Track Overview Telerik Software Academy Software Quality Assurance.

TRACK ASSURANCE warranty - Empire Cat · Track assurance program for Genuine Cat Undercarriage...

Transcript of TRACK ASSURANCE warranty - Empire Cat · Track assurance program for Genuine Cat Undercarriage...

-

1-800-EMPIRE-1www.empirecat.com

TRACK ASSURANCE :warranty Track assurance program for Genuine Cat Undercarriage coverage is four years, 4000 hours, or until the assembly is 100% worn – whichever comes first. What’s covered:u Oil leaks and breakage on new link assemblies, roller, and idlersu Oil leaks on dealer rebuilt exchange rollers and re-welded/re-shelled idlersu Breakage, under normal use, of new track shoes and sprockets/sprocket segmentsu Bushings with end grooving exceeding Cat re-use guidelines at turn timeu Severe heavy spalling that covers 30% or more of the link rail surfaceu Loose hardware

-

LINKSHardened for long life andexcellent sealability.Special heat treat processesgive Cat links consistentsurface hardness, superiorhardening depth, and strong

core hardness. This results in excellent wear resistance, strength, and durability forunmatched sealability and long life.

ROLLERSManufactured for increased life and lowcosts. Cat rollers are through hardened for longwear life, unmatched structural support, andresistance to deformation. Cat's Duo-Cone sealshelp ensure lifetime lubrication to extend life,

permit roller reshelling, and lower your costs.

SEGMENTSHardened forimproved wearresistance. Highsurface hardness and

excellent hardened depth and core hardnessmean Cat segments provide long wear life,resistance to bending and breakage, andmaximum hardware retention. The bolt-ondesign reduces replacement time.

PINS AND BUSHINGSMatched to links for strength and sealability. Catpins and bushings are dimensionally matched to thelinks and manufactured to provide excellent trackjoint integrity. This design helps ensure maximumsealability. High surface and core hardness translateinto increased strength and wear resistance.

SEALSDesigned for long life andlow costs. To keepabrasives out and oil in, theCaterpillar rigid seal designcombines high wearresistance and load

protection. The result is a "wet" joint at turn time, which extends bushing life and lowers your cost.

IDLERSManufactured for more wear resistance andless downtime. Whether cast, forged, orfabricated, Cat idlers provide superior structuralsupport and rebuild capabilities. Special heat

treat processes help ensure proper hardness levels, providing wearresistance. Duo-Cone seals help ensure lifetime lubrication. eliminatingidler maintenance and lowering operating costs.

TRACK SHOESHardened and temperedfor better wear resistance.Caterpillar track shoes arefurnace hardened andtempered for strength andresistance to bending and

breakage. We offer a variety of track shoeoptions to meet the requirements of your workenvironment.

14

5

2

3

6

7

4 PINS AND BUSHINGSMatched to links for strength and sealability. Cat pins and bushings are dimensionally matched to the links and manufactured

to provide excellent track joint integrity. This design helps ensure maximum sealability. High surface and core hardness translate into increased strength and wear resistance.

TRACK SHOESHardened and tempered for better wear resistance. Caterpillar track shoes are furnace hardened and tempered for strength and resistance to

bending and breakage. We offer a variety of track shoe op-tions to meet the requirements of your work environment.

SEALSDesigned for long life and low costs. To keep abrasives out and oil in, the Caterpillar rigid seal design combines high

wear resistance and load protection. The result is a “wet” joint at turn time, which extends bushng life and lowers your cost.

IDLERSManufactured for more wear resistance and

less downtime. Whether cast, forged or fabricated, Cat idlers provide superior structural support and rebuild capabilities. Special heat treat processes help ensure proper hardness levels, providing wear resistance. Duo-Cone seals help ensure lifetime lubrication. Eliminating idler main-tenance and lowering operating costs.

u Professional ExpertiseuField service capabilitiesuParts exchange programuIn-territory undercarriage shopuCustom track service managementuWet-bushing turn within two business daysuNew and parts exchange parts inventory stocked for same-day delivery

2 3

5 6

7

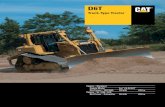

Caterpillar® undercarriage components work as a powerful system to propel your machine over all types of terrain — including Arizona and Southeastern California’s soil, which is some of the most abrasive and highest impact in the United States. These systems wear at balanced, manageable rates, providing consistently longer life with minimal downtime. Empire’s undercarriage management techniques, coupled with the systems’ high level of serviceability, assure maximum system performance and lower operating costs, even in the high-abrasion and impact applications that are typical to the southwest.

EMPIRE ADVANTAGECUSTOM TRACK SERVICETo ensure you get the absolute most from your machine, Caterpillar offers Custom Track Service (CTS), a service to help manage

undercarriage systems. Our parts and service representatives will perform inspections to project remaining wear life, in order

to schedule maintenance. Equipped with the advanced tools and necessary parts to perform cost-efficient, accurate

track work, CTS minimizes downtime and gets machines back to work quickly.

BENEFITS OF A WET-BUSHING TURNWet turns extend the life of the link by reducing internal

heat and wear. Plus, turned bushings with new oil and seals reduce noise for increased operator comfort.

The process consists of complete link tear down, every pin and bushing inspected for re-usability, new seals,

bushing turned and new oil. Caterpillar bushings can be wet-turned by Empire technicians in about two days. Most other

shops require three weeks to do a dry turn.

“Empire’s support capabilities combined with Caterpillar quality virtually eliminates any undercarriage related downtime and provides Ashton with the lowest cost per hour. Empire also adds value to the Ashton Companies with operation suggestions and in-depth knowledge of undercarriage works and wear.”

- Clint Schweigert, Equipment Manager The Ashton Company

:servicability

BREAKDOWN OF AN UNDERCARRIAGE SYSTEM

1 LINKSHardened for long life and excellent sealability. Special heat treat processes give Cat links consistient surface hardness, superior

hardening depth and strong core hardness. This results in excellent wear resistance, strength and durability for unmatched sealability and long life.

ROLLERSManufactured for increased life and low costs. Cat rollers are through hardened

for long wear life, unmatched structural support and resistance to deformation. Cat’s Duo-Cone seals help ensure lifetime lubrica-tion to extend life, permit roller reshelling and lower your costs.

SEGMENTSHardened for improved wear resistance.

High surface hardness and excellent hardened depth and core hardness mean Cat segments provide long wear life, resistance to bending and breakage and maximum hardware retention. The bolt-on design reduces replacement time.

Empire’s management techniques and Caterpillar’s long lasting undercarriage combine to provide you the most life at the lowest possible cost per hour.