measuring instruments that determinethe actual distance between the shoulders.

A Go/No Go gauge can be provided by Grant Prideco tofield check double shoulder connections primary shoul-der to secondary shoulder pin length and box depth. Thegauge does not provide dimensional information on thepin length or box depth.

-

29

Special Considerations WhenInspecting XT and XT-MConnections The stab flank to crest radius of the starting four to

five threads of the pin and box connections round offduring break-in and normal operation. Minor threaddamage may occur within these starting threads.This is not detrimental to the connection and shouldbe removed with a soft grinding wheel or a file.

The XT-M connection contains a 15 M-T-M seal nearthe pin and box secondary shoulders. This is the pri-mary sealing surface for the connection.

o Round pit type defects up to 1/32 inch indiameter and not exceeding 1/32 inch indepth are permissible.

o Multiple pits of this type are acceptable provided there is at least 1 inch circumferential separation between them.

o Circumferential lines or marks are acceptable provided they cannot be detected by rubbing a fingernail across thesurface.

o Areas highlighted in the figure below are the non-contacting areas of the seal. Damageor pitting is permitted in these areas of theseal, provided the balance of the contact surface is without damage exceeding the requirements above.

o XT-M connections may not be refaced.Damages exceeding requirements for the threads, seal and/or shoulder faces requirethe connection to be faced/chased.

Box Seal

Pin Seal

0.188

0.060

0.060

-

30

Field Inspection Drawing, Pin

Beve

lD

iaN

ose

Dia

Pin

Cylin

der

Dia

Thre

ad F

orm

Pin

Leng

th

-

31

HT Field Inspection Dimensions, Pin

2 3/

8 HT

SLH9

02

7/8

HTPA

CH

T26

HT3

1H

T38

HT4

0H

T46

HT5

0H

T55

HT6

5

90V

084

V 07

6SV

038R

V 03

8RV

038R

V 03

8RV

038R

V 03

8RV

050

V 05

0

4.42

9 - 4

.438

4.82

1 - 4

.830

5.15

6 - 5

.165

5.33

4 - 5

.343

5.49

6 - 5

.505

6.26

7 - 6

.276

6.28

2 -6

.291

6.15

0 - 6

.159

7.33

8 - 7

.347

7.49

1 - 7

.500

2.98

4 - 3

.141

3.04

7 - 3

.204

3.29

6 - 3

.453

3.93

7 - 4

.094

4.63

7 - 4

.794

4.85

9 - 5

.016

5.82

9 -5

.986

6.12

4 - 6

.281

6.85

7 - 7

.014

7.54

7 - 7

.704

2.60

7 - 2

.653

2.40

6 - 2

.452

2.71

9 - 2

.765

3.36

0 - 3

.406

3.88

0 - 3

.926

4.12

5 - 4

.171

4.67

8 -4

.724

5.09

4 - 5

.140

5.68

9 - 5

.735

6.61

6 - 6

.662

2.21

6 - 2

.263

1.96

7 - 2

.014

2.10

9 - 2

.156

2.57

4 - 2

.621

3.17

2 - 3

.219

3.30

6 - 3

.353

3.85

9 -3

.906

4.29

7 - 4

.344

4.66

6 - 4

.713

5.56

6 - 5

.613

Conn

ectio

nTh

read

Form

Pin

Leng

th(in

)B

evel

Dia (in)

Pin

Cylin

der

Dia (in)

Nos

eD

ia (in)

-

32

XT Field Inspection Dimensions, Pin

XT24

XT26

XT29

XT30

XT31

XT34

XT38

XT39

XT40

XT43

XT46

XT50

XT54

XT55

XT57

XT61

XT65

XT69

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

3.21

0 - 3

.219

3.11

6 - 3

.125

3.64

7 - 3

.656

3.36

6 - 3

.375

3.99

1 - 4

.000

4.14

7 - 4

.156

4.61

6 - 4

.625

4.49

1 - 4

.500

4.49

1 - 4

.500

3.64

7 - 3

.656

7.49

1 - 7

.500

7.29

1 - 7

.300

6.99

1 - 7

.000

7.24

1 - 7

.250

7.24

1 - 7

.250

6.24

1 - 6

.250

8.24

1 - 8

.250

7.80

4 - 7

.813

2.98

4 - 3

.141

3.20

3 - 3

.360

3.57

8 - 3

.735

3.70

3 - 3

.860

3.85

9 - 4

.016

4.10

9 - 4

.266

4.54

7 - 4

.704

4.77

0 - 4

.927

5.00

0 - 5

.157

5.04

7 - 5

.204

5.91

8 -6

.075

6.30

2 - 6

.459

6.45

3 - 6

.610

6.85

7 - 7

.014

6.70

5 - 6

.862

6.96

1 - 7

.118

7.70

3 - 7

.860

7.79

7 - 7

.954

2.49

0 - 2

.536

2.72

8 - 2

.774

3.02

9 - 3

.075

3.17

4 - 3

.220

3.23

5 - 3

.281

3.53

5 - 3

.581

3.84

4 - 3

.890

4.02

6 - 4

.072

4.23

4 - 4

.280

4.38

5 - 4

.431

4.92

0 -4

.966

5.30

6 - 5

.352

5.56

4 - 5

.610

5.68

0 - 5

.726

5.80

6 - 5

.852

6.21

3 - 6

.259

6.68

1 - 6

.727

7.05

6 - 7

.102

2.06

7 - 2

.114

2.30

9 - 2

.356

2.58

9 - 2

.636

2.74

0 - 2

.787

2.74

0 - 2

.787

3.06

3 - 3

.110

3.33

2 - 3

.378

3.53

1 - 3

.578

3.73

5 - 3

.782

3.92

7 - 3

.974

4.32

1 -4

.368

4.74

3 - 4

.790

5.02

0 - 5

.067

5.10

1 - 5

.148

5.26

2 - 5

.309

5.53

0 - 5

.577

6.07

4 - 6

.121

6.47

6 - 6

.523

Conn

ectio

nTh

read

Form

Pin

Leng

th(in

)B

evel

Dia (in)

Pin

Cylin

der

Dia (in)

Nos

eD

ia (in)

-

33

XT-M Field Inspection Dimensions, Pin

XT-M

24XT

-M

26XT

-M

29XT

-M

31XT

-M

34XT

-M

38XT

-M

39XT

-M

40XT

-M

43XT

-M

46XT

-M

50XT

-M

57XT

-M

61XT

-M

65XT

-M

69

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2R

5.05

4 - 5

.063

4.99

1 - 5

.000

5.49

1 - 5

.500

5.86

6 - 5

.875

5.99

1 - 6

.000

6.49

1 - 6

.500

6.24

1 - 6

.250

6.49

1 - 6

.500

5.61

6 - 5

.625

7.49

1 - 7

.500

7.29

1 - 7

.300

7.24

1 - 7

.250

6.24

1 - 6

.250

8.24

1 - 8

.250

7.80

4 - 7

.813

2.98

4 - 3

.141

3.20

3 - 3

.360

3.57

8 - 3

.735

3.85

9 - 4

.016

4.07

8 - 4

.235

4.54

7 - 4

.704

4.77

0 - 4

.927

5.00

0 - 5

.157

5.04

7 - 5

.204

5.91

8 -6

.075

6.30

2 - 6

.459

6.70

5 - 6

.862

6.96

1 - 7

.118

7.70

3 - 7

.860

7.79

7 - 7

.954

2.49

0 - 2

.536

2.72

8 - 2

.774

3.02

9 - 3

.075

3.23

5 - 3

.281

3.53

5 - 3

.581

3.84

4 - 3

.890

4.02

6 - 4

.072

4.23

4 - 4

.280

4.38

5 - 4

.431

4.92

0 -4

.966

5.30

6 - 5

.352

5.80

6 - 5

.852

6.21

3 - 6

.259

6.68

1 - 6

.727

7.05

6 - 7

.102

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

Conn

ectio

nTh

read

Form

Pin

Leng

th(in

)B

evel

Dia (in)

Pin

Cylin

der

Dia (in)

Nos

eD

ia (in)

-

34

GPDS Field Inspection Dimensions, Pin

GPD

S26

GPD

S31

GPD

S38

GPD

S40

GPD

S46

GPD

S50

GPD

S55

GPD

S65

V 03

8RV

038R

V 03

8RV

038R

V 03

8RV

038R

V 05

0V0

50

3.37

2 - 3

.382

3.88

4 - 3

.894

4.39

6 - 4

.406

4.90

7 - 4

.918

4.90

7 - 4

.918

4.90

7 - 4

.918

5.41

9 -5

.430

5.41

9 -5

.430

3.25

0 - 3

.407

3.93

7 - 4

.094

4.56

2 - 4

.719

5.00

0 - 5

.157

5.70

3 - 5

.860

6.04

7 - 6

.204

6.70

3 -6

.860

7.68

7 - 7

.844

2.71

9 - 2

.765

3.23

5 - 3

.281

3.86

0 - 3

.906

4.12

5 - 4

.171

4.67

8 - 4

.724

5.10

4 - 5

.150

5.68

8 -5

.734

6.61

6 - 6

.620

1.98

5 - 2

.031

2.42

3 - 2

.469

2.95

4 - 3

.000

3.14

1 - 3

.187

3.68

8 - 3

.734

4.11

0 - 4

.156

4.54

8 -4

.594

5.46

9 - 5

.515

Conn

ectio

nTh

read

Form

Pin

Leng

th(in

)B

evel

Dia (in)

Pin

Cylin

der

Dia (in)

Nos

eD

ia (in)

-

35

Field Inspection Drawing, Box

Beve

lD

iaC

Bore

Dia

C Bo

re W

all

Box

Dep

th

-

36

HT Field Inspection Dimensions, Box

2 3/

8 HT

SLH9

02

7/8

HTPA

CH

T26

HT3

1H

T38

HT4

0H

T46

HT5

0H

T55

HT6

5

90V

084

V 07

6SV

038R

V 03

8RV

038R

V 03

8RV

038R

V 03

8RV

050

V050

4.44

3 - 4

.448

4.83

5 - 4

.840

5.16

8 - 5

.173

5.35

1 - 5

.356

5.51

0 - 5

.515

6.28

1 - 6

.286

6.29

6 -6

.301

6.16

4 - 6

.169

7.35

2 - 7

.357

7.50

4 - 7

.509

2.98

4 - 3

.141

3.04

7 - 3

.204

3.29

6 - 3

.453

3.93

7 - 4

.094

4.63

7 - 4

.794

4.85

9 - 5

.016

5.82

9 -5

.986

6.12

4 - 6

.281

6.85

7 - 7

.014

7.54

7 - 7

.704

2.72

7 - 2

.789

2.53

9 - 2

.601

2.90

7 - 2

.969

3.42

2 - 3

.484

4.04

7 - 4

.109

4.31

3 - 4

.375

4.87

5 -4

.937

5.28

2 - 5

.344

5.87

5 - 5

.937

6.81

3 - 6

.875

0.09

40.

188

0.18

80.

188

0.31

30.

313

0.31

30.

313

0.31

30.

313

Conn

ectio

nTh

read

Form

Box

Dep

th(in

)B

evel

Dia (in)

Coun

ter b

ore

Dia (in)

Min

imum

CBor

e W

all

(in)

-

37

XT Field Inspection Dimensions, Box

XT24

XT26

XT29

XT30

XT31

XT34

XT38

XT39

XT40

XT43

XT46

XT50

XT54

XT55

XT57

XT61

XT65

XT69

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

3.21

7 - 3

.222

3.12

3 - 3

.128

3.65

4 - 3

.659

3.37

3 - 3

.378

3.99

8 - 4

.003

4.15

4 - 4

.159

4.62

3 - 4

.628

4.49

8 - 4

.503

4.49

8 - 4

.503

3.65

4 - 3

.659

7.50

5 - 7

.510

7.30

5 - 7

.310

7.00

5 - 7

.010

7.25

5 - 7

.260

7.25

5 - 7

.260

6.25

5 - 6

.260

8.25

5 - 8

.260

7.81

8 - 7

.823

2.98

4 - 3

.141

3.20

3 - 3

.360

3.57

8 - 3

.735

3.70

3 - 3

.860

3.85

9 - 4

.016

4.10

9 - 4

.266

4.54

7 - 4

.704

4.77

0 - 4

.927

5.00

0 - 5

.157

5.04

7 - 5

.204

5.91

8 -6

.075

6.30

2 - 6

.459

6.45

3 - 6

.610

6.85

7 - 7

.014

6.70

5 - 6

.862

6.96

1 - 7

.118

7.70

3 - 7

.860

7.76

7 - 7

.954

2.59

3 - 2

.655

2.83

1 - 2

.893

3.13

2 - 3

.194

3.26

7 - 3

.329

3.34

2 - 3

.404

3.63

8 - 3

.700

3.94

7 - 4

.009

4.12

1 - 4

.183

4.32

4 - 4

.386

4.48

8 - 4

.550

5.07

1 -5

.133

5.40

9 - 5

.471

5.66

7 - 5

.729

5.78

3 - 5

.845

5.90

9 - 5

.971

6.31

6 - 6

.378

6.78

4 - 6

.846

7.15

9 - 7

.221

0.18

80.

188

0.18

80.

188

0.18

80.

188

0.25

00.

250

0.25

00.

313

0.31

30.

313

0.31

30.

313

0.31

30.

313

0.31

30.

313

Conn

ectio

nTh

read

Form

Box

Dep

th(in

)B

evel

Dia (in)

Coun

ter b

ore

Dia (in)

Min

imum

CBor

e W

all

(in)

-

38

XT-M Field Inspection Dimensions, Box

XT-M

24XT

-M

26XT

-M

29XT

-M

31XT

-M

34XT

-M

38XT

-M

39XT

-M

40XT

-M

43XT

-M

46XT

-M

50XT

-M

57XT

-M

61XT

-M

65XT

-M

69

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2RV

042R

V 04

2R

5.06

8 - 5

.073

5.00

5 - 5

.010

5.50

5 - 5

.510

5.88

0 - 5

.885

6.00

5 - 6

.010

6.50

5 - 6

.510

6.25

5 - 6

.260

6.50

5 - 6

.510

5.63

0 - 5

.635

7.50

5 - 7

.510

7.30

5 - 7

.310

7.25

5 - 7

.260

6.25

5 - 6

.260

8.25

5 - 8

.260

7.81

8 - 7

.823

2.98

4 - 3

.141

3.20

3 - 3

.360

3.57

8 - 3

.735

3.85

9 - 4

.016

4.07

8 - 4

.235

4.54

7 - 4

.704

4.77

0 - 4

.927

5.00

0 - 5

.157

5.04

7 - 5

.204

5.91

8 -6

.075

6.30

2 - 6

.459

6.70

5 - 6

.862

6.96

1 - 7

.118

7.70

3 - 7

.860

7.79

7 - 7

.954

2.59

3 - 2

.655

2.83

1 - 2

.893

3.13

2 - 3

.194

3.34

2 - 3

.404

3.63

8 - 3

.700

3.94

7 - 4

.009

4.12

9 - 4

.191

4.32

4 - 4

.386

4.48

8 - 4

.550

5.07

1 -5

.133

5.40

9 - 5

.471

5.90

9 - 5

.971

6.31

6 - 6

.378

6.78

4 - 6

.846

7.15

9 - 7

.221

0.18

80.

188

0.18

80.

188

0.25

00.

250

0.25

00.

250

0.31

30.

313

0.31

30.

313

0.31

30.

313

0.31

3

Conn

ectio

nTh

read

Form

Box

Dep

th(in

)B

evel

Dia (in)

Coun

ter b

ore

Dia (in)

Min

imum

CBor

e W

all

(in)

-

39

GPDS Field Inspection Dimensions, Box

GPD

S26

GPD

S31

GPD

S38

GPD

S40

GPD

S46

GPD

S50

GPD

S55

GPD

S65

V 03

8RV

038R

V 03

8RV

038R

V 03

8RV

038R

V 05

0V0

50

3.38

0 - 3

.391

3.89

2 - 3

.903

4.40

4 - 4

.415

4.91

5 - 4

.927

4.91

5 - 4

.927

4.91

5 - 4

.927

5.42

7 -5

.439

5.42

7 -5

.439

3.25

0 - 3

.407

3.93

7 - 4

.094

4.56

2 - 4

.719

5.00

0 - 5

.157

5.70

3 - 5

.860

6.04

7 - 6

.204

6.70

3 -6

.860

7.68

7 - 7

.844

2.89

9 - 2

.961

3.41

4 - 3

.476

4.03

9 - 4

.101

4.30

5 - 4

.367

4.86

7 - 4

.929

5.27

4 - 5

.336

5.86

7 -5

.929

6.80

5 - 6

.867

0.18

80.

188

0.25

00.

250

0.31

30.

313

0.31

30.

313

Conn

ectio

nTh

read

Form

Box

Dep

th(in

)B

evel

Dia (in)

Coun

ter b

ore

Dia (in)

Min

imum

CBor

e W

all

(in)

-

40

-

41

HEAVY

WEIG

HTD

RILL

PIPE

Heavy weight drill pipe (HWDP) was developed to provide agradual transition from heavy drill collars to relatively light-weight drill pipe. By providing a gradual change in weight andrigidity, HWDP reduces connection fatigue problems andincreases drill stem service life. And because it bends moreeasily than drill collars, it simplifies directional control in high-angle and horizontal drilling. HWDP has less wall contactthan drill collars, reducing differential sticking tendencies.Spiraled HWDP configurations further decrease differentialsticking tendency while helping to remove cuttings out of theannulus. Grant Prideco offers three types of HWDP configu-rations to meet the challenge of severe drilling conditions.

Conventional HWDP Developed to provide a grad-ual transition from the heavy drill collar to the relativelylightweight drill pipe.

Heavy Weight Drill Pipe

24DTool Joint OD

BUpset Diameter

ANominal Size

CWear Section

UpsetDiameter

BElevator Upset

Diameter

180

180

31NominalLength

24

26

Conventional Heavy Weight Drill Pipe

-

42

Tri-Spiral HWDP Developed for high-angle applica-tions such as extended reach and horizontal drilling.- Equally spaced, three spiral upset design helps

improve cuttings removal, reduce differential sticking tendencies and torque and drag.

Heavy Weight Drill Pipe

24

B Upset Diameter

A Nominal Size

CSpiral Upset

DBox Tool

Joint

31NominalLength

24

Tri-Spiral Heavy Weight Drill Pipe

BElevator Upset

Diameter

D Pin Tool

Joint

26

26CSpiral Upset

CCenter

Spiral Upset

26

-

43

Heavy Weight Drill Pipe

Spiral-Wate HWDP Designed to handle maximumstress to save time and reduce drilling costs, especiallyin tough drilling environments.- Unique patented spiral design reduces differential

sticking problems, minimizes wear and improves circulation. Features more weight per joint and better hole cleaning characteristics than standard HWDP.

ANominal

Size

DPin Tool

Joint

CSpiralUpset

BElevator Upset

Diameter

DBox Tool

Joint24

42

214

24

11

31NominalLength

Spiral-Wate Heavy Weight Drill Pipe

-

44

Dimensional Data - Range IIS

Upse

tUp

set

Nom

inal

Wal

lSe

ctio

nD

ia.

Dia

.Te

nsi

leTo

rsio

nal

Conn

ectio

nO

DTe

nsi

leTo

rsio

nal

Per

Mak

e-up

Size

IDTh

ickn

ess

Are

aM

odul

us[C

][B

]Yi

eld

Yiel

dSi

ze a

nd[D

]ID

Yiel

dYi

eld

Per

Join

tTo

rque

(in)

(in)

(in)

(in2 )

(in3 )

(in)

(in)

(lb)

(ft-lb

)Ty

pe(in

)(in

)(lb

)(ft

-lb)

foot

(31 ft

)(ft

-lb)

2 7 / 8

1 1 / 2

0.68

84.

727

2.16

13

5 / 16

2 15

/ 1652

0,00

022

,400

NC2

6 (2

3 / 8IF

)3

3 / 81

1 / 235

7,70

06,

300

17.2

653

53,

800

3 1 / 2

2 1 / 1

60.

719

6.28

23.

702

43

7 / 834

5,40

019

,600

NC3

8 (3

1 / 2IF

)4

3 / 42

1 / 884

2,40

019

,200

25.6

579

511

,500

NC3

8 (3

1 / 2IF

)4

3 / 479

0,90

019

,200

23.4

872

811

,500

3 1 / 2

2 1 / 4

0.62

55.

645

3.49

04

3 7 / 8

310,

500

18,5

00H

T38

4 7 / 8

2 1 / 4

790,

900

34,2

0023

.96

743

20,5

00XT

394

7 / 887

1,40

040

,700

23.9

674

324

,400

42

9 / 16

0.71

97.

411

5.22

54

1 / 24

3 / 16

407,

600

27,6

00N

C40

(4 FH

)5

1 / 42

9 / 16

838,

300

27,8

0029

.92

928

14,6

00XT

394

7 / 872

9,70

037

,000

28.4

088

022

,200

4 1 / 2

2 3 / 4

0.87

59.

965

7.69

85

4 11

/ 1654

8,10

040

,700

NC4

6 (4

IF)6

1 / 42

13/ 16

1,15

1,10

043

,600

41.4

51,

285

22,5

00

53

1.00

012

.566

10.6

815

1 / 25

1 / 869

1,20

056

,500

NC5

0 (4

1 / 2IF

)6

5 / 83

1,41

6,20

057

,800

50.3

81,

562

30,0

00H

T50

88,8

0053

,300

5 1 / 2

3 1 / 4

1.12

515

.463

14.3

426

5 11

/ 1685

0,40

075

,900

5 1 / 2

FH7

1 / 43

1 / 41,

778,

300

78,7

0061

.63

1,91

141

,200

HT5

511

5,10

069

,000

5 7 / 8

4 0.

938

14.5

4215

.630

6 3 / 8

679

9,80

082

,700

XT57

74

1,40

3,10

010

6,20

057

.42

1,78

063

,700

6 5 / 8

4 1 / 2

1.06

318

.574

22.4

767

1 / 86

5 / 16

1,02

1,60

011

8,90

06

5 / 8 F

H8

4 1 / 2

1,89

6,10

087

,900

71.4

32,

214

50,5

00

Conv

entio

nal H

eavy

Wei

ght D

rill P

ipe

Tube

Too

l Joi

ntW

eigh

t (lb)

Nom

inal

Tu

beD

imen

sion

sM

echa

nica

l Pr

oper

ties

Tube

Mec

hani

cal

Prop

ertie

s To

ol J

oint

App

rox.

In

cl. T

ube

&

Too

l Joi

nts

NO

TE:2

7/8

H

WD

Pis

man

ufac

ture

d in

tegr

al o

nly

(non-w

elded

).

Cen.

End

-

45

SUp

set

Upse

tN

omin

alW

all

Sect

ion

Dia

.D

ia.

Ten

sile

Tors

iona

lCo

nnec

tion

OD

Ten

sile

Tors

iona

lPe

rM

ake-

upSi

zeID

Thic

knes

sA

rea

Mod

ulus

[C]

[B]

Yiel

dYi

eld

Size

and

[D]

IDYi

eld

Yiel

dPe

rJo

int

Torq

ue(in

)(in

)(in

)(in

2 )(in

3 )(in

)(in

)(lb

)(ft

-lb)

Type

(in)

(in)

(lb)

(ft-lb

)fo

ot(31

ft)

(ft-lb

)2

7 / 81

1 / 20.

688

4.72

72.

161

3 5 / 1

62

15/ 16

520,

000

22,4

00N

C26

(2 3 / 8

IF)

3 3 / 8

1 1 / 2

357,

700

6,30

018

.22

565

3,80

0

3 1 / 2

2 1 / 1

60.

719

6.28

23.

702

43

7 / 834

5,40

019

,580

NC3

8 (3

1 / 2IF

)4

3 / 42

1 / 884

2,40

019

,200

27.0

583

911

,500

NC3

8 (3

1 / 2IF

)4

3 / 479

0,90

019

,200

24.8

877

111

,500

3 1 / 2

2 1 / 4

0.62

55.

645

3.49

04

3 7 / 8

310,

500

18,5

00H

T38

4 7 / 8

2 1 / 4

790,

900

34,2

0025

.36

786

20,5

00XT

394

7 / 887

1,40

040

,700

25.3

678

624

,400

42

9 / 16

0.71

97.

411

5.22

54

1 / 24

3 / 16

407,

600

27,6

00N

C40

(4 FH

)5

1 / 42

9 / 16

838,

300

27,8

0031

.51

977

14,6

00XT

394

7 / 872

9,70

037

,000

29.9

993

022

,200

4 1 / 2

2 3 / 4

0.87

59.

965

7.69

85

4 11

/ 1654

8,10

040

,700

NC4

6 (4

IF)6

1 / 42

13/ 16

1,15

1,10

043

,600

43.3

11,

343

22,5

00

53

1.00

012

.566

10.6

815

1 / 25

1 / 869

1,20

056

,500

NC5

0 (4

1 / 2IF

)6

5 / 83

1,41

6,20

057

,800

52.3

41,

623

30,0

00H

T50

88,8

0053

,300

5 1 / 2

3 1 / 4

1.12

515

.463

14.3

426

5 11

/ 1685

0,40

075

,900

5 1 / 2

FH7

1 / 43

1 / 41,

778,

300

78,7

0063

.78

1,97

741

,200

HT5

511

5,10

069

,000

5 7 / 8

4 0.

938

14.5

4215

.630

6 3 / 8

679

9,80

082

,700

XT57

74

1,40

3,10

010

6,20

057

.42

1,78

063

,700

6 5 / 8

4 1 / 2

1.06

318

.574

22.4

767

1 / 86

5 / 16

1,02

1,60

011

8,90

06

5 / 8 F

H8

4 1 / 2

1,89

6,10

087

,900

74.6

72,

315

50,5

00

Tri-S

pira

lTMH

eavy

Wei

ght D

rill P

ipe

Tube

Too

l Joi

ntW

eigh

t (lb)

Nom

inal

Tu

beD

imen

sion

sM

echa

nica

l Pr

oper

ties

Tube

Mec

hani

cal

Prop

ertie

s To

ol J

oint

App

rox.

In

cl. T

ube

&

Too

l Joi

nts

Dimensional Data - Range II

NO

TE:2

7/8

Tr

i-Spi

ralTM

is m

anuf

actu

red

inte

gral

onl

y (no

n-weld

ed).

Cen.

End

-

46

SUp

set

Upse

tN

omin

alW

all

Sect

ion

Dia

.D

ia.

Ten

sile

Tors

iona

lCo

nnec

tion

OD

Ten

sile

Tors

iona

lPe

rM

ake-

upSi

zeID

Thic

knes

sA

rea

Mod

ulus

[C]

[B]

Yiel

dYi

eld

Size

and

[D]

IDYi

eld

Yiel

dPe

rJo

int

Torq

ue(in

)(in

)(in

)(in

2 )(in

3 )(in

)(in

)(lb

)(ft

-lb)

Type

(in)

(in)

(lb)

(ft-lb

)fo

ot(31

ft)

(ft-lb

)3

3 / 16

20.

594

4.84

02.

687

3 5 / 1

63

3 / 16

532,

400

28,4

00SL

H90

3 7 / 8

2 40

7,00

012

,000

19.4

860

46,

300

3 1 / 2

2 1 / 4

0.62

55.

645

3.49

04

3 5 / 8

310,

500

18,5

00N

C38

(3 1 / 2

IF)

790,

900

22,9

0013

,100

HT3

84

7 / 82

1 / 479

0,90

034

,200

30.3

994

220

,500

XT39

871,

400

40,7

0024

,400

42

9 / 16

0.71

97.

411

5.22

54

1 / 24

1 / 840

7,60

027

,600

NC4

0 (4

FH)

5 2

9 / 16

838,

300

20,9

0028

.90

896

12,6

00XT

39

729,

700

40,8

0024

,500

4 1 / 2

2 3 / 4

0.87

59.

965

7.69

85

4 5 / 8

548,

100

40,7

00N

C46

(4 IF)

6 1 / 4

2 13

/ 161,

151,

100

43,6

0049

.53

1,53

522

,500

5 3

1.00

012

.566

10.6

815

1 / 25

1 / 869

1,20

056

,500

NC5

0 (4

1 / 2 IF

)6

5 / 83

1,41

6,20

057

,800

59.1

61,

834

30,0

00H

T50

88,8

0053

,300

5 1 / 2

40.

750

11,1

9211

.764

65

5 / 861

5,60

062

,200

5 1 / 2

FH7

41,

265,

800

55,9

0055

.21

1,71

229

,200

HT5

577

,200

46,3

00

5 7 / 8

4 0.

938

14.5

4215

.630

6 3 / 8

679

9,80

082

,700

XT57

74

1,40

3,10

010

6,20

065

.38

2,02

763

,700

6 5 / 8

50.

813

14.8

3719

.285

7 1 / 8

6 3 / 4

816,

000

102,

000

6 5 / 8

FH

85

1,44

8,40

073

,700

73.4

02,

,275

38,4

00

Spira

l-Wat

eH

eavy

Wei

ght D

rill P

ipe

Tube

Too

l Joi

ntW

eigh

t (lb)

Nom

inal

Tu

beD

imen

sion

sM

echa

nica

l Pr

oper

ties

Tube

Mec

hani

cal

Prop

ertie

s To

ol J

oint

App

rox.

In

cl. T

ube

&

Too

l Joi

nts

Dimensional Data - Range II

NO

TE:3

3/1

6 Sp

iral-W

ate

TM, pr

evio

usly

refe

rred

to a

s 2-

7/8

, is

man

ufac

ture

d in

tegr

al o

nly

(non-w

elded

).

Cen.

End

-

47

DR

ILLCO

LLARS