Thruster brakes Type ( SMD with Eldro )

Transcript of Thruster brakes Type ( SMD with Eldro )

Thruster brakes Type ( SMD with Eldro ) with Eld Thrusters

Thruster brakes Type ( SMD with Eldro )

Components & Operation

and the side arm turns anti-clockwise and moves the brake

shoe away from the drum. Simultaneously, the synchronizing

arrangement turns the main arm clockwise and releases the

shoe from the drum. The shoes free the brake drum with a

pre-set gap. The brake is now released Turning of lever pulls out

the spring and stores energy for the next braking cycle.

When the thruster is de-energised, the spring force pulls down

the lever and pulls the side and main arms and the shoes clamp

with the braking force with spring force multiplied by the

leverage of the mechanism. The thrust rod is pushed

down by the spring force.

The breaking torque MB is proportional to the drum radius

RB, co- efficient of friction of liner on drum surface µ and the

normal Force F exerted by the spring at the brake shoe.

MB = µ x F x RB

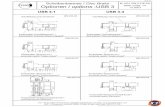

Components and Operation

The brake mounting base ( 5 ) has tow arms, Main arm (4 )

and side arm ( 8 ) fitted on it by hinge pins. Each of the arm

carry a cast iron brake shoe ( 9 ) fitted with woven brake

liner pad. A tie rod ( 6 ) connects the operating lever (1)

to the side arm by a swivel block (7). A hinge pin connects

the lever to the main arm (4). The lever (1) operated by the

thrust exerted by electro-hydraulic thruster (3) Which is

hinged to the base in a clevis. The brake torque setting

arrangement (5) pulls down the lever by pre-loaded

compression spring. Lower ends of the arms are inter-

connected by synchronisation mechanism. The arms have

a screw for setting the brake shoe to prevent rubbing of the

liners on the break drum when the brake is released.

When the thruster is energized, the thrust rod moves up and

turns the lever clockwise with hinge in main arm as pivot,

Thruster brakes Series SMD with Eld ThrustersThruster brakes Series SMD with Eld Thrusters

1. Increase brake shoe clearance to about 5 mm by turning tie rod adjusting nut. ( N Fig ).2. Pull out pin #1. ( Fig 3 ) in base and side arm.3. Swing side arm upwards. ( Fig 4 )4. Push base frame below brake drum.5. Align brake in radial and axial directions.6. Swing down side arm and fix it to the base by pin #1.7. Install thruster unit.8. Fix base frame on foundation.

Align brake shoes with the drum within ± 0.3 mm in all axes.

Adjustment of Reserve Stroke :

The brake should be adjusted such that only about

80% of thruster stroke is used. This is done to ensure

the brake is applied fully and also the wear of brake

liner is accounted for. This is done while

installing the brak

Replacement of Worn Out Shoes

Installation of Brake

The brake foundation is made as per the dimensional

catalogue.

Mount as follows :

1. Unscrew tie rod nut n to release brake shoes from drum.

2. Remove hinge pin in the shoe and remove brake shoe by

sliding it over the drum as shown

3. Replace brake shoe with new one in similar manner

and install it by putting hinge pin in arm

4. Repeat ( 2 ) and (3 ) for second arm.

5. Re- adjust brake

Release devices

The brakes is of fail-safe design and stops moving components

in the event of mains supply failure. Manual release, or other

release devices like Pneumatic or Hydraulic cylinders

arrangement can be offered, in lieu of or in addition

to the thruster.

When ordering please advice :* Order- no., For SMD 200 Eld - 23/5* optional feature such as limit switch manual release, drum, coupling, enclosure

Mbr torqeµ = 0.4

(Nm) (kg-m)

121280707581251205544013585140160467160575200 20SMD 160

Eld - 301/6

Eld - 201/6

Eld - 121/6

Eld - 201/6

Eld - 121/6

Eld - 80/6

Eld - 50/6

Eld - 80/6

Eld - 50/6

Eld - 30/5

Eld - 30/5

Eld - 23/5

Eld - 23/5

Eld - 30/5

195SMD 400

SMD 500

SMD 600

122512251215

136513651365

1215

240

240240

240

1175600

195195240

195

1040 500

900 380

ThrusterType

Brake Type

SMD 200

SMD 250

SMD 300

DCBA

640640

725725

865864

1000

850

195

160

160160

300740

160

160160

160

615 250

515 200

775

870

1000250465 455

190

150

385

300

370

300

170 400 420

130

100

325 340

270 280

15 236 225 90

19013

15016

180

120

14080

27 206

22 130

22 85

J K LHFE G

550

475

690

765

115240

240

100210

170 90

200

160

80 220 230

65

55

180 190

145 160

d *kgRQPN

11812 80110

10 95

10 75

90 80

70 80

18 50

16 30

14 19

SMD 315

SMD 630

Eld - 23/5

Eld - 30/5

Eld - 50/6

SMD 380

300 30400 40

420 42320 32

420 42550 55

1050 105

1800 1801100 110575 57

1400 1402200 220

5400 5403400 340

8200 8205500 5503300 330

3800 3806300 6309400 940

SMD 710280279027521015470450190500525 270 1140

7001355240

240

240150015001500

SMD 700Eld - 121/6

Eld - 201/6

Eld - 301/6

* Weight without Thrustor

With external torque spring

*HIGHER STROKE ON REQUEST

50

60/120*60/120*60/120*60/120*

6060

606050

5050

Stroke

50

60

60/120*60/120*60/120*

Thruster brakes Series SMD with Eld ThrustersThruster brakes Series SMD with Eld Thrusters

864 195Eld - 80/6 1700 17060

Eld - 121/6 24060/120 130

490

230

100010001000

94012010090

1009090

2750 275

60/120

400

630

710

315

Eld - 23/5

50

5050

Electro-Hydraulic Thrusters ( Eld )

Thruster Specifications :The centrifugal pump and motor are immuneform external overloading Standard motor design is suitable for 415 Voltes /50 Hz /3-phase supply. Other voltages (wye) connected, class ‘F’ windings have internal star point, and the three supply phases can be connected on the terminal board, irrespective of the phase sequence. The bi-directional radial flow impeller works with equal performance efficiency in both directions.

Construction Features and Operation :The two main sub-assemblys of the hydraulic thruster, the electricmotor and the hydraulic unit are co-axially assembled to form the working unit.In the switched off state (de-energised), the piston is at is lowest position due to external load (as brake spring of the drum brake),and the brake is applied. When energised, the electric, motor drives the centrifugal pump and delivers working fluid under the piston,under high pressure. This moves the piston axially in the guidedpath, and delivers thrust of force required to operate the attacheddevice (like thruster brake) via the piston rod and the eye-lug attached device to it. The working stroke can be step-lessly controlled by external load.

The delivered thrust is jerk-free,smooth, in constant magnitude andperfectly linear. Except at the end positions, the power intake of themotor is reduced as compared to the power demand while lifting.Thus, the thruster is insensitive to external over-loading. This makesthe thermal over-load protection to the motor unnecessary.

Performance Features :Compact, light weight and elegant design. Reliable and maintainance free operation. Smooth jerk free perfectly linear motion. Low noise,and does not emit electrical desturbances. IP-55,IP-65 degree of protection. Suitable for out-door installation. Low power input. Up to 720 operations per hour. Easy mounting and dismounting. Bi-direction operation. Immune from external over loading Immune from supply voltage variations. Class F insulation scheme.

Windings for any voltages up to 600V AC. 3ø

.

1. Pressure strap 2. Tubular pin

3. Housing 4. Piston assembly.

5. Guide ring 6. Oil seal.

7. Gasket 8. Circlip

9. D.G.B.Bearing 10. Circlip.

11. Motor housing. 12. Startor with winding.

13. Rotor assembly. 14. D. G. B. Bearing.

15. Grub screw. 16. Terminal board.

17. Cable screw nut. 18. Terminal box cover.

19.Terminal box gasket. 20. Fixing screw.

21. Middle flange. 22. Gasket.

23. Impeller. 24. Hex.Nut.

25. Oil seal. 26. Oil plug.

27. Hex. Socket head cap screw.

21

3

4

5

7& 22

68

9

1011

26

25

24

23

212018171615

13

1214

Electro-Hydraulic Thrusters ( Eld )

# The base mounting with type Eld- 50 , Eld-80,Eld- 121 , Eld-201 & Eld-301 is bolted and 90* rotatable, the top pressure lug is rotatable on all units.# Working fluid use transformer oil filled at factory# Safty Measures# Actuation time for all ELD Thrusters is Max 1.5 sec.Dust proof double seal. Double seat to oil chamber. Piston rod chromium plated to size.Piston rod tube to protect against ingress of foreign bodies with types Ed 121, Ed 201, Ed 301

TYPE Lifting Force Power

consu-mption

WStroke

MMCurrentconsu-mption

A

OilCapacity

LitresWeightK. G. A B C ED F G H K L M N O P R S

All cable entry3/4” B SConduit Threads

Eld 23/5 Eld 30/5, 50/6, 80/6 Eld 121/6, 201/6, 301/6

**

CD

CD

DC

E

E

FF

F

BA

P

H

S

MN GG

PH

AB

F

SM

N*

R

G

HP

A

E

FF

N

M

O

K

L

B

S

S

K R

O

K

L

O

L

Higher Stroke On Request*

Nm Kg-m

ELD-23/5ELD-30/5ELD-50/6ELD-80/6ELD-121/6

ELD-201/6

ELD-301/6

ELD-121/12*

ELD-201/12*ELD-301/12*

230300500800

1210

2010

3010

1210

20103010

23305080121

201

301

121

201301

5050606060

60

60

120

120120

165200330330330

550

550

330

550550

0.50.50.51.21.2

1.3

1.4

1.2

1.31.4

1.61.94.24.29.4

9.4

9.4

9.4

9.49.4

1114232542

42

44

44

4442

286370435450645

645

645

705

705705

5050606060

60

60

120

2634363638

120120

38

38

38

3838

1215181825

25

25

25

2525

1616202025

25

25

25

2525

2025303040

40

40

40

4040

1616202025

25

25

25

25

25

2018232335

35

35

35

3535

160160195195240

240

240

240

240240

80809797112

112

112

112

112112

8080

12012090

90

90

90

9090

4040606040

40

40

40

4040

200197254254260

260

260

260

260260

1616222225

25

25

25

2525

100

100100100

160160195195240

240

240

240

240240

R

100

100

100

100

100100

Electromagnetic Brakes Electro Hydraulic Thruster Brake Push Button Pendant Station Festoon Cable Track System Cable Trolleys

Current Collectors Shrouded DSL Bus Bar Crane Limit Switches Crane Hook Safety Latch Crane Hook Block Assembly

E-mail : [email protected] : 044-4261 4058 / 044-2471 5461Web : www.powermechengineering.com

EOT CRANE PARTS AND ACCESSORIES