THERMAL CONDUCTIVITY OF PYREX GLASS: SELECTED VALUES

Transcript of THERMAL CONDUCTIVITY OF PYREX GLASS: SELECTED VALUES

THIN. l I IsIwT "At w55WSIII flb 551. V55'

6 6t14-Pll

THERMAL CONDUCTIVITY OF PYREX GLASS:SELECTED VALUES

by

LOIS C. K. CARWILE and HAROLD J. HOGE

,,- LEARINGHOuSE1, t:-DERAL SCrE-TFJC AN)

/o • • " _ /('App Project reference: 1POIA5O1B1IA• - -f--

March 1966

Pioneering ResearchDivision TC-1

'i

DISTRIBUTION OF IRIS DOCUMENT IS UNUIMIIL...

The findings in this report are not to be construed as anofficial Department of the Army pcsition unless zo designatedby other authorized documents.

Citation of trade names in this report does n, , constitutean official indorsement or approval of the use of such items.

Destroy this report when no longer needed. Do not returnit to the originator.

a Distribution of° this

document is unlimited [AD

TECHNICAL REPORT66-14-PR

THERMAL CONDUCTIVI-TY OF PYREX GLASS:

SELECTED VALUES

by

Lois C. K. Carwile and Harold J. Hoge

Project reference: Series: Thermal

I1P14501B1]A Conductivity-I

March 1966

Pioneering Research Division

U. S. ARMY NATICK LABORATORIESNatick, Massachusetts 01760

FOREWORD

This report is the first of a series on the thermal conductiv- itities of materials of scientific ead engineering interest. The valuesselected are based on thorough study and critical evaluation of pub-

lished investigations. In a critice-l survey such as this one, much

depends on the judgment of the surveyors. The care that zhe authors

of the present survey have exercised may be judged from the commentsthey have made on the individual papers examined. Their comments on

the more important papers are in the text of the report. In addition,they have made many brief comments on less important papers; these

comments are given as annotations, immediately following the listingof the paper in the references.

AS

S. ]AVID BALILEY

Director

Pioneering Research Division

APPROVED:

KK

DUXE H. SIELING Z

Scientific Director

"1U. S. Army Natick Laboratories

W.W. VaughanJ• Brigadier General., USA

Commanding

} ,

ICONTENTS

Introduction I

Selection of Values 1

Reliability of the Tables 4

Data for Conversion of Units 0

References 7

"iii

I

ABSTRACT

The published literature on the thermal conductivity of Pyrexglass has been assembled and the results critically evaluated. Best

values of thermal conductivity as a function of temperature have beenselected. These are presented in both graphical and tabular form;

they cover the range 50 to 8500 K. An attempt was made to consult

all work that could significantly affect the choice of best values.

Published papers were located with the aid of Chemical Abstracts,

Fhysics Abstracts, the Thermophysical Properties Retrieval Guide,and some other general sources. In addition, relevant refex ýnces

in the papers themselves were followed up until a substantially"closed system" had been generated. as shown by the fact that no

new references were being turned up.

ivI

Introduction

Pyrex glass has sometimes been used as a standard material for the"calibration or checking of thermal-conductivity apparatuses, and aknowledge of its conductivity is often required for the making of cor-rections. Pyrex is a trade-mark name of the Corning Glass Works, andis not nece ssarily limited to glasa of a single composition. However.,there is strong indication that "Pyrex chemical resistant glass, CodeNo. 774" is the glass that has been used by many investigators. Inrecent years "Code No. 7740" has been adopted as the preferred desig-nation for the same glass.

The British glass sold under the trade-mark naue "Phoenix" isstated by the manufacturer (24) to be near in composition to Pyrex.Thermal conductivities of Phoenix glass have been included in thesurvey and in the graphs, because of the lack of data on Pyrex at lowtemperatures. All data referring to Phoenix glass are so identified.

Morey (25) gives for the composition of Code No. 774., in weight

[ percent: SiO2 , 80.5; B2 03 , 12.9; Na 2 0, 3.8; K2 0, 0.4; Al2 O3 , 2.2.Other investigators give compositions that do not differ greatly from

this composition. For example, the B20 3 content quoted by 5 different! ~investigators ranged from 11.50 to 12.9. Small differences in com-

i • l~~psition are not expected to affect the thermal conductivity ape

wciably, exept possibly when an Impurity is present that affects thetransmission of radiant energy.

For the density of Pyrex, the value found by Stephens (4) isprobably as reliable as any. He found by direct measurement,P = 2.233 g cm 3 at 21° C. Five other values from the referencesquoted in this report range from 2.22 to 2.234.

Selection of the Values

The data were evaluated by graphical methods. Deviation plotswere used, in which an equation represents the data approximately anddepartures from the equation are plotted; it was ultimately decidedthat the scattering of the data vas so great that deviation plots wereun ecessary, and simple graphs of thermal conductivity versus tempera-ture were used. The original data of some investigators were givenonly in graphical form. In such cases the abscissa and ordinate of

each plotted point were read from the graph and recorded for subsequent

use.

The selected relation between thermal conductivity and temperature

is shown by the master curve in Fig. 1. Table 1.1 represents thismaster curve; it was obtained by reading values at uniform intervalsfrom a large-scale version of the figure. The values were differencedand when necessary smoothed, but the table and the curve were kept con-cistent. The data from references (1) to (10) are shown in Fig. 1.These are considered the more important papers. References (11) to(19) contain data not plotted in the figure; often they contained onlya single k-value. In one case the data had not been released for pub-lication.

The greatest weight has been given to the data in the first threereferences listed. Birch and Clark (1) made absolute measurementswith a guarded hot-plate. Lucks, et al. (2) made measurements relativeto an Armco-iron standard, with the same heat flow in both the standardand the Pyrex. Challoner, Gundry, and Powell (3) made absolute measure-ments with radial heat flow in a sample in the form of a tube.

The data of Stephens (4) appear to be low, but their precision is0

high and they bridge the gap between about 90 K and room temperature.The value of k at 250C accepted by Stephens appears to contain a trans-position. We have corrected this by using the value 0.00253 insteadof the published value 0.00235. This makes the data of Stephens self-consistent. A further increase in this reference value would raiseall of Stephens' values proportionally. Plummer, Campbell, andComstock (6) measured thermal diffusivities, and used accepted valuesof specific heat and density to calculate thermal conductivity.Their values are the lowest reported in the major investigations.

The only values below 900K are those of Berman (7) and ofWilkinson and Wilks (8). In both investigations the glass was Phoenixrather than Pyrex. The data of Knapp (9), and of Smoke, Wisely, Ruh,Illyn, and Eichbaum (10) are high. Knapp (26) states that later work

has indicated that his results are in error.

Table 1.2 is identical with Table 1.1 and with the master curvein Fig. 1 except for tbe change in units. Linear interpolation in atable will introduce no appreciable error when the second differences

2

V .000

K

00i: 10 20 0T K

.00

--- --- -a -rc -i - -

-V-

E.002 ~U:::tih .4

44

030 20-0 300 CT9,Kf

* Fig. 1. Experiiiental data on therv

of data, (7) and (8.', relesimilar to Pyrex. The sineselected values. Low-ten%the large-scale inset gral

ado not exceed 4. When second differences exceed 4, higher-order in-• terpolation may be desirable to preserve the internal consistency of

""values taken from the tables. The error introduced by linear inter-polation in Tables 1.1 and 1.2 will always be small compared to theuncertainty already present in the values themselves. When valuesoutside the range of the ibles are desired, they should be read di-rectly from the master curves. :

Belie _,ý of the Tables

The master curve and the corresponding tabulated values of k arebelieved to be correct within ± 7 percent near room temperature.Where the data are more scarce or the measurements are more difficult,the uncertainty is &reater; it may reach 15 percent at the upper limitof the data.

There is some evidence that radiative heat transfer becomes sig-nifica in Pyrex at temperatures above about 7000K (26 0 R). Birch

0and Clark concluded that radiation would be negligible below 573 K. 4An upper limit for the error in k that would be caused by radiativeheat transfer may be obtained by assuming the Pyrex to be perfectlytransparent and the hot and cold plates to radiate and absorb asblack bodies. Then. for a sample 1 cm thick, the apparent conduc-

0tivity at 300 K would be 6 percent greater than the true conductivity.At 5060K the difference would be 23 percent; and at 700 K, 53 percent.These are upper limits, and the actual errors caused by lumpingradiative heat transfer with conduction are probably much less. In avery thick sample the effect of radiative transfer could of courseexceed the limits given above, because the difference, between the ap-

parent and the true conductivity is proportional to the thickness ofthe sample.

The estimated uncrtainty of ± 7 percent near room temperaturecould be reduced to 4 or 5 percent except for the possibility thatPjyrex glass may vary from sample to sample in a way not fully under-stood. Lucks (13) has recently measured a different sample of Pyrexin the same apparatus that was used in reference (2). The thermalconductivities found in the recent measurementsy wivch extended from323 to 4230K, are about 6 percent lower than those plotted in Fig. I,which are taken from reference (2). The transmittances of the twosamples were measured, and found to be different in the wavelength

ananlun laur m u iiinlnim m ml nnam u uan iiiniii l ln m u w m un u , , ,,.. .

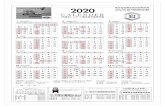

Table 1. Therml conductivity of Pyrex glass

(Values beloa lO0K ame based almost entirely on data for Phoenix glass.)

Table 1.1 Table 1.2

T k T. k

"" calcm OR Btu In.

50 0.00059 100 1.2

75 235100 .o0013 200 4,.27

51 1511o50 .00185 300 5.78

39 1114200 .oo224 400 6.92

30• 83250 .0o(54 500 7.75

22 60300 .002%6 600 8.35

i? 50350 .00293 7OO 8.85

15 431400 .00308 800 9.28

13 39450 .00321 900 9.61

12 33500 .00333 1000 10.0

,11 11

550 .00344 1100 0.12 4

600 .00356 10 10.813 6

650 .00369 1300 n.415 6

OO .00384 140oo 12.o18 8

750 .xooo2 1500 12.821

800 .004#23

28

850 .00o51

5-1 --

__ -' _________________________________

region of 3 microns. The difference was of the proper sign to account

for the difference in k, but the observed discrepancy of 6 percent

seems rather large to be accounted for by any difference in transmit-

In contrast to the experience of Lucks is that of Bullard and

Niblett (11), who sent one of their measured samples of Pyrex to Birch.They report that Birch found "no perceptible difference" between thethermal conductivity of this sample and that of his own sanple of

Pyrex.

Data for Conversion of Units

T(*S) = T(OK) x 1.8

T(*x:) = te'c) + 273.15

T(-R) = t(*F) + 459.67

watt ca cal cm, L

S = ' cm2 sec x 4.184o

Btu in. Calcm2~ x 290r2.9

*R fe hr K cm sec

Btu ft cal cm 241.91cm sec

6

in ll ll l lllllnlllll lllrl• m zml - -lll llllq ~ -ll~ -Im lll 1 11

References

Containing data plotted in Fig. 1.

1 . Francis Birch and Harry Clark, "The thermal conductivityof rocks and its dependence upon temperature and com-

Sposition, Part I," Am. J . Sci, 238, 529-58 (1940).

2. C. F. hIcks, G. F. Bing, J. Matolich, H. W. Deem, B. B.Thompson, "The experinental measurement of thermal con-ductivities, specific beats, and densities of metallic,transparent, and protective materials," U. S. Air ForceTech. Rept. 6145, Part I3 (July 1952), 32 p. (AD-95239).For description of apparatus, see ref. (27).

3. A. R. Challoner, H. A. Gundry, and R. W. Poueul, "A radialbeat-flow apparatus for liquid thermal conductivity deter-minations," Proc. Roy. Soc. (London) A24 5, 259-67 (1958).

1.. R. W. B. Stephens, "Mhe temperature variation of thethermal conductivity of Pyrex glass," Phil. Ming. As, 897-911 1932).

5- W. D. Kinmry, Thermal conductivitr. XIV. Conductivityof milticomponent systems,'" . Am. Cerm. Soc. 42j, 617-27

6. W. A. Plier, D. E. Campbell, and A. A. Cotock, "Methodof measuremnt of thermal diffusivity to 1000*C," J. Am.Geras. Soce. 45, 310-6 (1962).

7. R. Berma, "The thermal conductivities of sc dielectricsolids at low temperatures,' Proc. Boy. Soc. Lomdon A208,90-108 (1951). We have used the data for 'Phoenix' glass.See text.

8. K. R. Wilkinson and J. Wilks, "Some measuriements of heatflow along technical materials ix, the region Vo to 20K,*3. Sci. instr. and mys. in id. 26, 9-20 (U949). Givesdata for "Phoenix' glass.

T

t

9. W. J. Knapp, "Thermal conductivity of nonretallic singlecrystals," J. Am. Ceram. Soc. 26, 48-55 (1943).

10. E. J. Smoke, H. R. Wisely, Edwin Ruh, A. V. Illyn, B. R.Eichbaum, Prog. Rept. No. IV, Signal Corps ResearchProgram, Contract DA-36-039-sc-42577 (Sept. 1 to Dec. 1

1953), 159 P.; AD-29335.

Containing data not plotted in Fig. 1; the less important, incidental,or unpublished values.

11. E. C. Bullard and E. R. Niblett, "Terrestrial heat flow inEngland," Monthly Notices Roy. Astron. Soc. Geophys. Suppl.

6, 222-38 (1951). They sent a sample of Pyrex to Birch,who got a value in good agreement.

12. F. H, Rateliffe, "Preliminary measurements to determine theeffect of composition on the thermal conductivity of glass,"

Pays. Chem. Glasses 1,p 103.4 (1960). one thernml-conductivitydatum is quoted from Chaloner, Gundry, and Powel (3); also,the composition of the glass designated "A" establishes itas Pyrex, or something very simila to Pyrex. V]

13. C.P. Frocks, private comunication, 17 April 1062.

14. J. B. Rersey, "A method of measuring the thermal conductivityof rock cores," J. Appi. ays. 12, 498-501 (1941). Gives ak-valve and quotes one from the Corning Glass Works.

15. Edward F. Suidey II, "The measurement of the thermal conduc-tivity of gases at high temperatures with a shocktube;exerinmental results in argon at temperatures between1000*K and 3000"K, Catholic Univ. Ph. D.Tbsis (1957),. 43 P.

16. Rene Reulos, "Method for the measurement of the thermalconductivity of glasses," Rev. Optique 10, 266-72 (1931)-

17. P. W. Bridgmm-, "The thermal conductivity and compressibil-ity of several rocks under high pressures," Am. J. Sci. 7j,81-102 (1924). Gives k of Pyrex as a function of pressureto 12,000 kg cm,.

8

Ow 'fobNm ~ ~ -- -

18. W. W. Shaver. "Recent developments in glass research," in-mLposium on materials research frontiers (Am. Soc. Test-ing Materials special Tech. Pub. 243, 1958), p. 43-8.Tie k-valve for Pyrex appears to be off by a factor of 12.

19. Corning Glass Works, "Pyrex laboratory glassware," Catalog10-2 11960)v p..

Containing data for which another source is preferred.

20. W. D. Kingery and F. H. Norton, "The. measurement of thermalconductivity of refractory materials," U. S. Atomic Energy

comm. Rept. woX06416 (Nov. 19514), 6 p. Anpear to containSthe data on which the results in reference (5) are based,V

but does not cover the full temperature range.

21. C. F. Lacks, H. W. Deem, and W. D. Wood, "Thermal propertiesof six glasses and two graphites," Bull. Am. Ceram. Soc.39, 313-9 (1960).

I 22. Edward J. Soke and John H. Koenig, "fT1re l properties ofceramics," Rutgers Univ. Eng. Res. Ball. 40 (Jan. 1958),

V 53 p.

23. A. J. Croft, "'Materials and methods for the construction of1ow temerature apparatus," in Exrimtal Crpbedited by F. E. Hoare, L. 6. Jackson, and N. Kurti; Butter-

I• vorths, London (1961) p. 118-37. Gives data for "Pyrex andPhoenix glass" attributed to R. Berma. All values excepthis value for room temperature appear to have cone fromreference (7).

Containing no therml conductivity data on Pyrex.

21. The British Beat Resisting Glass Co. Ltd., Bilston,Staffordshire; private cominmcation, 27 June 1962.

25. G. W. Morey, The Rroer s of Glass (Reinhold Pub. Corp.,2d ed., 1954), p. 78.

26. W. J. Knapp, private counication, 20 December 1961.

9'

7 -"7 o-PIP

I|

27. C. F. Lucks, H. B. Thompson, A. R. Smith, F. P. Curry, H. W.DeemI, and G. F. Bing, #The experimental measurement of thermalconductivities, specific heats, and densities of metallic,t

transparent, and protective materials," U. S. Air Force Tech.

Rept. 6145, Part I (Feb. 1951), .27 P- (ATI-u7715). Describesthe apparatus used in reference (2).

10

4 --. m --wmm mm~mm m mm m n| -m~ m- -llllm - -mm l | - I mm

Unclassifiedsecutity ClassificationI DOCUMENT CONTROL DATA - R&D

(Securnty clasaificatzon of ttlie, body of abstract and ond& sne annotation must be entered when the ovrtall report is classlfied)

I OQIGINATIN 0 ACTIVITY (Corporate author) 72. RCPOAT SECURITY C "ASS;FICAT|ON

U. S. ARMY 1ATICK LABORATORI UnclassifiedNatick, Massachusetts 01760 12 b OuP

3 REPORT TITLE

Thermal Conductivity of Pyrex Glass: Selected Values

4 DESCRIPTIVE NOTES (Type of report and inclusive dates)

S AUTHOR(S) (Last name. first name. initial)

Lois C. K. Carwile and Harold J. Hoge

6. REPORT DATE 7a. TOTAL NO. OF PA$GES 7b. NO, OF REFS

March io66 0Ga. CONTRACT OR GRANT No. 9.. ORIGINATOR*S REPORT NUADER(S)

a6-14 PbPROJECT NO.

C. 9b. OTHER REPORT NO(S) (Anny oshernumbers aat may be assidmedBibs report)

d , Series: Thermal Conductivity-i10. A VA IL ABILITY!LIMITATION NOTICES

Distribution of this document is unlimited. Release to Clearinghouse for Federal

Scientific and Technical Information is authorized.

11. SUPPLEMENTARY NOTES 12- SPONSORING MILITARY ACTIVITY

U. S. Arnc Natick LaboratoriesPioneering Research Division

I Natick. -wassachusets 0176013.-ABSTRACT

The publishe literature on the thermal conductivity of Pyrex glass hasbeen assembled and the results critically evaluated. Best values of thermalconductivity as a function of temperature hare been selected. These arepresented in both graphical and tabular form; they cover the range 50 to 850 K.An attempt was made to consult all work that could significantly affect thechoice of best values. Published .papers were located with the aid of ChemicalAbstracts , Abstracts, the Ther2np ical Properties Retrieval Guideand some other general sources. In addition, relevant references in the papersthemselves were folloved up until a substantially "closed system" had been

generated, as shown by the fact that no new references were being turned up.

.A

AN

DD IA 1473 Unclassified

Security Classification

7-Z , -ý - - -

S_ ___ ncl!- ssif edKY * $.... LINK A LINK 9 LINK C

Thermal conductivity 7T - R r

Heat transfer 8 81heat resistant glass 9 9Pyrex glass 9 9 9Transport properties 8Thermophysical propertiesTemperatureCalibration 4,

Equipwent 4Corrections 4"]

INSTRUCTIONS

I. ORIGINATING ACTIVITY: Enter the name and address 10. AVAILArALITY/LIMITATION NOTICES: Enter any lin-of the contractor. subcontractor, grantee. Department of De- itations on further dissemination of the report, other than those

the report. osungimposed by security classificrtion, using standard statementssuch as:

2a. REPORT SECURTY CLASSIFICATION: Enter the over-all security classification of the report. Indicate whether (1) "Qualified requesters may obtain copies of tis

"Restricted Data" is included. Marking is to be in accord. report from DDC."

ance with appropriate security regulations. (2) "Foreign announcement and dissemination of this

2b. GROUP: Automatic downgrading is specified in DoD Di- report by DDC is not authorized."

rective 520P. 10 and Armed Forces Industrial Manual. Enter (3) "U. S. Government agencies may Obtain copies ofthe group number. Also, when applicable, show that optional this report directly from DDC. Other qualified DDCmarkings have been used for Group 3 and Group 4 as author- users shall request throughized..,,

3. REPORT TITLE: Enter the complete report title in all (4) "U. S. military agencies may obtain -.apies of thiscapital lettems. Titles in all cases should be unclassified, report directly from DDC. Other quwdified usersIf a meaningful title camot be selected without classifica- shall recriest throughtion, show title classification in all capitals in parenhesisimmediately following the title.

4. DESCRIPTIVE NOTES: If appropriate, enter the type of (5) "All distribution of this report is controlled. Qual-report, e.g.. interim, progress, summary. annual, or final. ified DDC users slall request throughGive the inclusive dates when a specific reporting period iscovered.

If the report has been furnished to the Office of Technical5. AUTHOR(S): Enter the namie(s) of authei(s) Is shown on Services, Department of Commerce, for sale to the public, indi-or in the report. Enter last name, first name, middle initial. cate this fact and enter the price, if known.It military, show rank and branch of service. The name ofthe principal author is an absolute minimum requirement. IL SUPPLEMENTARY NOTES: Use for additional explana-

6. REPORT DATE: Enter the date of the report as day. ory note%.

month. year; or month, year. If more than one date appears 12. SPONSORING MILITARY ACTIVITY: Enter the name ofon the report, use date of publication. the departmental project office or laboratory sponsoring (par-

7a. TOTAL NUMBER OF PAGES: The total page count ing for) the research and development. Include address.

should follow normal pagination procedures. ie., enter the 13. ABSTRACT: Enter an abstract giving a brief and factualnumber of pages containing information. sUMmnarV of the document indicative of the report, even though

7 it may also appear elsewhere in the body of the technical re-7b. NUMBER OF REFERENCES: Enter the total number of port. If additional space is required. a continuation sheetreferences cited in the report. shall be attached,

Ba. CONTRACT OR GRANT NUMBER: If appropriate, enter It is highly desirable that the abstract of classified re-Ihe applicable number of the contract or grant under which ports be unclassified. Each paragraph of the abstract shallthe report was written, end with an indication of the military security classification

8b, 8c, & 9d. PROJECT NUMBER: Enter the appropriate of the informat: on in the paragraph, represented as (TS), (S).military department identification, such as project number, (C). or (U).subproject number, system numbers, task number, etc. There is no limitation on the length of the abstract. How-

9a. ORIGINATOR'S REPORT NUMBER(S): Enter the offi- ever, the suggested length is from 154 to 225 words.

cial report number by which the document will be identified 14. KEY WORDS: Key words are technically me.aningful termsand controlled by the originating activity. This number must or short phrases that characterize a report and may be used asbe unique to this report. index entries for cataloging the report. Key words must be

9b. OTHER REPORT NUMBER(S): If the report has been selectet$ so that no security classification is required. Iden-

assigned any other report numbers (either by the originator 5iers, such as equipment model designation, trade name. .ili-or by the sponsor), also enter this nt4ber(s) tary project code name. geographic location. may be used as

key words but will be followed by an indication of technicalcontext. The assignment of links, rules, and weights isoptional.

UnclassifiedSecurity Classifiaton

nA- -

![Crystal Growth and Glass-Like Thermal Conductivity of ...€¦ · The theories of thermal conductivity [13] could be helpful in prediction and analysis of thermal conductivity of](https://static.fdocuments.net/doc/165x107/5f99d98acdb54a3faa23c9cc/crystal-growth-and-glass-like-thermal-conductivity-of-the-theories-of-thermal.jpg)