Tilt Drum vs. Two Opening Mixer. Advantages of Central Mix over Dry Batch Increased production...

-

Upload

vivian-hillhouse -

Category

Documents

-

view

218 -

download

2

Transcript of Tilt Drum vs. Two Opening Mixer. Advantages of Central Mix over Dry Batch Increased production...

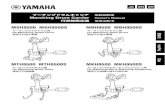

Tilt DrumTilt Drumvs.vs.

Two Opening MixerTwo Opening Mixer

Advantages of Central Advantages of Central Mix over Dry BatchMix over Dry Batch

Increased production capacity (approximately Increased production capacity (approximately 50%)50%)

Superior quality control (slump)Superior quality control (slump) Reduced wear on truck mixer blades & drumsReduced wear on truck mixer blades & drums Reduced man hours for truck mixer clean-upReduced man hours for truck mixer clean-up Overall cleaner plant operationOverall cleaner plant operation Sales tool for selling quality concreteSales tool for selling quality concrete

R & S Tilt Mixer DesignR & S Tilt Mixer Designas compared to Rexcon, Erie Strayer, Hagen, Heltzel, MTM and Con-E-Co.as compared to Rexcon, Erie Strayer, Hagen, Heltzel, MTM and Con-E-Co.

Completely eliminates approximately 30 Completely eliminates approximately 30 wear points (such as load rollers, roller wear points (such as load rollers, roller path, and guide rollers)path, and guide rollers)

Reduced maintenance cost over the life Reduced maintenance cost over the life of the mixer is substantialof the mixer is substantial

Mixing EfficiencyMixing Efficiency

R & S mixing efficiency is equal to or better R & S mixing efficiency is equal to or better than all competitorsthan all competitors

R & S Tilt Mixer design has been proven R & S Tilt Mixer design has been proven through mixer efficiency tests by independent through mixer efficiency tests by independent laboratories for tough specification jobs such laboratories for tough specification jobs such as nuclear power plants.as nuclear power plants.

30 second shrink mix batch gives 300yds/hr30 second shrink mix batch gives 300yds/hr

Exclusive Tilt MotionExclusive Tilt Motion

Provides superior cleanliness of charging, Provides superior cleanliness of charging, mixing, dust control and discharge operationsmixing, dust control and discharge operations

Mixer mouth falls away from charge head, then Mixer mouth falls away from charge head, then returns to a positive seal – no spillagereturns to a positive seal – no spillage

In a class by itselfIn a class by itself

Mixer Batch SizeMixer Batch Size

15 degree incline of the drum axis during the 15 degree incline of the drum axis during the charging and mixing cycle permits full capacity charging and mixing cycle permits full capacity batches without spillagebatches without spillage

All horizontal axis mixers have serious spillage All horizontal axis mixers have serious spillage problems both of wet and dry materialsproblems both of wet and dry materials

The offering of “spillage chutes” in competitive The offering of “spillage chutes” in competitive price sheets is indicative of this problemprice sheets is indicative of this problem

ShippingShipping

R & S Tilt Mixers are shipped completely R & S Tilt Mixers are shipped completely assembled and ready to operateassembled and ready to operate

As an example, some other mixers are As an example, some other mixers are shipped in 12 pieces requiring field shipped in 12 pieces requiring field assembly and alignmentassembly and alignment

DrumDrumLinersLiners

R & S Tilt Mixers are equipped standard with 3/8” ar steel R & S Tilt Mixers are equipped standard with 3/8” ar steel drum liners stitch welded into placedrum liners stitch welded into place

1” polyurethane drum liners are recommended1” polyurethane drum liners are recommended Full face 1” polyurethane blade liners are also available and Full face 1” polyurethane blade liners are also available and

recommendedrecommended ¾” polyurethane liners for the mixer dump chute and ¾” polyurethane liners for the mixer dump chute and

collecting cone in lieu of ¼” ar steel liners are available and collecting cone in lieu of ¼” ar steel liners are available and recommendedrecommended

Spray-in “Rawhide” lining also available for longer life and Spray-in “Rawhide” lining also available for longer life and cost efficiencycost efficiency