Towards a better model for reactive magnetron sputter...

Transcript of Towards a better model for reactive magnetron sputter...

Towards a better model for reactive magnetron sputter deposition

Title

Towards a better model for reactive magnetron sputter deposition

D. Depla, R. De Gryse

Towards a better model for reactive magnetron sputter deposition

440

400

360

320

2802.01.51.00.50.0

0.65

0.60

0.55

0.50

0.45

0.402.01.51.00.50.0

flow (sccm) increasing flowdecreasing flow

dis

ch

arg

e v

olta

ge

(V

) to

tal p

ressu

re (

Pa

)

A first experiment

S (Pumping speed) : 16 L/sPAr (argon pressure) : 0.4 PaI (current) : 0.4 AStep : 2 minutesTarget : AluminiumReactive gas : oxygen

Towards a better model for reactive magnetron sputter deposition

Why does the voltage change ?

0discharge

0 i ISEE

WV

mE====

ε ε γε ε γε ε γε ε γ

W0 : effective ionisation energy

εεεεi : ion collection efficiency (for magnetron : almost 1)

εεεε0 : fraction of maximum possible number of ions (for magnetron : almost 1)

m : multiplication factor : accounts for ionisation in the sheath

E : effective ionisation probability : influenced by electron recapture

γγγγISEE : ion induced secondary electron emission coefficient

A voltage change is related to 1) a change of the plasma composition (W0) 2) and/or a change of the target composition (γγγγISEE / E)

G. Buyle, “Simplified model for the DC planar magnetron discharge (PhD, UGENT,2005)D. Depla et al. J. Appl. Phys. 101 (2007) 013301/1-013301/9

Depla D. et al. SCT 200 (2006) 4329 -4338

Towards a better model for reactive magnetron sputter deposition

Why does the pressure change ? The Berg model

Prof. Berg in Ghent

Effective gas pressure

targ

et

q0

qP

qt

qc

o p t cq q q q= + += + += + += + +

S. Berg et al., TSF 476 (2005) 215– 230

Towards a better model for reactive magnetron sputter deposition

How to calculate these flows ?

(((( ))))tt t tq F 1 A− θ− θ− θ− θαααα====

(((( ))))cc c cq F 1 A− θ− θ− θ− θαααα====

pq pS====+

Total reactive gas flow

The chemical reaction on the target and on the substrate is defined by chemisorption.

pF

2 kTM====

ππππThe effective reactive gas pressure defines the flux

The coverage of the target and substrate is given by θθθθ

tθθθθ

FF

oxide

oxide

metal

metal

For more about the chemisorption mechanism : C. Li et al. J. Phys. D: Appl. Phys. 37 (2004) 1065–1073

t1− θ− θ− θ− θ

c1− θ− θ− θ− θcθθθθ

Towards a better model for reactive magnetron sputter deposition

How to calculate the θ’s ?

(((( ))))t t d t c

2F1 I Y

zα − θ = θα − θ = θα − θ = θα − θ = θ

At the target side

F

A balance between chemisorption and compound sputtering

t

t

d c

2F

z2F

I Yz

ααααθ =θ =θ =θ =

+ α+ α+ α+ α

tθθθθ t1− θ− θ− θ− θ

Towards a better model for reactive magnetron sputter deposition

How to calculate the θ’s ?

(((( )))) (((( ))))(((( ))))d t m td t c t

c c c c

s s

I 1 Y AI Y A2F1 1 0

z A A

− θ− θ− θ− θθθθθα − θ + − θ − θ =α − θ + − θ − θ =α − θ + − θ − θ =α − θ + − θ − θ =

At the substrate side t

θt

1 θ−

cθ

c1 θ−

FFF1

F2

F4F3

A balance between chemisorption and deposition of compound and metal.

(((( ))))

d t c tc

sc

d t m td t c tc

s s

I Y A2F

z A

I 1 Y AI Y A2F

z A A

θθθθα +α +α +α +

θ =θ =θ =θ =− θ− θ− θ− θθθθθ

α + +α + +α + +α + +

Towards a better model for reactive magnetron sputter deposition

Final solution scheme

The “trick” to solve : choose a pressure and calculate a flow.

p F θθθθt

qtqp

θθθθc

qc q0

1.2

0.8

0.4

0.0

flow

(sccm

)

2.0x10-3

1.51.00.50.0

pressure (mbar)1.20.80.40.0

flow (sccm)

2.0x10-3

1.5

1.0

0.5

0.0

pre

ssu

re (

mba

r)

SWAP X and Y axis

Towards a better model for reactive magnetron sputter deposition

Is the S-shape real ?

AlOx: O2 Partial Pressure vs. Flow

IRESS Partial Pressure Control

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

O2 Partial Pressure, mTorr

O2 F

low

, sccm

Increasing

Decreasing

Target Power = 600 W

Pulse: 75 kHz, 2.5 µsec reverse

20 sccm Ar: 2.40 mTorr

Measurement by W.D. SproulSee also W.D. Sproul et al. SCT 89(1997) 10-15

Towards a better model for reactive magnetron sputter deposition

Interpretation : let’s play(1)

2.0

1.5

1.0

0.5

0.0

flow

(sccm

)

2.52.01.51.00.5

total flow (sccm)

to the pump to the target to the substrate

1.0

0.8

0.6

0.4

0.2

0.0

theta

2.52.01.51.00.5

total flow (sccm)

substrate condition target condition

Towards a better model for reactive magnetron sputter deposition

Interpretation : Take care

The abrupt change mechanism is related to substrate condition, and is only noticed when plotting against the flow. As a function of the pressure (or mole fraction), there is no abrupt change !

1.0

0.8

0.6

0.4

0.2

0.0

theta

targ

et

0.040.030.020.010.00

pressure (Pa)

Towards a better model for reactive magnetron sputter deposition

A second experiment : playing with the pumping speed

0.25

0.20

0.15

0.10

0.05

0.00543210

-160

-120

-80

-40

0 S =16 L /s

S =32 L /s

S =65 L /s

S =130 L /s

flow (sccm)

pre

ssure

diffe

rence (

∆P

a)

volta

ge d

iffe

rence (

∆V

) PAr (argon pressure) : 0.4 PaI (current) : 0.4 AStep : 2 minutesTarget : AluminiumReactive gas : oxygen

Towards a better model for reactive magnetron sputter deposition

Interpretation : let’s play(2)

0.25

0.20

0.15

0.10

0.05

0.00543210

-160

-120

-80

-40

0 S =16 L /s

S =32 L /s

S =65 L /s

S =130 L /s

flow (sccm)p

ressure

diffe

rence

(∆

Pa)

vo

lta

ge

diffe

ren

ce (

∆V

)

Model Experiment

Clear shift of the critical points

The critical points are fixed !

General trend is good :A more narrow hysteresis athigher pumping speed

0.04

0.03

0.02

0.01

0.00

pre

ssu

re (

Pa

)

3.53.02.52.01.51.00.5

flow (sccm)

16 L/s 32 L/s 65 L/s 130 L/s

Towards a better model for reactive magnetron sputter deposition

A more detailed look

0.25

0.20

0.15

0.10

0.05

0.00543210

-160

-120

-80

-40

0 S =16 L /s

S =32 L /s

S =65 L /s

S =130 L /s

flow (sccm)

pre

ssure

diffe

rence

(∆

Pa)

vo

lta

ge

diffe

ren

ce (

∆V

) Vincrease

Vdecrease

Remarkable constant

Plasma composition changes strongly

Conclusion : influence of oxygen presence is negligible on V increase

Towards a better model for reactive magnetron sputter deposition

What causes the voltage increase ?

380

360

340

320

300

targ

et

vo

lta

ge (

V)

0.50.40.30.20.1

sputter time (s)

exposure time 5s 10s 20s 40s 80s 160s 320s 640s 1280s 2560s 4260s1.7x10-4 mbar

1

sta

tus

01

0

sta

tus

1

0

sta

tus

V

metallic mode

argon flow

oxygen flow

magnetron

target potential

∆t

Towards a better model for reactive magnetron sputter deposition

Chemisorption does !

oxid

efo

rmat

ion

chem

isor

ptio

n

mon

olay

erO

-20

-10

0

10

Vo

ltag

e ch

ange

(V)

102

103

104

105

oxygen exposure (L)

Constant pressure

experiments

Constant exposure

time

A chemisorption of oxygen results in a voltage increase.Oxide formation results in a voltage decrease, but …only at very high exposures

Towards a better model for reactive magnetron sputter deposition

Another problem

400

380

360

340

320

300

280

260

240

vo

lta

ge

(V

)

0.001 0.01 0.1 1 10time (s)

time

sta

tus

sta

tus

voltage

sta

tus

argon

oxygen

magnetron

VAr

VO2VoxAr

∆t

0.4 A

Thickness calculated is order of 2 nm

D. Depla et al. Solid Films 515 (2006) 468- 471

Towards a better model for reactive magnetron sputter deposition

Stability experiments Al/O2

time

sta

tus

sta

tus

voltage

sta

tus

argon

oxygen

magnetron

VAr

VO2VoxAr

∆t

-40

-38

-36

-34

-32

-30

V3

0m

s-V

Ar (V

)

6

102 4 6

1002 4 6

10002

waiting period (s)

The voltage changes without sputtering : Real ?

D. Depla et al. Plasma Sources Sci. & Techn. 10 (2001) 547 -555

Towards a better model for reactive magnetron sputter deposition

Stability experiments N2/Si

500

480

460

440

420

targ

et vo

ltag

e (

V)

8006004002000

time (s)

waiting period 0 s 1 s 12 s 120 s 1200 s 2430 s

Stability experiment for Si/N2

60 V

ch

an

ge !

D. Depla et al. Vacuum 66 (2002) 9-17

Towards a better model for reactive magnetron sputter deposition

Abrupt changes as a function of the mole fraction ?

40

30

20

10

0

-10

-20

-30

volt

age d

iffe

rence -∆

V(V

)

0.80.60.40.20.0mole fraction nitrogen

1.0

0.8

0.6

0.4

0.2

0.0

the

ta t

arg

et

0.040.030.020.010.00

pressure (Pa)

D. Depla et al. Vacuum 66 (2002) 9-17

Towards a better model for reactive magnetron sputter deposition

Some first conclusions

+ The Berg model shows the general trend.+ But … some details are hard to understand from this model.

Voltage increase by chemisorption. How does the target becomes oxidized ?

Sputter cleaning of the target : a much thicker layer than 1 monolayer is formed

Stability experiments : reaction and/or diffusion

Possible explanation : ion implantation and knock on implantation

Abrupt changes of the target as a function of the mole fraction

Towards a better model for reactive magnetron sputter deposition

True ? More proof.

1.8 MeV D+

14N(d,α0)12C

14N(d, α1)12C*

0.4 0.5 0.6 0.7 0.8

0

2

4

6

8

10

12

0

1

2

3

4

5

6

7

8

9

0.4 0.5 0.6 0.7 0.8

increasing N2 flow

decreasing N2 flow

Nitro

gen

pa

rtia

l pre

ssu

re

(10

-5 m

bar)

Nitrogen flow (sccm)

increasing N2 flow

decreasing N2 flow

Magnetron off

N

itro

gen

are

al de

nsity

(10

15 a

tom

s c

m-2)NRA measurements during

magnetron sputtering

See next talk for more details !

Guttler D., Abendroth B., Grotzschel R., Moller W., Depla DAPL 85 (2004) 6134 -6136

Towards a better model for reactive magnetron sputter deposition

Need for a new model : STEP 1

Implementation of ion implantation during reactive magnetron sputtering

First step : Let’s look to sputtering in combination with ion implantation

No chemical reaction !

Red : implantation profileGreen : the target

(((( )))) (((( ))))(((( ))))t

r S s0

ˆn x, t 2fI p x X x t t′ ′′ ′′ ′′ ′= + − ∂= + − ∂= + − ∂= + − ∂∫∫∫∫

Surface concentration ~ 1/Y

Towards a better model for reactive magnetron sputter deposition

Ag/N2 experiments

410 405 400 395 390binding energy (eV)

inte

nsi

ty (

a.u

.)

After Ar sputter cleaning

After nitrogen gas exposure

After nitrogen implantation

No chemical reaction between nitrogen and silver

Depla D. et al. VACUUM 69 (2003) 529 -536

Ion implantation of N2+

in a silver target, mounted in a magnetron

Towards a better model for reactive magnetron sputter deposition

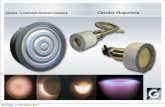

Ag/N2 experiments

Experimental set-up

Magnetron

Circular target : 2 inch

Target material : Ag

Ion source

shutter

Ion implantation of N2+

in a silver target, mounted in a magnetron

Towards a better model for reactive magnetron sputter deposition

Ag/N2 experiments

333.2

332.8

332.4

332.0abso

lute

tar

get

volt

age

(V)

80604020

sputter time (s)

Ion implantation of N2+

in a silver target, mounted in a magnetron

After implantation : magnetron running in pure argon

After implantation : waiting period + magnetron running in pure argon

350

345

340

335

abso

lute

tar

get

volt

age

(V)

806040200

sputter time (s)

increasing

implantation doseLonger waiting period

Towards a better model for reactive magnetron sputter deposition

Need for a new model : STEP 2

Chemical reaction between implanted reactive gas and target materialNo chemisorption

x 0

s b

D D-s

Ta

rge

t su

rfa

ce

q

x 0

implantation depth D

D D-s

θθ θθsm

θθ θθsr

θθ θθb

mθθ θθ

br

ions

What occurs in the target ?Implantation defined by the profileChemical reaction : reaction rate = knmnR with k the reaction rate constantMovement towards the target surface.

Towards a better model for reactive magnetron sputter deposition

Solution of step 2 in steady state

0

s b

D D-s

Ta

rge

t su

rfa

ce

q

x 0

implantation depth D

D D-s

θθ θθsm

θθ θθsr

θθ θθb

mθθ θθ

br

0

s b

D D-s

Ta

rge

t su

rfa

ce

q

x 0

implantation depth D

D D-s

θθ θθsm

θθ θθsr

θθ θθb

mθθ θθ

br

Start situation Start situation + ∆∆∆∆t

In steady state : when the slab reaches the surface, the chemical reaction finishes and the oxidation degree at the target surface must be equal to θθθθsr

The slab moves at a speed given by the erosion rate.The sputter yield of the target : Ys=θθθθrsYr+ θθθθmsYm defines the erosion rate.

D. Depla et al. J. Phys. : Appl. Phys. D, 40 (2007) 1957–1965

Towards a better model for reactive magnetron sputter deposition

Two ways of testing

ϕϕϕϕ

Oblique reactive ion implantation

Constant mole fraction f=1Variable metal sputter yield

Reactive magnetron sputtering

Variable mole fraction fConstant metal sputter yieldChemisorption/Knock-on possible

In both experiments the target condition is defined by the implantation of reactive species and the sputtering process

Towards a better model for reactive magnetron sputter deposition

Two ways of testing the model

40

30

20

10

0

-10

-20

-30

volt

age d

iffe

rence -

∆V

(V)

0.80.60.40.20.0mole fraction nitrogen

Oblique reactive ion implantation Reactive magnetron sputtering

1.0

0.8

0.6

0.4

0.2

0.0

de

gre

e o

f o

xid

atio

n

706050403020100angle of incidence

Experiment : 5 keV O2+ ion beam on Si

XPS measurement of degree of oxidationIon current density : 1015 - 1016 ions/(cm2.s)

Experiment : 50 W Sputtering Si/N2

Discharge voltage changecharacteristic to target conditionIon current density : 1017 ions/(cm2.s)

D. Depla et al. Vacuum 66 (2002)

Alay et al. Phys. Rev 50 (1994)

Towards a better model for reactive magnetron sputter deposition

First way

Implantation profiles : SRIM

Sputter yield dependency : H. De Witte UAntwerp, PhD (2001)k = 1x10-22 cm3/(at.s)

1.0

0.8

0.6

0.4

0.2

0.0

de

gre

e o

f o

xid

atio

n

806040200

angle of incidence(°)

experimental data (taken from Alay et al. Phys. Rev. 1994)

θb

θs

Towards a better model for reactive magnetron sputter deposition

Second way

Using the same reaction rate constant buta constant sputter yield for metal and compound

No abrupt change ?

40

30

20

10

0

-10

-20

-30

volt

age d

iffe

rence -∆

V(V

)0.80.60.40.20.0

mole fraction nitrogen

1.0

0.8

0.6

0.4

0.2

0.0

de

gre

e o

f o

xid

atio

n

0.160.120.080.040.00

mole fraction oxygen

θrb

θrs

Towards a better model for reactive magnetron sputter deposition

Second way (2)

Fits with the experiment : N has a lower affinity for Si than O.

1.0

0.8

0.6

0.4

0.2

0.0

degre

e o

f oxid

ation

0.60.50.40.30.20.10.0

mole fraction reactive gas

θrb

θrs

k=1

k=3.2k=10

k=100

k values in unit of 1x10-23

cm3/(at.s)

Towards a better model for reactive magnetron sputter deposition

Need for a new model : knock on and chemisorption

Chemical reaction between implanted reactive gas and target materialWith chemisorption and knock-on implantation

x 0

s b

D D-s

Ta

rge

t su

rfa

ce

q

0

implantation depth D

D D-s

θθ θθsm

θθ θθsr

θθ θθb

mθθ θθ

br

ions

neutrals

θθ θθsc

knock-on

Simplification : knock-on profile is identical to implantation profile

sm2F

z

αθ

smI

z

βθ

Towards a better model for reactive magnetron sputter deposition

Influence chemisorption

Fixed reaction rate constant : 1x10-23 at/(cm2.s)Knock-on probability ββββ=0

1.0

0.8

0.6

0.4

0.2

0.0

degre

e o

f oxid

ation

1.00.80.60.40.20.0

mole fraction reactive gas

α=0α=0.001α=0.01

α=0.05α=0.1α=0.5α=1

Walking from Uppsala to Ghent

Towards a better model for reactive magnetron sputter deposition

Influence knock-on

Fixed reaction rate constant : 1x10-23 at/(cm2.s)Sticking probability αααα = 0.01

1.0

0.8

0.6

0.4

0.2

de

gre

e o

f o

xid

atio

n

1.00.80.60.40.20.0

mole fraction reactive gas

sticking coefficient α=0.01

β=0β=0.001β=0.01β=0.05β=0.1β=0.5β=1

Towards a better model for reactive magnetron sputter deposition

Knock-on vs. ion implantation

Sputter yield Subsurface oxidation

Knock on vs. direct reactive ion implantation

0.5

0.4

0.3

0.2

0.1

targ

et

sp

utt

er

yie

ld

0.40.30.20.10.0

reactive gas mole fraction

chemisorption/knock-onreactive ion implantationchemisorption

1.0

0.8

0.6

0.4

0.2

0.0d

eg

ree

of

oxid

atio

n0.40.30.20.10.0

reactive gas mole fraction

chemisorption/knock-onreactive ion implantation

Towards a better model for reactive magnetron sputter deposition

How to calculate the flows ?

Effective gas

pressure

targ

et

q0

qP

qt

qc

o p c tq q q q= + += + += + += + + Essential the same as in the Berg modelbut one must account for knock on and ion implantation

sct sm s rb t

I zq F Y A

2 2

βθβθβθβθ = αθ − + θ= αθ − + θ= αθ − + θ= αθ − + θ

Towards a better model for reactive magnetron sputter deposition

Let’s model

Calculation of the critical points

Ac ααααt

k ββββ ααααc

380

(150)

2.0E-23

(4.9E-26)

0.22

(0.093)

0.35

(0.13)

0.17

(0.034)

Acααααt kββββααααc

3087 combinations6 results in a good fit

Towards a better model for reactive magnetron sputter deposition

Discharge voltage increase

-160

-120

-80

-40

0 S =16 L /s

S =32 L /s

S =65 L /s

S =130 L /s

vo

lta

ge

diffe

ren

ce (

∆V

) Vincrease

Vdecrease

0.14

0.12

0.10

0.08

θcs

,max

16 32 65 130

pumping speed (L/s)

25

20

15

10

5

dis

cha

rge

vo

ltag

e d

iffere

ren

ce(V

)

Towards a better model for reactive magnetron sputter deposition

Stability experiment

-40

-38

-36

-34

-32

-30

V3

0m

s-V

Ar (V

)

6

102 4 6

1002 4 6

10002

waiting period (s)

0.15

0.10

0.05

0.00

θrb

,20

s-θ

rb,s

tead

y s

tate

0.250.200.150.100.050.00

mole fraction oxygen

Target oxidation after 20 s without ion bombardment

Target oxidation during ion bombardment

Towards a better model for reactive magnetron sputter deposition

The future : things we should think about

… and the future :

+ The plasma contains more then neutral reactive gas molecules+ The deposition is not uniform+ The target erosion is not uniform+ Other types of magnetrons behave differently

Conclusions :

The implementation of reactive ion implantation is necessary to understand the details

Towards a better model for reactive magnetron sputter deposition

The future : deposition profile

0.08

0.06

0.04

0.02

0.00

oxyg

en

pre

ssu

re (

Pa)

1.81.61.41.21.00.80.6

flow (sccm)

0.9

0.7

0.5

0.3

0.1

0.9

0.7

0.5

0.3

0.1

0.9

0.7

0.5

0.3

0.1

0.9

0.7

0.5

0.3

0.1

1.00.80.60.40.2

θc

Profile Homogeneous

0

0.2

0.4

0.6

0.8

1

-90

-75

-60

-45

-30-15015

30

45

60

75

90

Implementing the deposition profile by segmenting the substrate. The future is combining this with a simulation program for transport

Mahieu S. et al.NIMB 243 (2006) 313 -319

Towards a better model for reactive magnetron sputter deposition

The future : erosion profile

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

-25 -15 -5 5 15 25position on the target (mm)

de

pth

(m

m)

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0.001.71.51.31.10.9

flow (sccm)

oxyge

n p

ressu

re (

Pa)

1.00.80.60.40.20.0

θsr

Implementing the erosion profile by segmenting the target based on the measured race track. The future is to measure the effective current density on the target.

Towards a better model for reactive magnetron sputter deposition

The future : rotating magnetrons

250

270

290

310

330

350

370

0 0.5 1 1.5 2 2.5

oxygen flow (sccm)

dis

ch

arg

e v

olta

ge

(V

)

0 RPM

1.1 RPM

2.4 RPM

5.8 RPM

8.9 RPM

19.5 RPM

26.5 RPM

40.1 RPM

64.1 RPM

Towards a better model for reactive magnetron sputter deposition

Time plays an important role

0.1

1

10

100

flow

(sccm

)

0.01 0.1 1 10time (s)

Berg model presented model

Same hysteresis, and some steady state, but different kinetics !

J. Musschoot et al.J. Phys. D : Appl. Phys. 39 (2006) 3989-3993

Towards a better model for reactive magnetron sputter deposition

Some things to remember

RSD2007, Leoben, Austria, 6 and 7 December 2007

ICTF14, November 2008in Ghent, Belgium

tθ

t1 θ−

cθ

c1 θ−

FFF1

F2

F4F3

tθ

t1 θ−

cθ

c1 θ−

FFF1

F2

F4F3 Berg model : a good starting point

x 0

s b

D D-s

Targ

et

su

rfa

ce

q

x 0

implantation depth D

D D-s

θθ θθs

mθθ θθ

sr

θθ θθb

mθθ θθ

br

ions

More detailed and necessary to describe the kinetics

Some things to remember …

Reactive Sputter Deposition (ed. Depla, Mahieu) : Beginning 2008, Springer

Towards a better model for reactive magnetron sputter deposition

Acknowledgements

+ R. De Gryse : introduction to the fun of magnetrons+ J. Haemers : development of sputter sources+ S. Mahieu : simulation and measuring of the deposition profiles+ L. Xiuyang : rotating cylindrical magnetrons+ G. Buyle : discharge voltage interpretation

+ S. Berg : long and nice discussions about reactive magnetron sputtering+ W. Möller : NRA measurements