Triveni and Engineering LTD

description

Transcript of Triveni and Engineering LTD

1

COMPANY PROFILE

Mr. Dhruv M. Sawhney, Chairman & Managing Director graduated with a Masters in

Mechanical Sciences from Emmanuel College, University of Cambridge, U.K. and M.B.A with

distinction from the Wharton School, University of Pennsylvania, U.S.A. He was on the Dean's

list for all terms, came second in the University, and is a life member of Beta Gama Sigma. Mr.

Sawhney has received the highest civilian award "Chevalier de la Legion d'Honneur" from

President Chirac of the French Republic.

Mr. Sawhney is a Past President of the Confederation of Indian Industry (CII), the Indian Sugar

Mills Association and the Sugar Technologists Association of India. He was the first Chairman

from the developing world of the International Society of Sugar Cane Technologists. Mr.

Sawhney has served on the Board of various public sector organizations and chaired Government

advisory councils on Industry, Energy and Sugar. He chairs the Commonwealth Leadership

Development Conferences founded by HRH Prince Philip, The Duke of Edinburgh in 1956 to

foster and broaden the understanding and decision-making ability of individuals in the

commonwealth countries. Mr Sawhney is Deputy Chairman of the Evian Group and Chairman of

the India Steering Committee of the World Economic Forum, Switzerland. He also chairs CII's

International and Internal Audit Committees.

Mr. Sawhney takes a keen interest in education, and was a past Governor of the Indian Institute of

Management, Lucknow, the Management Institute at the University of Delhi and Chairman of the

Doon School, Dehra Dun, one of India's most famous Public Schools. He is a Companion

Member of the Chartered Institute of Management, U.K. and chairs the Board of Trustees of

Delhi's oldest private charitable hospital. He was President of the All India Chess Federation for

12 years.

2

TRIVENI NGINEERING AND INDUSTRIES LIMITED

3

PERFORMANCE:

Particulars 2005-06 2008-09 % Increase

Sales (Gross) 12702.96 10212.92 24.38

Sales (Net) 11920.37 9610.50 24.04

Operating Profit ( EBIDTA) 2130.00 1724.46 23.52

Interest and Financial Charges 229.96 304.67 (24.52)

Depreciation and amortization 288.25 178.73 61.29

Profit before tax (PBT) 1611.79 1241.06 29.87

Tax liability- Normal 165.32 235.29

- Net deferred tax charges 131.51 10.57

Profit after tax (PAT) 1314.96 995.20 32.13

Surplus brought forward 82.40 44.55

Available for appropriation 1397.36 1039.75

APPROPRITATIONS

Provision for Dividend (included dividend

distribution tax)

Equity 147.54 93.95 57.04

Preference - 2.70 -

Transfers to molasses reserves 1.27 0.83

Transfer to capital redemption reserves 19.87 19.87

Transfer to general reserves 1150.00 840.00

Surplus carried forwarded 78.68 82.40

Earning per equity share of Re. 1 each (in Rs.) 5.88 4.77 23.27

4

During the year under review, the company reported a record performance across the

following parameters:

Net sales increased 24.04 % to Rs 11920.37 million.

Profit after tax increased 32.13 % to Rs 1314.96 million.

There was a remarkable growth in turnover in all the engineering units accompanied by an

attractive increase in their respective margins. The company is optimistic of a similar or higher

growth in turnover and profit of all businesses in Financial Year 2006-07.

Divisionwise breakup of total external sales (%)

79.17

16.86

2004-2005

SBG TBG CBG GBG WBG Others

1.190.36

1.5757

0.85

5

2005-2006

70.32

22.63

SBG TBG CBG GBG WBG Others2005-2006

2.481.691.77 1.12

6

CORPORATE INFORMATION:

Sl. No. Name and Address of Stock Exchange Stock Code

01. Bombay Stock Exchange Limited

Phiroze Jeejeebhoy Towers,

Dalal Street, Fort

Mumbai – 400023

532356

02. National Stock Exchange of India Ltd.

Exchange Plaza, 5th Floor, Plot no c/1, G block, Bandera (E),

Mumbai - 400051

TRIVENI

Enhancing shareholders value:

The Triveni public issue: The shares of Triveni Engineering & industries Limited are listed

on the Bombay stock Exchange and National stock Exchange, the major stock exchange of India.

The company issued 50 million equity shares in November 2005 and the issue was oversubscribed

more then ten times reflecting investor confidence. The equity shares of RS. 1 each were issued

through a book building process within a price range of Rs. 42.50. While 97% of the demand was

for shares in the upper band, the company prudently fixed the issue price at Rs. 48 in general

investor interest. Consequent to this issue, the equity shares of the company were listed on NSE

and BSE on 13 December 2005. As on 31 March 2006, reputed institutional investors including

mutual funds, foreign institutional investors and domastic banks held 21.53% of the company’s

shareholding. The closing price of Triveni share at NSE on 31 March 2006 was Rs. 125.95,

impaling a market capitalisation of Rs.32480 million. The company has increased the limit of

investment by FIIs to 49%, which will enable more international investors to participate in its

growth story.

7

8

Dec-06 Jan-06 Feb-06 Mar-060

2000

4000

6000

8000

10000

12000

4500

65006000 6300

75008000

7000

10800

8800 90009500

100009500

10000 1020011000

SHARE PERFORMANCE OF TRIVENI Vs BSE SENSEX

Triveni Share Price- BSE low Triveni Share Price - BSE highBSE Sensex low BSE Sensex high

At Triveni, our principal achievement is that we started with one business, but leverage our

engineering knowledge to extend into four other growing and profitable business.

9

SUGAR BUSINESS GROUP (SBG)

Highlights, 2005-06

13% increase in turnover from Rs. 7676.07 million in 2008-09 to Rs. 8663.25 million.

Recovery of the Deoband sugar unit of the highest in Western UP during the 2005-06 sugar

seasons.

60% increase in sugar capacity from TCD in 2008-09 to 40500 TCD.

Commissioning of the 7000 TCD Greenfield sugar unit in Sabitgarh in January 2006.

Outlook, 2006-07

Sugar prices are expected to stay firm for the next two years on account of domestic demand

and supply, high crude price influencing higher ethanol production as well as due to other

international factors.

The company will expend capacity from 40500 TCD to 61000 TCD in 2006-07

10

It will commission three Greenfield units in Chandanpur (6000 TCD) and Rani Nagal (5500

TCD) by the start of the 2006-07 sugar season; the third plant in Narainpur (6000 TCD) will

be completed in the fourth quarter of 2006-07; capacity expansion of the Ramkola sugar unit

from 3500 TCD to 6500 TCD will be complete by the start of the 2006-07 sugar season.

The company is setting up a captive 160 KLPD distillery for ethanol production that will be

commissioned in the fourth quarter of 2006-07.

Performance

The company achieved 7% higher crushed in 2005-06, a good performance as it competed

successfully with producers of alternative sweeteners to reduce cane diversion and increase

drawal of sugarcane. Further, the company produces Rs. 0.38 million tones of White sugar in

2005-06. Due to late rains, winter frodt and overfertilisation, the sugar recovereries in Western UP

were lower by around 0.6-0.7% than what had been achieved in 2008-09. Averages recover for

our sugar units declined from 10.08% in 2008-09 to 9.59% in 2005-06 due to the aforesaid. It is to

the company’s credit that despite poor

weather, the Deoband units reported one of the highest recoveries

among all Western UP sugar factories during the season under

review.

In Sugar Division area during the down turn, they invested in the modernization of the sugar

units to achieve benefits which are fully under their control and invested additionally in the

cogeneration plant to insulate themself from the sugar cycle, developing an alternative stable

revenue stream. Besides they invested in state-of-the-art vacuum pans in a joint collaboration with

sugar research international of Australia. The result of these initiatives is that when the industry

turned around, Triveni was in the right place at the right time with the right capacity and the right

efficiencies.

11

The government did not permit the import of white sugar during the last two years even when a

shortage was evident, but quite pragmatically allowed the import of raw sugar under an advance

License scheme with corresponding export obligations. Considering all the factors and as

described in detail in the Management Discussion and Analysis, the sugar outlook appears stable

till 2007.

The Khatauli sugar unit is being modernized and expanded to 16000 tcd and they are planning to

setup three new units, one of which will be set up at Sabitgarh, district Bulundshahar, UP. All

these units would have capacity of 5000-7000 tcd, expandable to 12000tcd. As a result, they

expect their sugarcane crushing capacity to significantly rise over our current base of 25250 tcd.

THE BRANDED SUGAR (SHAGUN)

The Company’s branded sugar is manufactured in ‘Khatauli’

and marketed under the Shagun Brand. The company

announced this sugar in 26 September 2003.the branded sugar

provides in 1-5 KG.packets. During the year under review, the

off take of Branded sugar increased by 44 % to 6522 MT.

While the market of branded sugar is not large, demand is

increasing due to increased urbanization and life style changes.And the branded sugar of Triveni

Shagun is packaged in a state-of-the-art sugar packaging section located in the sugar factory

premises. The sugar packaging section is considered to be the best designed sugar packaging

sections amongst all the players in branded sugar business in India.

THE COGENERATION GROUP (CBG)

12

Plant:

Khatauli and Deoband

Bagasse-based cogeneration

power is a renewable,

enviournmant friendly

driver of sustainable development. The government of India has issued the national electricity

policy, which calls for the promotion of cogeneration and generation from renewable

Sources of energy.

Performance, 2005-2006

222% increased in the division’s revenue from Rs. 188.03 million in 2004-2005 to Rs. 605.5

million.

304% increased in EBIDTA from Rs. 58.6 million in 2004-2005 to Rs. 237 million.

Commissioning of new 23 MW co-generation plant in Khatauli reported PLF of over 98% in

March 2006.

92% plant load factor for the Deoband unit across 207 days of working (99% and 100% PLF

in February and March 2006 respectively).

Power purchase agreement with Utter Pradesh Power Corporation Ltd. (UPPCL), the buyer

for the power supplied to the grid; timely payments from UPPCL for the power supplied.

Triveni’s co-generation units

DEOBAND:

Cogen plant at Khatauli was one of the quickest commissioning schedules for co-generation plants in India.

13

State of the art, bagasse-based co-generation unit with a capacity of 22 MW.

The company captivity consumed 31 % of the electricity produced by this plant and the rest

was supplied to the Utter Pradesh power corporation Limited, secured by a ten-year power

purchase agreement.

Plant operated at an average plant load factor of 92% for the 207 days it was operational in

2005-06; PLF could have been higher but for fuel shortage during the start of the sugar season

and high grid disturbances in January 2006. Plant achieved 99 % and 100 % PLF in February

2006 and March 2006 respectively.

KHATAULI:

State of the art and energy efficient, bagaees-based 23 MW cogeneration power plant

(commenced operation during 2005-06-sugar season).

The company captivity consumed 25 % of the electricity produced by this plant and the rest

was supplied to the Utter Pradesh Power Corporation Limited, secured through a 10- year

power purchase agreement.

One of the quickest commissioning schedules for co-generations plant in India. Commenced

the export of power in October 2005. After an initial period of stabilization, the cogen plant

has achieved full capacity; PLF was over 98 % for March 2006.

Additionally utilizes continuous Electro de-ionization (CEDI) process in its Boiler feed water

system (installed through the company’s water business Group) with the objective to

rationalize bulk acid and alkali handling as well as improve water quality. This is the largest

CEDI-based water treatment module in India and the first in a power plant in the country.

THE ENGINEERING BUSINESSES

Overview

14

GDP growth increased from 6.9% in 2004-2005 to 8.1% in 2005-2006, driven by the

manufacturing and power sector. The index of industrial production for February 2006 rose to

227.3, up 8.8% against the corresponding month of the previous year.

According to figures available, the IIP for mining, manufacturing and electricity sectors stood at

153.9, 242.3 and 186 respectively in February 2006 against 152.5, 221.3 and 170.7 in February

2005. The cumulative growth during April- February 2005-2006 in these three sectors was 0.5%,

9% and 5.3% respectively.

Power sector (including IPP and co-generation units)

India consumes almost 3% of the world’s commercial energy and is the sixth largest consumer

of energy in the World. During 2005, the recorded energy requirement was 626 billion units

whereas energy available was only 546 billion units, reflecting a shortage of 80 billion units

(13%).

Captive power

It is estimated that a capacity addition 100000 MW will be required by 2012 to bridge the

supply deficit. Electricity generation will have to grow at a minimum of 10% per annum in

order to support the targeted industrials and economic growth. The government expects to

bring around 5000 MW of electricity (2008) to the grid through the captive generation route to

supplement capacity addition.

Out of the country’s installed captive power generation of 18740 MW, steam generation

power accounted for 46%, followed by diesel-based power generation.

TURBINE BUSINESS

GROUP (TBG)

uvyfvhfyshcc gdftrth

The contribution of the division to the company’s revenue increased from 16.9% in 2004-2005 to 22.6% in 2005-2006

15

Turnover: Rs. 1.75 bnPlant: Bangalor

Overview

The turbine business unit was commissioned as a backward integration of the company’s sugar

buysiness.it is one of the largest manufactures of 1-12 MW steam turbine in the world with a 68%

market share in India’s high and low pressure turbine upto 18 MW.

Highlights, 2005-2006

71% increase in top line from Rs. 1626.4 million in 2004-2005 to Rs. 2779.9 million; 226%

increased in divisional profit from Rs. 114.3 million in 2008-09 to Rs. 373.1 million.

More than 500 basis point increased in EBIDTA margin from 11.1% in 2008-09 to 16.2%.

Current order book of Rs. 4.44 billion (159% of the division’s turnover in 2005-06).

Capacity increased from 300 MW in 2008-09 to 650 MW in 2005-06 in record time.

Outlook, 2006-2007

The company will expand its capacity by 70% effective from fourth quarter 2006-07.

Sales are expected to increase to over Rs. 5 billion in 2006-07, based on the strong domestic

demand and exports.

Increased exports to Europe and Asia, riding on the company’s worldclass technology, low

production cost and committed service. TBG exports are expected to increase to 20% of

turnover in two years.

Performance

The company’s turbine division posted an increase of 71% in its turnover from Rs.2779.9 million

in 2005-06. During the year under review, the division’s performance in terms of supply of

turbines, increased from 228 MW in 2008-09 to 425 MW in 2005-06 on account of a growing

power sector (co-generation and IPP) and growth in user industries (sugar, cement, paper,

pharmaceuticals and textiles etc.).

16

The contribution of the division to the company’s revenue increased from 16.9% in 2008-09 to

22.6% in 2005-06, indicating its growing importance.

GEAR BUSINESS GROUP (GBG)

Turnover: Rs. 275.5 bnPlant: Mysore, Karnataka

During 2005-2006, 51% of the GBG’s sales comprised product upto 7.5 MW, the rest above 7.5 MW.

17

Overview

The company’s gears division was started in 1976 to manufacture gears and gears boxes for the

turbine business group.competitiveness of this business has been reinforced through a technology

license agreement with Lufkin, the world leader in high speed gears.

Highlights, 2005-2006

89% increase in divisional revenue from Rs 238.8 million in 2004-2005 to Rs 450.3 million.

Increase in EBIDTA margin from 15.24% in 2008-09 to 20.85%.

Increased share of income from replacement activities from 25% of the total revenue in 2004-

2005 to 28% of the total revenue.

Manufacture of gear internals in the 15-25 MW segment under the terms of the new license

agreement.

Manufacture of several 50000 rpm speed gearboxes for ISRO for onward use in testing of

cryogenic engine pumps for satellites.

Emergence as the first company in India to manufacture a 36 MWhigh speed gearbox.

Outlook, 2006-2007

The company expects to enhance its presence in product segments like hydel gears and

provide high end technical solution in the low speed gearboxes segment.

Its expects to diversify its customer base, de-risking from cyclicality in any particular

industry.

Future growth of 30-35% expected in 2006-2007.

Performance

The company’s gear division posted an 89% increase in divisional revenue from Rs. 238.8 million

in 2008-09 to Rs. 450.3 million in 2005-06 and also EBIDTA margins improved from 15% in

2008-09 to 21% in 2005-06. It was protected from price increases in raw material due to long

18

term fixed price supply agreement with vendors. Besides, the company streamlined its

manufacturing and supply-chain process, rationalizing overheads and production costs.

WATER BUSINESS GROUP (WBG)

Turnover: Rs. 81.5 mn Plant: Noida

Overview

The company entered the business of water and waste-water treatment in 1984 as a turnkey

manufacture. The division was restructured in 2003 to manufacture and package equipment

aligned with its other engineering businesses.

Highlights, 2005-2006

The division’s revenue increased 69% from Rs. 81.6 million in 2004-2005 to Rs. 138.1

million.

EBIDTA increased 317% from Rs. 5.4 million in 2004-2005 to Rs. 22.5 million in 2005-2006.

EBIDTA margin strengthened from 6.6% in 2008-09 to 16.3% in 2005-06, reflecting the

impact of cost reduction.

The WBG exported components like the clarifier drive head to Envirex.

The unit has currently an order book of Rs. 130 million, which is an increase of over 140%

over the order book as on March 31, 2005.

Water business group posted a 69% increase in revenues from Rs. 81.60 million in 21004-05 to Rs. 138.1 million in 2005-06

19

Outlook, 2006-07

The division’s proposed Rs. 150 million expansion will comprise the setting up an office and

workshop for the WBG.

Following this expansion, the company will initiate the manufacture of critical components,

reducing its dependence on the capacity of subcontractors and enhancing cost efficiency.

The WBG exports three-digit growth in its top and bottom line in 2006-2007.

Performance

The company’s WBG posted a 69% increase in revenues from Rs. 81.60 million in 2008-09 to Rs.

138.1 million in 2005-06. The division’s EBIDTA increased 317% from Rs. 5.4 million in 2008-

09 to Rs. 22.5 million in 2005-06.the highlights of the year’s performance comprised:

A focus on team building; an increase in manpower from 45 on 31.03.05 to 56 on 31.03.06.

Successful commissioning of a double pass reserve osmosis system with a CEDI polishing

stage, as well as pilot for wastewater reuse system using the advance Memcor technology.

TRIVENI KHUSHALI BAZAAR

OVERVIEW

Triveni Khushali Bazaar is a one stop shop farmers and rural customers where they can buy agri-input, cattle feed, cycle, plastic furniture, FMCG, automobiles, building material and petroleum products.

Turnover: Rs. 12.4 mnPresence: Khatauli, Deoband & franchise store in Sisuali, Jansath & Ghatain

20

Triveni leveraged its rural presence with a Triveni leveraged its rural presence with a synergic

diversification into agri-retail through the commissioning of branded stores called Triveni

Khushali Bazaar. It is a one-stop shop for farmers and rural customers where they can buy agri-

inputs like seeds, fertilizers, pesticides; cattle feed, cycle, plastic furniture and FMCG;

automobiles like tractors and bikes; cement, diesel and petrol etc. Several companies like ITC,

DCM Shriram and Godrej enhanced their presence through rural retail stores.

The first Triveni Khushali Bazaar was commissioned in February 2005 and within two months,

generated revenues of Rs 12.4 mn. Encouraged by this success, company plans to open new stores

not only in the command area of the existing and proposed sugar mills but also in Western Uttar

Pradesh towns in near future.

Performance

For Triveni Khushali Bazaar, 2005-06 was the first complete year in existence. The division’s

strength increased from one store in 2004-2005 to 11 stores in 2005-06 corresponding to an

addition of 22,000 sq ft.The division’s stood at Rs. 162 million during the year under

review(including the period during which the business was carried out by the subsidiary).

SUSTAINABILITY BEYOND BUSINESS

Apart of these Businesses Triveni also participated actively in various SOCIAL AND

COMMUNITY SERVICES to enhance the quality of rural life in an around its areas of

influence.

Triveni Engineering and Industries Limited recognize that business growth is linked with societal

progress, resulting in social obligations being reconciled with business decisions.

EDUCATIONAL INITIATIVES

Schools: the company’s unit at Khatauli, Deoband and Ramkola run schools, where the admission

is open to all community sections with negligible fees.

21

It constructed a classroom and donated another to ‘The Government Model primary School’

and a prayer hall in ‘Government Junior College’ in Peenya.

Awareness programmes and workshops on literacy improvement, girl child education and the

abolition of dowry system were undertaken in sugar units in 2005-06.

The Deoband sugar unit conducted workshops in spreading awareness and educating the

community at large on safe drinking water.

The Khatauli sugar unit organized a programme in career counseling for student passing out

of school; it organized a sewing programme for ladies residing in the mill vicinity.

The Ramkola unit sponsored an inter school sports tournament.

HEALTH INITIATIVES

It organized two EYE CAMPS and two HEALTH CHECK-UP CAMPS in association with

I.M.A., providing free operation and treatment to all.

Dispensary and hospitals: Each of the company’s sugar units at Khatauli, Deoband and

Ramkola run a charitable dispensary and small hospitals.

Eye Camps: The Company’s Deoband unit organized two Eye camps through the District

Eye society for villagers; the sugar unit at Khatauli also organized an Eye camp in 2005-06.

Blood Donation Camps: The Company’s Khatauli unit organized blood donation camps.

OTHER SOCIAL INITIATIVES

Road Repairs: The Khatauli unit helped repair roads around the factory premises.

It repaired around 14 Kms of village approach roads and constructed 5 Km of new roads.

22

Trees: The Ramkola unit under took a programme of aggressive tree plantation in and around

the factory as a result of which 1100 trees were planted.

Food: The Deoband unit organized an annual langar and Gurugobind Sahib Path.

Culture: The Khatauli unit organized an Akhil Bhyartiya kavi Sammelan in which prominent

national poets participated.

It worked with ‘Child Labour Rehabilitation Cum Welfare Fund’ in Mysore.

It worked with the World Renewal Spiritual Trust, a unit of Brahma Kumaris in Mysore.

It contributed substantially and also participated actively in social activities and seminars, among

them noted a one ‘healthy lifestyle’s by Dr. Premasand from Mount Abu.

It participated in a chess tournament organized for raising funds for Tsunami relief with the help

of employee’s contribution.

It conducted Cricket and Football tournaments in Babbal, Rankhandi, Bhaila and other villages

RISK REVIEW

There are 12 types of risks, which can occur in the company at any time. These are:

1) Climatic Risk

2) Raw Material Risk

3) Regulatory Risk

4) Competition Risk

23

5) Liquidity Risk

6) Realization risk

7) Costs Risk

8) Funding Risk

9) Default Risk

10) Cyclicatic Risk

11) Technology Obsolescence Risk

12) Foreign Competition Risk

1) CLIMATIC RISK:

Cane is monsoon – dependent and monsoon failure could lead to a decline in cane availability.

Risk Mitigation:

The company’s units are situated in locations that enjoy abundant rain fall reinforced by

adequate irrigation facilities. High degree of irrigation in the western UP areas, where the

company’s three units are located, substantially insulates the cane crop from a monsoon failure.

The sugar units in the western UP are situated in the Doab, considered as one of the best regions

in India for cane cultivation, due to a fertile soil and adequate canal irrigation.

24

2) RAW MATERIAL RISK:

Cane is the main raw material for a sugar mill. Lower cane realizations may force farmers to

shift to other crops.

Risk Mitigation:

Cane is a rewarding crop over other cash crops. Further, cane prices announced by the central

and state governments ensure a reasonable return. The sugar mills help the growers to increase

yield and propagate premium verities, contributing to additional farmer income.

3) REGULATORY RISK:

The Sugar industry is influenced by the government’s sugar policy. Populist measures may

influence profitability.

Risk Mitigation:

The government has been pragmatic of late with respect of sugar policies. During the Last two

years, when production was low, the government allows the import of raw sugar under an advance

license with corresponding export obligations. This ensured that the immediate demands were met

and the exports could then take place from subsequent surplus stocks. There are currently only

few restrictions on the sugar industry, most important being the fixation of the cane price by the

government. Lately the sugar mills in western UP are paying a cane price higher then the

government recommended price and hence, this risk is only minimal.

4) COMPITITION RISK:

An increasing number of sugar mills in the company’s vicinity could increase the war for cane

and effect utilization and growth.

Risk Mitigation:

The companies have taken the following initiatives to ensure an adequate supply of required cane

from its command areas.

25

Maintaing strong farmer relations through timely payments.

Active involvement in cane development to increase cane yield and quality.

Reduce the diversion of cane for the manufacture of alternative sweeteners.

5) LIQIDITY RISK:

The company requires ready funds to meet working capital requirements. A lack of funds could

lead to a loss of raw material while a high cost could result in loss in profitability.

Risk Mitigation:

The company enjoys an excellent relationship with its bankers and has been able to mobilize its

working capital at competitive rates. The company also uses foreign currency loans and short-

term instruments like commercial paper to reduce overall cost. The company is rated A1+

(signifying highest safety) by ICRA with respect to short term loans, permitting is to access cheap

funds.

6) REALISATION RISK:

Any decline in sugar realizations could affect the Company’s performance.

Risk Mitigation:

The sugar units of the company are located in the vicinity of sugar deficit areas, like Delhi,

Haryana, Punjab and Rajasthan. As a result, it is able to earn relatively higher realizations.

Further, the sugar units produce substantial large crystal sugar brands its output, maximizing

realizations.

To insulate against advance realizations, the company commissioned a large cogeneration

capacity and has plans to set up a distillery, which are counter-cyclical to the sugar industry cycle

leading to stable earnings.

26

7) COSTS RISK:

An inefficient fiscal control may threaten margins and profitability, especially during an industry

downturn.

Risk Mitigation:

The company employs strict internal and budgetary controls adequately supported with an

effective management information system to keep costs low. The company has a centralized

procurement cell to meet the Requirements of all its sugar units; it is able to source large volumes

at the Best terms.

8) FUNDING RISK:

The company may not be able to complete its ongoing projects on schedule in the absence of

adequate financial resources.

Risk mitigation:

The company maximizes the equity contribution for its expansion. It’s gearing of less then one

allows it to borrow prudently and maximize the mobilization of low cost borrowing from the

sugar development fund.

9) DEFAULT RISK:

The company provides customized solutions in its engineering business. Any default in

receivables could skew its financial structure.

Risk Mitigation;

The company mitigates its risk through the following measures:

27

Appraisal of customer liquidity, both before initiating a contractual relationship with them and

also at different stages during the project.

Arranging timely receipts, both in terms of the advance at the initiation of the contract and at

various stages during the course of the project.

In the case of default, the company, after forfeiting the advance, can reengineer the Product

and supply it to another buyer after making suitable changes.

10) CYCLICATIC RISK:

As the turbine and gear divisions derive a higher share of their revenues from industries like

paper, sugar, steel and pharmaceuticals, a down turn in more than one can affect profitability.

Risk Mitigation:

The turbine and gear divisions supply their products to diversified sectors such as sugar,

cogeneration, independent power plants, paper and steel etc.Which mitigate the risk of cyclicality.

Further, there is an endeavor to enhance the product range with a view to enlarge the market size.

There is a focus to maximize the sourcing of profitable business from the supply of spares,

servicing, retro fitment and maintenance.

11) TECHNOLOGY OBSOLESCENCE RISK:

In a precision cum heavy engineering business, a company has to be quick to respond to

technology changes. Any delay could lead to a loss in market share.

Risk mitigation:

The company’s divisions are technology-conscious. Constant R&D initiatives, in – house product

development, extensive training programmes coupled with technology absorption from foreign

28

partners has made it possible for the company to upgrade its products. There is a system of

benchmarking product efficiencies with the best global standards.

12) FOREIGN COMPETITION RISK:

A number of international entrants could enhance competition.

Risk Mitigation:

The company enjoys established brand equity in the domestic and international markets in terms

of superior products and servicing, technology and refurbishment solutions, which will enable it

to withstand competition. The turbine division faces competition from imported products and yet

has maintained its market share at around 70 per cent. The company is focused on servicing

customer in innovative and efficient ways at a reasonable cost leading to prompt and reliable

services.

29

TECHNOLOGYS

TECHNOLOGIES IN SUGAR DIVISION:

Continuous Vacuum Pan

Syrup Clarifier System

Short Retention Clarifier

Continuous vacuum Pan

Developed by Triveni SRI Limited, a wholly owned subsidiary, in association with Sugar

Research International (SRI) of Mackay, Australia, the CVC was installed in the Deoband sugar

factory for usage on ‘C’ massecuite, the first time an SRI pan was installed for ‘C’ massecuite in a

sulphitation plant.

SRI is one of the sugar machinery technology authorities in the world; its subsidiary,

Triveni SRI Limited, has an exclusive license in India from SRI International for many of their

products. Owing to technical improvements made on the CVP, Triveni and SRI are now eligible

to jointly own the intellectual property for this new improved vacuum pan. Company has in the

past presented these details in a paper jointly presented with SRI at a convention of the

International Society for Sugar Sugarcane Technology.

30

Syrup Clarifier System:

Installed at the Deoband and Khatauli sugar plants to improve the quality of sugar, this

licensed product from SRI has been sold to EID parry in Tamil Nadu, where it is working

efficiently.

Short retention Clarifier:

To be installed in 2005-06 at the Khatauli unit and at the new plant, the clarification of

juice is achieved in only 30 minutes while in a normal clarifier juice is retained for approximately

150 minutes. This prevents the inversion of sugar and also leads to an improved sugar recovery

and quality.

Mill-Tandem:

Designed and manufactured by the company (captive technology), installed in company’s

sugar plants. The mill-tandem has proved to be one of the most efficient in India: reflected in the

reduction in Bagasse losses and increase in reduced mills extraction (RME); RME for the unit is

96 while that of the industry is around 95; bagasse loss in the unit is 1.6 compared to 1.9 for the

rest of the industry; strong design feature ensures a negligible downtime. Triveni has set up over

65 sugar plants and supplied over 300 cane mills to sugar factories in India and overseas.

TECHNOLOGIES IN TURBINE BUSINESS GROUP:

The business of turbines is perhaps more sophisticated then most other technology led

business on the grounds that it combines precision engineering with manufacturing. The

company’s most impressive accomplishment was the completion of an R & D project where in the

services of impact technologies (USA) and consulting professors from the Indian Institute of

31

Science, the Indian Institute of technology and the university of De Mont fort (UK) were utilized.

The result was the successful development of highly efficient low pressure twisted and tapered

blades. The company already has received orders for turbine incorporating these blades. The

company also developed new efficient turbine designs up to 22 MW.

TECHNOLOGIES IN GEAR DIVISION:

The company was selected by Lufkin France to execute a drafting and hi-end designing

assignment, which enhanced its high end design credibility. Due to pioneering engineering skills,

the company has established its reputation as a major player in the retro fitment segment for high

speed gears. As a result, it derives nearly 30 % of its revenue from this line of business, growing

its knowledge capability due to a continuous exposure to diverse technologies.

TECHNOLOGIES IN WATER BUSINESS GROUP:

Over the years, company has brought advance technologies to the Indian market through

close relationships with several business groups of US Filter Inc.:

Everex for conventional treatment equipment (license agreement since 1987).

Ion pure for continuous electro de-ionizing (CEDI) equipment.

Memcor for Membrane Bio-Reactor (MBR) and micro filtration membrane solutions and

equipment.

Process water system for process engineering and support.

The company expects to revolutionize India’s water and waste water treatment segments

through the introduction of various technologies relevant to the current / evolving market

needs, particularly the following:

32

CEDI Technology

Relevance: India’s water treatment business in the power sector

Source: Ion Pure (US Filter)

Replacing: Conventional de-mineralization based on resin.

Advantages:

Absence of chemical additives

Safe for human handling

Use of a tenth of the conventional space

Reduced boiler blow downs

Four year pay back

Membrane technology – micro filtration

Relevance: India’s wastewater treatment business in recycle / reuse segment.

Source: Memcor (US Filter)

Replacing: Conventional Clarifier and aerobic biological treatment

Advantages:

Barrier filtration technology that cans rationalize coli form content in polluted

water to less then safe limits making the water conducive for marine life.

Enhanced post- treatment water quality or downstream cities down to only 3-4

ppm BOD.

Zero discharge and the absence of additives to treat the water, minimizing side

effects.

Lower space requirement (a quarter of the normal plant size ) and a 40 % power

cost saving over the conventional system.

Minimal civic disruption; more then 70 % of value addition done in the

workshop.

33

Automated with minimal human interface.

FINANCIAL REWIEW

KEY PARAMETRES:

2006-07 2008-09

Return on Net worth (RONW) (%) 72.59 38.92

Return on Capital employed (ROCE) (%) 43.52 29.34

Total Debt Equity Ratio (Times) 2.74 0.79

EBDITA margin (%) 17.94 17.87

PAT margin (%) 10.36 11.03

Interest Cover (Times) 4.89 8.60

Book value (Rs. Per equity share of Re. 1, post bonus) 7.91 19.82

Financial and operational highlights

2004-05 2006-07 2008-090

2000

4000

6000

8000

10000

12000

5910.98

9610.58

11920.37

NET SALES

34

2004-05 2006-07 2008-090

500

1000

1500

2000

2500

646.487

1724.46

2130

EBIDTA

2004-05 2006-07 2008-090

200

400

600

800

1000

1200

1400

177.58

995.2

1314.96

Profit after Tax

35

2004-05 2006-07 2008-090

1

2

3

4

5

6

0.93

4.77

5.98

Earning Per Share (Post Bonus Issue)

2004-05 2006-07 2008-090

5

10

15

20

5.287.91

19.83

Book Value (Post Bonus Issue)

36

2004-05 2006-07 2005-060

0.51

1.52

2.53

3.54

3.74

2.74

0.79

Total Debt/ Equity Ratio

ACCONTING POLICIES:

Our company follows mercantile system of accounting to present credible reports to the

shareholders. The significant accounting policy followed by the company is stated in note 28 (1)

to the accounts.

PERFORMANCE:

The company followed the landmark in financial year 2008-09 with significant growth in

financial year 2005-06.

Net turnover was higher by 24% at Rs 11920.37 mn.

EBIDTA was higher by 24% at Rs 2130.00 mn.

PBT was higher by 30% at Rs 1611.79 mn.

PAT was higher by 32% at Rs 1314.96 mn.

EPS strengthened to Rs 5.88 from Rs 4.77 in the previous financial year.

37

As a result of this improvement financial performance and substantial equity infusion, the

financial condition of the company has strengthened as indicated by the various financial ratios.

TURNOVER

During the financial year under review, gross turnover increased by 60 per cent to Rs

10.21 bn, a record for the company. Sugar sales increased by 68 per cent, turbine sales by 33 per

cent and gear sales by 27 per cent. The cogeneration plant at Deoband commenced operations in

December 2004 and during the limited period of working in 2008-09 contributed Rs 183.3 mn to

the turnover.

Net turnover was 24% higher at Rs 11920.37 mn.there was an increase in turnover in all

the business segments. The turnover of the sugar operations increased by 13 % and that of

cogeneration by 222%. The turbine, gear and water divisions recorded an increase in turnover by

71%, 89%, and 69% respectively. The revenue of the various business segments are provided

below:

38

BUSINESS SEGMENT WISE GROSS REVENUE:

Rs. Million

Business segments 2008-09 2005-06

Sugar 7676.07 8663.25

Co-generation 188.03 605.50

Total - Sugar 7864.10 9268.75

Turbines 1626.41 2779.93

Gears 238.78 450.35

Water / waste water treatment 81.57 138.07

Total - Engineering 1946.76 3368.35

Others 21.16 157.79

39

39%

1%8%1%0%0%

40%

10%

2004-2005

Sugar Co-generation Turbines Gears Water- Waste Water Others

Total- Sugar Total - Engineering

34%

2%

36%

11%

2%

1%13%

1%

2005-2006

40

The net segment revenue provided here in is prior to the inter unit adjustments and further “other”

include operations of the agri centers up to October 25, 2005; following this date, the business

was carried out by a wholly owned subsidiary.

Sugar Division:

This division accounted for a gross turnover of Rs 8.13 bn, 78 per cent of the company’s revenue

in 2008-09.the revenue break - up in respect of its major products is given below:

Products 2008-09 2007-08 2006-07 2005-06 2004-05

Sugar 7461.8 4376.1 5087.6 4222.1 3571.8

Molasses 526.9 337.4 293.9 297.4 237.6

Bagasse 127.7 118.6 66.8 30.6 27.6

Others 15.2 14.0 9.6 10.0 22.7

A 22MW cogeneration plant was commissioned at the Deoband sugar unit with the twin

objectives to insulate the business from industry cyclicatic and provide steady alternatives

revenues.

Turbine

This division accounted for a gross turnover of Rs 1.75 bn, 17 per cent of the company’s revenue

in 2008-09. The product wise revenue break up is below:

41

Products and services 2008-09 2007-08 2006-07 2005-06 2004-05

Turbine 1486.9 117.3 959.3 806.8 720.1

Spares 133.1 118.7 121.3 113.3 127.0

Refurbishing 42.7 24.7 50.9 31.4 45.7

Others 84.7 56.9 56.2 43.4 26.7

Gears:

This division accounted for a turnover of Rs 275.5 mn, 3 per cent of the company’s revenue in

2008-09. Spares and services remained a high margin segment but accounted for only around 11

per cent of division’s turnover in 2008-09. The total division’s revenue grew by a CAGR of 29

per cent in five years.

Water / waste water treatment:

This division accounted for turnover of Rs 81.5 mn, 1 per cent of the company’s revenue in 2008-

09. While the base is currently small, in view of the company’s technology range and potential in

the industry, there is a substantial growth opportunity.

EXPENDITURE

Rs. MillionEXPENCES 2007-08 2008-09 % INCREASE

Raw material 6014.59 7621.63 26.72

Manufacturing Cost 521.41 614.70 17.89

Personnel cost 531.77 676.22 27.16

Administration & Selling Cost 395.33 511.58 29.41

Depreciation and Amortization 178.73 288.25 61.29

42

Finance Cost 304.67 229.96 (24.54)

Expenses as a % to Sales

5.43

62.58

5.534.111.863.17

2008-2009

Raw Material Manufacturing Cost Personnel Cost Administration and Selling

Depriciation and Amortization Finance Cost

43

5.16

63.94

5.674.292.421.93

2008-2009

Raw Material Manufacturing Cost Personnel Cost Administration and SellingDepriciation and Amortization Finance Cost

The various expenses are here below:

RAW MATERIAL:

With respect to the sugar operations, the increase was 18.74 percent due to an increase in

crush and cane procurement price. In the case of the engineering divisions, the increase was 55.66

per cent as against an increase in net turnover by 73.02 per cent.

MANUFACTURING EXPENCES:

In terms of the percentage to net sales, manufacturing expenses were marginally lower

then 2008-09.in the case of sugar operations, the expenses per unit of crush was Rs 131.11 per

MT of cane crushed as against RS 125.47 per MT in 2008-09. In respect to engineering units, the

44

total expenses were 2.36 per cent of the net sale whereas these were at 2.33 per cent of the net

sales in 2008-09.

PERSONNAL EXPENCES:

The increase in personnel cost was higher due to normal salary increase on an account of

the operations of the new co generation plant at Khatauli and new sugar unit at Sabitgarh. In the

case of the turbine, gear and water divisions, the personnel cost was also on account of increased

activity and expansion.

ADMINISTRATION AND SELLING EXPENCES:

With respect to the engineering division, expenses increased commensurately with

increased activity. There were additional expenses on account of the Sabitgarh sugar unit and the

Khatauli cogeneration plant, which were setup during the year.

DEPRICIATION AND AMORTISATION:

There was an increase in depreciation to the extent of Rs 112.92 million on account of

various projects capitalized during the year, namely the Khatauli co generation unit,

modernization an expansion of Khatauli unit, expansion of Deoband and the expansion of

infrastructure at the turbine and gear divisions.

FINANCE COST (NET):

The reduction was primarily due to decline in the finance cost on working capital due to

lower bank limit utilization by 37 percent owing to lower inventories carried as well as due to the

surplus funds including unutilized IPO proceeds. However, in the case of term loans, there was an

increased utilization by 52.5 per cent on account of various loans contracted for new projects,

Finance cost also reduced due to the overall cost of funds being lower.

45

MARGINS:

The PBIT margins of the company were 15.45 per cent higher at Rs 1841.75 mn. The

major contributories of the increase were the turbine and co generation operations where the

margins increased by 173 per cent and 265 per cent respectively.

The margins of the gear and water business also increased substantially and the margins of

the sugar operations declined marginally to Rs 2925 PMT of sugar sold as against Rs2959 PMT in

financial year 04-05.

SHARE CAPITAL:

The share capital increased from Rs 103.02 mn to Rs 257.88 mn. Outstanding preference

share of Rs 19.87 mn were fully re deemed on April 1st, 2005. The equity share capital increased

due to an issue of bonus share (in the ratio 3:2), which were allotted on 17-06-2005 and a fresh

issue of Rs 50 mn equity share in the recently concluded public issue which were allotted on 7 th,

December, 2005.

RESERVES:

Reserves as on March 31st, 2006 increased by 174.41 per cent from Rs 1838.27 mn as on 31st March 2005 to

Rs 5044.48 mn due to improved financial for the year under review as well as due to an accretion of share premium

of Rs 2350 mn relating to the public issue. The free reserve accounted for 96.27 per cent of the total reserves as on

31-03 –2006.

LOANS:

The total loans of the company declined by 10.55 per cent from Rs 4500.93 mn to Rs

4026.04 mn. Working capital limits reduced substantially by 38.41 per cent to Rs 1837.93 mn

whereas other loans increased by 44.25 per cent to Rs 2188.11 mn. The utilization of working

capital loans was lower due to lower average inventories during the year as well as due to a

parking of surplus funds (including unutilized public issues proceeds) in the cash credit account.

46

The increase in other loans was due to various funding availed for capital projects executed in the

financial year 2005-06.

FIXED ASSETS:

During the year under review, there were additions to fixed assets to the extent of Rs

3268.37 mn owing to various projects executed during the year.

INVESTMENTS:

During the year, the total investment reduced from Rs 229.75 mn to Rs 18.64 mn . The

investments in the preference share of group combines aggregating to Rs 211.50 mn were

redeemed and accordingly all such investments were realized during the year.

WORKING CAPITAL MANAGEMENT:

Net current assets marginally increased by 1.57 per cent to Rs 3572.68 mn in spite of a

new sugar unit and a cogeneration plant set up during the year.

Inventories reduced 7 per cent mainly on account of lower sugar stocks. However,

receivables increased by 50.55 per cent to Rs 1003.44 mn mainly on account of year end

dispatches, which could not be realized by the year end. The excise duty deposited substantially

increased from Rs 75.18 mn to Rs 251.70 mn in view of cenvat availed on capital goods, 50 per

cent of which would be available in the next accounting year. Current liabilities were higher as

advances from customers (mainly in the turbine division) increased from Rs 511.43 mn to Rs

798.63 mn.

FOREIGN EXCHANGE MANAGEMENT:

The company did not have significant foreign exchange exposure. The foreign exchange exposure

during the year was managed through forward covers as well as through derivatives. As at the

year-end, the amount involved in foreign currency in respect of payables and receivables was

equivalent to Rs 26.80 mn and Rs 35.77 mn respectively at the exchange rates that prevailed at the

year-end.

47

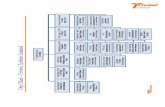

CORPORATE INFORMATION

Chairman and Managing Director

Mr. Dhruv M. Sawhney

Board of Directors

Dr. F.C. Kohli

Lt. Gen. K.K. Hazari (Retd.)

Mr. M. K. Daga

Mr. R. C. Sharma

Mr. V. Venkateswarlu

Mr. R. K. Kapoor (IDBI Nominee)

Vice President (legal) and Company Secretary

Mr. V.P. Ghuliani

Bankers

Punjab National Bank

Central Bank of India

Canara Bank

Oriental bank of Commerce

Union Bank of India

Standard Chartered Bank

State Bank of Travancore

UTI bank Ltd.

48

Auditors

M/s. J.C. Bhalla & Co.

Branch Auditors

M/s. Virmani & Associates

COMPANY’S BUSINESS LOCATIONS

Registered Office

Deoband, District Saharanpur

Utter Pradesh – 247554

Phone: (01336) 222497, 222185,222866

Fax: 222220

Corporate Office

‘Express Trade Towers’, 8th floor

15-16, sector 16 A, Noida 201301 (UP)

Phone: (0120) 5308000

Fax: 5311010-11

Share department/investors’ grievances

‘Express Trade Tower; 8th floor

15-16, sector- 16 A Noida 201301 (U.P.)

STD code: 0120

Phone: 4308000

Fax: 4311010-11

49

Email: shares@tr i venigroup . Com

Registrar and share transfer agents

For equity shares held in physical and electronic mode. M/s

Karvy computer share Pvt. Ltd. Karvy house,46, Avenue 4

Street No. 1, Banjara Hills Hyderabad 500034 STD Code :040

Phone: 23312454,23320751

Fax: 23311968

Email: mailmanager @ karvy.com

Turbine business group

12-A, peenya industrial Area, Peenya, Banglore-560058

STD Code: 080

Phone: 28394721(4 lines), 28394843, 28394771

Fax: 28395211

Gear business group

1, 2, 3 belagola industrial Area Metagalli, K.R.S. road,

Mysore-570016, STD code: 0821

Phone: 5280502, 5280501

Fax: 2582694

Fixed deposit section

Accounts Department

‘Express Trade Tower; 8th floor

15-16, Sector-16A Noida 201301 (U.P.)

STD Code: 0120 Phone: 4308000

Fax: 4311010-1

Email:[email protected]

50

Khatauli sugar unit

Khatauli, District- Muzaffarnagar

Uttar Pradesh –251201

STD code-01396

Phone: 272561, 272562

Fax: 272309

Deoband Sugar Unit

Deoband, District Saharanpur

Utter Pradesh – 247554

Phone: (01336) 222497,222185, 222866

Fax: 222220

Ramkola sugar unit

Ramkola, District-Kushinager

Utter Pradesh-247305

STD Code: 05567 Phone: 256021

Fax: 256248

Satigarh Sugar unit

P.O. Karora, Tehsil Khurja

Districrt-Bulandshare(U.P.)

STD Code: 05738

Phone:228894

Fax: 228893

Water business group

51

Express Trade Tower’ 8th floor

15-16, sector- 16 A

Noida 201301 (U.P.) STD Code: 0120 Phone: 4308000

Fax: 4311010-11

Cogeneration Khatauli

Khatauli, District- Muzaffarnagar

Uttar Pradesh –251201

STD code-01396

Phone: 272561, 272562

Fax: 272309

Cogeneration Deoband

Deoband, District Saharanpur

Utter Pradesh – 247554

Phone: (01336) 222497, 222185,222866

Fax: 222220

Branded Sugar Business

‘Express Trade Towers’, 8th floor

15-16, sector 16 A, Noida 201301 (UP)

Phone: (0120) 5308000

Fax: 5311010-11

52

Subsidiary Companies

Triveni SRI Limited

104, 1st floor,99 grand Plaza

Old Rajinder Nagar Market

New Delhi 110010

Upper Bari Power Generation Limited

1560, H.I.G. Ground floor

Sector 70, Mohal

Panjab 160062

Abohar Power Generation Limited

1560, H.I.G. Ground Floor

Sector 70, Mohali

Punjab 160062

53

SALE DEPARTMENT

Selling procedure of sugar

First of all the company gets the 100% production, which is sale according to sugar classification:

Free sugar : A turnaround in free sale sugar realizations commenced in February 2004, with

subsequent increase in May 2004 and January 2005.90% free sugar supply in open market by

Agent and agent will issue delivery order to sales office in muzaffarnagar, and sale office will

issue delivery order to sugar sale office Khatauli.then sugar office Khatauli issue delivery order

to sugar godwan.then sugar godwan on behalf of that delivery order send to a/c office kht. Sugar

godwan make invoice to the parties. The sugar unit Khatauli just has about 10-15 agents. All

agents take the commission @ 0.5%.

On free sugar, the govt. decides excise duty @ 85 per quintals and 2% education cess, 1-%

higher education cess.

On free sugar price decided by head office in Noida on the basis of demand and supply.

Levy sugar: levy sugar determined each year by the ministry of food and civil suppliers; govt.

of India. 10% levy sugar supply to different government agencies such as army, state govt.etc.On

levy sugar price Declared by govt. the basis of sugarcane recovery. On levy sugar have excise

duty @ 52 per quintals and 2% education cess; 1% higher education cess.

In case of cheque rejection : if bank seem to have any error in cheque due to some

reasons; such as in-sufficient balance, different sign.etc.then company can get interest and penalty

to the competent party upto date represent that cheque as per company policy.

Sale section Discussed by: Mr.kulvendre Singh

(Depti manager of sale department)

54

PURCHASE DEPARTMENT

Purchase department : purchase dept. purchase the raw materials for required dept. the company

make the committee for purchase the materials on the basis of length of materials. These are

categorized into two parts:

CPC (central purchase committee): this committee have made the purpose for bulk material

purchase. In CPC cover the 90% item of total purchase. In CPC include these items: Bearing,

Electrodes, lubricants, iron, steel, limb, sulpher, cement, chain, gunybags, motor electric,electric

cables, and all type of chemicals etc.

UPC(unit purchase committee): this committee have made the purpose for small material

purchase. in UPC cover the 10% item of total purchase.

Procedur e of purchase of material: first of all the Required dept. makes the indent and

approved by GM.this indent placed to the store dept.store manager see that material in this indent.

if in store room have not that material then this indent placed to the purchase dept.for purchase

that material.

A format of indent (required list of material)

Item Item name quantity UOM date urgent approx.

Floating of inquiry: this inquiry is related to take the actual information about indent. Its require

only 3-4party.

Preparation of comparative statement: A comparative chart is a formal document to take the

different prices from different parties about the material. Purchase manager prepares the purchase

order against the minimum price.

55

A format of comparative statement:

s.n. material

required

Quantity rate last purchased M/S. rates M/S. rates M/S. rates

Prepare the purchase order: according to the comparative statement purchase manager prepare

the P.O.and give the order to the party. Three copies are required to be send to accounting section,

purchase dept.and supplier.receive material to be send to store room. After checking the material

by required party to be supply to the party.

Sales tax: sales tax paid under two sections:

3B : for purchase the material same state @4%.

4C : when purchase the material from out side state @12%.

Discussed by: Mr. Mahavir Singh

(manager of purchase department)

IT AND CANE DEPARTMENT

IT dept have the all information about cane areas, farmer, issuing the purchee of farmer etc. IT

dept. maintain the all records of cane area as well as salary, cane development, GRP, store and

PF.

Because sugarcane is the only significant raw material for sugar industry.

Cane development staff: Triveni sugar mill has appointed dedicated cane development staff in

addition to a cane procurement team, helping farmers imbibe the best farm practices and achieve a

desired varietal mix with the objective to maximize recovery and yield. Cane development staff

56

providing access to advanced farming best practices, arranging timely remuneration and taking a

leadership position in community development.

In off-season the staff surveys to farmer’s sugarcane production, and gives the report to IT

dept.

After receiving the report, IT dept. prepare the purchee according to sugarcane. In this purchee

include 12 rows and 15 columns. The purchee can be classified into two parts:

Society purchee : in this purchee have included data only before supply the sugarcane.

Mill purchee : In this purchee have included data only after supply the sugarcane.

Growth of farmers : The company deals with approximately 2000000 farmers across its four-

unit.the Khatauli unit have approximately 50, 000 farmers (growers).

Price policy: The Indian government follows a dual pricing policy:

Statutory minimum sugarcane price(SMP ): the purchase price of sugarcane is announced by

the ‘central government’. The govt. fixed the price considering the recommendations by the

commission for agricultural costs and prices. in 2005-2006, the SMP declared by the government

was RS. 795 per metric tones for an average recovery of 9.0% plus RS. 8.8 for every 0.1%

increase in recovery. The recovery calculated on peak period.

State advisary price (SAP): A majority judgement of the supreme court dated 5 may 2004 held

that the state government in U.P., in exercise of its regulatory power as contained in the U.P.

sugarcane(regulation of supply and purchase) Act 1953, could fix the price of sugarcane.

Additional cane price: The state and central govt. declared the prices of sugarcane. both price

policy have a difference, the difference is called additional cane price.

57

Varieties of sugarcane: In sugarcane crop have the different varieties. on the basis of

varieties the government declared the different pricies.the varieties can be classified into three

parts:

Early variety: in this variety the crop is mature and sugarcane have maximum cane. on this

variety announced the premium at RS.5 per quintal. such varieties are COG64, COG83,

COG88230 etc.

General variety: general variety has minimum cane and maturity as compare to early variety. the

central govt. declared the price on general variety. such varieties are CO767, 8432 etc.

Rejected variety : rejected variety has very low cane and has very low maturity. rejected variety’s

price at RS. 2.50 (per quintal) low as compare to general variety.

Cane areas: every sugar unit has different capacity. The govt. can be allocated the areas on the

basis of mill capacity. the cane areas are classified into two parts:

Reserved areas: the govt. allocated these areas according to last year payment, capacity of mill

and distance of areas.

Assiend areas: Sometime the govt. allocates the reserve areas to the every sugar mill, if any mills

cover of their requirement than reminder of areas the govt. gives to other mill.

Purchase tax: the govt. announced the purchase tax every year. Every sugar unit gives the

purchase tax. In 2005-2006 the govt. announced the purchase tax @ RS. 2.0 per quintal.

Procedure of supply of sugarcane: Every mill has a procedure of supply of sugarcane.

Khatauli sugar unit has a supply capacity 150,000-quintal per day in sugar season. In this

procedure has many steps:

58

1. Firstly the mill makes the requirement.

2. Secondly the indent placed to the society.

3. The society distributed the purchee to the farmers.

4. Farmers supply of their sugarcane to the society.

5. The payment made by IT department.

Every sugarcane supplies through society. Societies take the commission a particular

percentage. In 2005-2006 season the society taking the commission @ RS. 3% on SMP. The

society can be classified into two parts:

Cane society

Cane council

Sometimes the govt. open of different centers in many areas. If farmers supply of their

sugarcane on these areas then farmers get some deduction on this supply. These areas give

deduction @RS. 5.75 per quintal to the farmers.

Sugarcane brings by different transportation. The cane manager decided of freight. The freight

can be decided on the basis of distance.

Payment to the farmers: the payment makes by the IT dept. every payment gives by the

cheque. All farmers have a bank account. Every payment gives through society. when bank

checking of purchase. After purchase checking the bank payment to the farmers. All payment

should gives within 15 days after receiving the sugarcane.

Sometimes any farmer has lost of their purchee, then farmer should be reported to the society

and IT dept. then IT dept. issue a duplicate purchee of the farmer.

59

Supply of burnt sugarcane: sometime in sugarcane crop has get burn from many reasons.

But society accepted of this supply on little deduction. on this burnt sugarcane gives the first

priority of supply.

The mill laboratory taking the sample of that sugarcane. the laboratory gives the report to

society.

Burnt sugarcane price declared by the DM on the basis of that laboratory report, general rate

and burnt cane recovery. After receiving the supply of that sugarcane, payment to the farmer

at the last of sugar seasons.

60

61

INTRODUCTION TO THE TOPIC

OVERVIEW OF SUGAR BUSINESS

The company’s installed capacity of 40500 tcd across the three units is among the largest

in India. The company’s Khatauli unit is credited with having crushed the largest quantity of

sugar across any unit in India in the 2005-06-sugar season.

RATIONALE FOR PRESENCE

India is the largest consumer of sugar and its per capita consumption is still below the

levels achieved by peer countries. With a projected increase in per capita incomes and an

improvement in lifestyle quality across India’s middle and lower economic classes, we expect that

sugar consumption will increase significantly on account of two factors: the crossover from the

consumption of gur and khandsari to sugar and an increase in direct consumption by all sections

of the Indian society.

COMPANY’S VALUE PROPOSITION

Sugarcane is the only significant raw material for the domestic sugar industry. Consequently,

any interruption in sowing or harvesting of sugarcane could lead to a detrimental impact on the

sugar industry at large and to our company.

Global sugar production is expected to increase from 144.05 MMT in 2004-2005 to 148.80 MMT in 2005-2006.

62

As a forward-looking organization, Triveni is actively engaged in mitigating foreseeable

risk factors. In relation to fostering the availability of sugarcane in its ‘command area’,

Cane Development Programme

Triveni protects farmer interests in a number of ways-ensuring consistent and equitable cane

purchases from farmers, providing access to advanced farming best-practices, arranging timely

remuneration and taking a leadership position in community development. In turn these initiatives

encourage farmers to allocate a significant acreage towards the cultivation of sugarcane, making

the arrangement mutually rewarding. The quality of the company’s output has helped it graduate

to the states of a major brand in India’s retail and wholesale markets, thereby enabling it to enjoy

a premium and a distinctive recall in a relatively unbranded marketplace.

The philosophy of the cane development and marketing is almost common for all the sugar units.

While in following paragraphs, description is for Khatauli but applies generally to Deoband &

Ramkola units as well. After identifying the constraints in the area of operation, the mill has

undertaken an ambitious programme of Cane Development for improvement in productivity and

quality of cane. The mill has separate cane development wing with qualified staff and experienced

personnel. For this purpose the operational area has been divided into sub-zones and the field

supervisory staff has been provided with the necessary facilities for efficient working and proper

supervision of the various cane development activities. The cane development programme is

planned with following activities:-

To educate the farmers regarding modern agricultural practices in sugarcane cultivation.

To replace the unapproved and degenerated cane varieties

To initiate and propagate the use of healthy and generically pure, seed material.

To initiate heat therapy for the treatment of cane seed through moist hot air treatment plant to

eliminate the diseases.

63

The details of various schemes of cane development being undertaken by mill are enumerated as

below:-

» Plantation of High Yield Variety of Sugarcane

» Seed Distribution

» Demonstration Plots

» Technical Assistance to Cane Growers

» Moist Hot Air Treatment

» Irrigation

» Ratoon Management

» Biological Laboratory

» Soil Analysis and Soil Treatment

» Control of Post Harvest Sugar Losses

» Awareness Among Cultivators

» General

64

COMPANY’S STRENGTHS

Advanced technological assets and capital equipment, represented by world-class continuous

vacuum pans at the B (sugar boiling) and C (sugar boiling) stages, resulting in boiling

consistency, uniform crystal size, reduced molasses purity, decline in steam consumption and

enhanced product quality. The technology and intellectual property for this equipment were

jointly developed with Sugar Research International, the premier Australian organization.

Positive recall in a competitive marketplace, translating into a premium and quicker off-take.

The location of the sugar manufacturing plants in the fertile Doab region (between the Ganga

and Yamuna rivers), resulting in a superior sugarcane quality and an exceptionally high yield.

Canal water availability over a large part of the region, representing one of the highest

penetrations of man-made water intervention in India, reducing the company’s dependence on

monsoon vagaries.

Established culture of cane cultivation in the region.

Largest cane crushing capability across any one unit in India (18.66 million quintals in the

2008-09-sugar season at Khatauli); a quicker crush enables the farmer to grow wheat on fallow

land and earn an attractive supplementary income.

Excellent cane procurement logistics, critical for any large sugar unit, demonstrated in the

systematic pooling of cane from no less then 220 purchase centers in the Khatauli command area

without any shortage or inventory pile-up.

Dependable relations with more than 160,000 farmers across the Khatauli, Deoband and

Ramkola command areas, resulting in a reliable and increasing supply of sugarcane.

Strong in-house technical and project management capability, resulting in the commissioning

of the Deoband co-generation project in the fastest implementation time lines; proposed

expansion of the Khatauli capacity from 11750 tcd to 16000 tcd.

65

Vast project execution experience in setting up sugar plants and carrying out expansions in

view of our earlier experience in sugar plant machinery and through our subsidiary, Triveni SRI

Limited.

INDUSTRY ANALYSIS

World Sugar

The forecast of the

world sugar balance

(October2004 to

September 2005)

indicates that

production will be 2

mn tones lower than consumption: world sugar output (October 2004 to September 2005) has

been estimated at 146.1 mn tones (raw value) as against 143.7 mn tones in the previous year while

consumption is estimated 2.1 per cent higher at 148 mn tones (raw value) with increased demand

coming out of Asia and the Far East.

Interestingly, leading trade house ED&F Man sees this global (2008-09, Oct-Sept) deficit

widening to 4 mn tones; its production estimate for 2008-09 is unchanged from its 2007-08

benchmark of 143 mn, while consumption, driven by Asia, is forecast to increase from 144 mn to

147 mn.

In fact, the principal factor behind the price rise over the past 18 months was the

conviction that global demand growth could outstrip production in 2008-09, depleting stocks, as

well as the belief that high oil prices may induce Brazil and other countries to divert more cane

towards the production of ethanol, reducing cane supplies directed towards sugar manufacture.

The total consumption of sugar increases by 1.2 MMT in 2003-04 to 18.5 MMT in 2004-2005.

66

Looking into the short-term, two developments are likely to tip yhr Asian balance: India’s

sugar consumption has been growing at an average annual rate of around 3 per cent over the last

ten years; besides, global sucrose demand, discounting the role of artificial sweeteners, is

expected to grow by around one mn tones a year. China too is likely to become a major importer

after 2007, given the limited availability of its resources to expand sugar production.

WTOSugar and dairy products are probably the most protected agricultural sector. As a result,

the impact of product-specific negotiations in the WTO Doha Round (as agreed in the July 2004

framework) on sugar was more significant then in the last WTO round of multilateral trade

negotiations.

The critical factors: the base period chose for the duty reduction commitments, the length

of the implementation period for making the reductions and whether sugar would be included in a

WTO list of sensitive products, which would allow it to escape a part of the WTO trade reform

process.

More recently, the World Trade Organization’s highest court issued a final ruling on April

28, 2005, ordering the European Union to stop dumping subsidized sugar illegally on the global

markets or face trade sanctions. The decision by the Who’s Appellate Body in Geneva gives the

EU up to 15 months to strictly comply with this directive. It is important to note that the export of

white sugar, especially from European Union, is heavily subsidized at prices less than 25 percent

of the prices prevailing in the European domestic markets. But for such exports, the international

prices of the white sugar would be higher and would in turn have a favorable impact on India’s

domestic prices.

In 2004, a panel of WTO experts estimated that the EU exported about four million metric

tones of sugar in 2004-05 (period under investigation) or about three times more then what the

rules permitted. As a result, any reform in this area will give Indian exports a significant boost and

have a positive impact on global prices.

67

India also suffers from a small quota in the Loma and ACP conventions, which gives

members a preferential price in the lucrative EU and US markets. Any increase in these quotas

could help domestic manufactures in the short term.

EthanolAt the 13th annual International Sugar Organization seminar in 2004, Chairman Francisco

varua (also President of the Philippines Sugar Millers Association) pronounced that ethanol could

become the sugar cane industry’s principal product by the end of the first decade of the new

millennium. Not only are fuel ethanol programmes spreading across the globe, but more players

are becoming aware of the need for cross-order trade to help the product become more

competitive against gasoline.

Since Brazil will need to raise ethanol production by 14 bn liters (25 mn tones sugar

equivalent) just to meet its growing domestic demand- this represents 175 mn tones of cane, 2.5

mn hectare of extra land and an addition 85 to 90 mills – FO Licht does not expect a large

Brazilian sugarcane crop to upset the world sugar balance, especially as ethanol is expected to

become dearer over the foreseeable future.

DOMESTIC INDUSTRY SCENARIO AND OUTLOOK

Industry Structure

The sugar industry in India is highly fragmented, with 566 sugar units spread over 16 states. The

total capital employed by the sugar industry is Rs 250 bn, annual sugarcane payments Rs 180 bn,

direct employment for 500,000 and the involvement of 45 mn farmer/families in cane growth.

The average size of each unit is approximately 3300 tcd, substantially below the new

international economic size of 7500 tcd. Nearly 35 percent of all Indian mills are in the private

sector, 6 per cent in the public sector and 59 per cent in the co-operative sector. Despite the large

68

recent profits shown by the Indian sugar industry, 112 mills – old and inefficient remained closed

during the year.

In a raw material-dependant industry, profitability is influenced by the following factors:

Cane availability:

Within the ‘reserved area’ of any factory, the yield and size of the area under sugarcane

are critical success drivers.

Economic size:

Without a minimum economic size of 5000 tcd (generally 10000 tcd in western Uttar

Pradesh), it is becoming increasingly difficult for a sugar unit to command pricing power.

Technology:

The ability to minimize sugar-processing losses depends on process technology.

Demand-pull:

The ability to draw a higher percentage of sugarcane from the reserved area reduces the

diversion to other sweeteners.

Sucrose content:

This is directly influenced by soil quality and cane development programmes initiated by

progressive manufacturers; a higher sugar content in sugarcane leads to the manufacture of more

sugar, while payment is still based on weight.

Operating efficiency:

The ability to bring cane in quickly from the fields and continuously operate a sugar unit

minimizes post-harvest sucrose evaporation.

OPERATIONAL PERFORMANCE:

69

The company achieved 7 % higher crush in 2005-06,a good performance as it competed

successfully with producers of alternative sweeteners to reduce cane diversion and increase

drawled of sugarcane. Further, the company produced Rs 0.38 million tones of White sugar in

2005-06. Due to late rains, winter frost and overfurtilisation, the sugar recovers in western UP