Tosello Micro Injection Molding

Transcript of Tosello Micro Injection Molding

Micro Injection M

oldingTosello

Guido Tosello

Micro Injection Molding

Tosello Micro Injection Molding

Micro Injection Molding

Guido Tosello

Hanser Publishers, Munich Hanser Publications, Cincinnati

Distributed in the Americas by: Hanser Publications 6915 Valley Avenue, Cincinnati, Ohio 45244-3029, USA Fax: (513) 527-8801 Phone: (513) 527-8977 www.hanserpublications.com

Distributed in all other countries by: Carl Hanser Verlag Postfach 86 04 20, 81631 München, Germany Fax: +49 (89) 98 48 09 www.hanser-fachbuch.de

The use of general descriptive names, trademarks, etc., in this publication, even if the former are not especially identified, is not to be taken as a sign that such names, as understood by the Trade Marks and Merchandise Marks Act, may accordingly be used freely by anyone. While the advice and information in this book are believed to be true and accurate at the date of going to press, neither the authors nor the editors nor the publisher can accept any legal responsibility for any errors or omissions that may be made. The publisher makes no warranty, express or implied, with respect to the material contained herein.

The final determination of the suitability of any information for the use contemplated for a given application remains the sole responsibility of the user.

Cataloging-in-Publication Data is on file with the Library of Congress

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying or by any information storage and retrieval system, without permission in writing from the publisher.

© Carl Hanser Verlag, Munich 2018 Editor: Dr. Julia Diaz Luque Production Management: Jörg Strohbach Coverconcept: Marc Müller-Bremer, www.rebranding.de, München Coverdesign: Stephan Rönigk Typesetting: Kösel Media GmbH, Krugzell Printed and bound by Druckerei Hubert & Co GmbH und Co KG BuchPartner, Göttingen Printed in Germany

ISBN: 978-1-56990-653-8 E-Book ISBN: 978-1-56990-654-5

The Author:

Guido Tosello, PhD Associate Professor Technical University of Denmark Department of Mechanical Engineering Produktionstorvet, DTU building 427A DK-2800 Kgs. Lyngby Denmark

The contributors to the “Micro Injection Molding” book are greatly acknowledged for their timely and professional inputs in connection with their respective chapters. They are Dr. Maksims Babenko, Dr. Giuliano Bissacco, Dr. Elaine Brown, Dr. Matteo Calaon, Dr. Ali Davoudinejad, Dr. Gualtiero Fantoni, Ms. Carla Flosky, Dr. Donata Gabelloni, Dr. Christian Andrew Griffiths, Prof. Hans Nørgaard Hansen, Dr. Aminul Islam, Prof. Hiroshi Ito, Dr. Ryo Kaneda, Dr. Giovanni Lucchetta, Dr. Da-vid Maximilian Marhöfer, Dr. Davide Masato, Dr. Paritat Muanchan, Dr. David Bue Pedersen, Dr. Volker Piotter, Dr. Danilo Quagliotti, Dr. Oltmann Riemer, Dr. Marco Sorgato, and Dr. Ben Whiteside. Gratitude and appreciation is extended to Dr. Mark Smith at Carl Hanser Verlag for his support throughout the book’s development, and to his coworkers for copyediting and typesetting the final version of the book.

Much of the early work presented in this book generates from research carried out during the period 2004–2009 by the Polymer Micro Technology Division of the European Network of Excellence 4M (Multi-Material Micro Manufacture), of which I have been fortunate to be an active member. The contributions during those early days from the core members and colleagues of the Polymer Micro Technology Divi-sion (Mr. Sabino Azcarate, Dr. Pieter J. Bolt, Prof. Stefan Dimov, Dr. Bertrand Fillon, Dr. Chris Griffith, Dr. Mathias Heckele, Prof. Lars Mattsson, Dr. Stephan Roth, Dr. Andreas Schneider, and Dr. Andreas Schoth) are greatly acknowledged. Fur-thermore, the contributions to the advancement of micro injection molding science and technology achieved during the European project COTECH (converging technologies for micro systems manufacturing) in the period 2008–2012, in which I was responsible for micro molding process control, metrology, and simulation, have also set the basis of much of the content present in this book. Key profession-als and great colleagues in the COTECH Consortium that are greatly acknowledged for inspiration and scientific insights are: Mr. Sabino Azcarate, Prof. Phil Coates, Dr. Franco Costa, Prof. Stefan Dimov, Dr. Chris Griffith, Mr. Helmut Loibl, Dr. Hum-bert Noll, Mr. Martin Philipp-Pichler, Dr. Manfred Prantl, Dr. Andreas Schoth, and Dr. Ben Whiteside. I would like to thank them for sharing their expertise, for valu-able discussions, and for a great friendship that has lasted throughout the years.

Acknowledgments

VI Acknowledgments

On the personal side, I would like to thank my family for their constant love, sup-port, encouragement, and understanding. This book is dedicated to the loving memory of my mother.

Guido ToselloTechnical University of Denmark

Department of Mechanical Engineering

Kgs. Lyngby, Copenhagen, Denmark

Micro injection molding is the preferred process technology for the mass pro-duction of polymer micro components. Micro molded parts are characterized by dimensional tolerances in the micrometer range, high surface finish in the sub- micrometer down to optical range, and high geometrical complexity. Micro injec-tion molding is used to manufacture highly valued micro medical components (sensors, implants, tubes, catheter tips), micro optics, microfluidic systems, and micro mechanical systems, among others. The global market of micro injection molding is expected to reach USD 1 billion by 2020 with a compound annual growth rate between 10–15% in the period 2013–2020. High demand for micro molded parts is seen from the medical, healthcare, automotive, and electronics sectors.

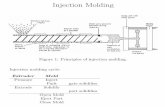

To exploit the micro molding technology process capabilities and take advantage of research and market opportunities, there was a need for a dedicated book that deals exclusively with micro injection molding and the knowledge to overcome the challenges of successfully managing and processing polymer materials at these ultra-small scales. This book meets that need. Micro injection molding is indeed not just a simple downscaling of conventional injection molding, and specific material-process-product interactions must be understood in order to achieve near zero-defect net-shape micro molded products.

“Micro Injection Molding” is written for engineers, researchers, project managers, consultants, and other professionals involved in precision polymer processing and micro manufacturing. The book provides a comprehensive, up-to-date, and detailed treatment of the main topics related to micro molding. It includes the underlying physics of micro polymer processing and replication at the micro/nano scales, as well as fundamentals of micro molding machine construction and tool making technologies (micro machining, surface treatments). The book also discusses in detail supporting technologies for high-precision micro molding such as quality control of micro parts, micro additive manufacturing for micro product prototyp-ing, and process simulation. Process variations such as vacuum-assisted micro molding and multimaterial processing (micro two-component injection molding,

Preface

VIII Preface

metal and ceramic micro molding) bringing further opportunities for advanced micro manufacturing are presented in detail as well.

The book is composed of 13 chapters organized in four parts (see table below):

� Part 1 – Polymer Materials and Process Micro Technology � Part 2 – Tooling Technologies for Micro Mold Making � Part 3 – Micro Molding Key-Enabling Technologies � Part 4 – Multimaterial Micro Processing

“Micro Injection Molding” Book Chapters Organized in Four Parts

Part Chapters Illustrations1. Polymer Materials and Process Micro Technology

1. Micro Injection Molding Machines Technology

2. Micro Molding Process Monitoring and Control3. Polymer Materials Structure and Properties in Micro Injection Molding Parts4. Surface Replication in Micro Injection Molding

2. Tooling Technologies for Micro Mold Making

5. Micro Machining Technolo-gies for Micro Injection Mold Making

6. Ultra-Precision Machining Technologies for Micro Injection Mold Making7. Surface Treatment of Mold Tools in Micro Injection Molding

IXPreface

3. Micro Molding Key-Enabling Technologies

8. Vacuum-Assisted Micro Injection Molding

9. Modeling and Simulation of Micro Injection Molding10. Metrological Quality Assu-rance in Micro Injection Molding11. Additive Manufacturing for Micro Tooling and Micro Part Rapid Prototyping

4. Multi-material Micro Processing

12. Micro Powder Injection Molding

13. Multimaterial Micro Injection Molding

Guido Tosello, PhD, is Associate Professor at the Technical Uni-versity of Denmark, Department of Mechanical Engineering, Section of Manufacturing Engineering. He is senior lecturer, research manager, supervisor of PhD, MSc, and BSc pro jects, and industrial and management consultant. Guido’s principal research interests are the analysis, characterization, monitor-ing, control, optimization, and simulation of precision molding processes at micro/nano scales of thermoplastic materials.

Technologies supporting precision/micro/nano molding processes are of research interest, for example: advanced process chain for micro/nano tools manufacturing, quantitative validation of injection molding simulation, additive manufacturing, dimensional and surface micro/nano metrology, measurement calibration and uncertainty, statistical process control, design of experiment, polymer materials characterization, design and manufacture of 3D precision/ micro components and micro/nano structured surfaces, and multimaterial and micro insert molding.

Guido Tosello is the recipient of the “Technical University of Denmark Best PhD Research Work 2008 Prize” for his PhD thesis “Precision Moulding of Polymer Micro Components”; of the 2012 Alan Glanvill Award by The Institute of Materials, Minerals and Mining (IOM3) (UK), given as recognition for research of particular merit in the field of polymeric materials; of the Young Research Award 2014 from the Polymer Processing Society (USA), in recognition of scientific achievements and research excellence in polymer processing within six years from PhD gradua-tion; and of the Outstanding Reviewer Award 2016 of the Institute of Physics (UK) for his contribution to the Journal of Microengineering and Micromechanics.

About the Author

XII List of Contributors

�� List of Contributors

Dr. Maksims Babenko University of Bradford, RKT Centre for Polymer Micro and Nano Technology, UK

Dr. Giuliano Bissacco Technical University of Denmark (DTU), Department of Mechani-cal Engineering, Lyngby, Denmark

Dr. Elaine Brown University of Bradford, RKT Centre for Polymer Micro and Nano Technology, UK

Dr. Matteo Calaon Technical University of Denmark (DTU), Department of Mechani-cal Engineering, Lyngby, Denmark

Dr. Ali Davoudinejad Technical University of Denmark (DTU), Department of Mechani-cal Engineering, Lyngby, Denmark

Dr. Gualtiero Fantoni University of Pisa, Department of Civil and Industrial Engineer-ing, Italy

Ms. Carla Flosky University of Bremen, LFM Laboratory for Precision Machining, Institute of Manufacturing Technologies, Bremen, Germany

Dr. Donata Gabelloni Erre Quadro s.r.l., Pisa, ItalyDr. Christian Andrew Griffiths Swansea University, College of Engineering, Swansea, UKProf. Hans Nørgaard Hansen Technical University of Denmark (DTU), Department of Mechani-

cal Engineering, Lyngby, DenmarkDr. Aminul Islam Technical University of Denmark (DTU), Department of Mechani-

cal Engineering, Lyngby, DenmarkProf. Hiroshi Ito Yamagata University, Graduate School of Organic Materials Sci-

ence, Department of Organic Materials Science, Yamagata, JapanDr. Ryo Kaneda Yamagata University, Graduate School of Organic Materials Sci-

ence, Department of Organic Materials Science, Yamagata, JapanDr. Giovanni Lucchetta University of Padova, Department of Industrial Engineering,

Padova, ItalyDr. David Maximilian Marhöfer Technical University of Denmark (DTU), Department of Mechani-

cal Engineering, Lyngby, DenmarkDr. Davide Masato University of Padova, Department of Industrial Engineering,

Padova, ItalyDr. Paritat Muanchan Yamagata University, Graduate School of Organic Materials Sci-

ence, Department of Organic Materials Science, Yamagata, JapanDr. David Bue Pedersen Technical University of Denmark (DTU), Department of Mechani-

cal Engineering, Lyngby, DenmarkDr. Volker Piotter Karlsruhe Institute of Technology, Material Process Technology,

Eggenstein-Leopoldshafen, GermanyDr. Danilo Quagliotti Technical University of Denmark (DTU), Department of Mechani-

cal Engineering, Lyngby, DenmarkDr. Oltmann Riemer University of Bremen, LFM Laboratory for Precision Machining,

Institute of Manufacturing Technologies, Bremen, GermanyDr. Marco Sorgato University of Padova, Department of Industrial Engineering,

Padova, ItalyDr. Guido Tosello Technical University of Denmark (DTU), Department of Mechani-

cal Engineering, Lyngby, DenmarkDr. Ben Whiteside University of Bradford, RKT Centre for Polymer Micro and Nano

Technology, UK

Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VII

About the Author . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . XIList of Contributors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . XII

PART 1 Polymer Materials and Process Micro Technology . . . . . . . 1

1 Micro Injection Molding Machines Technology . . . . . . . . . . . . . . . 31.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Patent Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Architectures and Solutions for Micro Injection Molding Machines . . . . 91.3.1 Introduction to Functional-Based Modelling . . . . . . . . . . . . . . . . . . 91.3.2 Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121.3.3 Functional Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 Micro Molding Process Monitoring and Control . . . . . . . . . . . . . . 312.1 The Need for Process Monitoring in Micro Molding . . . . . . . . . . . . . . . . . 31

2.2 Micro Molding Sensor Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322.2.1 Volumetric Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322.2.2 Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342.2.3 Pressure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352.2.4 Ultrasonic Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.3 Visualization Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382.3.1 Tool Design for Visualization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Contents

XIV Contents

2.3.2 High-Speed Imaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392.3.3 Thermal Imaging Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.4 Data Acquisition and Archiving Systems . . . . . . . . . . . . . . . . . . . . . . . . . . 422.4.1 Data Acquisition Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422.4.2 Synchronization of DAQ Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 442.4.3 Communication and Storage Strategies . . . . . . . . . . . . . . . . . . . . . . 44

2.5 Applications for Process Monitoring Systems . . . . . . . . . . . . . . . . . . . . . . 452.5.1 Qualification of Machine Performance . . . . . . . . . . . . . . . . . . . . . . . 452.5.2 Material Quality Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 472.5.3 Process Window Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 482.5.4 Simulation Boundary Conditions and Validation of Results . . . . . 502.5.5 Sensor Development and Validation . . . . . . . . . . . . . . . . . . . . . . . . . 512.5.6 Intelligent Process Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3 Polymer Materials Structure and Properties in Micro Injection Molding Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.2 Specific Properties of Polymers for Micro Injection Molding Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.3 Materials Scaling Effects in Micro Injection Molding . . . . . . . . . . . . . . . . 593.3.1 Rheology in the Micro and Nano Dimensional Ranges,

at Low, High, and Ultra-High Shear Rates . . . . . . . . . . . . . . . . . . . . 603.3.2 Polymer pvT Properties at the Micro Scale . . . . . . . . . . . . . . . . . . . 633.3.3 Thermal Properties of Polymers at the Micro Scale . . . . . . . . . . . . 653.3.4 Mechanical Properties of Micro Molded Components

(Micro Tensile Test and Nano Indentation) . . . . . . . . . . . . . . . . . . . 67

3.4 Molecular Orientation and Crystallinity in Micro Molded Parts . . . . . . . 703.4.1 Amorphous Polymers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 713.4.2 Semi-Crystalline Polymers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.5 Micro/Nano Composites in Micro Injection Molding . . . . . . . . . . . . . . . . . 76References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4 Surface Replication in Micro Injection Molding . . . . . . . . . . . . . . . 834.1 Replication of Micro and Nano Structures . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.2 Engineering of Micro- and Nanostructured Surfaces . . . . . . . . . . . . . . . . 864.2.1 Lithographic Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 874.2.2 Non-Lithographic Electrochemical-Based Techniques . . . . . . . . . . 88

XVContents

4.3 Replication Assessment of Polymer Surfaces at the Sub-Micrometer Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 914.3.1 Dimensional Evaluation of Replication Fidelity . . . . . . . . . . . . . . . 924.3.2 Applications of Profile Measurements . . . . . . . . . . . . . . . . . . . . . . 934.3.3 Applications of Amplitude and Slope Replication of

Polymer Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 944.3.4 Applications of Areal Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 974.3.5 Application of Angular Intensity Distribution Measurements . . . 99

4.4 Influence of Tooling and Process Para meters on Replication of Microstructures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1014.4.1 Replication and Optimization of Deterministic Structures . . . . . . 1014.4.2 Replication Quality of Large Area Nano-Structured Surfaces . . . . 1044.4.3 Influence of Process Parameters on Surface Replication . . . . . . . 106References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

PART 2 Tooling Technologies for Micro Mold Making. . . . . . . . . . . . . 113

5 Micro Machining Technologies for Micro Injection Mold Making . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.2 Process Chains for Micro Mold Making . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

5.3 Micro Mechanical Material Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1215.3.1 Size Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1225.3.2 Cutting Forces and Tool Deflection . . . . . . . . . . . . . . . . . . . . . . . . . . 1245.3.3 Machine Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

5.4 Micro Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1255.4.1 Cutting Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5.5 Micro Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.6 Micro Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

5.7 Thermal Material Removal Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

5.8 Micro Electrical Discharge Machining . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1295.8.1 Micro EDM Sinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1325.8.2 Micro Wire EDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1325.8.3 Micro EDM Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1335.8.4 Wire Electrical Discharge Grinding . . . . . . . . . . . . . . . . . . . . . . . . . 1335.8.5 Micro EDM Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.9 Application Examples of Machining Technologies for Micro Mold Making . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1355.9.1 Micro Mold Produced by Direct Tooling . . . . . . . . . . . . . . . . . . . . . . 135

XVI Contents

5.9.2 Micro Mold Produced by Indirect Tooling . . . . . . . . . . . . . . . . . . . . 136References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

6 Ultra-Precision Machining Technologies for Micro Injection Mold Making . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

6.1 General Aspects of Ultra-Precision Machining . . . . . . . . . . . . . . . . . . . . . 143

6.2 Diamond Machining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1446.2.1 Diamond Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1446.2.2 Diamond Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1476.2.3 Shaping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

6.3 Abrasive Machining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1526.3.1 Process Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1526.3.2 Ultra-Precision Grinding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1536.3.3 Polishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

6.4 Applications of Ultra-Precision Machining . . . . . . . . . . . . . . . . . . . . . . . . . 1596.4.1 Fresnel Lens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1606.4.2 Micro Beam Splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1606.4.3 Diffractive Optical Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1616.4.4 Retroreflectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

7 Surface Treatment of Mold Tools in Micro Injection Molding . . 1697.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

7.2 Investigation of DLC Surface Treatment Effects in Micro Injection Molding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1707.2.1 Surface Treatment for Improved Demolding . . . . . . . . . . . . . . . . . . 1707.2.2 An Experimental Case Study for Improving Part Demolding

Using Surface Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1717.2.3 Validation, Verification, and Results . . . . . . . . . . . . . . . . . . . . . . . . 172

7.3 Temperature Effects on DLC-Coated Micro Molds . . . . . . . . . . . . . . . . . . . 1737.3.1 DLC Coatings Used on Micro Molds . . . . . . . . . . . . . . . . . . . . . . . . . 1737.3.2 An Experimental Case Study for Identifying the

Temperature Effects on DLC-Coated Micro Molds . . . . . . . . . . . . . 1757.3.3 Validation, Verification, and Results . . . . . . . . . . . . . . . . . . . . . . . . 176

7.3.3.1 Linear and Superficial Thermal Expansion During Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

7.3.3.2 Finite Element Analysis Results . . . . . . . . . . . . . . . . . . . . . 1777.3.4 Main Findings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

XVIIContents

7.4 A Novel Surface Treatment Texturing of Micro Injection Molding Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1807.4.1 Mold Tool Texturing and Demolding Force . . . . . . . . . . . . . . . . . . . 1807.4.2 An Experimental Case Study for Tool Texturing . . . . . . . . . . . . . . . 1817.4.3 Validation, Verification, and Results . . . . . . . . . . . . . . . . . . . . . . . . 184

7.4.3.1 Nano-Structured Surfaces Replication and Demolding Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

7.4.3.2 Main Findings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

7.5 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

PART 3 Micro Molding Key-Enabling Technologies . . . . . . . . . . . . . . . 191

8 Vacuum-Assisted Micro Injection Molding . . . . . . . . . . . . . . . . . . . 1938.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

8.1.1 Air Evacuation in Injection Molding . . . . . . . . . . . . . . . . . . . . . . . . 1938.1.2 Vacuum-Assisted Micro Injection Molding . . . . . . . . . . . . . . . . . . . 1948.1.3 Cavity Air Flow in Micro Injection Molding . . . . . . . . . . . . . . . . . . 195

8.2 Advantages and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

8.3 Equipment and Design Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1978.3.1 Active Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1978.3.2 Mold Design for Vacuum-Assisted Micro Injection Molding . . . . . 1988.3.3 Cavity Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2018.3.4 Vacuum Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

8.4 Effects on Replication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2028.4.1 Height of Replicated Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2028.4.2 Feature Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2038.4.3 Part Morphology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

8.5 Venting Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2068.5.1 Effect of Micro Injection Molding Process Parameters . . . . . . . . . . 2068.5.2 Effect of Polymer Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

8.6 Concluding Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

9 Modeling and Simulation of Micro Injection Molding . . . . . . . . . 2139.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

9.1.1 The Micro Injection Molding Process . . . . . . . . . . . . . . . . . . . . . . . . 2139.1.2 Why Simulate the Injection Molding Process? . . . . . . . . . . . . . . . . 214

XVIII Contents

9.2 Mathematical Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2159.2.1 Viscosity of Plastics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2159.2.2 Thermodynamics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2179.2.3 Flow of Plastics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

9.3 State-Of-The-Art and Challenges of Micro Injection Molding Simulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

9.4 Best Practice Strategies for Micro Molded Component Simulations . . . . 2229.4.1 Modeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2229.4.2 Meshing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2259.4.3 Material Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2269.4.4 Validation and Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

9.5 Examples of Simulation-Aided Design and Simulated Phenomena . . . . . 2319.5.1 Gate Design Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2329.5.2 Hesitation Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

9.6 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

10 Metrological Quality Assurance in Micro Injection Molding . . . 24110.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

10.2 Quality of the Measurement Process: Calibration and Traceability . . . . . 24210.2.1 Accuracy and Precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

10.2.1.1 Repeatability and Reproducibility . . . . . . . . . . . . . . . . . . . . 245

10.3 Metrology for Micro Injection Molding . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24610.3.1 Dimensional Metrology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24610.3.2 Surface Metrology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

10.3.2.1 Areal Topography Measurements . . . . . . . . . . . . . . . . . . . . 252

10.4 Instrumentation for Micro Injection Molded Parts and Micro Injection Molding Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25710.4.1 Optical Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

10.5 Uncertainty of Dimensional and Surface Topography Measurements of Micro Molded Parts and Micro Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27710.5.1 Assessment of the Uncertainty for Micro Injection Molding

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

XIXContents

11 Additive Manufacturing for Micro Tooling and Micro Part Rapid Prototyping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

11.1 Additive Manufacturing Process Technologies and Materials . . . . . . . . . 28911.1.1 Additive Manufacturing Methods for Polymer Materials . . . . . . . . 29311.1.2 Additive Manufacturing Methods for Metal Materials . . . . . . . . . . 295

11.2 Additive Manufacturing Technologies for Micro Tooling . . . . . . . . . . . . . 29711.2.1 AM Technologies for Micro Injection Molding Hard Tooling

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29811.2.2 AM Technologies for Micro Injection Molding Soft Tooling

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29911.2.3 Indirect Methods for Micro Tooling Production . . . . . . . . . . . . . . . 303

11.3 Additive Manufacturing for the Direct Manufacturing of Micro Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

PART 4 Multimaterial Micro Processing . . . . . . . . . . . . . . . . . . . . . . . . . 315

12 Micro Powder Injection Molding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31712.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

12.2 Process Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31912.2.1 Feedstocks for Powder Injection Molding . . . . . . . . . . . . . . . . . . . . 319

12.2.1.1 Binder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31912.2.1.2 Powder Particle Properties . . . . . . . . . . . . . . . . . . . . . . . . . 32012.2.1.3 Feedstock Preparation and Rheological Properties . . . . . . 321

12.2.2 Debinding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32112.2.3 Sintering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

12.3 Powder Injection Molding of Micro Components (MicroPIM) . . . . . . . . . . 32212.3.1 Dissimilarities between Powder and Plastics Injection Molding . . 32312.3.2 Dissimilarities between Macro- and MicroPIM . . . . . . . . . . . . . . . . 324

12.4 2C Powder Injection Molding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

12.5 Simulation of MicroPIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33012.5.1 MicroPIM Simulation by Use of Commercial Programs . . . . . . . . . 33012.5.2 MicroPIM Simulation Using Modified or Newly

Developed Software Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

12.6 Summary and Outlook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

XX Contents

13 Multimaterial Micro Injection Molding . . . . . . . . . . . . . . . . . . . . . . . 33913.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

13.2 Multimaterial Molding and Multimaterial Micro Molding . . . . . . . . . . . . 34013.2.1 Introduction and Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34013.2.2 Application Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34313.2.3 Advantages and Disadvantages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34413.2.4 Variants of Multimaterial Molding . . . . . . . . . . . . . . . . . . . . . . . . . . 345

13.3 Two-Component Micro Molding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34613.3.1 Polymer–Polymer Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

13.3.1.1 Hypotheses on Adhesion of 2K Molded Polymers . . . . . . . 34913.3.1.2 Experimental Investigations and Results . . . . . . . . . . . . . . 35113.3.1.3 Other Factors Affecting Bonding between Polymers . . . . . 35813.3.1.4 Effects of Surface Roughness on the Bonding of

Two Polymers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35913.3.1.5 Effects of Environmental Factors . . . . . . . . . . . . . . . . . . . . 361

13.3.2 Polymer–Polymer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36413.3.2.1 Challenges for 2K Injection Molding: Bonding and

Interface Dilemma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36513.3.2.2 Special Considerations for the Polymer–Polymer

Interface of Micro Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

13.4 Adhesion Modification for Multicomponent Molding . . . . . . . . . . . . . . . . 370

13.5 Other Quality Issues for Multicomponent Micro Molding . . . . . . . . . . . . 372

13.6 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

PART 1Polymer Materials and

Process Micro Technology

1�� 1.1�Introduction

The present chapter introduces the design of micro molding machines from two different perspectives: analysis of patents on the technology, and design architec-tures and solutions for the micro injection molding machines.

The first analysis is oriented to provide a quantitative scenario on the attempts to exploit research for commercial uses, and it is performed taking into account patents applications worldwide. It helps in situating the micro injection molding domain in the industrial market (particularly on the machine manufacturing side). Conversely, the second part of the present chapter focuses on some relevant archi-tecture aspects of micro injection molding machines that have been analyzed from a functional perspective. The choice of the machines is based on interesting archi-tectures that have been the target of various researches in the recent past and that are often cited within the present book.

�� 1.2�Patent Analysis

Patents data can provide an overview of the main technologies related to an arti-fact. A landscape study of the patents concerning micro injection molding ma-chines and their components has been performed. Such study identified a patent set selected from a patent database provided by Erre Quadro s. r.l. (http://www. errequadrosrl.com/).The patent set contains 2809 individual patents. They cover a period of 135 years and have been filed by more than 500 assignees coming from 17 countries. Many of them (>75%) belong to the last two decades, when patents and their use in-creased thanks to the internet adoption and patent spread.

Micro Injection Molding Machines TechnologyGualtiero Fantoni, Donata Gabelloni, Guido Tosello, Hans N. Hansen

4 1 Micro Injection Molding Machines Technology

Different analyses have been carried out on the selected patent set.

First, a linguistic analysis has been performed to identify expressions (i. e., multi-word terms) that are specific to the particular patent set. Figure 1.1 illustrates the most relevant expressions used in the patent set on micro injection molding machines. The size of the expressions within the tag cloud is proportional to their frequency of occurrence in the selected patent set.

The tag cloud reports many of the components of the machines and a particular interest in the mold cavity as a key element in the specific case of micro injected components.

Figure 1.1 Tag cloud in the patent set on micro injection molding machines

Patents filed in states that are members of the World Intellectual Property Organi-zation (WIPO) are assigned, by the patent office, to one or more IPC 1 classes. Thus, each IPC class can be interpreted as a corresponding technological area. Table 1.1 provides a list of the 10 largest IPC classes within the investigated set of patents. As expected, the main topics are those related to techniques for “working plastic” and “organic macromolecular compounds” of various origins.

Table 1.1 Main 10 IPC Classes Sorted According to Occurrence within Patent Set

Class Class descriptionB29C working of plastics; working of substances in a plastic state in general, shaping or joining of

plastics; shaping of substances in a plastic state in general; after-treatment of the shaped products

B22D casting; powder metallurgy; casting of metals; casting of other substances by the same processes or devices

B29B working of plastics; working of substances in a plastic state in general; preparation or pretreatment of the material to be shaped; making granules or preforms; recovery of plastics or other constituents of waste material containing plastics

1 International Patent Classification

51.2 Patent Analysis

Class Class descriptionB29L working of plastics; working of substances in a plastic state in general indexing scheme

associated with subclass B29C, relating to particular articlesC08J organic macromolecular compounds; their preparation or chemical working-up;

compositions based thereon working-up; general processes of compoundingB29K working of plastics; working of substances in a plastic state in general indexing scheme

associated with subclasses B29B, B29C, or B29D, relating to molding materials or to materials for reinforcements, fillers, or preformed parts

C08L organic macromolecular compounds; their preparation or chemical working-up; compositions based thereon; compositions of macromolecular compounds

C08K organic macromolecular compounds; their preparation or chemical working-up; compositions based thereon; use of inorganic or non-macromolecular organic substances as compounding ingredients

H01L basic electric elements; semiconductor devices; electric solid state devicesB29D working of plastics; performing operations; transporting/producing particular articles

from plastics or from substances in a plastic state (making granules B29B 9/00; making preforms B29B 11/00)

Figure 1.2 shows how patents are distributed in time according to filing date. Re-ferring to such figure, the distribution shows a growing trend (more regular with respect to other machines and disciplines) but with several fluctuations and some anomalies (e. g., the year 2000).

Figure 1.2 Temporal distribution according to filing date

An important remark concerning Figure 1.2: patents become accessible to the pub-lic only after publication, which on average takes place about 18 months after a patent has been filed. During this period patents undergo examination by a patent office. This may explain, at least in part, the noticeable drop that can be seen in the last two years.

6 1 Micro Injection Molding Machines Technology

Some of the most important information that can be extracted from patents meta-data is related to the companies that own the property of the patents, i. e., the assignees. The top 10 assignees found in the patent set are shown in Table 1.2.

Table 1.2 Assignees: Top 10 List

Top assignee % PatentsNissei Plastic Ind. Company 4.2%Toshiba Mach. Company 2.7%Sumitomo Heavy Industries 2.6%Moldmasters 2.4%Husky 1.5%Fanuc 1.4%Ube Ind. 1.2%Dai Nippon Printing Company 1.1%Yoshida Kogyo 1.0%Toyota Motor Corporation 1.0%

The values of the percentages of patents owned by each assignee show that the patent ownership is rather spread and there is not a big player that has a remark-able fraction of patents. However, Nissei Plastic Ind. Company is the most relevant, followed by Toshiba Mach. Company and Sumitomo Heavy Industries. Such distri-bution is typical of innovative products built on the basis of pre-existing technolo-gies and where innovation and disruption happen mainly within the companies’ R & D division.

Additional interesting information concerns where the assignees of the patents are located (such data are different from the headquarters of multinational companies but often refer to the plant or division where the invention has been conceived and tested). However, before presenting the geographical distribution, it is important to notice that assignees can be further distinguished in two categories: public and private. Public assignees are institutions or organizations like universities and re-search centers. Private assignees are companies and individuals.

Figure 1.3 and Figure 1.4 show the concentration of private and public assignees, respectively. The different colors in the images represent the different concentra-tions of assignees. Therefore, in Figure 1.3 the light blue areas represent a smaller number of private assignees than the dark blue regions. Similarly, in Figure 1.4, the red areas reveal the countries where a high number of public assignees filed patents, with respect to the green ones.

71.2 Patent Analysis

Figure 1.3 Geographical distribution of private assignees in the reference patent set. The figure is presented in the color supplement

Figure 1.4 Geographical distribution of public assignees in the reference patent set. The figure is presented in the color supplement

The analysis reveals that the highest concentration of private assignees—in terms of countries—is in Japan. However, both north-central Europe and the north-west of the U. S. show several private companies playing an important role. On the other hand, the majority of public assignees is concentrated in small areas. It is interest-ing to notice that in China there is a higher concentration of public assignees than that of private ones. However, it is worth underlining that only Chinese patents with a translation in English have been considered in the present analysis and therefore the image in Figure 1.4 underestimates the Chinese volume.

8 1 Micro Injection Molding Machines Technology

Independently from the geographical origin of the assignees and their public or private nature, they can be active in different jurisdictions. Such information is highly relevant, since it can be related to the market where assignees produce and distribute their products.

Figure 1.5 Distribution of jurisdictions within the patents in the reference patent set

Figure 1.5 shows that most of the patents are filed in the United States and in Japan, followed by the European and Chinese jurisdictions. Such a distribution is quite predictable, since they are the countries where both the market and the pro-duction have a higher probability to succeed.

Other metadata that can be found in patents are the inventors of the innovations patented. Table 1.3 shows a list of 10 top inventors, whose patents have been found in the patent set, including information about their presumed employment com-pany (at the time of filing).

Table 1.3 Inventors: Top 10 List and Their Presumed Employment Company

Top Inventor CompanyGanz, Martin Ettlinger Kunststoffmaschinen GmbH, Wittmann BattenfeldTaniguchi, Yoshiya Toyo Machinery & MetalOlaru, George MoldmastersAnger, Anton Anton Anger MaschinenbauLaveau, Richard TechmireBabin, Denis MoldmastersThibault, Carl TechmireBourbonnais, Alain TechmireMundwiler, Ulrich Straumann HoldingGruber, Peter A. International Business Machines Corporation