Train while producing. ConCepT Turn 450 · Train while producing. ConCepT Turn 450 EN4545 . 05/15 ....

Transcript of Train while producing. ConCepT Turn 450 · Train while producing. ConCepT Turn 450 EN4545 . 05/15 ....

Train while producing.ConCepT Turn 450

EN

4545

. 05

/15

. Sub

ject

to c

hang

e du

e to

tech

nica

l pro

gres

s. E

rror

s an

d om

issi

ons

exce

pted

.

CnC training with industrial performance

That’s e[M]ConoMy:[ ]

eMCo LM800

eMCo WinnC control units

[Tool turret]- 12 stations VDI 30 axial- Six stations driven upon request- Milling of polygons- Synchronized thread cutting

[Spindle]- High drive power- Thermo-stable assembly- Large rotational speed range- Spindle connection KK5- Maximum bar Ø 45 mm

[Control unit]- Up-to-date digital AC controlling

technology- LCD colour monitor- Integrated industrial PC and PLC- WinNC: all common NC control units on one machine

[Work area]- Best possible ergonomics- Unobstructed chip fall- Completely covered guideways

[Machine base]- Easy to transport - Large cooling reservoir- Easy to clean

A new dimension of CnC training suitable for industrial purposes. equipped with a C axis, driven tools and digital drive systems and components,

the function and performance of the Concept Turn 450 is in accordance with state-of-the-art industrial machines. Furthermore, with its interchan-

geable control system WinnC, it is perfectly adapted to the requirements of training situations today.

Concept Turn 450

[Machine covers]- Comprehensive protection against flying chips

- 100 % cooling medium tight- Optimal vision in the work area

- Large door safety glass

[Shelf]- Fold-out PC keyboard with PC mouse

[Short bar loader]- Shorter feed times- Individual part loading possible- Central diameter adjustment- Easy to operate- Quick and simple refitting- Small installation area

Hand wheel (Stainless steel)

Eccentric bolts (Stainless steel)

Geared wheel (Stainless steel)

Contour milling on the jacket surface

Milling of hexagon pieces

Metric thread M16 x 1

Contour milling on the face side

[Workpieces]

[engineering]

Simple to program using the EMCO WinNC control units

Simulation suitable for training using Win3D-View

0

1413121110987654321

0

20

40

60

80

100

120

140

1000 2000 3000 4000 5000 60000

1590

7000

M [Nm] P [kW]

n [rpm]

Performance and torque diagram for the main spindle

n Universal applicationsn Digital drive engineeringn Extraordinary dynamicsn Optimal thermostabilityn High processing accuracyn Compact machine assemblyn Made in the Heart of Europe

Highlights

n Concept TURN 450 TC with tailstockn Concept TURN 450 TCM with tailstock, C axis and driven tools

Versionsperformance

n Bar loadern Chip conveyorn 3 jaw chuck - 170 mmn Collet attachment 173 En Automatic doorn Integration into FMS or CIM systemsn Attractive tool packagen Part collecting devicen Driven tools

options

[Shelf]- Fold-out PC keyboard with PC mouse

The conversion to another control system is carried out within a minute by calling up the respective software and by simply replacing the controller specific module

The unique concept of the interchangeable control can be fitted to all Concept machines. In doing so, the user is trained on all CNC industry controls that are common on the market.The result: All CNC technicians can be applied more flexibly. And this is a decisive plus: for qualified employees as well as for the business.

[The interchangeable control]

Stro

ke X

239 257

Stroke center sleeve

SPF 65

KZF 173E

KFD-HS 160

Stroke Z

53

LK240

6

310

700

30

120

430

161

121

47

127145

120

130

460

47

-70 160

LK300

Details in millimeters

Work area

235 16301480

1865

38212250

330

15

201

1030

1345

1928

353

1

1 ......Option1

1

1

1198 2003 605 438,5418,5

1152

368

Details in millimeters

Machine layout

ConCepT Turn 450

EN

4545

. 05

/15

. Sub

ject

to c

hang

e du

e to

tech

nica

l pro

gres

s. E

rror

s an

d om

issi

ons

exce

pted

.

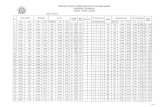

[Technical data]

Work area Swing over bed Ø 430 mm (16.9‘‘)Swing over cross slides Ø 210 mm (8.3‘‘)Distance between centres (Spindle nose – tailstock centre tip) 687 mm (27.0‘‘)Maximum turning diameter Ø 220 mm (8.7‘‘)Maximum turning length 310 mm (20.1‘‘)Maximum bar diameter Ø 45 mm (1.77‘‘)Travel Travel in X 160 mm (6.3‘‘)Travel in Z 310 mm (12.2‘‘)Main spindle Speed range 0 – 6300 rpmSpindle torque 78 Nm (57.5 ft/lbs)Spindle connection DIN 55026 KK 5 (A2-5)Spindle bearing (inside diameter) Ø 80 mm (3.1‘‘)Spindle bore Ø 45 / Ø 53 mm (1.77/2.1‘‘)C axis Resolution of the round axis 0,01°Rapid motion speed 1000 rpmSpeed 78 Nm (57.5 ft/lbs)Main motor Drive power (100% / 40% ED) 9 / 13 kW (12/17.4 hp)Tool turret Number of tool positions 12Tool holding shaft according the VDI (DIN 69880) 30Tool cross-section for square tools 20 x 20 mm (0.78 x 0.78‘‘)Shank diameter for boring bars Ø 32 mm (1.3‘‘)Turret indexing time 0.14 SecsDriven tools DIN 5480 Number of stations 6Power 4.0 kW (5.4 hp)Torque 16 Nm (11.8 ft/lbs)Speed range 0 – 5000 rpmFeed drives Rapid speed X / Z 20 / 24 m/min (787.4 / 944.9 ipm)

Feed drivesFeed force in the X / Z axis 4000 / 6000 N (899.2 / 1348.8 lbs)Acceleration time 0.1 SecsPosition variation Ps (according to VDI 3441) X / Z 0.003 / 0.005 mm (0.00014 / 0.00016‘‘)Standard tailstock Quill stroke 120 mm (4.7‘‘)Quill diameter Ø 60 mm (2.2‘‘)Quill thrust 5000 N (1124 lbs)Cooling agent equipment Tank volume 230 liter (60.8 Gal)Pump performance at 3.5 (optional 10 bar) 0.57 (2.2) kW (0.77 hp)Dimensions Rotary axis height above the floor 1152 mm (45.4‘‘)Machine height 1940 mm (76.3‘‘)Machine setting up area (B X T) 2250 x 1650 mm (88.6 x 64.2‘‘)Total weight 3300 kg (7260 lb)

Bar length 100 – 800 mm (3.9-31.5‘‘)Bar diameter 6 – 45 mm (0.24-1.77‘‘)Material supply E.g. 13 bars with Ø 45 mm (1.8‘‘)Length 1200 mm (47.4‘‘)Width 1150 mm (43.3‘‘)Weight Approx. 330 kg (727.5 lb)

eMCo LM800

eMCo WinnC control units

EMCO MAIER Ges.m.b.H.

Salzburger Str. 80 . 5400 Hallein-Taxach . Austria

Phone +43 6245 891-0 . Fax +43 6245 86965 . [email protected]

www.emco-world.com

ZERTIFIZIERT

TÜV AUSTRIA CERT GMBH

EN ISO 9001

ZERTIFIKAT NR. 20 100 20419

Sinumerik Operate 840D sl/828D FANUC Series 31iSinumerik 810D/840D FANUC Series 21Sinumerik 820 FANUC Series 0Sinumerik 810 Emcotronic TM02FAGOR 8055 TC

![[XLS] · Web view450. 90. 450. 900. 900. 225. 450. 450. 900. 450. 225. 270. 4.5. 450. 450. 450. 450. 450. 450. 450. 450. 450. 900. 450. 450. 450. 112.5. 900. 900. 450. 112.5. 450.](https://static.fdocuments.net/doc/165x107/5b3c17127f8b9a213f8d0b42/xls-web-view450-90-450-900-900-225-450-450-900-450-225-270-45.jpg)