2001. KUHLMANN, Paulo Roberto Loyolla. O Serviço Militar ...

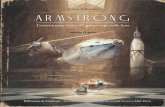

Tokyo, April 2014 Dr. Thomas Kuhlmann

Transcript of Tokyo, April 2014 Dr. Thomas Kuhlmann

1

European Sugar Beets:

Future „Crude“ for the

Chemical Industry

Tokyo, April 2014

Dr. Thomas Kuhlmann

2

Pfeifer & Langen GmbH & Co. KG

Emil Pfeifer

1806 - 1889

Valentin Pfeifer

1837 - 1909

Eugen Langen

1833 - 1895

… an independent family business for more than 140 years

3

Pfeifer & Langen IHKG: A strong group in food business

Pfeifer & Langen Industrie- und Handels KG

Turnover: 1.6 bn €

Employees: 3,000

Sugar: 2 mt

Instant beverages, chocolate,

dried milk products Snack products

4

Worldwide Sugar Consumption

Food Industry

164 mio. t

Ethanol

40 mio. t

Chemical Industry 4 mio. t

Growth rate 2 % Growth rate 0 %

Growth rate 46 %

EU 18 mio. t

EU 1 mio.t

EU 1 mio.t

208 mio. t Sugar

5

World Sugar Production by Company (2012/13 in 1,000 t)

0 500 1.000 1.500 2.000 2.500 3.000 3.500 4.000 4.500 5.000

20. Cosun

19. Tongaat

18. Cristal Union

17. Shree Renuka

16. Bajaj Hindusthan

15. Guanxi Nanhua

14. Turkseker

13. Sta Terezinha

12. American Crystal

11. Feesa

10. Thai Roong Ruang

9. Pfeifer & Langen

8. Wilmar

7. Biosev

6. Nordzucker

5. Mitr Phol

4. Tereos

3. Raizen

2. AB Sugar

1. Südzucker

9. Pfeifer & Langen

6 Quelle: Ribera CEFS – ISO Seminar 2013

Sugar Beet Factory

Ethanol Factory

Cane Sugar Refinery

Beet & Cane Sugar Refinery

Production sites of the European Sugar Industry

7

Pfeifer & Langen in Europe

Production Site

Sales Office Lage

Appeldorn

Jülich

Könnern

Euskirchen

Elsdorf

Mieska Gorka

Glinojeck

Sroda

Gostyn

Oradea

Radechiv

Tchortkiw

8

Top commodities in Agro business … World & Germany 2012*

http: //faostat.fao.org/site/339/default.aspx; (2012) FOOD AND AGRICULTURE ORGANIZATION OF THE UNITED NATIONS (Faostat)

rank commodity Production/Mt

1 Sugar cane 1.833

2 Maize 872

3 Rice, paddy 720

4 Wheat 671

…

7 Sugar beet 270

Top 10: World

rank commodity Production/Mt

1 Cow milk 31

2 Sugar beet 28

3 Wheat 22

4 Potatoes 11

5 Barley 10

Top 5: Germany

10 % of worldwide sugar beet production in Germany

Renewable Resources

9

Agro commodities vs. crude oil … … carbon based price comparison

0

400

800

1200

1600

2000 2002 2004 2006 2008 2010

US$/

t Carb

on

crude oil (WTI)

sugar (NY no11)

corn (FOB, Gulf of mexico

Renewable Resources

10

From field to factory …

A survey of our value chain …

sugar beets sucrose thick juice2

Extrac- tion

Purifi- cation

Concen- tration

Crystalli- zation

„Carbo-Kalk“ (CaCO3)

molasses beet pulp

pellets

raw juice1

1: 17% sucrose; 2: 64% sucrose

Cleaning

beet parts

soil

11

The sugar beet

Some facts about sugar beets:

within Top 7 of worlds agro commodities

10 % of worldwide sugar beet production in Germany

Share of worlds sugar production: 20 %

harvested in autumn

water: 76,5 %

dry substance (DS): 23,5 %

sucrose: 16,5 %

pulp: 3,7 %

N-compounds: 1,0 %

ash: 0,5 %

other: ~1,8 %

12

European sugar beets…

… comparing yields on the field 1)

1): Source: FAO Stats; sugar, starch or potential yield by cellulose hydrolysis

“carbohydrate” per hectare and year

10 t/a 5 t/a

Top 25 % suppliers: 16,5 t/ha in 2011

13

1990 2011 1950

Yield in: t sugar/ha

10

5

5.0

7.8

11.6

7.6

8.9 10.6

13.8

European sugar beets …

… an economic, reliable and sustainable

feedstock Pfeifer & Langen beets

Ø cane

Ø beet

Pfeifer & Langen’s beet acreage is ~ 87,000 ha: 1 t/ha yield increase lead to 87,000 t additional sugar

Ø2011 yield Pfeifer & Langen suppliers: 13.8 t/ha; Top 25%: 16.5t/ha; genetic potential 25 t/ha

14

feed

Bagasse Beet pulp

Flexible use of co-products only in the beet industry

33 % Energy surplus at sugar

production

23 % Energy surplus at sugar

production

Pulp material: cane vs. beet

15

Beet pulp as raw material

feed biogas fuel chemistry materials

Areas of application for beet pulp …

… today and tomorrow

Today‘s application

Pilot scale

Concept idea

Dried / Pressed pulp

16

Thick juice

Thick juice

Composition: 68 % DS

64 % sucrose

4 % „non sugar components” (Amino acids , salts, etc.)

Today: - intermediate product in sugar production

- ethanol production

Storage: - bulk, in tanks, up to 9 month

Opportunities: - all season available feedstock for „over the fence

production concepts“

- good properties in whole cell fermentation processes1

The all round substrate …

… all season available, easy to handle

1: Calabia, B. P. und Tokiwa, Y.; Biotechnol. Lett. (2007); 29; 9; 1329-1332.

17

Feedstock from sugar industry for fermentation processes

amino acid content of substrates related to amino

acids from yeast extractat 120 g/L C-source and 15 g/L yeast extract

0%

5%

10%

15%

20%

25%

30%

35%

alan

ine

glyc

ine

valin

e

leuc

ine

allo-iso

leuc

ine

isoleu

cine

thre

onine

serine

+ga

ba

proline

aspa

ragine

aspa

rtic acid

met

hion

ine

glut

amic a

cid

phen

ylalan

ine

glut

amine

lysine

histidine

tyro

sine

tryp

toph

ane

Conte

nt

in r

ela

tion t

o a

min

o a

cid

s

from

yeast

extr

act

/ %

cane sugar

corn starch

thick juice

raw juice

only in raw juice

Amino acid content of potential feedstock

18

strain A105; end of fermentation

0%

20%

40%

60%

80%

100%

no YE 15 g/L YE 30 g/L YE

yie

ld /

%

crystalline sugar

thick juice

raw juice

Saving costs with beet syrups by nutrient potential benefits for fermentation industry

Example: lactic acid fermentation

Benefits of sugar syrups in real applications

Potential to save process costs

19

molasses

Molasses

Composition: 74 – 77 % DS

47 – 48 % sucrose

30 % „non sugar components“

(3 % betaine, proteins, ash, etc.)

Today: - substrate for yeast production

- substrate for ethanol production

Storage: - bulk, tank

Opportunities: - use as substrate for ethanol fermentation (and ETBE)1

1: Šárka et al., Zuckerindustrie (2012), 138, 2, 105-111

The „crude oil“ of sugar industry

… all season available, yeast industry´s favorite

20

Crystalline sugar

Crystalline sugar

Composition: white sugar ≥ 99,5 °S < raw sugar

Today: - used for food

- used in chemical industry

- used for fermentation processes (ethanol, etc.)

Storage: - bulk, silo

Opportunities: - for enzyme processes/ chemical conversion

requiring high purities

Price/ market: EU market is devided:

1. Quota system: for food use

2. Out of quota:1 for non food industrial applications

Just pure like …

1: fabricator needs a licence

21

Isobutanol>Isobutene >Buthylrubber

Sugars as Feedstock for industrial biotech

Isoprene

Levulinsäure

Lactic Acid 1,4 BDO Succinic Acid

1,3 PDO

Ethanol

5 HMF

PHA´s

High performance molecules for Pharma Functional food et ceterea …

Chemical Way

Biotechnological Way

Renewable raw materials

Sebacinacid Polyamide (Nylon)

22

Classical Route:

Example 1: Succinic Acid*)

„Green Route“:

n-Butane

+ O2 [VPO]

Maleic Anhydride

Benzene

+ O2 V2O3/MoO3

Mannheimia

Succiniproducens Succinic Acid + CO2

C6-Sugar

*) Wagemann, K.; CheManager; 6/2014; S. 6

Examples for renewable Raw material in chemical industry

23

Classical Route:

Example 2: 1,4-Butanediol*)

„Green Route“:

Acetylene

Butadiene

*) Wagemann, K.; CheManager; 6/2014; S. 6

2CH2O

[Cu] Butynediol

C6-Sugar 1,4-Butanediol

Escherichia coli

+ H2O -2CH3COOH

+ H2

1,4-diacetoxy- 2-butene

CH3COOH

O2

Examples for renewable Raw material in chemical industry

24

Example 3: Acrylic Acid*)

Propene

*) Wagemann, K.; CheManager; 6/2014; S. 6

Acrylic Acid

Lactic Acid

3-Hydroxypropionic Acid [3PHP]

Acetylene

O2

C6-Sugar Lactobacillus

- H2O

Glycerol Acroleine - H2O

+CO /

+H2O

Examples for renewable Raw material in chemical industry

„White Route“:

25

Sugar Factory as a biorefinery…

… a win-win situation

Biorefinery concepts in sugar & glucose industry

Raw sugar

Beet

White sugar (Food)

Thick juice (Storage)

Sugar Factory Biotechnology

Biochemicals

Bioenergy By-products By-products

Expanding capacities of sugar factories Cheap raw sugar raffination „green energy“ from by-products

26

Tomorrow: „Chemical site“

Beet Raw sugar (Cane)

Bioenergy From residues and

wind energy

BioTechnology Bioethanole Bioethylene

Food Glasshouses, (use excess heat and + CO2 from production)

Food Sugar

Feed

Biorefinery concepts in sugar & glucose industry

Example: Agro & Food Cluster „New Prinsenland“

27

Combined site with a glucose factory

Example: Natureworks (Blair, Nebraska, USA)

Evonik: L-Lysin (Feed additive, capacity: 280.000 t/a)

Purac / Nature works: Lactic Acid for PLA (Bioplastic, capacity: 140.000 t/a)

Cargill: Sweetener Bioethanol

Biorefinery concepts in sugar & glucose industry

28

Könnern … one of the largest and

modern sugar factories in Europe

Sugar Factory Könnern

29

Daily production of the sugar factory „Könnern“

18.000 t sugar beets

2.700t sucrose

4.900 t thick juice

Extrac- tion

Purifi- cation

Concen- tration

Crystalli- zation

630 t „Carbo-Kalk“ (CaCO3)

450 t molasses 4.600 t beet pulp

pellets

18.000 t raw juice

Cleaning

180 t “beet parts”

900 t soil

A sugar factory as a production site

30

Thick Juice tank

Power Plant

Waste Water Treatment

Water Reservoir

Stockyard for Beets

Sugar Production

External Biogas

Water reservoir

... sugar factory meets demand of a biorefinery

Opportunities for a sugar based biotechnology

Fact sheet: Könnern

Processing:

1.4 mt beets per campaign

16.500 t beets per day

Storage capacity:

140.000 t crystalline sugar1)

160.000 m³ thick juice

On site:

CHP Plant

Waste water treatment

…

1) 80.000 t thereof in planning

A sugar factory …

… is the interface between agro-industry and chemical industry

… offers a feedstock, energy, supplies and infrastructure like a chemical site

… makes a seasonable crop all season available

… helps saving investments costs by various synergy effects

Bio-refinery

Sugar Silo

31

どうもありがとうございました