TS 11000: 2013 Electrical Distribution System Installation ... · ST Electrical Distribution System...

Transcript of TS 11000: 2013 Electrical Distribution System Installation ... · ST Electrical Distribution System...

Sup

erse

ded

by T

HR

EL

1700

1 S

T

Electrical Distribution System Installation Connection and Inspection

TS 11000: 2013

Safety standard

Version 1.0 Issued Date: 23 December 2013 Effective Date: 23 December 2013

Important Warning

This document is one of a set of standards developed solely and specifically for use on the rail network owned or managed by the NSW Government and its agencies. It is not suitable for any other purpose. You must not use or adapt it or rely upon it in any way unless you are authorised in writing to do so by a relevant NSW Government agency.

If this document forms part of a contract with, or is a condition of approval by, a NSW Government agency, use of the document is subject to the terms of the contract or approval.

This document may not be current. Current standards are available for download from the Asset Standards Authority website at www.asa.transport.nsw.gov.au.

© State of NSW through Transport for NSW Page 1 of 28

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 2 of 28

Standard Approval Owner: D Spiteri, Chief Engineer, Rail, Asset Standards Authority Authorised by: G Bradshaw, Principal Manager, Network Standards and Services Approved by: J Modrouvanos, Director Asset Standards Authority on behalf of the ASA

Configuration Control Board

Document Control Version Summary of Change 1.0 First issue

For queries regarding this document

www.asa.transport.nsw.gov.au

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 3 of 28

Preface

The Asset Standards Authority (ASA) develops, controls, maintains, and publishes standards

and documentation for transport assets for New South Wales, using expertise from the

engineering functions of the ASA and industry.

The Asset Standards Authority publications include the network and asset standards for NSW

Rail Assets.

This document has been developed by the Chief Engineer Rail section of the Asset Standards

Authority, reviewed by a committee of TfNSW cluster representatives, and approved by the

Asset Standards Authority Configuration Control Committee.

This document details the requirements for connection of installations, or installations proposed

to be connected to, the RailCorp distribution system

The document complies with the requirements of the Electricity Supply (Safety and Network

Management) Regulation 2008 and the Service and Installation Rules for NSW August 2012. It

cancels and replaces RailCorp Standard EP 17 00 00 06 SP Installation Inspections.

This document is to be read in conjunction with Transport Standard EP 95 00 30 03 SP

RailCorp Network Management Plan Chapter 2 – Customer Installation Safety and

EP 17 00 00 12 SP Demarcation of RailCorp Low Voltage Distribution System.

The significant changes include:

responsibilities within the Transport Cluster

electricity supply relationships

responsibilities of Installation owners or custodians

Distribution Network Service Provider (DNSP) responsibilities

applications for connection

Certificate of Compliance - Electrical Work

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 4 of 28

Foreword

In developing this document there are sections relating to internal procedures and forms

associated with the Distribution Network Service Provider (DNSP) that have been carried

forward from the previous RailCorp standard.

The document includes those internal procedures and forms and is published on behalf of the

DNSP on the ASA website. This has been done to ensure that relevant requirements are not

lost. In future editions it is envisaged that some or all of these will be incorporated into internal

DNSP documents.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 5 of 28

Table of contents

1. Introduction .......................................................................................................................................6

2. Purpose ..............................................................................................................................................6

2.1 Scope..................................................................................................................................................6 2.2 Application.........................................................................................................................................6

3. Reference documents.......................................................................................................................7

4. Terms and definitions.......................................................................................................................8

5. Organisational responsibilities......................................................................................................10

6. Electricity supplies..........................................................................................................................11

6.1 Relationship of this document to legislation and the customer installation safety plan ...................................................................................................................................................11

6.2 Accredited service providers.........................................................................................................11

7. Installation owner or custodian responsibilities .........................................................................11

7.1 Safety of installation .......................................................................................................................12 7.2 Qualified electricians ......................................................................................................................12

8. Distribution network service provider responsibilities...............................................................12

9. Applying for connection of a new installation or an alteration to an existinginstallation .......................................................................................................................................12

9.1 Process ............................................................................................................................................13 9.2 Small scale renewable energy micro generation systems .........................................................13

10. Notification of electrical works ......................................................................................................13

10.1 Local DNSP connection..................................................................................................................15 10.2 Tests required..................................................................................................................................15 10.3 Installations not to be connected ..................................................................................................15

11. Inspections ......................................................................................................................................16

11.1 Work requiring inspection..............................................................................................................16 11.2 Electrical Testing Methodology .....................................................................................................17 11.3 Defects .............................................................................................................................................18 11.4 Inspection reports ...........................................................................................................................19 11.5 Disciplinary action ..........................................................................................................................19 11.6 Qualifications of installation inspectors.......................................................................................20

12. Audit inspections ............................................................................................................................21

13. Forms ...............................................................................................................................................21

Appendix A Discretionary inspections flowchart .......................................................................................22

Appendix B Installation inspection flowchart .............................................................................................23

Appendix C Visual inspection check list......................................................................................................24

Appendix D Guidelines for completing defect forms .................................................................................26

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 6 of 28

1. Introduction

Each Distribution Network Service Provider (DNSP) has a legislative responsibility to ensure

that installations connected to its distribution system are safe and do not pose a risk to life,

health, or property. This is to protect the consumer and also to protect the DNSP so that its

system reliability is not jeopardised by unauthorised or faulty installations.

2. Purpose

This document details the requirements for connection of installations, or installations proposed

to be connected to, the RailCorp distribution system.

2.1 Scope

This standard provides the requirements for the following aspects of installations and

inspections:

the application process for connection of a new installation or alteration to an existing

installation; commonly called the 'Application for Connection'

the notification process for the self test regime of electrical works; commonly called the

'Certificate of Compliance - Electrical Works'

the Distribution Network Service Provider inspection and testing regime

2.2 Application

This document applies to the following:

all installations connected or proposed to be connected to the RailCorp distribution

system

all installations connected or proposed to be connected to the Local Distribution Network

Service Provider system via an isolating transformer.

This document does not apply to high voltage installations, the 1500 V dc railway traction

system or the railway signalling system.

This document applies to all installation owners or custodians and their electrical contractors, all

Transport for NSW, Sydney Trains, NSW Trains or other rail transport entity employees.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 7 of 28

3. Reference documents

Legislation

NSW Electricity Supply Act 1995

Electricity Supply (General) Regulation 2001

Electricity Supply (Safety and Network Management) Regulation 2008

Electricity (Consumer Safety) Act 2004

Electricity (Consumer Safety) Regulation 2006

NSW Department of Trade and Investment

Code of Practice – Electricity Service and Installation Rules of New South Wales 2007

Code of Practice – Distribution Risk Management 1998

Service and Installation Rules of New South Wales 2012

NSW Department of Energy and Water Code of Practice – Installation Safety Management

1997, Appendix 2

Electricity Association of NSW Guide to The Training of Personnel Working on or Near

Electricity Works 1999

Australian standards

AS/NZS 3000 – Wiring Rules

AS/NZS 3017 – Electrical Installations – Testing and Inspection Guidelines

Transport standards

EP 12 00 00 02 SP - Low Voltage Distribution and Installations Earthing References and

Definitions

EP 12 10 00 10 SP - System Substation Earthing

EP 12 10 00 11 SP - Distribution Substation Earthing

EP 12 10 00 20 SP - Low Voltage Distribution Earthing

EP 12 10 00 21 SP - Low Voltage Installations Earthing

EP 17 00 00 12 SP – Demarcation of RailCorp Low Voltage Distribution System

EP 95 00 30 03 SP RailCorp Network Management Plan Chapter 2 - Customer Installation

Safety

ESB E001 – Low Voltage Electrical Standards

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 8 of 28

4. Terms and definitions

application for connection a document submitted to the DNSP requesting approval to connect

a new installation or change the loading of an existing installation

authorised electrician a person who is authorised under the Home Building Act 1989 to do

electrical wiring work

CCEW Certificate of Compliance - Electrical Works

custodian the person that has responsibility for an installation.

DNSP distribution network service provider

distribution network service provider a person who owns or controls a distribution system

distribution system the electricity power lines and associated equipment and electricity

structures that are used to convey and control the conveyance of electricity to the premises of

wholesale and retail customers, or to convey and control the conveyance of electricity to, from

and along the rail system. A distribution system does not include a transmission system.

EDA Electrical Distribution Authority. The name of the business unit accountable for the rail

transport DNSP responsibilities. The EDA currently resides in Sydney Trains.

electrical installation the electrical wiring and associated equipment that are used to convey

and control the conveyance of electricity within premises to which electricity is supplied from a

distribution system, but does not include anything connected to and extending or situated

beyond an electrical outlet socket

electrical installation work means the work of installing, adding to, altering, disconnecting,

reconnecting or replacing an electrical installation

LDNSP local distribution network service provider

Local Distribution Network Service Provider the organisation which owns and controls the

principal distribution system in the geographical distribution area in which the installation is

located. The geographical areas of the LDNSP's are defined in the Service and Installation

Rules of NSW

low voltage a voltage exceeding 32V ac or 115V dc but not exceeding 1000V ac or 1500V dc

LV low voltage

high voltage a voltage exceeding 1000V ac or 1500V dc

HV high voltage

isolating transformer: A transformer with protective separation between the input and output

windings. It is used to separate the earthing systems between the RailCorp distribution system

and the Local Distribution Network Service Provider.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 9 of 28

Qualified Electrician see authorised electrician

switchboard an assembly of circuit protective devices, with or without switchgear, instruments

or connecting devices, suitably arranged and mounted for distribution to, and protection of, one

or more submains or final subcircuits or a combination of both.

switchboard, main a switchboard from which the supply to the whole electrical installation can

be controlled

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 10 of 28

5. Organisational responsibilities

Rail Corporation New South Wales (RailCorp) is the holding and property management

company for major rail and rail property assets in the Sydney Metropolitan Rail Area.

Consequently the railway electrical distribution system is the 'RailCorp Distribution System'.

The RailCorp Distribution System is generally located within the Sydney Metropolitan Rail Area,

bounded by the geographical extremities as follows:

Hamilton in the North,

Kiama in the South,

Wallerawang in the West (Bowenfels is the extent of the 1500V DC system), and

Glenlee (Campbelltown) in the South West.

Electrical Distribution Authority (EDA) within Sydney Trains is the Distribution Network Service

Provider (DNSP) for all installations covered by the application of this standard within the

Sydney Metropolitan Rail Area.

The Service and Installation Rules of NSW nominates RailCorp as

the DNSP and will be updated to Sydney Trains with the next

edition.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 11 of 28

The Asset Standards Authority (ASA) publishes the Standards applicable to the RailCorp

Distribution System including installations

The Local Distribution Network Service Providers (LDNSPs) are Ausgrid, Endeavour Energy

and Essential Energy.

6. Electricity supplies

Electricity supplies to installations within the Sydney Metropolitan Rail Area are either derived

directly from the RailCorp high voltage (HV) distribution network or from the Local Distribution

Network Service Provider via an isolating transformer. This isolating transformer forms part of

the RailCorp low voltage (LV) distribution network. In these situations the EDA becomes the

DNSP from the secondary terminals of the isolating transformer.

The demarcation of supplies is documented in EP 17 00 00 12 SP “Demarcation of RailCorp

Low Voltage Distribution System”

6.1 Relationship of this document to legislation and the customer installation safety plan

The Electricity Supply (Safety and Network Management) Regulation requires Distribution

DNSPs to have plans in place to manage specific aspects of their distribution systems. One of

the requirements is the management of customer installation safety.

The Customer Installation Safety Plan is document EP 95 00 30 03 SP RailCorp Network

Management Plan Chapter 2 - Customer Installation Safety and governs all installations within

the electrified rail corridor. This plan addresses the specific rail requirements associated with

installations, including requirements detailed in the Service and Installation Rules of NSW.

6.2 Accredited service providers

The Customer Installation Safety Plan does not include an accreditation system for contestable

works on the RailCorp distribution system.

Connections to the network can only be carried out either by or under the direction of

DNSP-authorised staff.

7. Installation owner or custodian responsibilities

Installation owners or custodians are responsible for the following:

safety of installations

ensuring that electrical works are performed by qualified electricians

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 12 of 28

7.1 Safety of installation

Installation owners or custodians are responsible for the maintenance of their installations to

ensure the safety of persons and property and the prevention of bushfires.

7.2 Qualified electricians

To carry out electrical works on installations, electrical contractors must be fully licensed in

accordance with the Home Building Act.

The licenses are administered by the Office of Fair Trading NSW.

Installation owners or custodians are responsible for ensuring that any contractor or trades

person they engage to carry out electrical works are appropriately licensed. In the case of

project works the custodian is deemed to be the Project Manager.

8. Distribution network service provider responsibilities

The Distribution Network Service Provider (DNSP) is responsible for the following:

managing applications for connections and associated network loadings

monitoring the standard of electrical work

confirming that appropriate testing procedures have been implemented by the installing

electrical contractor

To achieve its responsibilities, the DNSP has an inspection program to monitor the performance

of electrical contractors.

Related topic:

Inspections, Section 11.

9. Applying for connection of a new installation or an alteration to an existing installation

Submitting a completed Application for Connection form is a mandatory requirement for all new

connections or connection alterations. The electrical contractors or installers acting on the

installation owner or custodian's behalf shall complete the standard Application for Connection

form. For project work this may be done by the Authorised Engineering Organisation (AEO)

designer as part of the design deliverables.

Where a temporary connection is required for a short time and at the conclusion of that time no

connection will be needed, eg for construction of a bridge, then the Application for a Temporary

Connection form shall be used.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 13 of 28

Related topic:

Forms, Section 13

9.1 Process

Applications are to be submitted in accordance with the details embedded on the Application for

Connection form.

The relevant installation inspector, or their representative, will determine if the associated

substation and the supply main switchboard have the capacity to supply any additional load

required.

For alterations to existing installations, it is the responsibility of the installing electrical contractor

or Authorised Engineering Organisation (AEO) designer to determine if the installation has the

capacity to accept additional load and to design the installation accordingly. The installation

owner or custodian shall be consulted and approve any increased electrical load.

For services originating from a LDNSP the Application for Connection form shall be submitted to

the LDNSP with a copy to the DNSP.

Related topic:

Forms, Section 13

9.2 Small scale renewable energy micro generation systems

Small scale renewable energy micro generation systems include solar, wind and biomass.

These systems shall only be connected to the network via an inverter that complies with

AS4777 –Grid connection of energy systems via inverters and has a capacity no more than

10kW for single phase connections or 30kW for three phase connections.

The installing electrical contractor or Authorised Engineering Organisation (AEO) designer shall

demonstrate that the design satisfies the criteria as specified in the Service and Installation

Rules of NSW Clause 8.6.3 prior to approval.

10. Notification of electrical works

All electrical installation work shall be tested to verify compliance with AS/NZS 3000, the

Service and Installation Rules of NSW, and relevant standards, before being permanently

connected to the supply.

Compliance is the responsibility of the installing electrical contractor.

The current Fair Trading NSW Certificate of Compliance Electrical Work (CCEW) form shall be

used by electrical contractors for notifying the Distribution Network Service Provider (DNSP) of

electrical installation work as required by the Electricity (Consumer Safety) Regulation 2006.

Supplies of Compliance Certificates can be obtained from electrical wholesalers.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 14 of 28

The NSW Electricity (Consumer Safety) Regulation obligates electrical contractors to provide a

completed CCEW form to installation owners or custodians and the DNSP covering the details

of their electrical installation work, the required test results, and who carried out the work.

The Certificate of Compliance Electrical Work is to be submitted to

the DNSP for all electrical work carried out on an installation

contrary to note 1 in the Guide to the Testing, Connection and

Notification Requirements for the Certificate of Compliance

Electrical Work.

A CCEW form shall be submitted to the DNSP within 14 days after the completion of any safety

and compliance tests.

A separate CCEW is required to be submitted to the DNSP after correcting any notified defect in

an installation.

All CCEW forms shall be completed in full, with particular attention to the following details:

clear identification of the customer’s address and contact number

clear identification of the repairs carried out or load to be connected

actual test values for the earthing system integrity and insulation resistance for the 'Test

Report' section

legible signature and license details entered by the electrical contractor for the

certification section

If the CCEW form has not been clearly or correctly completed then the Installation Inspector will

return the form to the person submitting it, advising them that a new or suitably corrected CCEW

form must be resubmitted within five working days. Failure to comply with these requirements

shall initiate disciplinary action.

In the case of work that is discovered other than by way of a CCEW form, the Installation

Inspector shall inform the installation owner or custodian that the work has not been notified and

that a CCEW must be submitted.

In the event of the installation being a RailCorp Asset then the installation inspector is to report

to the Line Manager responsible for the premises or their representatives, in accordance with

the DNSP Safety Management process.

Related topics:

Disciplinary action, Section 11.5

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 15 of 28

10.1 Local DNSP connection

For new connections to a Local Distribution Network Service Provider (LDNSP) a Certificate of

Compliance Electrical Work (CCEW) shall be submitted to the LDNSP concerning the

connection to their network at the completion of the works. Simultaneously, the CCEW

concerning the installation connected to the isolating transformer shall be submitted to the

DNSP.

For alterations or additions to existing connections the CCEW shall be submitted to the DNSP.

10.2 Tests required

All electrical installation work shall be tested to verify compliance with AS/NZS 3000, the

Service and Installation Rules of NSW and relevant standards, before being permanently

connected to the supply.

The minimum inspection shall include testing the work in accordance with the requirements of

the NSW Department of Energy and Water Code of Practice – Installation Safety Management,

Appendix 2.

The test methods shall adhere to the Electrical Installation Testing Guidelines offered in

AS/NZS 3017, and use calibrated instruments which are periodically checked to ensure they

remain operational and safe.

Test results shall ensure all the outcomes specified in Clause 1.8 of AS/NZS 3000 are

established.

10.3 Installations not to be connected

Installation work can only be connected to the electricity supply once testing and inspection

activities prove compliance with the following standards and codes of practice:

AS/NZS 3000 and supporting standards

Service and Installation Rules of NSW

Transport Standards

For the following installation work, connection to the electricity supply can only be carried out by

an individual who has been, or is supervised by a person, appropriately authorised by the DNSP

and possesses formal training with respect to the task undertaken:

consumers mains and main switchboard, or

installations in environments classified as hazardous areas by relevant Australian

Standards including AS/NZS 2381 Section 1.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 16 of 28

11. Inspections

The Distribution Network Service Provider (DNSP) shall carry out inspections of selected new

installations and additions and alterations to existing installations for compliance with the

relevant codes, regulations and standards.

The inspection shall consist of a visual examination to check compliance with the rules, the level

of technical expertise for finish of the work, and includes sufficient testing to verify that the

electrical contractor has performed the appropriate tests.

The inspection shall include a thorough visual check of the earthing system to ensure that it

meets dc traction system special requirements.

All inspections will be carried out within three months of receipt of notification of electrical works.

Related topic:

Installation inspection flowchart; Appendix B

Visual inspection check list; Appendix C

11.1 Work requiring inspection

New installations, additions and alterations to installations are subject to mandatory and

discretionary inspections.

The inspection of additions and alterations is limited to that portion of the installation set out in

the Certificate of Compliance Electrical Work (CCEW), unless during the installation it is obvious

that portions of the existing installation are defective and immediately dangerous.

Installations requiring a mandatory inspection shall not be placed in service until a complete

installation inspection has been performed.

Where an installation is found to have been energised by an unauthorised contractor prior to

inspection, it shall be inspected and the matter referred to the Manager EDA.

If the installation is found to be immediately dangerous, the defective portion is to be

disconnected from the supply and danger tagged out of service. A defect notice is then to be

issued.

All work that has been found to be defective must be reinspected.

Installation inspections are separate to the 'self test' which must be

carried out after every job in accordance with Clause 33 of the

Electricity (Consumer Safety) Regulation 2006.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 17 of 28

11.1.1 Mandatory inspections

Clause 3.8 of the NSW Department of Water & Energy Code of Practice – "Installation Safety

Management" states the following installation work, as applicable to this Standard, must be

inspected:

consumers mains and main switchboards

installations in environments classified as hazardous areas by AS/NZS 2381 Section 1

All other installation work shall be inspected on a discretionary basis.

Related topic:

Discretionary inspections, Section 11.1.2

11.1.2 Discretionary inspections

The Distribution Network Service Provider will carry out discretionary inspections of selected

installations based upon the following broad criteria:

the type of installation work involved

whether the work is major or minor job

location; whether the works are accessible to the public

risk profile

the electrician’s previous performance in that particular type of work

Inspection requirements, in terms of percentage of work to be inspected, will be periodically

reviewed as the familiarity of installing contractors in the market changes, in particular with

demonstrated knowledge of transport standards.

Related topic

Discretionary inspections flowchart; Appendix A

11.1.3 Progress Inspections

Where any part of the electrical installation will be concealed such as underground or behind a

lined wall, then it may be appropriate for progress inspections to be carried out during the

installation. Such inspections may be initiated locally and without receipt of formal notification

from the electrical contractor.

11.2 Electrical Testing Methodology

AS/NZS 3017:2007 and AS/NZS 3000:2007 Section 6, provides guidelines for testing of

electrical installations.

The procedures for carrying out the electrical tests that form part of an installation inspection are

set out in the DNSP procedures

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 18 of 28

11.3 Defects

Work that does not comply with AS/NZS 3000, the Service & Installation Rules of NSW and

transport standards shall be considered to be defective.

All defective work shall be notified to the customer and to the installing contractor.

Three copies of any notification shall be produced:

customer's copy

installing contractor's copy

DNSP copy, which is held by the DNSP installation inspector

Each notification is to be uniquely numbered.

All defect correction work is required to be re-inspected.

Related topic:

Guidelines for completing defect forms; Appendix D

11.3.1 Major defects

Major defects are those considered to present a high risk safety hazard to life, health or

property. Electrical installation work containing major defects shall not be connected to the

network. Major defects are listed in the NSW Department of Water & Energy Code of Practice -

Installation Safety Management, Appendix 3.

If major defects are encountered during an inspection, the installation inspector shall isolate the

section of the installation containing the major defect if possible. If this is not possible the entire

electricity supply to the installation may need to be disconnected.

If any part of the electrical installation is disconnected it shall be suitably tagged with a warning

not to connect and the nature of the defect.

If the disconnection of a defective installation will result in subsequent hazards or the installation

is considered system critical then the defect must be rectified immediately. For example, station

lighting defects or the Rail Management Centre. The installation owner or custodian is also to

be notified immediately.

11.3.2 Minor defects

Minor defects are defects that are not considered to be major defects.

For minor defects, a period of 21 days grace is allowed for the defects to be rectified. If it is not

rectified within this period a 'final notice' is to be forwarded to the installation owner or custodian.

If it is still not rectified within 14 days of the date of the final notice then the matter is to be

discussed with the installation owner or custodian before disconnecting supply.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 19 of 28

11.3.3 Re-inspection

Work will not to be re-inspected until a notification that the work is ready for re-inspection has

been received by the DNSP. Notification is via a new Certificate of Compliance Electrical Work

(CCEW) form.

The DNSP will have a follow up system to ensure CCEW forms for reinspection are received.

Costs associated with reinspection will be charged to the installing electrical contractor.

11.3.4 Defects in other parts of the installation

If during an inspection of a consumers’ installation other parts of the installation not indicated on

the CCEW form is found to be dangerous, or is likely to become dangerous, then the installation

inspector is to report the defect in accordance with the DNSP procedures.

The inspector shall list the identified defects and address a hazard report to the installation

owner or custodian responsible for the premises, or their representative, in accordance with the

DNSP Safety Action Management process.

If the supply to the installation is not disconnected at the time of inspection, then the hazard

report shall include the period within which the installation is to be made safe or otherwise

supply will be disconnected.

The installation shall be re-inspected after that period has expired to ensure that the installation

has been made safe.

11.4 Inspection reports

Results of inspections shall be recorded.

Inspections records shall be maintained for a minimum of seven years.

11.5 Disciplinary action

If a person breaches any law applicable to the provision of electricity supply, electrical safety or

electrical installation work, the DNSP may report that person to the appropriate authority or take

legal action itself. The action taken will depend on the seriousness of the breach, or the

frequency of breaches. The DNSP may also disconnect the installation from the network.

Breaches occur where a person or contractor:

carries out installation work that is defective or unsafe

fails to carry out the required tests

fails to notify the DNSP after carrying out electrical installation work

deceives or attempts to deceive any of the DNSP employees as to any fact, matter or

thing relating to an electrical installation

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 20 of 28

makes a representation in any document in relation to any electrical installation, which

they have supplied, that is false or misleading

connects an electrical installation to the RailCorp network without the DNSP approval

fails to rectify defects when notified

Disciplinary action may include

issuing a verbal or written warning

issuing a formal interview or counselling

referring an electrical contractor to the Office of Fair Trading

referring to the Commercial Tribunal

11.6 Qualifications of installation inspectors

DNSP personnel that assume an installation inspector role as part of their daily activities shall

be qualified according to the type of installation. Types of installations include:

low voltage installations

consumers' aerial lines

11.6.1 Low voltage installations

Inspectors of low voltage installations shall meet the following requirements:

hold a supervisor certificate (electrician) or a contractor licence (electrical) issued by the

Office of Fair Trading or approved equivalent which entitles them to work without

supervision

have demonstrated the necessary knowledge of transport standards and testing

requirements

hold a current Rail Industry Safety Induction card

have a minimum of five years experience working as a qualified electrician

11.6.2 Consumer aerial line

Inspectors of consumer aerial line installations shall meet the following requirements:

be qualified and have met the requirements of the Electricity Association of NSW Guide

to The Training of Personnel Working on or Near Electricity Works to inspect and test

overhead lines

have the necessary knowledge and experience, in particular of transport standards to

undertake the inspection of the particular type of work to be inspected

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 21 of 28

11.6.3 Installations located within hazardous areas inspector qualifications

For installations located within hazardous areas installation inspectors shall be appropriately

trained and qualified to carry out hazardous area inspections.

12. Audit inspections

Audit inspections will be carried out to observe that legislative requirements have been met with

regard to electrical installations, installing contractors and the inspection and testing function to

measure the effectiveness of the Installation Inspection program,.

The frequency of the audits will be at a level which contributes to maintaining or exceeding

existing minimum safety outcomes.

Audit inspections will be co-ordinated by the Manager EDA, Sydney Trains.

13. Forms

The following forms are available on the ASA Website and are used when implementing this

standard:

EP 95 00 30 03 SP FM 01 – Information regarding application for connection

EP 95 00 30 03 SP FM 02 – Application for Connection

EP 95 00 30 03 SP FM 32 – Application for Temporary Connection

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 22 of 28

Appendix A Discretionary inspections flowchart

Discretionary inspections follow a process that includes the following stages:

Preliminary assessment stage

Assessed Contractor stage

Defect identification

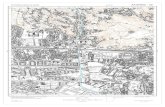

Figure 1 - Discretionary inspections

A.1 Preliminary assessment stage

The first three Certificate of Compliance Electrical Work (CCEW) jobs received from each electrical contractor are to be assigned for an inspection.

If there are no major defects in three consecutive jobs, then the contractor's jobs move to the 'Assessed Contractor' stage.

A.2 Assessed contractor stage

Additional jobs received from an electrical contractor will be inspected depending on the risk

profile.

If access is not available, another job may be assigned for inspection or access to the job

arranged for a later date at the discretion of the inspector.

If no major defects are detected during the inspection, the 'Assessed Contractor' stage

continued as more jobs are notified.

A.3 Defects

If a major defect is detected during an inspection, the contractor is moved back to the

'Preliminary inspection' stage.

Major defect details for the jobs are to be recorded in the inspector's database for each contractor.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 23 of 28

Appendix B Installation inspection flowchart

Figure 2 - Installation inspection flowchart

Related topic:

Visual inspection check list; Appendix C

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 24 of 28

Appendix C Visual inspection check list Table 1 - Visual Inspection Checklist

Inspection Category Inspection aspect Comments/Example

Protection against direct contact with live parts

Insulation, enclosure

Protection against indirect contact with exposed conductive parts

Double insulation or isolating transformers

Protection against hazardous parts Enclosure, guarding or screening of flammable materials, hot surfaces and parts that may cause physical injury

Protection against spread of fire Penetration of fire barriers

General condition of the electrical equipment

Signs of damage that could impair safe operation, disconnection of unused electrical equipment

All wiring and equipment which could be susceptible to mechanical damage is adequately protected

General

Insulated joints in any continuous earthed metallic structure

Fencing, water pipes

Sufficient current carrying capacity

Voltage drop with allowable limits

Installation conditions Enclosure, depth of burial, mechanical protection and other conditions affecting the de-rating of any cabling

Aerial installation conditions

Connection of wiring

Consumer mains

Protection against external influences

Location Suitable access and egress

Protective devices Overload and residual current rating, fault current rating

Isolating devices Main switches, isolating transformers

Connection devices Neutral and earth bars, and active links

Connection and fixing of wiring and switchgear

Correct identification and labelling of electrical equipment

Neutral/active labelling

Switchboards

Protection against external influences

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 25 of 28

Wiring systems Conductor size Current-carrying capacity and voltage drop

Identification of cable cores

Adequate support and fixing

Connections and enclosures

Particular installation conditions Underground, aerial, emergency systems

Segregation from other services and electrical installations

Protection against external influences

Enclosure

Electrical equipment Isolation and switching devices for protection against injury from mechanical movement devices and

motors

Isolation and switching devices for protection against thermal effects

Motors, room heaters, water heaters

Switching devices for particular electrical equipment

Socket outlets, cooking appliances

Particular installation conditions and the suitability for connection of the equipment under these conditions

Locations affected by water, explosive atmospheres, extra-low voltage, high voltage

Compliance with required Standard

Connection, support and fixing

Protection against external influences

Earthing Earth/Neutral connection at transformer/switchboard (where applicable)

Earth grid

Earthing conductors Size, identification

Equipotential bonding conductors Size, identification

Connections, joints and terminations

Protection against external influences

Correct connection to earthing arrangements for other systems (Note that this could mean separation rather then connection)

Signalling, communications, traction

Creation of earthed situation that may require earthing of additional electrical equipment

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 26 of 28

Appendix D Guidelines for completing defect forms Following is an extract of section 9 & 10 of the Energy Authority of NSW publication -

“Recommend Standard Inspection Procedure for Existing Electrical Installations” (June 1981). It

is included as guidance to inspectors in completing defect forms

9.0 REPORTS TO CONSUMERS

9.1 Reports of defects or unsatisfactory conditions found in installations should be set out in such a manner that they will be clearly understood by the consumer or his contractor and so as to assist the contractor as much as possible in locating and identifying the faulty portion and in determining what action he must take to remedy the fault.

9.2 Each item of the report should consist of a clear statement describing the defective condition. Attempts to set out the method of rectifying the fault should be avoided. For example, if it is found that trees and vines have grown up and fouled aerial conductors, the report should read somewhat as follows:

“The aerial conductors to the garage were fouled by trees and vines”.

and NOT

“Trees and vines, fouling aerial conductors to the garage, to be cut back”.

(The consumer may prefer to rectify the defect by raising or re-routing the aerial conductor instead of by cutting his trees.)

9.3 It is, of course, important to identify the particular portion of the installation to which the report refers in order that the contractor will not be in doubt as to the portion requiring attention.

9.4 In setting out the results of their inspection, Inspectors should appreciate the importance of always using correct terms, and should remember that the use of “trade jargon” frequently leads to serious misunderstandings. Experience has shown that if the correct terms are consistently used by the inspection officers, they will always be understood by Electrical Contractors and will be rapidly adopted by them.

9.5 The words “not satisfactory” or “unsatisfactory” should not be used to avoid specifying defects. Such an expression, however, may be used to describe a condition provided it us qualified by stating the reason or reasons why it is not satisfactory. It may also be used in the case where the whole of an installation is found to be in such bad condition that there would be little point in specifying particular defects. Such a report would read:

“The whole of the installation was in such an unsatisfactory condition that it requires a complete overhaul”.

10. SAMPLE DEFECT STATEMENTS

10.1 The following sample statements indicate the proper method of reporting defects that will commonly be found by Inspectors. These sample statements need not, of course, be followed exactly if an alternative statement is either more concise or more definite and conforms to the principles set out in these guidelines.

10.1.1 The rigid pendant in the kitchen was insecure.

10.1.2 The ceiling switch in the bathroom was insecure, thus placing strain on the conductors.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 27 of 28

10.1.3 The conduits on the back verandah were not securely fixed in position where they passed along the back wall.

10.1.4 The conduits on the back verandah were not mechanically and electrically continuous as they had pulled apart at the fittings.

10.1.5 The flexible cord for the radiator was frayed and damaged.

10.1.6 The flexible cord, from the plug socket in the second bedroom to the standard lamp in the hall, was damaged where it passed through the doorway.

10.1.7 The insulation on the flexible pendant in the kitchen was perished, thus exposing live conductors (temporarily made safe by taping).

10.1.8 The use of lampholder and adaptor to join the flexible cord for the radio was not satisfactory.

10.1.9 The improvised hand-lamp consisting of a lampholder mounted on a wooden block and having an unguarded lamp was not satisfactory. (Situated in the garage.) DISCONNECTED -LABELLED

10.1.10 The frame of the motor in the garage was not earthed.

10.1.11 The frame of the washing machine was earthed by means of a conductor not forming part of the flexible cord supplying the machine.

10.1.12 The earthing conductor above the bench in the garage was broken.

10.1.13 The earthing conductor adjacent to the laundry door was not securely fixed.

10.1.14 Some of the joints in the earthing conductor near the switchboard were not soldered or suitably clamped.

10.1.15 The metallic conduits in the garage were not earthed.

10.1.16 The connection of the earthing conductor to conduits at the main switchboard was not electrically effective.

10.1.17 The main earthing conductor on the southern side of the house was not connected to the water service (no earth clip fitted.)

10.1.18 The resistance between earth and metallic conduits at the switchboard was high (measured 200 ohms).

10.1.19 The metallic conduits in the following locations were not earthed:

(a) Kitchen,

(b) Back verandah,

(c) Main switchboard.

10.1.20 The metallic conduits in the garage were not earthed in a satisfactory manner. (Earthed to a separate electrode instead of to the main earth.)

10.1.21 The sheathing of an isolated length of lead covered cable in the garage was not earthed and was not protected against mechanical damage.

10.1.22 The switch for the plug socket in the dining room did not control the active conductor.

Sup

erse

ded

by T

HR

EL

1700

1 S

TTS 11000: 2013

Electrical Distribution System Installation Connection and Inspection Version 1.0

Effective Date: 23 December 2013

© State of NSW through Transport for NSW Page 28 of 28

10.1.23 The main switch was broken and inoperative in the “ON” position and thereby the installation was not longer under the control of a main switch.

10.1.24 The metal cover of the switch in the bathroom was alive, (temporarily made safe by lining the switch cover with an insulating material.)

10.1.25 The plug socket in the dining room was not controlled by a switch.

10.1.26 The switch controlling the plug socket in the dining room was inoperative in the “ON” position.

10.1.27 The cover of the light switch in the bathroom was broken thus exposing live metal (temporarily made safe by taping).

10.1.28 The porcelain base of the power circuit fuse on the main switchboard was broken thus exposing live contacts (temporarily made safe by taping).

10.1.29 The heating element of the toaster was broken and likely to made contact with the frame., (toaster and the permanently attached flexible cord DISCONNECTED - LABELLED).

10.1.30 The electric jug was not provided with a lid and thus exposed live conductor. DISCONNECTED - LABELLED.

10.1.31 The aerial conductors to the garage were fouled by trees and vines.

10.1.32 The insulation resistance between earth and the neutral conductor of the power circuit was extremely low. (measured.__ ohms).

10.1.33 The insulation resistance between the frame and the elements of the radiator was very low. (measured .__ ohms).”